About the service

Editing is a service for leveling a part . It is carried out using special equipment and tools. Corrections are required over time for all car owners. Therefore, this service is quite relevant.

Driving a car with damaged rims is dangerous. The presence of a defect leads to increased tire wear, imbalance of the wheelset, and decreased vehicle controllability. As a consequence of this, the risk of an emergency increases. Buying a new drive will cost a considerable amount of money. It's better to straighten it.

Editing is done as follows:

- The part is being inspected.

- The car wheel is unscrewed.

- Equipment is being prepared. The wheel is placed on a special device and fixed.

- The tire is separated from the disk.

- The part is installed on the machine.

- Correction in progress. Work is carried out with radial and axial displacements.

Pricing factors

The cost of straightening a machine disc is influenced by a number of factors. Therefore, in different places you can order this service at different prices. The price depends on the following factors:

- Place of service provision.

- Difficulty of work.

- Part size.

- Automobile model.

- Qualification and experience of the master.

- Urgency of work.

- Tools and equipment used.

- Reputation of the service company.

- The need to call a specialist.

- Availability of promotions and discounts.

- The need for additional work.

The larger the disc size, the more expensive its restoration will cost. The higher the qualifications and more experience of the master, the higher the price for his work will be. The more famous the service station, the more expensive its services are. The more complex the work, the more expensive it will cost. Additional work (cleaning, grinding, painting, polishing, filling cracks) is paid to the specialist separately.

Varieties

Depending on the type of disc, editing is possible:

In the latter case, a slipway with pressure shafts is used. Cast products are straightened using a machine with a hydraulic press. Restoring stamped parts costs a little less because the work is easier and faster.

Depending on the size, the following types of discs can be straightened:

Reduction can be performed in the following ways:

- From a private master.

- At the service station.

- On one's own.

The service can be provided locally:

- On the territory of the auto repair shop.

- At the address where the car is located.

How to repair rims

The condition of domestic roads makes us increasingly pay attention to such an event as repairing car rims. Repair of car wheels, depending on their type, can be divided into two types: repair and restoration. Moreover, the second type of repair relates more to the restoration of alloy wheels.

repair stamped and steel wheels ourselves, using a sledgehammer. But the external appearance of a repaired dent is very, very deceptive. A simple recommendation for repairing standard wheel rims, which are steel and stamped, is that if you get a dent on the rim, you should contact a tire shop. The equipment will allow you to roll the disc or roll it out.

With regard to alloy wheels, everything is a little more serious. Experts do not recommend repairing light alloy wheels using the rolling method. The structure of the metal is damaged and the cast disc loses its quality.

Repairing alloy wheels is a more serious matter due to the characteristics of the disk material. You should know that a real master will never undertake repairs to alloy wheels, as a rule, in two cases: if there is a crack at the base of the spokes or a crack near the mounting holes. He won’t take it, even if he is a “magician and wizard of argon welding.”

Repairing wheel rims with your own hands is a completely doable undertaking. But, under one condition: if the damage to the disk does not affect its parameters. As a rule, repairing and painting discs with your own hands is carried out in the case of small cracks on standard discs, which can be welded by conventional welding. This is the so-called disk restoration.

Restoration of alloy wheels can be done with your own hands if you are proficient in argon welding. If not, then the way out is service.

Approximate prices

The estimated cost of straightening wheel rims depending on their size and type is shown in the table below.

| Disc part size | Price in rubles for straightening a cast product | Cost in rubles for straightening a stamped part |

| R13 | 600 | 600 |

| R14 | 700 | 700 |

| R15 | 800 | 800 |

| R16 | 900 | 900 |

| R17 | 1000 | 1000 |

| R18 | 1500 | 1500 |

| R19 | 2000 | 2000 |

| R20 | 2500 | 2500 |

| R21 | 3000 | 3000 |

| R22 | 3500 | 3000 |

| Moto | 1500 | 1000 |

Little-known, recently opened service stations may have slightly lower prices. A private master can perform straightening for an amount starting from 400 rubles .

Steel wheels can be easily straightened

Straightening is nothing more than the action of restoring the rim to its original shape. The process consists of eliminating all kinds of irregularities and deformations of the steel wheel that occur during everyday driving. For this purpose, special machines are used, which, due to the elasticity of the alloys, eliminate unwanted changes in shape.

It seems that everything is simple, but it is not. Depending on the alloy rim used for production and how it is made, the straightening procedure and heating temperature vary. Therefore, rim straightening should be done by someone who is experienced and knows what they are doing. Otherwise, you may do more harm than good.

Steel discs can be easily straightened - a broken disc is bent

The basket of straightening services usually does not exceed 900 rubles for one steel rim, but it all depends on both its size and the degree of damage.

Where to order?

You can try to align the disk yourself. But you need to understand that this requires knowledge, experience, special equipment (a special straightening machine), and a set of tools. If you have doubts about your own strengths and capabilities, it is better to seek help from specialists.

Today in Russia there are many private auto repairmen who offer their repair and restoration services in garages. It's risky to contact them. When removing the cover, you can scratch the disc or cut the rubber. Therefore, this work must be done carefully and competently. The risk of damage to the disc and tires for craftsmen who perform work in the garage is high. Lately there have been a lot of negligent specialists. Therefore, you should contact private masters on the advice of good friends.

If your budget allows, then it is better to order disk editing at a service center. It is important to contact reliable and trusted companies. The service station must have existed for a long time, have a positive reputation, qualified staff, and a list of necessary documents (license, certificates). It is also important that the organization issues a guarantee certificate for the work done.

Editing a stamped disc with your own hands

Regardless of the car enthusiast’s care and driving style, wheel rims often fail. During the operation of the car, the discs are constantly exposed to destructive factors and require timely restoration. Since wheel rims are important elements of the car's chassis, you should not delay their restoration. Violation of the rim structure affects the general condition of the vehicle's chassis system and its individual elements. If the geometry of the rims is violated, the tires also wear out prematurely. Editing disks (standard and steel) is often done by the hands of car enthusiasts. At the same time, it is necessary to understand that self-editing disks does not make it possible to completely restore the geometry of the rims, in the absence of specialized equipment and appropriate skills. You can restore the rims yourself only if the structure of the paintwork of the element is damaged. If the rim has been subjected to mechanical stress and has lost its geometry, you cannot do without the help of professionals.

The role of rims

Wheel rims deserve more attention, and not the generally accepted attitude, according to the principle: “they go and go.” Why? Because the condition of the car’s rims affects many aspects of the condition of the car’s systems, cost savings and traffic safety.

Being an integral element of the chassis and suspension of a car, faulty rims affect the following parameters:

- Serviceability of suspension elements. Radial or axial displacement of a damaged disk leads to failure of the steering mechanism, shock absorbers, and suspension elements.

- Savings and safety. A faulty wheel rim means tire failure, which means the cost of replacing it, increased fuel consumption and decreased safety while driving.

Repair of stamped and cast wheels.

These types of work differ in methodology and materials used.

Repair of stamped and steel wheels is carried out by rolling the rim using special equipment. Often, car enthusiasts carry out emergency repairs using improvised means (for example, a hammer). It is necessary to understand that in order to properly restore the structure, the rim will need to be rolled. Editing cast wheels is a more complex and time-consuming procedure. In this case, the conditions of the garage will not allow you to achieve the desired result. The casting restoration process requires expensive equipment and special skills.

Welding, as a rule, is used only in cases of damage to steel rims. Restoration of light alloy wheels is carried out using a different method and only with minor damage to the structure. As a rule, car workshops do not recommend restoring the structure of the lung rims on the right. It's not just about lost customers. Editing disks of this type is carried out using complex techniques that require special technical installations. One of the restoration methods is cold straightening. Second, straightening the rim by preheating and then restoring the geometry. Both methods involve the use of precise and proven equipment, which is unlikely to be available to the driver.

Restoring steel wheels

If your rims aren't looking their best, might it be better to do a full regeneration with sandblasting and painting? Then they will return to their ideal appearance, which will benefit the entire car.

Sandblasting of steel wheels is carried out in an automatic sandblasting machine. Has a speed regulator that prevents damage to the coating. After this treatment, the rim must also be additionally protected with anti-corrosion liquid.

Steel discs can be easily straightened by rolling the disc on a machine

Then it's time for sanding to remove any scratches or dents, followed by powder coating. There are many colors to choose from, so you can really stand out.

Painting steel wheels starts with a powder coating and then electrostatic powder paint is applied. The part is then sent to an oven where the paint is cured at 180°C. If the chosen color requires it, the rim can also be coated with a clear varnish.

It is worth noting, however, that painting and sandblasting a steel rim costs from 1,700 to 2,700 rubles, which, combined with the cost of straightening, may not be profitable.

Welding discs.

As a rule, stamped rims rarely suffer from cracks. Most often they bend. In this regard, straightening is more often used for this type of rim than welding. Casting, on the contrary, is often subject to cracks. As a rule, cracks can be detected by professionals and only using special equipment. Argon welding is rarely used for casting. This is explained by the fact that welding is not very productive for disc restoration. The casting has a rather fragile structure that is difficult to reconstruct. Even experienced specialists will not undertake welding, taking care of the safety of the car enthusiast.

Thus, it becomes clear that repairing light alloy rims is a complex procedure requiring expensive equipment and special skills. Steel wheels are less finicky to maintain and can be easily restored. If the structure of a light alloy wheel is damaged, it is imperative to stop operating the vehicle and contact a professional. Timely elimination of the malfunction will preserve the safety of the driver and passengers, and will also extend the life of the vehicle’s chassis and tires. Be vigilant and regularly check the condition of your vehicle's wheels. Good luck in servicing your favorite car.

Hello colleagues! Today I flew right side into a hole (filled with water). I bent the front disc and it flattened almost immediately. I had to put on the spare tire in the rain (as luck would have it, it was deflated and I also had to pump it up). The dent on the inside is decent. Is it possible to straighten it with a hammer or just roll it?

If “rolling”, then where do they do it and on what? Or is this only relevant for cast and forged?

“rolling” turned out to be an ordinary sledgehammer Got it

I'll have to take another look at the rear disc. Although it didn’t go down there, it did.

In general, anyone can skate. On what equipment? Probably not every tire shop has this.

Later I'll replace the disk with a whole one. It's in stock, but it's a long way to get there.

If the shelf (the place where the tire sits) is not bent, then it’s ok. If it weren’t dented, then the tire wouldn’t go flat, IMHO. I'll try to straighten it and pump it up tomorrow.

If it gets bad, I’ll try to take it to the nearest tire shops. Otherwise, you will have to drive 50 km with the spare tire to a garage in the Moscow region.

On the Yauza, on the descent from Preobrazhenka to the Gannushkina embankment, there is a good ride for discs at Tinomontazh! vosmilie:

To everyone who responded, THANK YOU! The problem is solved. :ura1 Using a hammer and a bottle of water. After the first edit and pumping it was poisoning quite a bit. Subsequent light chasing and testing by pouring water into the groove around the disk eliminated all problems. There were no bubbles at all. I pumped it up to normal, set it up, and drove it forward and back with sharp braking (so that the tires sat down without strain). Control measurements after an hour and two did not reveal any pressure drop. I will monitor the first few days (measurements in the morning and evening with an electronic pressure gauge. By the way, a good Chinese thing).

Do-it-yourself repair of alloy and steel wheels

Hello, dear car enthusiasts! What do rims mean to you? Personally, what role do you assign to them, first of all? Aesthetic or practical?

Don't let these questions seem strange to you. After all, let’s be honest, it’s a very rare motorist who thinks about the role and significance of a wheel rim in everyday life.

Only fans of car tuning, and perhaps that’s all. And we, the majority of car owners, remember about rims only when we find ourselves in a hole, and we absolutely need car rims repaired.

It is important to always remember! A faulty wheel drive means extra costs for repairs or replacement of parts:

- failure of steering mechanism elements;

- failure of suspension elements. In particular - shock absorbers;

- violation of the wheel alignment, with the resulting “eating” of rubber;

What does wheel rim repair include?

First, let's define the concept of when wheel rim repair is required. The issue, in fact, is given relevance by the state of the road surface in domestic traffic directions.

Even with careful driving in normal mode, we constantly get our car wheels into holes, potholes, etc. Particularly dangerous are holes in asphalt with sharp edges and a depth of more than 10 cm. Any, even the most branded, high-quality disc sometimes receives irreparable defects from such “encounters.”

And if you adhere to the principle when driving a car: more speed - fewer potholes, then car wheel repair is not far off for you.

We can talk a lot about the beauty, quality and performance characteristics of different types of rims. Now we are talking about renovation. Therefore, repairing stamped steel wheels is an easier and more cost-effective procedure.

- Repair of stamped wheels can be carried out at any tire service station using the rolling method. Naturally, if you have the equipment. As a matter of urgency, you can repair a stamped disc yourself using a sledgehammer. Although, this does not mean that the stamped disk, after sledgehammer repair work, does not need rolling.

- You can no longer repair light-alloy aluminum wheels in a garage. Repairing alloy wheels requires a method called straightening. And its technology involves the use of special equipment.

- Welding steel wheels is also a simpler task than welding alloy wheels. Argon welding is already required here.

What is corrected during the repair process, both steel and alloy wheels? First of all, the radial and axial displacement of the disk caused by the impact. Then, naturally, mechanical damage to the disk in the form of cracks is eliminated.

How to repair wheel rims

Car wheel repair can be divided into two categories: wheel repair and restoration. At the same time, restoration is a category into which cast and alloy wheels fall. The technological process of restoring alloy wheels involves their restoration, i.e. recovery.

Repairing stamped steel disks with your own hands is a completely doable procedure. When straightening a disk with a sledgehammer, we can eliminate visible defects, without guaranteeing geometric accuracy.

Therefore, you still shouldn’t engage in amateur activities, but spend only 15 minutes to roll a stamped wheel at a tire shop. And the geometry of the disk will correspond to the norm, and the structure of the metal will not be damaged.

the repair of aluminum cast wheels yourself. Not because this is their income. No. The fact is that two methods are used to repair a cast disk: straightening using the cold extrusion method and the method of spot heating with subsequent extrusion of the damaged section of the disk.

Both methods involve the use of a special machine, with alignment, hydraulics and special attachments. If you have such a machine lying around in the garage, then repairing alloy wheels with your own hands is a doable task.

Welding wheel rims . When repairing steel wheels, welding is rarely used. The structure of the metal is such that cracks on stamped discs are rare. The same cannot be said about "casting".

Repairing alloy wheels allows technicians to identify cracks on the wheel. Elimination of cracks on cast wheels is carried out using argon-arc welding.

You should know that a true professional in repairing alloy wheel rims will never undertake welding cracks on the rim in the area of the entire seating area and at the base of the spokes (any). The loads on the wheel rim during movement are such that welding is not able to eliminate the damaged structure of the rim. This is a matter of your safety, first and foremost.

Painting car rims . This type of disk maintenance can most likely be called an aesthetic and preventive measure. The technology for painting stamped wheels and cast wheels is practically the same. For stamped steel wheels, painting is an important element of protection against corrosion, thereby increasing their service life.

These are the types and features of wheel rim repair that currently exist. We can do some disk repairs ourselves, but some procedures are best left to professional people and special equipment.

Good luck with your steel and alloy wheel repairs. Better yet, keep your eyes on the road, and wheel rim repairs will be unfamiliar to you.

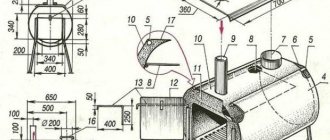

Making a stand for wheel correction

The stand is intended for correcting uneven stampings and light alloy wheels with your own hands and can be developed at home. Compared to manual processing, it significantly improves productivity and quality of edits.

To make a disk straightening machine, follow this procedure:

- install the shaft on the frame, where fasten the universal hub;

- Place the product that needs to be fixed on the hub;

- secure the bed to the stand. The stand itself is attached to a hydraulic station, which will power the mobile hydraulic cylinder. A tool for straightening discs is mounted on its rod;

- control the cylinder using a hydraulic distributor with a pressure reduction valve;

- To be able to install the cylinder at any angle relative to the product being repaired, use a pair of movable brackets.

In order for a machine for rolling cast discs to fasten products with different diameters, its hub must be equipped with centering washers of the required diameters (a total of 18 fasteners will be required).

Manufacturing of balancing machine

To extend the life of the wheels, they must be periodically balanced on an appropriate machine. You can also make this device for improving the quality of disks with your own hands.

And to do this you need to follow these steps:

- make racks. To do this you will need 2 steel strips 30*4 mm. At the top of the rack in a semicircle with a diameter of 32, you need to install a ball bearing;

- the base is made of a steel sheet with a thickness of 0.5 cm and dimensions of 30 * 50 cm. The sheet is attached to a pair of 3 * 4 cm wooden beams. The entire knot is secured with two pieces of 3*3 cm, 13.5 cm long;

- the second rack is done in the same way. The distance between a pair of posts should be 15 cm. And their verticality can be checked with a level.

The simplest balancing machine for wheel rims

To use equipment for correcting rims with your own hands, you will need to install an arrow pre-cut from plywood. It will indicate static equilibrium.

Advantages of stamped discs over cast ones

Car enthusiasts still continue to argue about which rims are better: stamped or cast. Each type of these disks has its own pros and cons, that is, advantages and disadvantages, which we will try to understand. The first are produced by cold stamping of two parts - the central element and the rim. And then the parts are connected by spot welding. They are made of steel.

A cast wheel is created by casting a liquid alloy into a special mold and then finishing it. As a rule, alloy wheels are made from aluminum, sometimes from magnesium. The main disadvantage of “stamping” is its unpresentable appearance. They look visually an order of magnitude worse than casting. In addition, due to the characteristics of steel itself, rust forms on the metal faster and more often. However, both the first and second drawbacks can be easily eliminated. Sandblasting works well against corrosion, and an attractive appearance is achieved with the help of caps.

Rolling methods

There are two ways to roll a stamped disc:

- Full. Partial. During full rolling, the entire disc is processed. It is placed on a special stand, where, using an alloy steel rolling roller, straightening occurs along the entire circumference. This method has its advantages and disadvantages. Full rolling allows for better balancing of the disc, but also contributes to a change in the structure of the metal. When the roller applies pressure to the rim, it not only straightens the surface, but also increases the density of the outer layer of metal. At the same time, the density of the internal part remains unchanged. When metal of varying densities within the same part is subjected to stress, severe stress occurs, which can subsequently lead to cracks. Those who have rolled a disc know that it is not recommended to perform this procedure several times on one part.

- The second method is partial. In this case, the rolling roller does not process the entire rim, but only the area that has a defect. Partial or soft rolling allows you to extend the service life of the metal and not change its structure, with the exception of the damaged sector. In addition, it takes significantly less time. However, it is more difficult to achieve wheel balancing after such treatment.

What is disk editing?

Disc straightening is the process of recreating the original geometry of a stamped or cast product after it has been damaged or fatigued as a result of too much use and physical wear. To ensure that the wheel is corrected, the car owner needs to come with his car to a service station, where the technician will perform the following procedures on the damaged wheel:

Disc straightening press

- To begin, the wheel is removed from the hub using a balloon or hydraulic wrench.

- The product is cleaned of dirt with a brush and then washed under running water.

- The technician will carefully examine the disc for damage and cracks due to deformation.

- After this, the wheel is placed on a special straightening press, securely fixed on it, and the specialist begins his work.

- The first thing that happens is the correction of the curvature along the inside of the product, during which it acquires the correct rounded shape. This happens due to the operation of a hydraulic press, which exerts a force of 5 to 10 tons, depending on the manufacturer and power of the device.

- Quite often it happens that the structure of the disk itself is not touched, but due to a strong impact, one of the edge edges on the side is jammed. For this purpose, a rolling mill is used; the product, rotating, passes through a system of rotors, where the wheel is restored.

- Stamped steel disks are much easier to edit, since their metal bends easily and to achieve the result you only need to restore the geometry. If the disc turns out to be light alloy, then microcracks may form in it, which can cause it to burst. In such cases, the master resorts to argon welding, eliminating the defect.

You might be interested in this About the wheel bolt pattern on the Daewoo Nexia

Editing alloy wheels

- After welding, he grinds the disc and paints it, first removing the old paint layer. Editing steel wheels is much easier; they can be painted using a regular spray can, especially if after that decorative caps are installed on them.

- Upon completion of the operation, the wheel is tested on a special balancing machine, and if everything is in order, a tire is put on it, and the finished product assembly is fixed back to the hub. If the disc needs painting, then the whole procedure will take about a day, if not, then the driver will leave the service station in 1-1.5 hours.

Important!

Regardless of the quality of the work done, most likely the structure of the metal will already be damaged, and the driver should be careful on the road, monitoring every manifestation of vibration while driving, especially at high speed. No professional can give a 100% guarantee on his work, since he does not know how the disk will actually behave after repair, and it may even burst.

That is why official dealers, at the slightest bend in the wheel, immediately insist on replacing the disc. However, if we are talking about steel stampings, then straightening them is a common thing, since simple bending does not in any way affect the properties of the ductile and easy-to-work metal. The only thing that will definitely need to be done when the stamped discs have already been straightened is to paint the restored products to avoid the formation of corrosion.

Rolling of stamped discs