What is this

A caisson for a water supply well or septic tank on your own land plot is a sealed device with the following functions:

- creating a positive temperature inside the cavity to prevent water from freezing;

- protection of the volume from the ingress of groundwater and melt water;

- ensuring the optimal distance of the pump from the wellhead;

- concentration of water supply or treatment units in one place;

- preventing people, animals and insects from entering the closed area.

The concentration of all elements allows for compact inspection and maintenance work. Sealing the space increases service life, protects the pipeline, hydraulic accumulator, treatment tanks, and pump from defrosting.

The need for a caisson when constructing a well is to locate the pump as close as possible to the surface of the earth. This makes it easier to install and maintain large and massive units. But there is a risk of defrosting and failure, which is prevented by a closed insulated cavity.

Types of caissons

The main feature of a caisson is a closed cavity. It is located on a private plot, usually underground, due to space saving and rational use of the surface.

The design is made vertically. In a horizontal section the following is performed:

- square;

- rectangular;

- round.

According to the material used:

- Wood

(larch), - the caisson looks like a closed classic well for water. - Metal

- vertical pipe of large diameter (from 1 meter). To increase strength, corrugated products are used. - Concrete (reinforced concrete)

, - a common arrangement of a well (inspection, overflow, connecting, etc.)

The latter option replaced the wooden device due to its improved consumer qualities. An alternative to a concrete caisson is polymer products.

Why are caissons installed?

To supply water to residential premises, it is not enough to drill a well and install pumping units; you also need to take care of protecting the structural elements from external influences. To achieve this goal, a special device is installed - a caisson. It will not allow equipment to fail and water to freeze in pipes at subzero temperatures.

In addition, installation of a caisson is necessary:

- to prevent melt and groundwater from entering the volume;

- for ease of maintenance of units that deliver water, as well as purify it due to its location in one place;

- to prevent animals, people, insects from entering the closed area;

- to ensure an acceptable distance between the wellhead and the pump.

The caisson is installed for ease of maintenance of units delivering water.

Concrete structure

Concrete rings for caissons are well-proven industrial products. The advantages and disadvantages of reinforced concrete are presented in the table with alternative products.

| Characteristic | Concrete | Metal | Polymer |

| Strength, rigidity | High (for reinforced products) | Medium, requires reinforcement in the form of corrugation or bandage strength rings | Weak, requires the use of additional stiffeners |

| Tightness of the structure | Low, difficult to provide | High with additional corrosion protection measures | High |

| Weight | The highest compared to other types. Prevents floating from groundwater | Medium (with a thin-walled structure with ribs). Prevents ascent | Low, can be carried by two people. It is necessary to make the structure heavier or additionally attached to the base |

| Installation | A pit up to two ring sizes wide is required. Lifting is possible only with lifting equipment | The size of the pit is 20~50 cm wider on each side. Installation possible without mechanical means | The distance from the caisson wall is 20~50 cm. Installed by two or three craftsmen without additional lifting equipment |

| Lifetime | Over 50 years or more | Up to 10 years, depends on anti-corrosion measures | 20~30 years or more - determined by the quality of the plastic |

| Possibility of making it yourself | Yes, mainly for rectangular sections | Doable with qualified welding | Difficult to implement due to ensuring the strength and tightness of the adjacent walls being connected |

| Price | Lowest - inexpensive raw material, use of own resources | High due to material | High, industrial production only |

Analysis and comparison of indicators shows that it is advisable to use a concrete caisson:

- at low groundwater levels;

- carrying out preliminary drainage measures;

- ability to use lifting equipment;

- using our own resources for the production and installation of concrete parts.

Caisson for a well made of polymer-sand rings: advantages and disadvantages

Caisson made of polymer-sand rings

Well, now let's talk about a caisson made of a polymer-sand mixture, these are also rings, but their height is only 200 mm, and the diameter can be 750 or 1000 mm. Based on these sizes of rings, a hole can be dug of any size and a well of the required height can be assembled.

Advantages:

- Simple installation - the fastening is tongue-and-groove, everything is very simple, it will not be possible to install it crookedly.

- Good tightness - the rings do not need to be treated with additional waterproofing; the grooves are sealed with sealant.

- Lightweight - can be brought in a GAZelle or in a trailer, no manipulator is needed for installation in a pit, easily moved by two adults in one shift.

- Do not break down over time.

Stages of work

The caisson is tied to the location of the well or septic tank. Therefore, design is carried out according to local conditions:

- analysis of the composition of the earth;

- identification of the groundwater horizon;

- clarification of the depth of soil freezing;

- taking into account the dimensions of equipment located in the internal cavity of the caisson;

- ease of installation and maintenance of water pumping units.

The practical construction of a caisson for a well made of concrete rings is divided into several stages:

- carrying out excavation work:

- choice of location (tied to the location of the well);

- laying trenches for pipelines;

- excavation excavation;

- carrying out measures to protect against shedding;

- filling the remaining free space with earth;

- installation:

- arrangement of drainage;

- making the base;

- installation of rings;

- waterproofing and thermal insulation measures;

- arrangement of the caisson:

- installation of pumping equipment;

- connecting pipelines;

- commissioning operations.

- installation of the cover.

Excavation

Digging a pit for a caisson is carried out mechanically or manually. This is determined by the size of the pit and the composition of the soil. Clay and loam, rocks are processed using an excavator. Light sandstones and sandy loams are amenable to manual labor, provided that the depth should not exceed two to three meters.

The work is carried out in the spring and summer. The best option is in the absence of precipitation.

The depth of the pit is determined by the size of the structure and the level of soil freezing. Drainage is carried out at the bottom of the pit - a trench is dug along the contour, up to 20~40 cm deep, the width of a shovel bayonet, and filled with crushed stone.

ATTENTION! The walls of the pit may crumble. Precautions must be taken. The best option is to install a protective fence.

The foundation is being made - the bottom is made of concrete. Reminiscent of a monolithic foundation. It is advisable to provide embedded metal parts for connection with the vertical structure. The slab is installed on a bed of coarse sand (griss).

Waterproofing

Unlike metal or polymer products, the caisson is prefabricated and consists of individual parts. In addition, concrete is a hygroscopic substance. Due to such factors, it is necessary to waterproof the caisson made of concrete rings:

- The outer wall and seams are coated with waterproofing material. To improve adhesion, pre-treatment with a deep penetration primer of the AQUA-Stop series is recommended. It is advisable to use bitumen-based mastics or molten tar as insulation.

- The ends, before direct installation in place, are treated with silicone sealant. This substance can simultaneously serve as a connecting element between adjacent parts. But the mechanical shear strength of the seam will be less than that of a cement-sand mortar.

- To increase strength and tightness, it is recommended to bandage the seam with mesh material (serpyanka tape).

- The internal cavity of the caisson is impregnated with AQUA-Stop series sealant and treated with Penetron or a similar waterproofing material.

ADVICE. Particular attention must be paid to the exit points of the pipelines - this is the most vulnerable place in the concrete caisson. The main leaks occur through them.

Pay special attention to sealing the seams between the rings

Concrete compacted in a factory almost does not allow water to pass through; we can only talk about capillary penetration if the products are of high quality. Practice shows that in wells assembled from standard concrete rings, leaks occur mainly due to leaky seams

It is important even at the installation stage to ensure that the seams between the rings are filled with mortar. It is mixed using Portland cement and sifted sand in a ratio of 1:3

The result will be much better if you add Penetron Admix to the mixture, it will give the solution waterproofing properties.

Careful sealing of seams is an indispensable condition for high-quality waterproofing

Purpose and where is it used?

A sealed caisson has two functions:

- Protecting the top of the well pipe and internal equipment from groundwater penetration. This saves space for installing large technological structures and increases the service life of the well.

- Protection of equipment located inside the caisson, as well as water supply pipes, from the influence of low temperatures during the cold season. To provide an insulating system, the container is covered with insulating materials.

Caissons are erected for any underground structures with a high water content due to their waterproofing.

Return to contents

The main purpose of a well for a well

The main function of wells is to protect the well and water supply equipment from all kinds of negative external influences.

Installing a sealed and insulated chamber on top of the well shaft allows the head to be lowered below the freezing level of the soil. This, in turn, allows pumps and associated plumbing units and units to operate uninterruptedly throughout the year, regardless of temperature changes. The caisson well also protects against melt and rainwater, wind-blown dust and debris from entering the well.

Of course, you can do without a buried caisson by building an insulated building in the form of a shed or small house above the wellhead. However, this option has a number of disadvantages over the well type. Another outbuilding in the form of a house above the well will “eat up” the extra square meters of the garden area. While an underground well, equipped with a lid, will not stand out above ground level at all.

Secondly, to insulate an external building, much more effort and materials will be required. A well-caisson buried in the ground will itself be insulated on the sides with a layer of soil. All that remains is to take care of insulation and a tight fit of the top cover to prevent cold air from penetrating inside.

Thus, a special microclimate is formed inside the well, almost independent of the vagaries of nature. Therefore, most private homeowners decide to equip a well with their own hands, instead of another outbuilding.

Materials and tools

Before starting excavation work, assess the scope of work and your financial capabilities. Concrete caisson rings require machinery to install due to their heavy weight. It is recommended to order truck crane services in advance. You can dig a hole using an excavator.

View outside and inside

Prepare the necessary tools for installation:

- Concrete mixer.

- Boards and hacksaw.

- Hammer.

- Leveler for concrete.

- Small household tools (spatulas, rollers, hammer, tape measure).

The cost of hiring equipment may vary depending on the specific region of Russia.

Materials you will need:

- Sand and crushed stone for mixtures.

- Concrete.

- Reinforcement mesh.

- Concrete rings for a well. One with a diameter of 1 m will cost at least 1000 rubles. A concrete caisson 1.8 m high requires three such rings.

- Floor slab.

- Nails.

- Wire.

- Bitumen mastic (20 liters - about 620 rubles).

The approximate amount for purchasing consumables is about 15 thousand rubles.

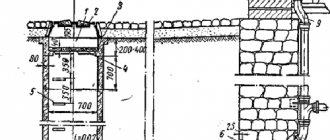

Caisson installation diagram

How to pour concrete walls

To ensure a smooth concrete wall, it must be poured within 1 day. This will avoid the formation of horizontal joining seams, which reduce the strength and tightness of the structure.

The required volume of solution and the amount of ingredients for its preparation must be calculated in advance. It is better to fill in dry weather, starting work early in the morning. The solution is poured gradually. The layers are compacted. It is better to expel air bubbles with a vibrator or reinforcing rod.

Upon completion of the work, you need to erect a canopy. It will protect the structure from precipitation and/or direct sunlight. Heat can cause concrete to crack as it hardens, so it needs to be moistened periodically. It takes 7 to 10 days for concrete to completely harden, depending on weather conditions.

Advantages

The durability of concrete is the main advantage of this design over other types. By choosing this option, you will forget about the issues of equipment replacement and repair for the next 30 years. Even a brick caisson cannot compare in strength to cement. Plastic shelters will definitely not withstand such a load for a long time. Corrosion is not terrible for concrete, which cannot be said about metal caissons.

In addition, there are three more advantages:

- Short installation times. You can mount and install the rings on top of each other in just a few hours. With the help of a crane, it is quite possible to cope with this task in half a day. The duration of the overall process is limited only by the rate of concrete hardening.

- Easy to repair. In an emergency, you don’t have to dismantle the entire structure. Undamaged elements can be easily removed and reinstalled. Other types of caissons usually require complete disassembly.

- Saving money. Based on the estimate of materials, the shelter will be cheaper than similar types. Easy installation does not require significant investment in equipment and workers.

How to do it?

2 construction options

One of the options for constructing a caisson is the use of concrete rings, usually with a diameter of 100-150 cm.

To build a caisson for a well with your own hands, experts recommend using 2 methods:

- Pour a monolithic structure from concrete reinforced with reinforcement or metal mesh.

- Use cast concrete rings with a diameter of 100-150 cm.

Carrying out work

Before starting work, the groundwater level should be examined. Professionals recommend doing this in the spring. If the future bottom of the structure is dry, then it can be covered with gravel and compacted. If there is moisture, it is necessary to build a completely insulated caisson. Next, to construct a monolithic concrete protection, the following list of works is performed (it will be easier to construct an object with a square or rectangular cross-section):

- Digging a pit around a well. Can be done manually or using special equipment.

- Analysis of the condition of the bottom of the structure.

- Construction of an insulated bottom. To do this, lay a 10 cm sand cushion, compact it and moisten it with water.

- Laying polyethylene film. It should extend beyond the perimeter of the future wall.

- Fastening the mesh for reinforcement. It is laid on wooden pegs so that it is inside the concrete layer.

- Pouring concrete. The material must completely cover the film with a layer thickness of 100 mm.

- Construction of wooden formwork. For this purpose, strong boards are used. If the soil is dense and does not crumble, formwork is formed with one wall, otherwise - double. Reinforcing mesh or metal rods are installed in the space between the walls.

- Waterproofing of the structure. A plastic film is attached to the boards with a stapler - it will act as a water barrier.

- Installation of outlet pipes. Used to form technological holes for pipes and electrical cables.

- Pouring concrete mixture. Using a lance or a vibrating drill, the solution is bayoneted. This prevents the formation of an air cushion.

- Exposure period. The solution dries within a month. To prevent increased release of moisture from the concrete, the formwork is covered with film.

The final stage

Often, wood is used to make the lid and it is insulated with special materials.

- Creating a cover. This element is made from boards insulated with a special material. If possible, buy a ready-made concrete slab with a hole for a manhole, or cast it from a solution.

- Waterproofing caisson walls. Using bitumen mastic, the concrete surface is treated.

- Communications liner. Lay pipes and power cable.

When using concrete rings, the algorithm for carrying out the work is similar, the only difference is in the use of ready-made blocks to form the walls.

General disadvantages of a caisson made from rings for a well:

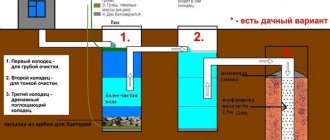

- Bottom - in polymer sand, a hole is cut to the required diameter of the well, then everything is sealed with sealant, but over time the sealant is destroyed and water begins to flow into the caisson. In caissons made of reinforced concrete rings, sometimes a bottom is not installed if the well is intended for technical needs. But if it comes to drinking water, then before installing the rings, the base of the bottom must be compacted with clay, a cushion made of sand and the bottom concreted.

- Flooding - none of these products guarantee long-term waterproofing; over time, water will begin to flow into the caisson if the groundwater is high. But for a drinking water well this is a serious drawback. In the spring, melt water can contain the corpses of rodents and imagine that due to a poorly installed well head or the well head itself is of poor quality, such water can get into your well with drinking water, and this is, at a minimum, food poisoning!

Flooding of the caisson with melt water

Let's draw conclusions in which cases it is possible to install a caisson from rings for a well:

if there is no way out, when the site area is small;

- there is no nearby groundwater;

- you are in a flood-proof area (on the slope of a mountain).

But if you are in a lowland or near a river bed, then installing a buried caisson made of rings is dangerous!