In order to ensure maximum coziness and comfort in a country house and on a personal plot, good owners, first of all, try to provide all communications, including water supply.

But sometimes it happens that the location of the house is at a considerable distance from communication lines, and there is no possibility of connecting a water supply to it. In this case, most home owners think about alternative power sources.

One of the sources of uninterrupted water supply to a private home is the use of automatic pumping stations. The modern pumping equipment market today is very well saturated with all kinds of models of pumping stations.

From the entire range of brands, we suggest drawing your attention to pumping stations of the popular Marina brand. To understand the uniqueness and practicality of Marin pump equipment, in this article we will talk about the advantages of using pumping stations of this brand, and also give recommendations regarding the proper operation and maintenance of this type of unit.

- 2 Device features

- 3 Operating principle

- 4 Possible malfunctions and DIY repairs

- 5 Model range

- 6 Practical operating experience

Device Features

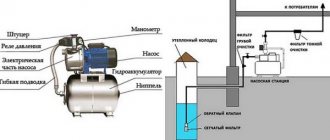

As a rule, Marina pumping stations consist of the following structural elements:

An example of installing a Marina pumping station. (Click to enlarge) self-priming pump mechanism;- a membrane tank in which there is a small amount of water under a certain pressure;

- to maintain stable pressure in the tank, a trivial nipple is used;

- a pressure switch that regulates the automatic switching on and off of the unit when the pressure drops, and accordingly, when the pressure reaches the required level;

- a protective relay that turns off the station when the engine overheats;

- a check valve that maintains the water level during an emergency shutdown of the pumping unit;

- system of connecting pipes and adapters.

Common problems and their solutions

Attention!

- Do not repair or disassemble the pump.

- Do not operate the pump without grounding!

- The pump should never run without water!

- The temperature of the pumped liquid is from 10C to 350C .

- Do not allow air to enter the suction line!

| Malfunction | Causes | Remedies |

| The pump is not working. | — Lack of voltage in the network. — The shaft is blocked. | — Check the voltage; — Turn off the voltage and rotate the shaft using access to it from the fan side. |

| The pump works, but does not pump water. | — Air has not been completely released from the pump housing. — Air entering the suction pipe. | — Stop the pump, unscrew the plug from the filler hole. By rocking the pump and suction pipe, ensure air escapes. Refill with water, screw in the cap and turn on the pump. — Check the tightness of the connections on the suction pipe. Check that there are no elbows or reverse angles on the suction pipe. |

| The periods of turning the pump on and off do not correspond to the established settings. | — The check valve is open due to blockage by a foreign object. Changing the air pressure in the hydraulic tank. | — Remove the suction pipe and unlock the valve. If it drops below one and a half barrels, pump up through the spool. |

| The pump does not create the required pressure | — The relay is adjusted to too low a pressure. — The impeller or pressure line is blocked. — Air entering the suction pipe. | — Adjust the pressure switch. — Turn off the power, dismantle and clean the pump or pressure line. — Check the tightness of the connections on the suction pipe. Check that there are no elbows or reverse angles on the suction pipe. |

| The pump works without shutting down | — The relay is set to too high a pressure. | — Try to reconfigure according to the instructions or contact a service center. |

Operating principle

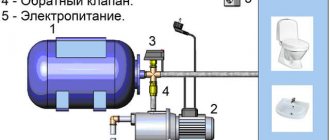

The functioning of the Marina pumping station is as follows:

Pumping station diagram. (Click to enlarge) When the power is turned on, the suction pump begins to draw water from the source;- water enters the tank to the required level, while the pressure switch turns off the suction device;

- When the user consumes water, in other words, when the water level in the membrane tank drops, the pressure switch turns on the suction pump, which again supplies water to the required level.

As you can see, the operating principle of Marina pumping units is quite simple and understandable.

You may be interested in an article about pumping stations for a private home. Read an informative article about Gilex Jumbo pumping stations here.

What is the Marina pumping station?

This is a complex installation designed for automatic water supply, which allows for proper production and distribution of water in almost any area.

The design of the device is made in such a way that water can be pumped both from small reservoirs and from deep wells , tanks and wells. The production of such pumping stations has been going on for more than 60 years; during this period of time, the device has gained popularity among many consumers, including large enterprises and organizations.

The pumping station contributes to the uninterrupted supply of water to country cottages and summer cottages, and also allows you to increase the pressure in the main water pipelines.

In addition, the station can be used to irrigate summer cottages - the principle of operation is quite simple and does not require any special skills.

Possible malfunctions and DIY repairs

It is an undeniable fact that no matter how high-quality and efficient a device is, sooner or later malfunctions still occur in it.

This axiom also applies to Marina pumping stations.

Therefore, we will describe the causes of malfunctions of this type of equipment, as well as how to fix them yourself. The causes of malfunctions are the following important points.

The pumping station is not working.

Causes:

- no electricity supply;

- voltage fuse blown;

- stupor of the mechanism impeller.

Troubleshooting:

- check the electrical connection diagram;

- clean the suction pump;

- try to turn the impeller of the unit; if it is jammed, this means that there is a problem in the working mechanism that needs to be fixed.

The pump unit is functioning, but no water is flowing.

Causes:

- no water supply;

- malfunction of the check valve;

- leakage in the pipelines leading to the station.

Troubleshooting:

- check the presence of water;

- add water to the membrane tank;

- lower the intake hose deeper;

- remove the causes of leaks in incoming water pipelines.

The pumping station works intermittently.

Causes:

- violation of the tightness of the hydraulic storage tank;

- violation of membrane integrity;

- air has entered the suction pipe;

- malfunction of the pressure regulator;

- rupture of main pipes.

Troubleshooting:

- the tightness of the tank may be compromised by corrosion, so the affected areas should be cleaned of rust, and the entire range of work should be carried out to eliminate the causes of depressurization;

- if a membrane breakthrough is detected, then it is worth installing a new membrane;

- it is necessary to eliminate the appearance of air in the system by filling all pipelines with water;

- the pressure switch may be clogged, in this case, thoroughly clean this unit;

- When pipes break, the leak must be removed by sealing leaks or replacing certain sections of the pipeline.

The pumping station operates stably, but does not turn off.

Causes:

- malfunction of the pressure switch.

Adjusting the pressure switch. (Click to enlarge)

Troubleshooting:

- it is necessary to adjust the functioning of the pressure switch.

Analyzing the causes of malfunctions at the Marina pumping station, we can come to the conclusion that, as a rule, pressure switches, membranes, and leaks in main pipelines fail.

Therefore, in order to prevent this type of malfunction, it is necessary to carry out regular maintenance of the unit.

You may also be interested in an article about AL-KO pumping stations. Read the article about setting up and adjusting the pumping station yourself here.

After reading this article, you will learn everything about Aquario pumping stations.

Pumping station design

The body of the device is made of cast iron or steel, which are highly resistant to corrosion. Thanks to the good performance characteristics of the device, the station is capable of providing constant fluid pressure and supply, as well as maintaining the required pressure.

The pumping device is equipped with a reliable protective mechanism, which is needed to stop the device from operating under high electrical voltage.

The design operates according to the following principle:

- inside the ejector there is a special small tube;

- using this tube, the pump automatically sucks in water;

- one part of the water goes directly into the tank, the other part of the sucked liquid is recirculated and allows the self-priming process to occur.

The main elements that make up the design of this Italian-made device:

- membrane tank;

- pressure gauge;

- a unit that allows for water suction;

- special pressure switch.

The lineup

The line of pumping units of this brand has the following classification:

- Pumping station Marina-Speroni RSM 5/25

- APM series units are designed to lift water from deep sources located at a level of up to 30 meters;

- pumping stations of the HC Marina Speroni series have characteristics such as increased power and increased productivity;

- the CAM series of pumping devices represents the most budget-friendly and economical units that can draw water from a depth of up to 9 meters;

- A special feature of Indromat pumping stations is the presence in the design of the units of an electronic control device, which turns off the operation of the unit during a “dry” start.

Pumping station CAM 198/25 Having reviewed all the characteristics of Marina pumping stations, we can say that they have the following advantages:

- low power consumption;

- long period of operation;

- ease of installation and maintenance;

- stability of operation.

Operation of the Marina pumping station

The launch of this device should be carried out strictly according to the instructions that come with the sale of the product.

Any wrong step can lead to the station not working and you not being provided with water. The installation instructions will help you clearly fulfill all the conditions for further operation of the device. If you have never done such a thing and do not want to risk an expensive device, it is better to seek help from specialists.

General characteristics of the Marina water pump

The Speroni Marina pumping station is a complex piece of equipment that organizes water supply for private homes. The product is compact in size and easy to use. The pump is installed on the surface of wells or wells, and water is drawn through a submerged hose. The complex equipment operates automatically, without interruptions and with good water pressure, which prevents failure of automatic washing machines or dishwashers during their operation. In addition to water supply, the pumping station can pump out liquid from swimming pools or basements, and it can also be used as a watering system for a personal plot.

Additional Information. The birthplace of this product is Italy. It was there that about 60 years ago, experienced engineers set themselves the task of producing a pumping station that could efficiently perform several functions.

Performing initial adjustment

When the springs on the pressure switch for the pumping station are completely weakened, the setting is made from scratch:

- The pump is put into operation and the pressure in the system is increased to a value when the pressure in the tap farthest from it becomes acceptable. Let's say it's 1.5 bar. The unit is turned off.

- Then the station is disconnected from the power supply, the cover on the relay is removed and the nut on the large regulator is tightened until a click is heard, indicating that the contacts have closed.

- The cap is placed in place and the pump is started, bringing the pressure to 2.9 bar.

- The unit is disconnected from the power supply, the cover is opened again and the nut is tightened on the small spring until a click indicates that the contacts have opened.

The station turns on and off frequently

For uninterrupted operation of the pump, it is recommended to install a voltage stabilizer

If a pipeline in the ground is damaged, pumping equipment may turn on and off more often than expected. When turned on, the necessary pressure is created in the system and the liquid enters the storage tank. In this case, part of it goes into the ground due to cracks or kinks in the pipe. If all components of the station are working normally, the problem must be looked for in the pipes. To do this, they dig up the entire highway and look for leaks. This can take a long time, so before starting excavations on the site, all other causes must be ruled out.

When the power supply is insufficient, the equipment is forced to constantly turn on so that the impeller can reach the required speed to pump water into the system. The cause may be either the power source or the mechanical or electrical part of the device. The inlet and outlet pipes become clogged after prolonged use, so they are washed with a cleaning solution. Unstable voltage in the home network causes uneven operation of the pump. Check the voltage indicator while the station is running. If necessary, install a stabilizer.

During long-term use, the storage tank may have microcracks through which liquid escapes. It is not advisable to carry out repairs - it is better to replace it completely.

A pressure of about 1.5 atmospheres is created in the accumulator. When the rubber membrane is filled with liquid, the pressure increases and squeezes water into the pipes. If air escapes due to cracks, the required pressure does not arise. Cracks in the steel structure can be welded or the container can be replaced.