Knowledge and practical application of drilling techniques is basic in the field of repair. It is necessary to know not only the general rules, but also the nuances when working with various materials, for example, metal, wood, brick, tile and others.

When working with a drill, you must follow safety precautions

General principles of drilling

Drilling holes is the most common activity of a repairman, so it is important to know a few basic rules that will allow you to avoid mistakes when carrying out repair work:

- Choosing the right tools. There are many drill bits available in stores that specialize in selling repair items. Each is used for a specific type of material, so you should not choose a brick drill for drilling wood.

- Definition of markup. The markings are indicated on the material using a marker. To prevent the drill from sliding on the material, paper tape should be placed under the marker.

- Determining the optimal drilling speed. In this case, both the material and the diameter of the blade matter. If drills with a diameter of no more than 3 mm are used, then all manipulations should be carried out at low speeds.

Important! The drill should not be skewed in any direction.

Repair work should be carried out with gloves

Advantages and disadvantages

In addition to the fact that various attachments allow you to transform a regular drill into many other tools, they have many other advantages.

- A familiar tool. It is enough to get used to working with the drill itself, after which it will be much easier to work with any attachment. There is no need to get used to the new handle, weight and operating features of an independent tool.

- Saving. Even if you purchase absolutely all types of attachments in all the variety of sizes and materials, such a purchase will still be much cheaper than purchasing several separate tools for each type of work.

- Ease of replacement. All attachments are very easy to remove and secure, and in terms of reliability they are not much inferior to a conventional jigsaw, grinder or milling device.

- Convenient storage. In order to store all the individual tools that are necessary for construction and repair, you will need more than one room, but perhaps an entire hangar. You can store drill attachments in a regular box or a special suitcase. This way they will always be at hand and at the same time will fit even in a regular drawer under the sink or on a shelf in the pantry.

Unfortunately, like any additional equipment, along with its advantages, attachments have their disadvantages.

- Low efficiency. Compared to expensive professional tools, attachments are not able to cope with such a volume of work and maintain such high productivity.

- Difficulty of work. It is much more convenient to work with a special cutting or grinding tool than with a regular drill with an additional attachment. In order for the cuts to be even, you will have to ruin more than one sheet of metal while you acquire the skill.

- You have to use both hands. Often this can lead not to simplification, but to complication of the operation (and even to danger). For example, during roofing work, busy hands mean an inability to hold on to a fence or rope.

Subtleties of drilling for various materials

The technique of drilling any material has its own subtleties that the repairman must take into account.

Each material has its own drilling technique

Vertical or horizontal hole

When starting to make a hole, it is necessary to firmly secure the canvas. This can be done using a workbench or a vice. You can also use a dowel.

The drilling process is as follows:

- The drill is switched to drilling mode.

- Set the speed. In this case, it is worth remembering the main rule: the smaller the diameter of the nozzle, the higher the speed should be.

- If a through hole is needed, then a wooden block is placed under the material.

- If it is necessary to make a blind hole, then the parameters of its depth and diameter must correspond to the screw for screwing in.

- The tool must only be used at right angles. After the end is fixed in the block, the drill must be switched to maximum power.

To make a horizontal hole, you only need to move the workpiece.

Hole perpendicular to surface or at an angle

To make a perpendicular hole, you will need a protractor or square. If the work is done at home, it is recommended to place a regular CD disc under the product, so that the reflection of the disc equipment coincides with the piece that is visible. In this case, the perpendicularity of the hole will be maintained.

Those who are interested in how to drill a hole at 90 degrees with a drill should choose a vice as a means of fixation. The part is pressed tightly so that the drill can be screwed in perpendicularly.

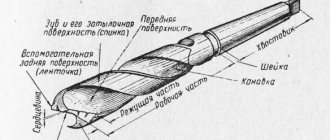

How to drill metal

In this case, it is important to choose the right drill bits. Conventional ones can be used for metals that are not too hard, such as copper, but for stainless steel you should choose products made from titanium carbide.

Important! Even the most experienced workers make the most common mistake when drilling metal - they perform the work at too many revolutions. In reality, it is better to choose medium speed.

There are also a few other key points to consider:

- before drilling a thin iron plate, it is fixed between two pieces of wood;

- to facilitate the drilling process and cool the drills, it is recommended to use lubricating oil;

- if it is necessary to make a hole in a metal pipe, it must be firmly secured and a wooden beam placed inside so that the pipe does not flatten during operation.

For drilling metal, it is best to choose a diamond drill bit.

How to drill concrete

In everyday life, every man encounters concrete drilling when it is necessary to hang a picture or hanging shelves on the walls to decorate the house. Of course, it is best to choose a hammer drill or impact drill in this case, however, if the wall thickness is no more than 12 cm, then you can use a regular drill.

For the job to be successful, you should consider these tips:

- before starting work, you need to make sure that there are no communication systems at the drilling site;

- you should choose parts made of hard metals or alloys.

- If during drilling you encounter dense areas of concrete, it is best to break them with a punch.

How to drill wood

Wood is the most pliable material that is easy to sand and lends itself well to drilling. To work with a drill, you will need special attachments.

Many repairmen are interested in the question of how to drill a perpendicular hole in wood with a drill. It should be noted that the process is not complicated. Initially, you need to make markings with a pencil to determine the points for drilling. Then, turn the drill on at full power and drill a hole.

Wood is the easiest material to drill

How to make a groove in a wooden board

To make a groove in wood, you can choose a simple scheme:

- around the wood drill, mark the holes so that their middle is at a distance of approximately ½ of the diameter of the drill;

- then drill the marked holes with a depth of no more than 3 mm;

- all holes are deepened;

- use a file to remove all irregularities.

Important! Knowing how to drill a hole straight in wood with a drill and choosing the right drill bit, the job can be completed in a matter of minutes.

How to drill a brick

To drill into a brick wall, proceed as follows:

- perform marking;

- Place an old drill or core on the marked points, hit it with a hammer several times to form a depression;

- place a drill in the drill and turn it on impact mode;

- Drill holes using smooth movements.

Drilling tiles

When working with tiles, the impact mode of the drill should be used with caution. It is best to turn it off before work, otherwise chips will form on the tiles.

If you need to make a small hole, then you should choose a special drill for working with tiles and glass. They drill the hole until it stops. Next, change the equipment to a concrete drill and continue working.

It is impossible to drill tiles using the impact mode of the drill.

Basic classifications and functions

The corner nozzle usually operates according to the following schemes:

- mechanical axis transfer;

- flexible axis change.

Devices of the first type are often located on a professional instrument and are one with it. These drills have a speed of no more than 1800 rpm, which allows them to provide enough torque to perform difficult tasks. These tools are indispensable when working with metal parts, and the attachments themselves can have expanded functionality. For example, a means to reduce vibration, which simplifies and speeds up work.

The second type of attachment is usually located in drills and is a flexible shaft, one end of which is attached to a screwdriver, and a bit or drill is installed on the other.

Nozzles are distinguished according to the following characteristics.

- Material of manufacture. Here, parts are usually used that can withstand heavy loads and are made of high-quality metal, which ensures the ability to withstand strong mechanical stress. Such devices can be used to drive screws into hard surfaces.

- Ways to change the axis. They are a gearbox that is enclosed in a plastic case and can withstand high loads. When working with such tools, you can reduce the load on your hands, but the torque in the drill will be small.

- Bit extension height. Affects the functionality of the nozzle.

- Handle rotation angle. Increases ease of use and makes it possible to work with the tool with two hands.

- Presence of reverse. You can remove screws, not just screw them in.

The simplest guide attachment for a drill with your own hands

The nut is removed from the drilling tool. Next, measure its diameter on a plastic bottle and mark it with a felt-tip pen. As a result of these actions, a complete circle should be obtained.

The resulting template, which will need to be cut out later, is marked on the bottle cap so that the width is sufficient.

Next, the bottle or can is trimmed. The template that was previously applied to the bottle and its cap needs to be cut out. Then take the lid and install it into the jar from the front side, achieving maximum fit.

After the glue has dried, a drill is inserted into the nozzle and then used like a plastic nut, fixing it on the tool and starting drilling the hole.

Important! To make the job as safe as possible, it is recommended to sand the edges of the can so that they become smooth and even.

Safety precautions

If handled incorrectly, the tool can cause serious injury to a worker, so it is important to know the basic safety rules:

- Before each use, the instrument must be inspected for defects.

- If you are going to make a hole in the wall, you need to make sure that there are no communications in the selected location.

- It is highly not recommended to use a drill in a room with a high level of humidity.

- Do not use a tool that has been exposed to water.

- While working, you should not put too much pressure on the drill, and before pulling out the drill, you need to release the pressure.

- To replace the drill, you should turn on the drill and wait until it stops completely.

- If the drill body gets hot and the motor starts to hum, you need to postpone work and let the tool cool.

Following safety precautions reduces the risk of injury

Advantages and disadvantages

The use of additional accessories for drilling tools has both its supporters and opponents. Nevertheless, it is worth taking a closer look at the advantages and disadvantages in order to objectively assess the usefulness. So, the advantages of using such devices.

- Savings on equipment purchases. It is quite logical that buying a nozzle or even an entire structure will be much cheaper than a new technical device. For example, an inexpensive set of cutters will cost from 1,500 rubles to 2,200 rubles, and a milling machine will cost from 3,500 rubles and more.

- Space saving. Storing such devices will require much less space in the garage than new bulky tools.

- Large selection of devices. You can find not only classic drilling devices. Miracle attachments will turn a drill into a lathe, a metal cutter, and a construction machine for screwing in piles - there can be a great many options.

Of course, this list is far from complete. Each person can find additional benefits that are meaningful to them. The disadvantages include, first of all, limited functionality. Obviously, the attachment cannot compare in quality with a full-fledged machine. It is also necessary to check before purchasing whether this device fits your drilling tool. In our age, when there are an infinite number of manufacturers, it is extremely easy to make a mistake with your choice and buy a completely unsuitable thing.

Errors when working with a drill

Professionals highlight three points:

- It is strictly forbidden to pick up the rotating chuck with your hand - the electric drill should be held by the body.

- If work is done with gloves, they must be the correct size. There is no need to take textiles with a “spare”, since the fabric can get into the cartridge and cause injury.

- When the tool is turned on, do not press with all your might, otherwise you may damage the tool and drill.

If you carry out the work in accordance with the recommendations, choose the right drill and place for drilling and avoid the most common mistakes, then drilling any hole will not be difficult.

Features of choice

Before purchasing a large and expensive set of drill attachments, you need to think about the feasibility of such a purchase. First, you need to know the purpose and operation of each attachment. Secondly, you must have minimal experience working with such a tool. And thirdly, you need to know the expected frequency of use of each attachment

If such a purchase is considered advisable, you should pay attention to the following features

- Price. Quality tools cannot be too cheap. However, the highest price on the counter is not a guarantee of long service life. It is best to stay in the middle price segment.

- Manufacturer. It is better to choose products from trusted manufacturers rather than new and untested brands. At the same time, you should carefully study the documentation and beware of fakes.

- Place of purchase. The risk of running into manufacturing defects and counterfeits is much lower when purchasing construction tools in a specialized store rather than in a regular market or supermarket.

- Package. A quality instrument is always well packaged. The box contains all the necessary information about both the product itself and the manufacturer. Inside the box there must be all accompanying documentation, including instructions.

- Guarantee. A manufacturer that is confident in its product will always provide a guarantee for any attachment. If the store does not write it out when selling, the purchase should be made elsewhere.