Aluminum has occupied a large niche in industrial production for the second hundred years. The material is used in mechanical engineering and the aviation industry, in construction and electronics, in advertising and design, etc. This popularity is due to its unique properties, a combination of which is not found in any other metal. It is plastic and easy to form, has high electrical and thermal conductivity, is light in weight compared to other industrial metals and is not subject to corrosion. After grinding, finished aluminum products have an aesthetic appearance and do not require additional processing.

I mill steel and aluminum using a hand router

Do you want to save this video?

- Complain

Report a video?

Sign in to report inappropriate content.

Liked?

Did not like?

We mill steel and aluminum with a hand router, milled a steel corner 7 mm thick with a regular wood router.

milling cutter, metalworking, end mill, vice, ballerina, how to mill correctly, universal milling machine, how to sharpen a cutter, milling machine operator, miller, milling work, steel milling, milling lessons, milling, milling machine video course, russian miller, how to learn to mill, boring work , collet, how to choose a vice, how to mill, collet chuck, CNC, how to mill aluminum, cnc, doulin, technology, router, milling, indicator stand, sine table, turner, universal machine, milling machine, CNC router, pashkin frezer, removal weld seam, how to sharpen a drill, manual metal router, aluminum, milling, how to mill gears, weld removal, tool, work, lesson, vices, drill, copper, mill, machine, chamfo, metal router, grinding a weld seam, machines, CNC milling machine, facing, homemade products, weld cleaning, aluminum milling, thermodrill, duralumin v95t1, duralumin circle v95t1, aluminum ak6, aluminum milling, cut aluminum pieces, cutting aluminum, sheet amg6 ak4-1cht v95pcht2, aluminum v95 v95t1 , aluminum circle v95t1 v95, rolled rod plate d16t, aluminum with rt-reception, cutting aluminum d16t into pieces of workpiece, cutting aluminum billets, duralumin d16, d16t and d16, rods d16t amg6 amg6 v95t1 with rt-t atp, duralumin d16t, laser engraver, mclaser, processing, laser machine, CNC laser machine, laser machine from China, CNC laser engraver, milling, milling, Chinese cutters, aluminum amg6, duralumin 16 amg6 v95t, cutting d16t, cnc machine, cnc milling, aluminum cutting milling cutter, Makita, metal cutting, Makita 3612, metal cutter for drill, metalworking, cutter review, cmt tools, buy metal cutters, metal end mill, buy metal cutters, types of metal cutters, metal cutters for a milling machine , cutter for metal, cutter buy, carbide cutter, cutter for metal, cmt-shop, good cutters from China, test of Chinese cutters, video camera, video stabilization, slider carriage, do-it-yourself slide track, bearings for, lasercut, SLR camera, video DSLR, homemade router, saw blades for steel and aluminum, aluminum processing, machine for aluminum, DSLR, slider, cutters for metal in the mid-price range, infolaser, test drive, dovetail, carbide replacement inserts, milling (product category), aluminum ( chemical element), Dmitry Sabrekov, woodturning, km2, homemade milling cutter, cool life hacks, incredible life hacks, cool life hacks, life hacks for school, life hacks for survival, technology (industry), brilliant life hacks, Siberian vocational college, turner it sounds proud, milling cutter df 1200, milling cutter for cutting alucobond, milling cutter + for composite panels buy, milling cutter for alucobond, analogue of festool, Bosch for composite, bosch milling cutter, milling cutter + for alucobond buy, processing of steel composite panels, milling cutter for composite, milling cutter for composite, CNC. milling. homemade machine., milling alucobond, milling steel composite, milling cutter for steel composite, disc milling cutter for steel, simple life hacks, life hacks that will make life easier, wattsan machine, wattsan, laser engraver China, wattsan laser machine, 3dtool, laser machine price, buy laser machine, laser machine for wood, laser machine for cutting plywood, lasercut, yusto, yusto, inflazer, cheap laser machine, gard, garden group, kamac, kamach, the most, top10, top, life hack, 10 incredible, life hacks, 10 life hacks, homemade machine, carpentry, slotting, laser machine 1610, aluminum milling, metal milling, workshop, slotting machine, metal cutters, speed, composite, grinder, gtb-2100-s, kraspan, disk, alucobond, guide rail, guide rail, adjustable carriage, artstanok, artkor, artcor, art machine, milling and engraving machine, steel processing 3, sheet metal cutting, v90, steel composite cutter, replaceable insert cutter, zias cutter, makita cutter, cutters in Moscow, df1200 cutters, zd milling machine with CNC, CNC machines, festool cutter, rokit cutter, facade panel cutter, composite cutter, composite disc cutter, Kraspan cutter, panel cutter, alucobond cutter, kitai rulit, China bugaga, prusa i3, prusa i2, prusa, prusa i4, carbon, pla, abs, anet, 3d printing, 3d printer, 3d printer, copper milling, 3d printer, 3d print, 3d printing, 3d printed, hips, aliexpress, picaso, picaso, printbox3d, china, china, china rules, China bugaga, printbox, printbox, 3d printing technologies, 3d technologies, prusha, prusha printer, yutimeyker, anet, 3d cnc milling machine, cnc milling machines, cnc on aluminum, do it yourself cnc, build cnc, super homemade homemade lathe

Is it possible to process aluminum on a router without coolant?

Aluminum has occupied a large niche in industrial production for the second hundred years. The material is used in mechanical engineering and the aviation industry, in construction and electronics, in advertising and design, etc. This popularity is due to its unique properties, a combination of which is not found in any other metal. It is plastic and easy to form, has high electrical and thermal conductivity, is light in weight compared to other industrial metals and is not subject to corrosion. After grinding, finished aluminum products have an aesthetic appearance and do not require additional processing.

Features of aluminum milling

With a large number of advantages, it also has several disadvantages, due to which aluminum and its alloys are among the most difficult to process on a milling machine.

Firstly, despite its softness and pliability when cutting, it is prone to excessive chip formation. Long chips, which are formed during the milling process, clog the grooves of the cutter and wrap around the cutting tool. This can lead not only to disruption of heat flow from the cutting area, but also to blunting and breakage of the cutter/drill.

End mill wrapped with aluminum shavings

Secondly, during milling of aluminum, so-called build-up occurs - the fusing of small particles onto the edge of the tool. This clogs the grooves and makes it difficult to remove chips. In addition, such surfacing causes overheating and imbalance of the cutting element, which can lead to jamming of the equipment and its failure.

Deposition of aluminum on the cutting edge of a cutter

To minimize the consequences of milling aluminum, it is recommended to use only the most sharply sharpened two- and three-flush cutters made of carbide materials.

Preferred way to work with aluminum

If the issue of chip formation can be solved by the correct selection of cutting tools, then the problem of fusing aluminum onto a cutter can be solved only by increasing the cutting speed. It is impossible to achieve the required speed parameters on a conventional machine, so the best option for milling aluminum and alloys is a CNC machine. This equipment

is capable of ensuring optimal tilt of the tool relative to the plane of the metal at a spindle speed of 18 thousand revolutions per minute.

Machining aluminum on a CNC milling machine

At such speeds, the temperature of the cutter itself and the surface of the material in the cutting zone increases, so for timely heat removal it is necessary to use a coolant or, in other words, a cutting fluid. Otherwise, there is a high probability of corrosion on the cutting tool or its breakage. The coolant can be oil or emulsion. The optimal system when operating a milling machine with aluminum is considered to be an “oil mist” installation, which evenly sprays oil onto the cutter from several sides during the cutting process. With this processing method, the resistance and durability of the tool increases by 3-4 times.

The oil mist system continuously moisturizes the cutter, while simultaneously cooling it and preventing the adhesion of aluminum chips

The main requirement for coolant is stable operation. Uneven or pulsating flow of coolant leads to differences in the temperature field of the tool and the appearance of microcracks, reducing the service life of the cutter.

“It was smooth on paper...”

The unconditional attractiveness of tandem technology, VSO + increased cutting depth, contains its own “fly in the ointment”. This is a problem of increasing vibration. This phenomenon is inevitable and highly undesirable. And it will not be possible to fight it using traditional methods. Ensuring high rigidity of a four-link system, including a machine tool, a fixture for fixing, a processing tool, and a workpiece, is no longer enough.

It is necessary to take into account the harmonic law, according to which the cutter and spindle vibrate. Simply put, it is necessary to take into account, in addition to the static, also the dynamic characteristics of the resulting vibrations.

Example. Theoretical calculations, confirmed by practice, show that HCA machining of Al parts is best performed with an end mill having 3 spiral grooves. An increase in their number reduces the efficiency of chip removal due to a reduction in the cross-section of each groove in proportion to the increase in their number.

The reverse option, reducing their number to 2, also does not work. It will lead to an increase in unwanted harmonics. This is due to the following. The frequency with which the cutter oscillates no longer coincides with the number of blows that a pair of cutting edges make on the part (at spindle speeds reaching 20,000 rpm).

Special software products allow you to evaluate the optimal speed of its rotation. They allow you to evaluate the tonality of the device’s own vibrations. To do this, “listening” of the machine-tool system is carried out. The problem is solved by a specially designed microphone connected to the PC.

Milling aluminum with a hand router

Very often, home craftsmen perform a number of jobs that cannot be done without a hand router. The most common and versatile is the manual plunge router.

Drawing of a hand router.

Using a hand-held milling cutter, you can make figures of various shapes from wood, from rectilinear to very complex, which is rather an art than just work.

List of works that can be performed using the specified tool

As already mentioned, it is possible to make parts of the most varied shapes with a manual milling machine, and all operations that are performed by the specified equipment are conditionally divided into the following categories:

Elevator diagram for a router.

- Making grooves, quarters and grooves. In order to make any grooves in the workpiece that can be open or closed, it is very difficult to do without a manual router. Most often, such elements need to be manufactured when permanent or detachable connections are made.

- Making edges. This operation is performed when elements such as glazing beads, cornices, platbands and other moldings are made. It can be performed when decorating furniture and other wood crafts. In addition to the fact that such elements carry a functional load, they also act as decorative elements.

- Execution of complex contours and surfaces. This operation is performed during the manufacture of exclusive furniture and other artistic works made of wood. When making furniture, when several elements need to be repeated with high precision, templates are used. In this case, it turns out to almost perfectly repeat complex shapes on different workpieces.

- Execution of special elements. A hand router can also be used to make special elements, such as tenons, clamps, grooves and others that carry only a functional load. In mass production, special machines are used to make them, but if you need to make several elements at home, you can do it with a hand milling machine.

Return to contents

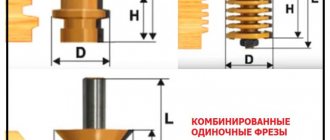

What cutters are used and their purpose

This tool processes wood using cutters, which consist of a shank and a working part. The diameter of the shank is usually 6, 8, 12 mm, and the shape of the cutting part can be very different and made of different materials. If it is necessary to process soft wood, then cutters made of tool steel are used, and for harder wood or aluminum, cutters should be made of carbide alloys.

Milling according to template.

To do the job correctly with your own hands, you need to accurately secure the cutter. Its fixation in a vertical position is ensured by the immersion mechanism. To ensure this position, various devices are used. This can be a guide bearing, which is attached to the cutter, or a guide bushing, mounted on the surface of the router; other devices can also be used.

Differences in processing aluminum on CNC machines

The fundamentally important differences between CNC equipment for aluminum and those many devices that process wood or plastic need to be known and taken into account by everyone who operates them.

The process of milling aluminum using CNC machines is considered to be very cost-effective. They are used in the production of parts in small batches. Although, working in automatic mode, it is possible to produce large volumes of products of high quality. Dimensional accuracy cannot be achieved any other way.

Setting up the router

In order to do the job, you need to adjust the depth of the cutter. The essence of this setting is that after the cutter reaches a certain depth, the limiter is triggered and it cannot move further. If work must be carried out to great depth, then it must be done in several stages.

If we compare the router with other electric tools, it operates at a much higher speed, it usually exceeds 10,000 rpm.

Device of a milling machine.

This is necessary in order to obtain a better cut surface. It is necessary to regulate the speed, since if it is very high, charring of the part may occur. The rotation speed of the cutter depends on its diameter and the material with which the work is being done.

The quality of the surface is not affected as much by the speed of rotation of the cutter as by the speed of its linear movement. The larger the diameter of the working tool, the higher the speed of its movement should be. The higher the hardness of the workpiece, the lower the rotation speed of the working tool should be set. If the cutter has a diameter of 40 mm, then its rotation speed should be within 10,000 rpm, and for a cutter with a diameter of 10 mm it can be 20,000 rpm.

To perform various jobs, you can use parallel or counter rotation of the working tool; counter milling is usually used, in which the cutter and router move in one direction. Climb milling is rarely used, only in cases where there is a possibility of obtaining a flake. This can lead to the router being torn from your hands, so you need to work with even greater care.

Return to contents

Work order

First, the cutter is properly secured, then the engine is set to the required speed and the milling depth is adjusted. In order to ensure correct movement of the cutter, additional devices are used.

The milling cutter is installed on the workpiece, its guide element is pressed against the guide edge and the engine is turned on. First, the cutter smoothly plunges to the required depth, and then slowly moves along the selected path.

During attachment of the working tool and adjustments, the equipment must be disconnected from the power supply. You need to take a stable position and do the work carefully and carefully.

It is necessary to ensure reliable fastening of the workpiece that is being processed so that it does not tear off during operation. At one time it is necessary to cut off a layer not exceeding 3 mm. Your clothing should not contain any parts that could become wrapped around the cutter during operation and cause injury. It is recommended to connect a vacuum cleaner to the router or use a respirator, as this produces fine dust that can harm the body.

General operating rules

Despite its ease of use, the router is a dangerous tool if you use it without following simple rules. So, the basic rules for working with this unit are as follows.

- The sleeves of clothing should fit snugly to the arms. If you have long hair, then you need to pick it up to prevent it from getting caught in the cutter and then getting tangled.

- Before starting work, be sure to check the network cable for insulation damage. Damage to the cord occurs when the cable accidentally hits a cutter that has not yet stopped. Any abrasions found in the insulation must be insulated.

- Prepare the workplace so that there are no foreign objects (wrenches, screwdrivers, screws, etc.) that could get under the working tool and damage it.

- Use only well-sharpened tools (cutters). You can check the sharpness of the blade with your finger: to do this, you need to run it along the blade at an angle of 90 degrees. If the edge is sharp, you will feel the skin slightly catching on the sharp edges. Otherwise, your finger will easily slide off the blade.

- Before using a cutter with a thrust bearing, be sure to lubricate it with one drop of oil. The bearing should rotate easily and without delay.

- When installing the equipment into the collet, make sure that the cutter shank fits into it at least 20 mm.

- Each time you install a router bit, remove carbon deposits and wood residue from the edges using a soft metal plate.

- Use special safety glasses. It would be good if they were dustproof.

- Be sure to protect your respiratory system from fine dust, which is generated in abundance during milling, especially if parts made of chipboard and MDF are processed. As protection, you can use a respirator or a regular medical mask purchased at a pharmacy.

- Always secure the workpiece to the table using clamps. Holding the workpiece with one hand during processing is prohibited.

- Correctly select the rotation speed of the unit’s spindle, depending on the diameter of the installed equipment. You should also pay attention to the hardness of the wood. The higher the hardness of the material, the lower the rotation speed should be set.

- The cutter should plunge into the workpiece to a depth of no more than 3 mm in one pass.

- Before starting to process the workpiece, you should turn on the milling cutter and wait until the cutter reaches the required speed, and then begin inserting the cutter into the wood. If you start milling at low speeds or at the initial speed of the tool, the cutting part of the equipment will hit the workpiece, forming chips on it. In addition to damaging the part, the router can jump to the side and injure the operator.

- You should hold the unit so that you can see the rotating equipment and control its immersion in the material.

- Since the cutter rotates clockwise, the movement of the cutter should be directed in such a way that the blades of the equipment move towards the material, as shown in the figure below.

- The milling cutter must be held firmly in your hands, but without undue pressure on the workpiece. It should be pressed evenly and the unit should be driven smoothly, without jerking, throughout the entire trajectory of movement.

- If you work with a milling cutter at low speeds, and even for a long time, then it needs to be allowed to cool periodically. The unit should be started at maximum speed (idling) for 20-30 seconds so that the engine is well ventilated by the air flow created by the impeller mounted on its shaft.

- To stop milling, for example, the edge of a workpiece, you must first remove the cutter from the wood and then turn off the unit. But when milling a deep groove, you first need to stop the feed of the tool, turn it off, wait until the equipment stops completely, and only then remove the cutter from the recess.

Aluminum milling technology with and without CNC

Currently, [aluminum milling] is one of the most commonly used processing methods for this material.

Aluminum is a structural material that has found wide application in a wide variety of industrial fields.

Meanwhile, it is not often used without preliminary processing, which allows the workpiece to be given the required shape and size.

Today, it is milling that makes it possible to process aluminum not only quickly, but also with the highest quality.

In general, this metal has a whole range of unique properties, among which are lightness, strength, and the absence of corrosion processes that destroy the surface.

One can also note the high thermal and electrical conductivity of this material. All this explains the enormous popularity of aluminum in a variety of industrial fields.

Currently, 3D milling of aluminum can be carried out not only on 3D CNC machines, but also at home manually, and if you follow the technology for performing the work, the result in both cases will be at a high level.

Main varieties, their pros and cons

CNC milling machines are characterized by the fact that they can be used to produce various parts, including plywood and different types of plastic. Both synthetic and natural materials can be milled.

The cutter, which is a working tool, is, first of all, sharp. In addition, the tool is sharpened in advance for various types of work, including for processing edges and rounding edges.

Of course, the device is popular because it allows you to customize the production of parts requested from different industries. However, the disadvantages of this type of equipment is its high cost. In addition, this device has high demands on power supply, consumables, and equipment.

Laser machines boast precision processing of various types of materials, which puts them among the most popular devices of this type. In addition, after installing laser type machines, you can easily set up for another job as they are silent. The operation of laser engraving equipment is carried out by directing a powerful jet of particles.

Thus, when processing the material, direct physical contact with it is not required. As is the case with milling machines, they are configured to work with a huge number of materials - synthetic and natural.

The disadvantage of laser machines is that they are not suitable for processing PVC. And there is a very logical explanation for this. Typically, polyvinyl chloride, when exposed to high temperatures, begins to release carcinogenic substances that negatively affect the environment. In addition, during the cutting process, PVC releases a substance that reduces the efficiency of the device itself significantly.

The advent of plotter machines made it possible to solve a lot of problems in printing companies. The working tool of plotters is a knife that is so sharp that it can process very delicate sheet and roll materials. This working tool moves in a horizontal plane. Compared to laser machines, it is still a cheaper type of device, which is also its important advantage.

Important!

To create three-dimensional products in 3D or 2D, only CNC milling machines are suitable.

Processing Features

Due to the fact that aluminum has increased ductility, it is quite difficult to carry out any processing. This process requires a special approach and strict adherence to the established sequence.

The process of milling it, regardless of the chosen method, increases the risk of various types of defects, such as dents and gouges, appearing on the metal surface.

In this case, if milling is performed incorrectly, the likelihood of severely damaging the workpiece increases. Even when working on a modern 3D CNC machine, even at the stage of attaching an aluminum part to the workbench, it can be damaged.

In this case, experts advise that when using automatic equipment for milling aluminum, instead of mechanically fastening the part, use a vacuum method of fixation.

This is especially true for thin-walled sheet material, which is also large in size.

It should also be noted that aluminum has increased sensitivity to various types of vibration, including from tools. Vibration can also cause various types of defects to appear on the surface of aluminum.

When working with aluminum on a machine, you should select the appropriate milling mode with particular precision so as not to damage the aluminum workpiece.

Also, you should not process this type of metal on machines on which the fastening of the working cutter is not carried out according to the rules, and the collet has not been balanced.

Otherwise, the surface at the cut site will not be even and smooth, which means the quality of the part itself will suffer greatly.

Even though aluminum is considered a relatively malleable material, milling it is considered a technically complex process, even if the most maximum cutting conditions are used.

When milling aluminum manually at home, the requirements for control of the work process only increase.

Features of working with the material

It is important to pay attention to some points:

- The increased plasticity of aluminum complicates any processing. The main requirement of technologists is compliance with the accepted sequence;

- An incorrect approach to milling increases the risk of damage to workpieces, including at the stage of their fastening. Therefore, preference is given to the vacuum fixation method;

- the material is highly sensitive to various types of vibration, which can contribute to the appearance of defects on the surface;

- special attention is paid to the accuracy of selecting the milling mode and balancing the collet.

Modern 3D milling machines with a CNC unit are engaged in complex processing of aluminum profiles at maximum speeds and with higher quality. You can create three-dimensional reliefs on a metal surface. When programming all material processing operations, it is important to establish control over the technical parameters of the process.

We process aluminum for home needs

Nowadays, 3D milling of aluminum workpieces can be performed not only on CNC milling machines, but also manually on home equipment. For many, it is important to use a CNC machine that works with aluminum to produce the auto parts they need. Instead of buying in a store, they process blanks, producing things they need for their home or car with their own hands. The main thing is to maintain knowledge of the technology and take into account the processing features.

You need to have a power tool, a hand router; many home craftsmen have them. It does not have a gearbox or gearbox, but the functionality of the device is excellent.

Before starting work, the tool needs fine tuning and adjustment. A big plus of a manual router is the ability to work in two planes (vertical and horizontal), with minimal physical effort.

The guarantee of quality results lies in compliance with the process technology and full control over its progress. If you work at low speeds when milling aluminum, you can eliminate the risk of metal deformation.

It is equally important to free the surface to be treated from sawdust and adhere to safety regulations.

Milling using a machine

The highest quality and most popular method of milling aluminum is its processing on a special machine on which a cutting tool is installed that gives the material the specified shape and required size.

Modern 3D units equipped with a CNC unit allow this type of processing to be performed with maximum precision and the highest quality.

Such advanced installations make it possible to mill aluminum of absolutely any complexity, including even obtaining a three-dimensional relief on the surface of the metal.

It should also be noted that for aluminum, high-speed milling, which can be performed by 3D units with CNC blocks, is the most preferable and effective.

This is due, first of all, to the fact that the fastest spindle rotation speed is specially combined with the ability to increase the depth of metal cutting at any time.

The use of completely new methods for processing aluminum leads to the fact that currently the technological methods of processing itself are regularly revised.

Modern technologies, as well as the latest 3D CNC equipment, make it possible to perform milling not only as quickly as possible, but also with higher quality.

This makes it possible to gradually abandon the production of certain types of housing parts, successfully replacing them with more economical components with complex shapes.

This is especially true for industrial production such as aircraft and automotive manufacturing. Also, when carrying out milling on automatic units today, great importance is given to vibration problems.

In this case, today they are trying to equip machines with more advanced calibration and quality control systems. The use of CNC significantly expands the capabilities of milling equipment.

Thus, with the help of these blocks it is possible to program all operations for processing aluminum, and in addition, it is possible to better control all technical parameters.

Today, the use of modern equipment when performing aluminum milling makes it possible to achieve high precision work.

Pros and cons of processing aluminum on a milling machine

This material is characterized by high ductility. This is good quality. But, when performing milling, it is precisely this that is a serious prerequisite for damage to the workpiece. The appearance of dents, scratches, and other defects that are very noticeable on the product.

It is possible to damage a metal workpiece even at the stage of fixing it to the workbench of the latter.

That is why it is recommended to fix all aluminum workpieces not with mechanical clamps, but with the use of special vacuum tables.

This solution has no alternative when performing engraving work and applying various images to thin and ultra-thin foil. It is physically impossible to secure it mechanically.

Due to the high probability of defects occurring on the workpiece during its processing, aluminum is very sensitive to the effects of the slightest vibrations of the machine and processing tools. This must be taken into account. Since, if the milling mode is incorrectly selected, or if incorrectly secured (unbalanced) collets or cutters are used, the finished surface of the cut may become jammed. The part will be rejected.