Many city dwellers dream of moving to a quiet suburban village. However, living away from the bustle of the city brings not only pleasure, but also a lot of additional troubles. So, in the city it never occurs to anyone to find out where the sewage drains go. But in a country house it is often necessary to build autonomous systems, and it is not always possible to make them gravity-flowing, so you need to purchase a pump for a septic tank.

When improving a house, one cannot do without the construction of engineering systems, including a sewerage system. Ideally, the drainage system operates autonomously, and the liquid moves by gravity. However, this option cannot be constructed in all cases. Then it is necessary to include additional equipment in the scheme - a pump for septic tanks.

What are the differences?

Some may think that there can be no problems with purchasing pumps for septic tanks, since the stores have a fairly wide selection of equipment. However, when faced with the problem of choice in practice, many experience serious difficulties. Therefore, it is worth getting acquainted in advance with the principle of operation of the equipment, as well as with its varieties.

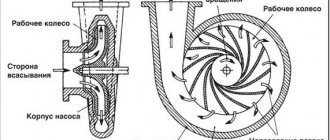

For sewerage, both a drainage and a fecal unit can be used. What are the differences between these varieties? The difference between fecal pumping equipment is that it is able to work with a liquid medium containing solid inclusions. While a conventional drainage unit when pumping liquid with hard inclusions will fail due to impurities entering the impeller.

Advice! To ensure that the drainage unit can operate without interruption, it is equipped with a filter that traps solid particles. When using fecal pumps, the size of inclusions is limited only by the diameter of the inlet pipe.

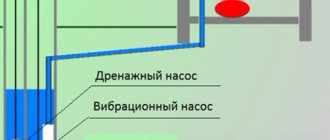

Thus, the choice of pumping equipment is made depending on the purpose of its use. So, if a unit is selected for pumping water that has already been purified in a septic tank, then a drainage version of the pumping equipment is installed. If, when building a wastewater disposal system in a private house, it is not possible to create a gravity-flow option, then a fecal pump is required to pump the wastewater.

Another type of equipment for septic tanks is an air pump. This unit is used in biological treatment plants. The operation of such a station is controlled by a compressor, it provides:

- air supply to the aerator;

- airlift operation - an air pump is used to pump liquid between compartments.

Characteristics of fecal pumps

| Name | Power | Lift height/pressure | Performance | Notes | Price |

| Grundfos SEG 40.12.2.1.502 | 1200 W | 20.5 m | 18 m3/h | Cable length 10 m, chopper | 1025$ |

| Ebara Right 75 M/A | 500 W | 8.6 m | 14 m3/h | Permissible diameter of solid inclusions 35 mm | 250$ |

| Speroni SEM 150-VS | 1700 W | 11 m | 24 m3/h | Float switch, chopper | 560$ |

| Homa Barracuda GRP 16 BD | 900 W | 20 m | 18.7 m3/h | Chopper | 1160$ |

| Ebara DW M 150 A | 1600 W | 16 m | 42 m3/h | Permissible diameter of solids 50 mm, float switch | 620$ |

| Speroni CUTTY 150/N | 1500 W | 17 m | 21 m3/h | Chopper | 770$ |

| Irtysh PFS 50/125.120 | 1100 W | 6 m | 16 m3/h | Float switch | |

| Irtysh PFS 50/125. 98 | 1100 W | 4 m | 7 m3/h | Float switch | |

| Irtysh PF2 50/140.138 | 3000 W | 22 m | 25 m3/h | Float switch | |

| Gilex Fekalnik 150/7N 5302 | 550 W | 7 m | 9 m3/h | Allowable diameter of solids 35 mm, float switch | 105$ |

| Gilex Fekalnik 200/10 F 5301 | 880 W | 10 m | 12 m3/h | Allowable diameter of solids 35 mm, float switch | 70$ |

| Gilex Fekalnik 255/11 N 5303 | 1100 W | 11 m | 15 m3/h | Allowable diameter of solids 35 mm, float switch | 125$ |

Below you can see a fecal pump in action - pumping sewage out of a cesspool.

How can it be installed?

Based on the installation method, three types of equipment can be distinguished:

- superficial;

- semi-submersible;

- submersible

Superficial

This equipment option has a low price. A feature of the equipment is that it must be mounted at a distance from the liquid tank. Such equipment has a low level of waterproofing, so if moisture gets into the engine compartment, the unit may fail.

External pumps are rarely installed permanently; as a rule, they are used periodically, for example, when basements are flooded. Surface pumps for septic tanks are rarely used; they have insufficient performance and a high risk of breakdowns.

Submersible

This option equipment is installed directly in the pumped medium. Therefore, it has a waterproof body, which is made of corrosion-resistant materials. The unit is installed inside the tank, and so that the equipment can be removed at any time, it is attached to a steel chain or cable.

Special guides are installed in the tank itself to hold the body of the unit, and the suction pipe should be located at the bottom of the tank. Submersible pumping equipment is quite powerful, so it is not advisable to use it in dachas and other facilities with a small amount of wastewater.

Semi-submersible

This equipment is equipped with a special float, so the compartment with the motor is located above the liquid level, and the suction pipe is located at the bottom of the container.

How to choose and what to pay attention to?

It is sometimes very difficult for the inexperienced layman to understand the large number of different models. Therefore, first you need to determine the maximum task that the device you purchased will perform.

For example , you plan to pump water for irrigation from a well in the summer, as well as pump out a septic tank or drainage system. There is no point in buying two different pumps. It is enough to choose a more powerful model that will do an excellent job of pumping out the drainage system.

When choosing a drainage pump, you need to pay attention to three main characteristics :

- Device performance.

- Pressure

- Pumped out medium.

performance you need can be determined by dividing the tank volume by the time required to carry out this operation.

Performance calculation example

Given: a container measuring 6 x 2 x 2 m, which needs to be pumped out in 5 hours.

Calculate the volume:

6 x 2 x 2 = 24 m3

We calculate the productivity: 24 / 5 = 4.8 m3 / hour

This means we need a pumping device with a performance no less than this value.

Napor . To calculate it, you need to know the height and distance to which the liquid will be supplied. The height is calculated by simply measuring the distance from the pump immersion level to the wastewater discharge point. It is necessary to take into account water resistance and keep in mind that there will be a loss of one meter of pressure for every ten meters of a horizontal pipeline

Example of head calculation

The drainage system is installed in the tank at a depth of 3 meters. The water discharge pipeline is laid on an uneven surface at a distance of 25 meters, the maximum lifting point is 1.5 meters.

Let's calculate the minimum permissible pressure of our pump using the formula:

Depth x Height x Distance x 0.1 (loss factor)

In our case: 3 x 1.5 x 25 x 0.1 = 11.25 meters.

It turns out that we need a device with a pressure of at least 11 meters.

Important! Drainage units have a large pipe diameter, so when making a purchase, pay attention to this and, if necessary, buy a special hose.

The pumped medium is also of great importance. Determine the maximum permissible particle sizes in the liquid and, based on this, select the drainage model.

Pumping heavily contaminated media

When installing sewer systems in a house, it is not always possible to lay pipes with the required slope. It may be necessary to install plumbing fixtures at a lower level than the entrance to the riser (for example, in the basement) or at a considerable distance from the riser.

In such cases, a submersible fecal pump with a grinder for the septic tank is used. This equipment is equipped with a cutting mechanism that shreds large debris before it is further transported.

Installation

To make a vacuum pump for pumping out sewerage with your own hands, you do not need to disassemble factory equipment. Its technical capabilities are suitable for use for such purposes. The installation of a mesh with small cells will make the operation of the device more efficient. This design will allow only fractions of the required size to pass through.

Assembly and installation are performed according to the following scheme:

- A frame is assembled from steel slats, connecting individual elements by welding.

- The frame is covered with a mesh with cells no larger than 10*10 mm. This size can prevent large debris from entering the work area. The baby sewer pump copes well with smaller fractions.

- A cable, rope or cord is secured to the top of the frame.

- Pumping equipment is installed inside the structure and firmly fixed.

- The cage is immersed in a cesspool or well, trying to place the equipment in the central part. With greater immersion, silty deposits will be drawn in from the bottom; location on the surface leads to clogging with fatty deposits. In both cases, the result will be a temporary stop of the device.

Making a choice

Let's figure out how to select pumps for septic tanks. When selecting a unit, it is important to consider the following parameters:

- tank depth;

- sizes of inclusions that may be present in wastewater;

- performance, which depends on the amount of liquid that needs to be pumped.

Understanding labeling

To make the right choice, you need to be able to read the labels. So:

- if the marking contains only numbers, then this unit is only suitable for pumping relatively clean water, the size of foreign particles should not exceed 5 mm;

- if the label contains the letter “F”, then such a unit is suitable for working with environments with contaminants, including long-fiber ones;

- the presence of the letter “H” on the label indicates that the unit can be used in an aggressive environment, since the body and working parts are made of stainless steel.

Types of fecal equipment

Unlike traditional analogues, which are vulnerable to various types of blockages, fecal equipment can easily cope with wastewater containing solid particles.

The main purpose of a septic tank pump is to pump wastewater

Depending on the installation method and design solution, there are three main types of fecal pumps: surface, submersible and semi-submersible.

Surface-type equipment is used for pumping water from local treatment facilities. They are compact and low cost.

Surface-type devices are capable of pumping out liquid whose inclusion sizes do not exceed 5 mm

Surface pumps are good because they can be placed at a considerable distance from the well (up to 9 meters). In this case, the pump itself remains on the surface, and only the suction pipe is immersed in the drains.

Manufacturers design devices differently. Surface models can be a full-fledged station operating in automatic mode, or a compact unit operating in manual mode.

Water pumps for septic tanks are divided into two groups:

- Non-self-priming - lift liquid from a depth of up to 7 meters. In this case, the suction hose is completely filled.

- Self-priming - capable of lifting wastewater from a depth of up to 8 meters. But the suction hose does not fill with water.

The operation of most devices of this type is based on centrifugal force. But still, the so-called vortex devices are most in demand. Although they work only at shallow depths, they are famous for their greater power with minimal noise during operation.

If you focus on the type of engine, then there are gasoline, electric and diesel devices

A surface pump can only be installed permanently indoors. If there is no suitable room near the septic tank, experts recommend making a pit or caisson near the tank, into which to place the unit.

Submersible models are designed to pump out household waste containing large long-fiber impurities from storage tanks of autonomous sewers.

Submersible models are able to operate uninterruptedly in aggressive environments

Submersible pumping equipment is characterized by high power, which can reach 40 kW, and the ability to pump dense impurities with fractions up to 4 cm in size. Such a device cannot become clogged, since its flow channels are quite wide. The equipment is made of chemically resistant materials: cast iron, stainless steel.

The main difference between models of this type is the presence of a special float, thanks to which the engine remains above the surface of the water.

Semi-submersible pumps are used for pumping mainly small holes

An electric motor is used as a drive in semi-submersible models. They are characterized by an improved cooling system. The steel body and mechanical end seal reliably protect the device from moisture and destruction.

A significant disadvantage of submersible devices is the small diameter of the flow channels. This significantly limits the possibility of using them when pumping liquids with solid inclusions whose diameter exceeds 15 mm.

How to install a submersible unit?

Let's figure out how to install the submersible unit yourself. The work is not too difficult, but it does not tolerate negligence.

Advice! The delivery package of any pumping equipment necessarily includes instructions, which must be studied before installation.

Algorithm of actions when installing a submersible pump for septic tanks:

- guides are attached to the wall of the tank, which will hold the body of the unit, and a suction pipe is installed at the bottom;

- lay outlet pipes, which must be equipped with a valve that protects against the reverse movement of liquid and a gate valve;

- an automation system is connected to the unit, setting the level at which the float should operate, starting the work;

- lower the pump to the bottom of the container;

- carry out commissioning work.

Advice! To extend the service life of the unit and prevent equipment failure due to power surges, it is necessary to connect the pump through a voltage stabilizer.

When installing septic tank pumps equipped with grinders, you must adhere to the following recommendations:

- place the equipment so that the chopper is located in front of the blades;

- the control system should be located in a place with open access;

- The pump cable must be reliably sealed and laid without kinks.

Materials and components

Topikstarter purchased Eurocubes cheaply - three pieces for two thousand rubles. Looking ahead, we can note that such a low price is associated with the specifics of the application - the containers were used for chemicals (raw materials for superglue), while food containers are much more expensive. The remaining contents were cleaned and disposed of (washed with gasoline/acetone/solvent on an iron tray, the drain was burned, the coals were packaged and thrown into the trash). In addition to the cubes, for a future installation aazinus bought:

- compressor made in China (3 thousand rubles);

- finely dispersed aeration elements (2 x 800 rubles);

- American load for bacteria (2 thousand rubles) - in fact, just a plastic mesh, but expensive, so I sawed it and made loads from plastic mesh for fences.

The rest of the additions - all that was left from the construction was insulation (EPS), and sewer pipes (110 mm), and other “small things”.

Service

It is recommended to carry out a preventive inspection once a year, and during seasonal operation - at the beginning and end of the season. During operation, you need to periodically monitor the oil level. If the oil has acquired a grayish tint, it means that water has entered it. And frequent blockages may indicate that the shredder is worn out.

So, a pump for a septic tank must be selected taking into account operating conditions. The stability of the autonomous sewage system, and, therefore, the level of comfort in the house will depend on how correctly the equipment is selected, as well as on its reliability.

Installation operation

aazinus

I started it up, the installation worked for three months - taking into account the decrease in level, the cleaning volume was 2.5 m³. It seemed to me that this was not enough: I cast it from concrete (waste wire, old cement, pieces of iron, the interior of the CBPB) and other waste in insulation. The result is a distribution well with an adjustable level and minimal aeration, for:

- smoothing the volley discharge from the jacuzzi (350-400 liters);

- distributing wastewater from it through filtration fields;

- maintaining and regulating the level of wastewater above groundwater so that VOCs are not collected back from the ground.

To prevent the geese from pecking at the insulation, I covered the top with boards, iron and covered it with earth, insulated the pipe and the air duct, and tied a heating cable to the side of the air duct. The filtration field is made from a drilled pipe (20 meters, you could buy a perforated one, you could use what you had), the drainage pipe is 20 meters.

Sandy drainage: ditch, from 0.5 to 1 meter; on top, after backfilling, geotextiles to prevent silting; insulation to prevent freezing (the same EPS leftover from the construction site); priming. Sandy loam with loam soil with good permeability, although aazinus did not take exact measurements, the volume of drainage is also “by eye”. The level of all liquids in the installation is adjusted to the level with the ground using a distribution well. The total cleaning volume is about 5.5 m³: three eurocubes, that’s 2.5 m³, plus a distribution well, another 2.5 m³ and about 0.5 m³ in the drainage pipes. During the first year of operation, pumping was not needed - only a small amount of sludge accumulated.

To speed up infection, increase the mass of bacteria and improve the degree of cleaning, expanded clay is filled in all chambers in addition to the loading grids. Immediately after entering, the drains in the first chamber become contaminated with silt, which the airlifts carry into the second and third compartments. In fact, liquids rotate like in a washing machine - aeration causes constant circulation, and due to the location of the aerator near the wall, the “oxygen flow” blows over the loads with bacteria growing in them. The degree of purification can be seen in the photo (distribution well).

Subtotal.

aazinus

I came to the conclusion that there is no point in messing with Eurocubes; it’s easier to cast them from concrete, but then you have to wait for dry weather. While the distribution well was being filled, albeit in the summer heat, I did not turn off the pumps for pumping for several days... You can wash the toilets with harsh chemicals - the smell appears, disappears within a day - the bacteria die, but then multiply again. This is the system I made.

I will replace the clamps with soldered polypropylene pipes. In cold weather there are air leaks and you have to tighten them up. The system has been working for a year and fully serves the house. We'll see later. I did it out of poverty, I would have regretted it before the time, but now, in a crisis, there is a lot of time. I express my special gratitude to the forum - I learned a lot of knowledge here. I am also grateful to forum member Shcherb39 and his topic about a surface septic tank made from Eurocubes.

In winter, aazinus dismantled the installation and eliminated air leaks, which provoked the formation of condensation in cold weather and the need for constant heating of the air duct.

Photo of nodes.

A distribution well with a submerged aerator - the bubbling is weak, but it is sufficient for post-treatment; the main aeration processes take place in the chambers.

Homemade aerators - the quality of work cannot be compared with the factory model, where perforation is performed with a laser.

An improved homemade aerator - the slots are cut with a drill, a flat grinding wheel, the bottle is soldered to the HDPE using a heat gun.

Connection to the installation through a corrugated hose from a washing machine, also by soldering.

As of installation as of summer 2015.

aazinus

The liquid has become cleaner - air leaks have been eliminated, the sump has acquired flora and fauna - mosquito larvae eat up organic matter in huge quantities, the water has become cleaner than in winter. I believe that it is quite possible to compare the eco-consequences of factory VOCs and my homemade product with complex cleaning. Let me remind you that such a ready-made installation for 5 m³ (8-10 people) costs about 150 thousand rubles, plus installation, plus various accessories. Everything cost me about 30 thousand rubles, but taking into account non-market pricing.

By non-market pricing, the craftsman means:

- free labor (two Uzbeks helped for accommodation);

- own free labor, both in assembly and in studying thematic materials and design;

- waste - expired cement, wire and used metal for reinforcement, EPS, tools, pipes, fittings, etc. (about 90% of consumables remained from the construction of the house). All this was thrown away, therefore, also free.

But if all of the above were translated into market prices, the total amount would increase significantly. However, companies at that time offered to “master” such a volume for an amount from five hundred thousand to a million rubles.

aazinus

I don’t regret that I took it up and got in touch. This, of course, is not a hypersonic interceptor, but just a sewer, but it’s warm that I’m not polluting my site and not trashing Mother Nature.

And the effectiveness of a homemade installation is visible to the naked eye.

This liquid from the distribution well is still supplied to soil filtration and drainage for final cleaning.

As of May of this year:

- The setup isn't perfect, but still serves a family of four;

- In four years, the sludge in the third section was pumped out once, and not once in the first two; pumping is planned for this summer;

- The design of airlifts needs to be changed, as they get clogged and have to be cleaned. If this is not done, the quality of cleaning immediately decreases.

Scope of application

The scope of application of drainage pumps is determined based on their design features:

- A series of prolonged rains, spring floods or heavy melting of snow. Such a situation can lead to the fact that the storm sewer system will not fully cope with its purposes, which will result in flooding of cellars, basements of buildings, basement floors, etc. In this case, installing a drainage pump in the basement will allow emergency drainage work to be carried out .

- This unit can be installed on a permanent basis in the basement. A properly configured automation system will control the level of incoming groundwater and keep the room dry.

- Also, the installation of a drainage pump can be provided for servicing artificial reservoirs. Without this unit, it is impossible to maintain the required filling level in an artificial reservoir, or to carry out periodic drainage to replace and clean water.

- Accumulating tanks for drainage or domestic sewerage, storm sewers. Provided that they do not provide for independent liquid drainage.

- In addition, the installation of a drainage pump can be provided for discharging settled water into centralized collectors, natural reservoirs, filtration fields, or pumping it into reservoirs for subsequent technological use.

- Current sanitary rules prohibit even small car washes and workshops from operating without local treatment facilities. Dirty water is collected in primary collectors and pits, and then a sewer drain pump pumps it into the tanks of the treatment plant.

- These devices are actively used for irrigation agricultural work; they pump liquid from artificial and natural reservoirs to irrigated areas.

- This equipment is characterized by its versatility; it can be used not only for dirty, but also for clean water in autonomous water supply systems, filling high-mounted containers.

Middle segment (from 4,000 to 15,000 rubles)

The models are equipped with powerful engines and are made in a cast iron body. Thanks to this, they have high productivity and cope well with pumping thick masses. Due to their fairly large weight, they are mainly used permanently in sewerage systems of country or village houses.

GILEX Fecal 330/12

pros

- high pressure

- immersion depth 8 m

- high-quality assembly

Minuses

- no chopper

From 5,296 RUR

Powerful model with moderate weight. Confidently copes with thick fecal matter. It pumps water with sand and silt well, however, due to the lack of a grinder, particles larger than 25 mm in size can damage it. The main area of application is pumping wells (regular and sewer) and cesspools.

Sturm! WP9775SW

pros

- cast iron body

- low noise during operation

Minuses

- chopper is not sharp enough

From 6,700 ₽

A good option for stationary use in the sewerage system of a country or village house. The model has high performance, moderate power consumption, low noise and vibration. The presence of a chopper allows the unit to cope even with thick masses.

PATRIOT FQ500

pros

- cast iron body

- build quality

Minuses

- short power cable

- no chopper

From 5,760 ₽

An excellent mid-priced model for a septic tank in a small country house. High-quality assembly, a stainless steel motor and a cast iron body will ensure long-term trouble-free operation. A power of 500 W does not allow for good pumping of thick wastewater, so it is necessary to use bioreagents in the sewer well.

Advantages and disadvantages

The most significant advantages of a device such as an airlift include:

- simplicity of design, in which there are no moving or rubbing parts;

- the content of suspended matter in unlimited quantities in the liquid supplied by airlift;

- the ability to easily mount and dismantle an airlift, the elements of which are connected to each other using threads (this procedure may be required when reconstructing the device, as well as when performing its maintenance);

- resistance of the inner part of the pipes that make up the airlift to overgrowing;

- resistance to chemically aggressive environments, which is ensured by the use of airlift pipes made from appropriate materials;

- long service life.

Naturally, the airlift also has disadvantages, the most significant of which are:

- insufficiently high coefficient of efficiency (efficiency);

- impossibility of using liquids from shallow wells for lifting.

It should be noted that the efficiency of airlifts depends for the most part not on the intensity of the supply of compressed air to their internal part, but on the diameter of the supply pipe and the depth of its immersion into the well or well.

When calculating an airlift, specialists select the best ratio of these parameters, thereby achieving the highest possible efficiency for a specific case of using such a device.

The main septic tank pump is clogged - a simple solution to a complex problem

Often the cause of such a pump malfunction is the wrong choice of unit for cleaning the septic tank. If you have chosen a device that is not capable of pumping out water with solid impurities, and foreign substances begin to get into it, then you cannot avoid repairing the pump. Fortunately, this is very easy to do at home.

The work algorithm looks like this:

- To begin, disconnect the pump from the power supply and remove it from the septic tank;

- Dismantle the inlet pipe and remove the pump housing cover;

- Carefully remove foreign substances from the housing - dirt and debris;

- Rinse the inlet pipe thoroughly;

- If possible, install a small mesh in the housing that will act as a filter;

- After this, the pump parts should be dried, assembled and the unit should be run at idle speed so that it begins to suck in air.

A filter can only be installed if it does not interfere with the rotation of the moving elements of the engine and the pump itself. Otherwise, it is better to abandon this modification.

Popular manufacturers and prices

Choosing a sewer pump for a private home is not difficult if you know what you need and have the funds.

Some of the most popular are pumps from the German company Grandfos . They are presented in a large assortment. The quality of the products is not satisfactory, and everyone can find a model that best suits their needs. The price of such a pump starts from 10,000 rubles.

Pumps from the Italian company Perdollo . These are fairly light and compact devices that are reliable and durable. The product line is presented in various series intended for country houses, cottages and industrial enterprises. Cost – from 18,000 rubles.

The Wilo brand is distinguished by German quality, durability, energy efficiency and a high level of automation. Price – from 15,000 rubles.

Domestic pumps of the brands Dzhileks, Irtysh and Gnom . They are somewhat inferior in durability and ease of use to imported equipment, but they have a favorable price ( from 3,000 rubles ) and conscientiously perform their functions.

There are many offers on the market, and the choice is always yours. The main thing is to approach it responsibly and find the option that suits you. In this case, there will be much less problems and much more comfort in your country life.

Rating of the best drainage pumps

| Nomination | place | Name of product | price |

| Best Submersible Sump Pumps | 1 | Grundfos Unilift KP 250-AV1 | 16 600 ₽ |

| 2 | Pedrollo TOP 3 | 9 304 ₽ | |

| 3 | AL-KO Dive 6300/4 | 7 990 ₽ | |

| 4 | Pedrollo TOP 2 | 7 260 ₽ | |

| 5 | VORTEX DN-900 | 3 240 ₽ | |

| 6 | Quattro Elementi Drenaggio 550 F | 2 920 ₽ | |

| Best Surface Sump Pumps | 1 | GARDENA 60006E LCD inox Premium | 25 100 ₽ |

| 2 | AL-KO Jet 3000 Classic | 3 687 ₽ | |

| 3 | STAVR NP-800 | 2 989 ₽ |