Dark and light IR emitters

By definition, “bright” sources are capable of emitting light.

The streams they emit are perceived by vision, although it is still difficult to call them bright lighting and should not be used for this purpose at all. “Dark” devices deliver a flow of heat invisible to humans, felt by the user’s skin, but not visually detected. The boundary value between “light” and “dark” is considered to be a wavelength of 3 microns. The limiting temperature of the heated surface is 700º.

The property of infrared emitters to supply thermal energy is actively used in greenhouses, chicken coops and farms to support young animals

The most famous representative of a “dark” heating unit is the Russian brick stove, which has successfully heated low-rise buildings for many centuries. Among the “light” ones, as we already understand, is an incandescent electric light bulb, if it supplies no more than 12% of light. Its main energy is directed towards generating heat.

Features of the design of light fixtures

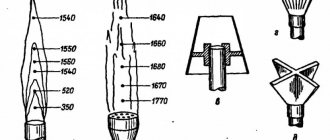

Structurally, light sources are similar to a typical incandescent lamp. However, there are differences in the filament bodies. For bright infrared devices, the temperature cannot exceed a limit of 2270-2770 K. This is necessary to increase heat flow by reducing light emission.

Just like standard light bulbs, the filament body, made of tungsten filament, is placed in a glass bulb. Only the flask is equipped with reflectors, thanks to which all radiant energy is focused on the heated object. In this case, a small part of the energy is spent on heating the bulb base.

The bulb of light infrared sources heats up to high temperatures, so it also participates in the process of heat transfer into space. The thermal energy from the heated flask is not focused by the reflector and goes out into the untreated space; it is the component that reduces the efficiency of the device.

In design and connection method, infrared lamps are very similar to conventional incandescent light bulbs. However, their operating temperature of the filament body is significantly lower, due to which the service life is increased many times over.

The productivity of a light infrared source on average does not exceed 65%. It is increased by placing a tungsten heating body in a tube or similar flask made of quartz glass. This solution makes it possible to increase the wavelength to 3.3 microns and reduce the temperature to 600º.

This option is used in quartz IR heaters, in which chromium-nickel wire is wound around a quartz rod and the whole thing is placed together in a quartz tube.

Light infrared emitters have low performance. The efficiency of their infrared flux usually does not exceed 65%

The essence of the work is the double use of filament wire. The released thermal energy is partially used for direct heating, and partially for increasing the temperature of the quartz rod. A red-hot rod also emits heat.

The advantages of tubular devices include, quite reasonably, the resistance of all components made of quartz and ceramics to atmospheric negativity. The downside is the fragility of ceramic parts.

Specifics of operation and design of dark heaters

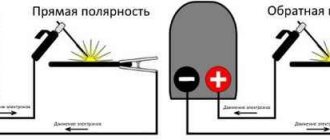

The so-called “dark” sources of IR fluxes are much more practical than their “light” counterparts. Their radiating element differs in structure for the better. The heated conductor itself does not emit thermal energy; it is supplied by the surrounding metal shell.

As a result, the operating temperature of the device does not exceed 400 – 600º. To ensure that thermal energy is not wasted, dark emitters are equipped with reflectors that redirect the flow in the desired direction.

Long-wave emitters of the dark group are not afraid of shocks and similar mechanical influences, because the fragile polymer or ceramic element in them is protected by a metal casing and a protective heat-insulating layer. The efficiency of emitters of this group reaches 90%.

But they are not without their drawbacks. Dark group heaters depend on the design features of the device. If the distance between the main radiating element and the surface of the device is large, then it will be washed and cooled by the air flowing past. As a result, efficiency decreases.

Due to their design features, dark models are installed for heating rooms with low ceilings and areas that require linear heat supply. Light - placed where processing of rooms with high ceilings and vertically elongated areas is required.

Basic criteria for choosing gas camping stoves

Before you go to the store to buy a camping stove, you need to carefully weigh your choice by considering the main parameters of these devices.

An indicator such as power deserves primary attention. On average, cooking 1 liter of food requires about 1 kW of thermal energy. On a hike, one person needs approximately 0.5-0.7 liters of product at a time. Based on these data, it is easy to calculate the required power level of the unit. For example, three tourists for an expedition will need a stove with a power of 1.5-2 kW. The weight of standard units ranges from 0.8 to 2 kg.

This indicator depends on several factors:

- the material from which the tiles are made;

- burner area;

- body part size;

- design features, for example, the nature of the placement of the fuel tank, which can be built-in or removable.

Since on a hike you have to carry all your things on yourself, the weight of the camping tile is of great importance. When choosing a suitable model for expeditions, you must take into account fuel consumption. This indicator is usually written down in the technical data sheet, which is attached to the stove. It is expressed either by the time it takes to boil 1 liter of water, or by the amount of gas consumed in 1 hour. There is one pattern here: the more time it takes for the liquid to boil, the lower the fuel consumption.

The dimensions of the hob impose restrictions on the width of the utensils used, and therefore on the volume of food that can be cooked at one time. If a container with a capacity of 5 liters is placed on the tile, then such a unit is capable of feeding approximately 5-7 people in one cooking session.

Note! Camping stoves equipped with ceramic gas burners do not require wind protection, since the flame is hidden inside the burner

Classification and technical characteristics of gas burners

All models are divided into types and classes in accordance with their functions and technical characteristics such as combustion temperature and flame shape, the presence or absence of piezo ignition, etc.

- Tourist gas options.

- Supercharged blowtorches.

- High temperature gas units.

There are many technical characteristics of these devices, but you need to understand them in order to make a reasoned and competent choice of model for a particular job.

Using a burner at home.

They are as follows:

- Operating time of the device from the can.

- Presence or absence of air leaks. If there is a suction function, the combustion temperature increases significantly.

- A type of solder that varies depending on the metals being welded. If the device is universal, it can work with any solder.

- Presence or absence of piezo ignition.

- The presence or absence of a gas temperature regulator.

- Maximum combustion/heating temperature.

- Size and type of connection between the device and the gas cartridge.

- Type of cans.

- Weight and dimensions of the kit with a spray can.

Let us separately note the collet connection of the burners in the form of nozzles for cans. A collet is a special bushing for connecting cylindrical parts.

Based on combustion temperature, gas mini-units are also divided into three groups:

- The simplest models with a minimum temperature in the range of 700 – 1000°C. In such devices, air flows independently, which in principle is not enough. Hence the modest temperature.

- If the model is equipped with an air supply channel for the supply of additional air, the combustion temperature can reach 1200°C.

- In burners with ejectors, air enters the flame due to rarefaction. This raises the combustion temperature to a fundamentally new level up to 1500 – 1600°C.

- The use of gas rather than air helps to achieve serious temperatures of 2000 - 2400 ° C by concentrating the air in the hearth.

Advantages of modern gas appliances in everyday life and industry:

- small weight and dimensions;

- economical in gas consumption;

- no smell;

- heat up quickly;

- don't make noise;

- are adjusted automatically;

- complete gas utilization.

Types of portable burners

Gas burners are devices that differ in design and purpose, but they are united by a common feature - they operate using gas.

Portable devices designed to operate from a small tube filled with propane-butane or other gas should not be confused with ovens or powerful welding units that operate from natural gas or a large cylinder.

We offer a brief overview of the main design elements of an inexpensive gas cartridge burner, which serves as an excellent example of a home device. It may be useful for repairs in the country or for a barbecue.

Using a compact device, you can quickly light a barbecue, heat bolts or nuts in the cold, melt plastic parts, and process heat shrinks. The flame temperature (up to +1300°C) is enough for soldering metal pipes.

This is an example of a burner type that is popular among users, but the range of devices is much wider. Let's look at the most popular types.

Difference by area of use

An open flame may be required at home, on vacation, and during installation work. One of the areas of application is tourism. When camping, use a simple device to light a fire and heat up canned food.

Burners with a directional torch of a “pistol” type are often used in installation work when soldering copper pipes and for bending plastic elements.

High-temperature high-power lamps can also process steel parts, but this requires hard solder and a slightly modified soldering technique.

Gas portable burners are also used for the following work:

- processing of wooden parts;

- lighting a barbecue or a fire in the country without the use of chemicals;

- calcination and cutting of metal blanks;

- singeing animal carcasses during butchering;

- thawing frozen pipelines.

This useful device is always at hand for craftsmen who love to improve their homes and improve their garden plots on their own. The burner can be useful in a car repair shop, during the construction of a greenhouse or other structures.

Division according to the method of attaching the can

The fuel cartridge is a consumable item. As soon as the fuel runs out, it is disconnected from the burner, and a new cartridge is installed in its place.

There are several ways to attach a cartridge to a device:

- threaded - fixed with a thread, in other words - screwed on;

- collet - put on and slightly rotated to one side;

- valve - secured with a retainer;

- pierced - connected with light pressure.

Threaded models are more common than others. They form a strong connection between two elements that can be separated at any time. Punctureable ones, on the contrary, cannot be turned off until the gas in the can runs out.

The weakness of collet devices is the rapid loosening of the clamp, resulting in loss of gas.

Valve burners, which are usually designed for heating food, are considered more reliable.

Differences in gas burners by fuel type

Manufacturers use various fuels to fill consumable cartridges. The choice of liquefied gas is based on the purpose of the burners, the required flame temperature, and power. To improve the characteristics of the composition, several different types of fuel are sometimes mixed.

The following combinations of substances are used most often:

- a mixture of propane and butane (70:30) - mainly for summer use, but with a heating device it is also used in winter;

- a combination of propane, butane and isobutane in various proportions;

- a mixture of MAPP - methyl acetylene-propadiene-propane, most often used for welding at temperatures of 1600-2500 ° C.

But there are cans filled with one gas, for example, butane.

The choice of fuel is important when work is to be done in harsh conditions - in the cold or at high altitudes. And in the summer, any universal gas is suitable for lighting a barbecue or fire.

Travel lamps

Low-temperature devices are used to perform a wide range of work, suitable for both domestic use and professional construction. These blowtorches often replace electric hair dryers where only autonomous operation is possible.

The main disadvantage of burners without an injector is the low flame stability, especially noticeable during sharp tilts and turns. The splashing of liquefied gas does not have a significant effect in more expensive devices that have a special gearbox and heating circuit.

Typically, such devices are not used for soldering. They are mainly used to light firewood and coals or to heat materials that allow the use of an open flame. The lamp is indispensable for thawing pipes, heating car engines, burning paint to remove it, unpacking strips on tow, and other rough work.

Conclusions and useful video on the topic

The process of connecting the cylinder to the stove:

Rules for connecting a propane cylinder:

Connecting bottled gas to the hob:

To connect a propane cylinder to a gas stove, you do not need to have any competence or special skills. All you need is a wrench and common sense. And don’t forget, after connecting, before starting cooking, use soapy water to check for leaks at the connections.

Would you like to talk about your own experience in connecting gas household appliances to a liquefied gas cylinder? Do you have useful information on the topic of the article? Please write comments, ask questions, post photographs related to the topic of the article in the block below.

OCCUPATIONAL SAFETY REQUIREMENTS AFTER WORK COMPLETION

5.1. Upon completion of work, it is necessary to tidy up the workplace and remove debris. 5.2. Hand tools and accessories should be cleaned of dirt and stored in a designated storage area. 5.3. At the end of the work, you should take off your overalls, safety shoes and other personal protective equipment and put them in the designated storage location, and, if necessary, hand them over for washing and cleaning. 5.4. At the end of work, you should wash your hands thoroughly with warm water and soap, and if necessary, take a shower. 5.5. Any malfunctions and malfunctions of the tools and equipment used during work, as well as other violations of labor safety requirements, should be reported to your immediate supervisor.

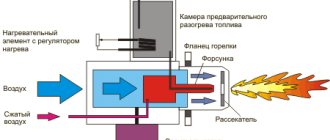

Supercharged lamps

The design and purpose of ejector blowtorches is more specific. These devices are used for processing non-ferrous metals. Due to their high temperature and ability to regulate the flame, these devices are excellent for soldering and hardening of metals, and other heat treatments that require high temperature accuracy and a strictly defined cone.

The specifics of the application seriously adjust the size of the nozzles and burners. Miniature devices are used for soldering thin metal and jewelry. Mid-class torches have a cone thickness of 3-9 mm; they are more suitable than others for electrical soldering of cable joints, aluminum and copper tubes.

Due to their high power, larger products can be used in the following areas:

- artistic forging;

- precision stamping and bending of metal.

It is these tools that home craftsmen use as the basis for homemade hardening furnaces and gas forges.

In the case of ejector options, the concept of flame instability is purely figurative, although there is a possibility of periodic flashes of gas, in the core the temperature remains relatively stable. The gas preheating circuit is used more to increase the efficiency of burners, speed them up to operating power, and more accurately control the temperature.

What are they?

Today on the market you can find a variety of models of propane burners: oxygen-propane, gas welding, household, air-propane, with piezo ignition, mini-burner, with a compressor, propane-butane, etc. Let's consider the key features of some types of devices.

Manual

These burner models are most often used for installing bitumen roofing. Their distinctive characteristic is a high level of comfort of use. In addition, the flame can be easily adjusted using a specially designed lever mechanism.

Air-propane

Burners not only with gas, but also with air (or oxygen) are considered one of the safest. Thus, whenever possible, give preference to such models.

Valve

Such devices are relatively light in weight, and they are also quite easy to use. Valve burners are easy to repair and repair and can operate even in strong winds.

Tourist gas cylinder. What's inside?

Standard gas cylinders for burners use a mixture of butane, propane, and isobutane. The proportions in which they are “mixed” determine how well the burner will work, and, first of all, in the cold.

The vast majority of cylinders contain a mixture of propane/butane (isobutane) (either 30:70 or 20:80). Burns much more stable, incl. and at sub-zero temperatures, a cocktail in which instead of butane there is isobutane (or butane + isobutane), because in its chemical properties it is more homogeneous and has a higher octane number. Problems when using such a tourist gas cylinder begin at minus 15 degrees.

Coleman Propane Fuel Propane Tank

The higher the propane content, the more expensive the fuel for the burner. In special gas mixtures that are intended for use at low air temperatures, the so-called “winter gas” (the designation on the cylinders is the word “winter” or a snowflake), the propane content is 50% or higher. Manufacturers claim that they are suitable for use at air temperatures down to minus 25-30 degrees.

100% propane gas for Coleman Propane Fuel camping burners, which can be used at air temperatures down to minus 42 degrees (boiling point of propane). Cylinder volume 465 g. costs about 600 rubles. For this gas, a special, thick-walled cylinder is used, since propane requires more pressure to compress. Such a cylinder is intended only for use in propane burners and lamps of the same brand; its weight is much more noticeable than that of cartridges of the same volume filled with butane or gas mixtures.

100% isobutane/butane filler is found in tourist gas cylinders, in particular domestically produced ones such as “Eurogas” and “Tierra” (they are also called Kazan cylinders) and Korean “Pathfinder” and “Neogaz”. Without a doubt, they can be used on summer hikes, when the thermometer does not drop below plus 5-10 degrees, although manufacturers claim sub-zero temperatures.

Experienced tourists have a whole arsenal of little tricks that help gas burn in the cold. But, in our opinion, it’s easier not to be perverted, but to take either an oil burner or a multi-fuel burner on a winter hike. Gasoline burns vigorously even in severe Arctic frost.

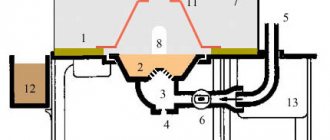

How the device works

The device operates in the infrared wavelength range. For this type of radiation, the air is transparent, so the radiation does not heat it. Only surrounding objects that absorb infrared rays are heated, as a result they become a source of heat.

Due to the peculiarities of the device’s operation, it turns out to be very effective in large spacious rooms compared to other heaters, for example, an electric boiler.

Such devices make it easy to heat rooms with high ceilings, since energy is not wasted on heating the air.

The source of infrared rays in the device is a ceramic perforated panel. It heats up to the required temperature, at which it begins to emit electromagnetic waves.

The device of an infrared gas burner.

Smooth adjustment of the infrared burner allows you to customize it for each specific task. Due to their high efficiency, such devices are perfect for installation in open areas of cafes, on verandas, in gazebos and in large workshops.

Among other things, the heater provides protection against gas leakage. For these purposes, a special valve is installed. This element has a sensitive thermocouple. If wind or any other external influence extinguishes the flame, the gas supply will stop.

Information regarding the operating principle of the device is provided solely for familiarization and understanding of the basic operation of the burner. Making a homemade heating boiler with an infrared burner is highly not recommended.

The fact is that even in the simplest units, which are not very expensive, there are many sensors that monitor the operation of the boiler.

A backdraft sensor must be installed to prevent the flame from blowing out, an overheating sensor, gas leaks, a temperature sensor that regulates the temperature of the coolant, and a thermostat.

In order for all of the above elements to work effectively in tandem, it is necessary to correctly write a control program for the microcontroller. Even a person who understands programming will need several weeks of intensive work on the software.

Among other things, it is worth keeping in mind that not a single gas service will allow you to connect uncertified gas equipment. And this is correct, because the cost of error in this matter is too high.

Moreover, it is better not to “get inside” even into factory devices without appropriate training.

Popular brands

A range of gas cylinders for burners is presented on the market by many manufacturers. Of these, the following brands are considered the most famous and popular.

"Pathfinder"

Domestic brand of the group. The assortment is represented by attributes for tourism: portable stoves and burners, cans for them and other equipment. All products are tested in real conditions and improved taking into account identified shortcomings.

The manufacturer produces two types of cans: threaded and collet. Based on the gas composition, models are produced for year-round use, in winter or warm periods (spring-summer-autumn).

Kovea

South Korean brand. It has been on the market since 1982 and is famous for gas equipment and its accessories. The brand's products are in demand by tourists, motorists, professional craftsmen and home craftsmen. The company constantly replenishes its range with new modernized models.

Some products have been awarded prestigious awards.

Topex

A Polish brand whose product quality is marked by many international certificates. Products of this brand are widely known and enjoy great popularity.

READ How to properly connect an electrical panel

Trump

A Russian brand whose products are manufactured in South Korea. The company produces cylinders of 2 types - collet and threaded.

Jetboil

An American manufacturer that produces a kit for camping cooking, consisting of a burner, a container for food and threaded containers for the device. The cylinders are filled with a mixture of isobutane and propane and can be used all year round.

Replaceable gas containers are available in 3 volumes: 100 g, 230 g, 450 g.

Research

Czech brand specializing in composite cartridges.

Precautions for use

A hot water burner, like any tool that produces a flame during operation, is a high-risk tool.

Therefore, when using it, you must follow a number of rules that will help protect yourself and others, as well as carry out the planned processes efficiently:

- regularly carry out a preliminary inspection of the structure, make sure that the equipment is in good condition and that there is no risk of gas leakage due to a damaged hose or connections;

- when igniting gas, do not stand in front of the nozzle, do not direct the fire towards the gas cylinder, hoses, or people;

- in the process of fusing various materials, carefully control the flame, avoid excessive heating and accidental fires;

- do not go beyond the working area with the device;

- Do not work near gas cylinders or gas pipelines - the safe distance is at least 10 meters.

Fire extinguishers and sandboxes should be present at the workplace to help suppress a fire in the event of a fire. If the connecting hose or glass is clogged, the device cannot be used. This may be indicated by popping noises, kickbacks, or overheating of the equipment.

Having identified such problems, you should turn off the device by shutting off the fuel supply. Do not use wire or other sharp objects to clean the mouthpiece.

To protect your eyes from the harmful effects of infrared and ultraviolet radiation, it is advisable to use special glasses with light filters. You need to work in clean, oil-free workwear and non-slip shoes

In addition, the device must be extinguished correctly. First of all, the fuel supply is shut off, and then the lever is released.

It is not recommended to leave the tool turned on during breaks in work: it is better to extinguish the flame. If a significant break is planned, you need to shut off the gas supply to the cylinder by tightening the reducer valve.

How to choose a torch for connecting copper pipes is described in detail in the following article. We recommend that you read the useful information material. The torch soldering technology is given here, the process is outlined in great detail.

Recommendations for using a burner with piezo ignition for gas cylinders

A gas burner, when it comes to safety rules during use and/or storage, has quite logical rules, which most products have in one way or another related to fire, namely:

- Under no circumstances should you connect the device to a gas cylinder with the valve open;

- It is risky and unwise to use a damaged or faulty burner. If a defect is detected, immediately shut off the gas supply and disconnect the burner from the cylinder;

- You should be careful when igniting: no gas leaks should be observed/felt; also, if the burner with the cylinder falls, it is necessary to check the integrity of their connection, as it could be broken;

- The device is also sensitive to strong gusts of wind, which can extinguish the flame, however, the gas will continue to escape, it is recommended to constantly monitor the flame;

- Naturally, there will be a warning about ignition near explosive, combustible and flammable substances;

- It is necessary to ensure the cleanliness of the burner and cylinder valve, as well as the flame power regulator and piezoelectric element;

- Of course, you should not place a gas cylinder with a burner installed on it near either open sources of fire or, in general, near heated objects - the cylinder, firstly, is filled with explosive and flammable material, and, secondly, it is under pressure ;

- After use, the burner nozzle remains heated for some time, so care should be taken in both handling and storage.

How to avoid burner failure?

Since the most common reason for a gas burner with piezo ignition to stop working is the breakdown of its most important element - the piezo, it is important to take care of its safety. Do not damage the device or allow water to get inside the burner, especially if you are going camping.

At best, you will have to light the gas burner with matches, unless you remember to take them with you

Do not damage the device or allow water to get inside the burner, especially if you are going camping. At best, you will have to light the gas burner with matches, unless you remember to take them with you.

The duration of use of the gas burner should not exceed 10-15 minutes, after which it is necessary to give the device a little time to cool down

Even if the piezoelectric element is damaged in some way, you should not be upset, because today there are many autonomous piezoelectric ignition devices on sale. That is, it is the same piece, only portable.

So, you don’t have to unscrew the gas burner every time to put on a new piezo ignition, and such a portable piezo ignition will definitely come in handy not only outdoors, but also at home.

Do not forget that the cause of the malfunction may be simple contamination of the nozzle or a slipped ring, therefore, to identify the cause of the breakdown, it is important to conduct a thorough diagnosis of the device. If the piezo is working properly, you just need to try to light the burner to understand which part caused the burner to malfunction

Burners in Tourism

Burners in tourism are a very useful thing. They are indispensable for climbers, speleologists and other people traveling to places where there is no firewood. And for all other tourists, they simply make life much easier. After all, how nice it is to warm up some tea without getting out of the tent when it’s raining outside. Or when you've been tramping all day with heavy backpacks and dreaming of anything other than searching and sawing/cutting firewood. Or maybe you are wandering around a nature reserve without permission, where a sharp-eyed forester is only looking out for smoke from a fire. In all these cases, a burner will help you out! Which exactly? I hope that after reading this article you will make your choice.

So. What are they? Almost everyone knows about gas burners, but for some reason they often forget about the existence of gasoline and multi-fuel devices that run on both gasoline and gas.

Let's start with gas burners.

Gas-burners

No, after all, let’s start not with gas burners, but with cylinders that can be used with these burners.

Main types: Collet and threaded. Collet ones are cheaper: a collet cylinder with 220g of gas will cost you an average of 75 rubles, and a threaded cylinder of the same size will cost about 140 rubles (update: 220 rubles in 2021). But threaded cylinders are more reliable and are available in different sizes. Also, cooking with collet cylinders is noticeably slower. There are adapters from a collet cylinder to a threaded standard and vice versa, I will show them below. There are also cylinders from Campingaz. They are not very common in Russia and few burners are produced for them. I don't recommend relying on them. And “pierceable” ones - they cannot be disconnected until the cylinder is completely used up. Also, Campingaz and “pierceable” cylinders are each placed only on its own special type of burner. There are no adapters.

Remember: CYLINDERS ARE NOT INTENDED FOR REFUELING! Using overfilled cylinders can end tragically! Buy new cylinders!

Now let's move on to the burners themselves. They are classified according to the types of cylinders that can be connected to them.

Burner for cylinders with thread

Lightweight, compact, and now also a very cheap burner. Ideal for small groups, making tea at small rest stops. Reliable, nothing really breaks. Usually more powerful than hose burners.

One of the disadvantages is low stability. It would be dangerous to place a large pot on such a burner. And such a burner uses only expensive cylinders. Of course, you can buy this adapter for collet cylinders:

But the cost, weight and size of such an adapter often exceed or equal the cost, weight or size of the burner itself, so the adapter is not popular.

You've probably heard about the Jetboil burner. In essence, this is the same burner for a threaded cylinder, but with a radiator attached to the mug that comes with the kit.

Thanks to the radiator, water boils much faster, thereby saving time and fuel. When carried, the mug fits the burner itself and a 230 gram cylinder. The disadvantage of the system is that if you use other dishes, all the advantages will disappear). Although no, not all: Jetboil can be suspended using a special system from the ceiling of a tent, from a tree or from a climbing harness when climbing vertically. And in the cabin of a yacht rocking on the waves, Jetboil will allow you to boil a mug of tea on a freezing watch. As sometimes happens, the name of the company has become a household word. The products of other companies that copied the idea are often also popularly called “Jetboil”. You may hear: “Covey Jetboil.” Now there are Jetboil models with a hose that allow you to cook in large pans.

If you buy a pan from such a system separately and place it on any other burner, the effect will be the same as that of the original system.

And by the way, the Jetboil design is not the most economical and fast-boiling. MSR has made an even more successful burner-pan system in its Reactor burner.

Let's see, after all, what is the point of hose burners.

Burners with hose:

Burners for collet cylinders only:

-The presence of piezo ignition greatly simplifies the use of the burner. But you should remember that it often breaks down and does not work at high altitudes. Therefore, you must carry matches or a lighter along with the burner; a flint and steel would be a win-win option.

-As I said above, gas does not burn well in the cold. In order not to completely frostbite your hands, while warming the cylinder so that it somehow burns, you need to take care of the “winter” gas. Its increased frost resistance is determined by a different ratio of butane and propane in the mixture. Cylinders with this gas are specially marked and are more expensive, you can’t go wrong. And they only come in threaded versions! Or collet cylinders with winter gas have been carefully hidden from the author of the article for years...

A gasoline burner will help to finally solve the problem of using a burner in cold conditions.

Gasoline burners

“I’m sitting, not bothering anyone, I’m fixing the primus stove,” the Behemoth Cat used to say from the well-known novel. Previously, a primus stove was in the kitchen of every home, but later it remained only with tourists. If you talk to old climbers, they will definitely tell more than one story about the Soviet primus “Bumblebee” - it was a very dangerous burner, often exploding. Now everything has changed, many different reliable foreign models have appeared. Actually, “Primus” is the name of the company, which has migrated to all gasoline burners in Russian.

A gasoline burner looks different.

Or reminiscent of that Soviet “Bumblebee”

It was made, however, in the USA...

Or equipped with a hose

The hose connects a special canister of gasoline to the burner itself. In my opinion, this system is safer.