Types of hot melt adhesive

Hot melt adhesive (hot melt adhesive, hot melt adhesive) is a thermoplastic solid substance with a specific operating temperature.

When heated, the consumables soften, acquire a viscous-flow state, and connect various materials, and when cooled, they polymerize, reliably gluing the surfaces.

Hot-melt adhesive gained popularity primarily due to its wide range of applications, short setting time and, of course, versatility.

To apply hot melt adhesive use:

- Standard manual glue guns.

- Professional pistols with connected foot pedal.

- Glue machines.

- Rollers or glue heads.

- Other special equipment.

For ease of use, hot melt adhesive is supplied in various release forms, which are also called cartridges, due to the fact that, by analogy with a firearm, they are loaded (filled) into a glue gun.

As mentioned above, cartridges can be in the form of rods, pads or granules, used in some types of professional tools and automatic packaging lines.

Properties of hot melt adhesive

Thermoplastic adhesive has a number of interesting properties, due to which it has become widespread:

- Tensile strength. According to the manufacturers, in order to separate glued objects from each other, a force of up to 150 kg will be required.

- Short polymerization time of a few seconds, however, depending on the thickness of the applied layer and the ambient temperature. Good fusibility should also be noted. So hot melt adhesive begins to liquefy at a temperature of 80 degrees, depending on the composition.

- Long service life, frost resistance, resistance to excess moisture, direct sunlight.

- Relatively low cost.

- Adhesiveness that allows you to reliably connect a huge number of different materials.

- Hot-melt adhesive, depending on impurities, may have increased stickiness and reduced viscosity. To do this, in the first case, rosin is added, and in the second, paraffin or wax. Also, the addition of heat-resistant antioxidants when heated slows down the oxidation reaction. However, all this applies only to organic glue.

- High temperature resistance. Some types of hot-melt adhesive have a softening temperature of 80°C, while for others this figure reaches 150°C.

- Heated hot melt adhesive does not have an unpleasant odor, and when heated there are no toxic fumes. But despite the low toxicity of the composition, safety precautions must still be observed.

To remove old hot melt adhesive, you can use Sanywax cleaner, which is a clear liquid with a faint citrus odor. Its density is 0.834-0.85 g/cm3. Sometimes WD-40 is used.

Characteristics of hot melt adhesive

As already mentioned, hot melt adhesive has several forms of release:

- Rods (sticks) – we will talk about them separately.

- Granules – due to their flowability, they are easy to deliver to the heating chambers of semi-automated and automated lines, suitable for professional heat guns. Among the advantages are convenient transportation and storage, a wide selection of compositions for any task. It should also be noted that it can be applied in a variety of ways, including applicators.

- Pillows are small rectangular pieces, used in professional heat guns. Also produced for various tasks.

- Cylinders - similar to the previous option.

Purpose of hot melt adhesive

The above cartridges for glue guns are used in production and professional activities, where it is necessary to carry out voluminous work in a short period of time.

Granular hot melt adhesive is often used on automatic and semi-automatic lines for the production of trays, cardboard boxes, promotional materials, and book and magazine products.

In addition, similar adhesive compositions are used for gluing non-woven materials, including mattress spring blocks, wood, leather and even stone.

In addition to its use in production and construction, hot-melt adhesive has shown itself to be an indispensable component of design, in particular floral works, homemade products and crafts.

Thanks to fillers such as zinc oxide, titanium dioxide, calcium carbonate and others, the required color of the composition and its properties are formed, which allows you to select consumables for specific tasks.

Hot melt adhesive material

Hot-melt adhesive consists of 50% thermoplastic polymers, and the rest of the mass is occupied by plasticizers and resins.

Depending on the base, the following adhesive compositions are distinguished:

- Hot-melt adhesives based on ethylene vinyl acetate (EVA) have become widespread primarily due to the ratio of cost to quality. They can be safely called universal, as they are suitable for joining many materials, including cardboard, wood, plastics, fabrics and even ceramics with metal. Among the advantages of EVA hot-melt adhesives, one should note high rates of fluidity, adhesion and stickiness, short hardening time; they are used exclusively in low-temperature equipment (including hot-melt guns) due to the melting point of 78-80°C.

- Polyamide

- Compositions based on polyolefin (Polyolefin, PO) - compared to EVA, they have high heat resistance, adhesion and cost-effectiveness. In addition, they have increased flexibility at sub-zero temperatures. The record melting point among similar compositions is 180°C. They are used for spot gluing of packages, and are applied by spraying or the linear-spot method.

- Options with residual stickiness, pressure-sensitive (Pressure-Sensitive Adhesives, PSA) - retain the stickiness of the surface, therefore they are preferable for working with surfaces that have a large area, in particular when it comes to difficult-to-glue materials. Used in construction and industry.

- Medium Pressure Sensitive (EPSA) - suitable for bonding heat-sensitive materials and parts with a large surface area. These formulations are based on alpha poly-olefins (APAO), which can maintain tack for 6 minutes.

- Polyurethane (Reactive Hot Melt Adhesives, PUR) - used in woodworking, automotive, electronics, and printing industries. The reason for this is the special properties, including the highest adhesion, flexibility at sub-zero temperatures, heat resistance and resistance to solvents. The polymerization time strongly depends on external factors and can last up to 2 days.

Among thermosetting adhesives, POR options should be noted.

They are distinguished by their better ability to adhere to untreated surfaces, such as polypropylene and polyethylene.

In POR and PUR, polymerization is irreversible, unlike thermoplastic adhesives.

Dimensions and weight of hot melt adhesive consumables

Hot-melt adhesive in the form of cylinders, or rather pins, is manufactured with precise diameter, which ensures the reliability and safety of glue guns.

The use of pins of non-standard sizes can cause problems with the adhesive equipment.

Variants with a diameter of 43 mm and a length of 4 cm have become widespread.

As for the sizes of granules and pillows, they are approximately the same from different manufacturers; they may have an irregular shape, given that small deviations are acceptable.

Characteristics of hot-melt adhesive rods

As already mentioned, the release form in the form of hot-melt adhesive rods is the most common due, first of all, to ease of use in conjunction with hot-melt guns of both professional and household class.

There are rods on the market with various properties and characteristics, which are usually indicated on the packaging.

Purpose

Hot-melt adhesive in rods differs primarily in color, which usually indicates its purpose.

However, it should be noted in advance that although there is a clear unification here, not every manufacturer adheres to it, which should be kept in mind when choosing these consumables.

Usually available to the buyer:

- White translucent rods are universal, used both in industry and for domestic needs.

- Opaque colored rods are similar to the previous option, but the only difference is that their color performs a camouflage or decorative function. They are mainly used for gluing colored objects.

- Opaque white rods - have different purposes, depending on the manufacturer and composition. Some can only glue glass, while others are a universal option for connecting white objects (similar to the previous point).

- Transparent yellow rods - have a universal composition, which is mainly intended for gluing wooden, cardboard and paper products. There are opaque yellow sticks, with which they should not be confused, again, by analogy with the second point.

- Gray or black rods are elastic sealants designed to insulate electrical conductors and seal seams, therefore they are not directly related to hot-melt adhesives as such.

The actual purpose of the glue stick may differ from the list above, it all depends on the manufacturer, and therefore this list should not be taken as a selection guide.

Material

Hot-melt adhesive rods are most often produced on the basis of ethylene vinyl acetate, due to which they have a low melting point, which was already noted earlier, and therefore it is possible to use them in conjunction with low-power glue guns.

There is also a relatively low cost.

The base can also be polyamide or modified silicone.

The latter is well suited for working with fabrics.

Dimensions and weight of hot melt glue sticks

The diameter of the produced glue sticks can be 7 – 12 mm.

The most popular sticks are 7 and 11 mm. The length of such glue sticks reaches 100 – 300 mm.

A package of 6 – 10 rods weighs about 50 – 150 g.

Why do you need to divide hot melt adhesive by diameter?

This also determines the choice of the diameter of the glue gun rods by the developers. The smaller the diameter, the less effort is required to squeeze the melt out of the melting chamber. To work with the refills for a 7 mm glue gun, very little effort is required, which means that the gun can be used by almost any adult or even a child.

Read also: Program for calculating the resistance of resistors

Seven-millimeter rods are used in low-power and non-hot hot glue guns with small dimensions and weight. The melting point of such material rarely exceeds 160 o C, so the gluing device is very light and economical. They are convenient for gluing paper, film, packaging goods, and temporarily fixing parts on the desktop. If you need to glue tiles on the ceiling, it is much more convenient to do this with a glue gun with a seven-millimeter “cartridge”.

It seems convenient, but the productivity is only 10-15 g/min, which is enough for spot gluing, but not enough for full gluing. Therefore, for gluing metal, glass, wood, and plastic, 11 mm glue gun rods are used. In addition to the increased productivity to 25-30 g/min, the control temperature increases from 160 o C to 195 o C. The glue gun turns out to be twice as large and heavier, but it can glue almost anything that can withstand high temperatures.

Some glue gun manufacturers deliberately produce very inexpensive models with reduced tube diameters, for example, 7 mm and 11 mm, encouraging buyers to purchase only branded sticks. Therefore, before making a purchase, you should clarify three parameters:

- Melting temperature of the glue stick and compare it according to the passport with the characteristics of the gun;

- For what materials is the selected brand of hot-melt adhesive rod intended?

- The exact diameter of the rod, otherwise it may happen that your glue gun has a 7 mm clip, they offer to buy 11 mm.

You can even take with you an old package of thermal rods or look at the passport for the gun, which should contain all the necessary data on consumables. Otherwise, you will not be able to exchange or repair a burnt hot-melt glue gun under warranty.

How to choose hot melt glue for a glue gun?

Working with granules, pads and cylinders is supported only by professional equipment, the instructions for which indicate not only the ability to use hot-melt adhesive in one of these forms of release (or all together at the same time), but also clear recommendations on what composition should be used.

The situation is a little different with heat guns for household use, which sometimes do not receive any sane instructions at all, and therefore the rods for them have to be selected based on personal experience, or simply at random.

Here are just some tips for choosing them:

- Sticks should only be purchased with the diameter recommended by the manufacturer of the specific gun model. As a rule, this is a “caliber” of 7 or 11 mm.

- The length of the sticks can be any, regardless of the gun purchased, but only if the tool is designed to work with them.

- The temperature regime of the rod plays a special role, due to the fact that this parameter must correspond to the capabilities of the glue gun. Typically, hot melt adhesive melts at a temperature of 80 degrees, and most manufactured hot melt guns heat up to a temperature of 150 - 200 degrees, which guarantees compatibility.

The hotter the tool’s thermocouple can heat up, the faster the stick will melt.

Hot-melt adhesive made from some materials melts only starting at 150 degrees, which requires a high-temperature adhesive machine.

If the packaging of glue sticks does not have highly specialized recommendations for use from the manufacturer, or the designation “EVA” is indicated, such sticks can be safely purchased without fear that they may not fit the existing heat gun.

Hot glue gun: design and operating features

The shape of a glue gun is similar to a regular gun, which is why it got its name. The device is filled with a glue stick, which, when heated, melts to a fluid consistency. The rod must be installed from the back of the tool, tucking it into a special receiver. During operation, its tip enters the heating module, and in about 4-5 minutes the glue melts. When the trigger is pressed, the composition comes out of the nozzle onto the surface of the product.

The design of the glue gun includes the following elements:

- Heating module. Located in the barrel, it is a metal reservoir, at the bottom of which there is a heating unit. More expensive models have multiple heating units to melt the glue.

- Ring pusher. This is the glue supply mechanism that most often breaks, mainly due to excessive force by the user.

- Clutch. It looks like a tubular receiver located under the glue heating chamber. The coupling is needed to seal the system elements so that the molten composition does not get into them.

- Nozzle (nozzle, nozzle). Allows you to direct the flow of glue in the desired direction. There is a shut-off valve inside that prevents the solution from flowing out freely. The outside of the nozzle is coated with a heat-resistant alloy that protects it from damage. This part of the gun must be cleaned regularly to remove any glue residue.

Distinctive features of hot glue guns

When choosing, you need to pay attention to the quality of the hot glue gun body. The box itself should be made of durable polymers that can withstand heat without burning your hand. There are models with a viewing window where you can see the remaining glue. The handles often have anti-slip inserts, and the package includes a stand. An interesting design is the spray gun, which significantly speeds up the application of glue to large surfaces. When purchasing a gun, you must compare the diameter of its barrel with the size of the glue stick - they must match.

Required glue heating temperature

The glue begins to melt already at +80 degrees, but the process will be very slow. Therefore, guns make it possible to melt the material at +150…+200 degrees, which seriously increases productivity. In expensive professional models, the heating temperature of the glue reaches +500 degrees.

Glue feed speed

Typically glue guns can dispense 5-20g of glue per minute, although the rate depends on heating time and user need. The upper limit of the indicator, in fact, is the limit of the capabilities of both the device and the master, otherwise there is a high risk of making a mistake. However, special high-speed guns (30 g of glue per minute and above) are sold for professionals.

We recommend: How to choose glass adhesive

What you need to know about hot melt adhesive?

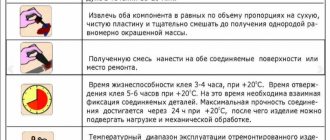

As a rule, the hardening time of a particular hot melt adhesive is indicated on the packaging (in the instructions).

Usually we are talking about complete polymerization after 15 - 30 minutes, however, it is recommended to use the glued product no earlier than after 2 - 3 hours.

As already mentioned, thermoplastic adhesive compositions usually have low toxicity, but in case of prolonged work it is recommended, in addition to using a respirator, to organize good ventilation in the work area.

You can only protect yourself from burns due to careless handling of a glue gun by wearing protective gloves.

In any case, caution and safety precautions should always be observed.

Hotmelt adhesive manufacturers

The companies Akfix, Dremel, BRAUBERG, KWB, STAYER, SANTOOL produce thermoplastic glue for glue guns.

ADTEK offers a wide selection of shapes and adhesive bases. Also worth noting are such domestic manufacturers as Zubr, Kedr and PRACTIKA.

Thermal gun is a universal tool that provides reliable connection of various parts and objects. To get a good result, you need to choose the right consumables - glue gun sticks.

What is hot melt adhesive

Hot-melt adhesive is a plastic composition that, when heated to a certain temperature, turns into a liquid state. At the same time, it penetrates into the smallest holes and cracks of the surfaces being glued, and when hardened, it becomes hard again, providing reliable adhesion. Other names: glue stick, hot or thermoplastic glue, hot glue gun cartridge.

Clear glue sticks

This glue can be used when working with paper, cardboard, wood, glass, plastic, leather, cork, ceramics, stone and other materials.

Thermoplastic adhesive has many advantages:

- Bonding strength. In this parameter, the material is superior to many other adhesives.

- Fast drying. The process of fixing parts takes from a few seconds to ten minutes (depending on the applied layer), and the item can be used within five minutes after connection.

- Long service life. The glue is not exposed to a number of destructive factors: atmospheric conditions, ultraviolet radiation and others.

- Possibility of removal without traces. You can remove hot glue from the surface without risking ruining the item by reheating it.

- Use as a sealant. Due to its high penetrating ability and moisture resistance, the composition can be used to seal seams and cracks.

- Ability to glue dissimilar materials. Glue rods have virtually no limitations when fixing surfaces that differ in structure and properties. For example, it is suitable for any plastic, wood, and can even glue metal and ceramics.

- Safety. When heated, it does not emit toxic substances.

- Low price relative to other adhesives.

- Virtually unlimited shelf life if storage conditions are met.

Choosing hot melt adhesive for a glue gun

Thermal gun is a universal tool that provides reliable connection of various parts and objects. To get a good result, you need to choose the right consumables - glue gun sticks.

What is hot melt adhesive

Hot-melt adhesive is a plastic composition that, when heated to a certain temperature, turns into a liquid state. At the same time, it penetrates into the smallest holes and cracks of the surfaces being glued, and when hardened, it becomes hard again, providing reliable adhesion. Other names: glue stick, hot or thermoplastic glue, hot glue gun cartridge.

Clear glue sticks

This glue can be used when working with paper, cardboard, wood, glass, plastic, leather, cork, ceramics, stone and other materials.

Thermoplastic adhesive has many advantages:

- Bonding strength. In this parameter, the material is superior to many other adhesives.

- Fast drying. The process of fixing parts takes from a few seconds to ten minutes (depending on the applied layer), and the item can be used within five minutes after connection.

- Long service life. The glue is not exposed to a number of destructive factors: atmospheric conditions, ultraviolet radiation and others.

- Possibility of removal without traces. You can remove hot glue from the surface without risking ruining the item by reheating it.

- Use as a sealant. Due to its high penetrating ability and moisture resistance, the composition can be used to seal seams and cracks.

- Ability to glue dissimilar materials. Glue rods have virtually no limitations when fixing surfaces that differ in structure and properties. For example, it is suitable for any plastic, wood, and can even glue metal and ceramics.

- Safety. When heated, it does not emit toxic substances.

- Low price relative to other adhesives.

- Virtually unlimited shelf life if storage conditions are met.

There are significantly fewer disadvantages of hot-melt adhesive:

- low plasticity of the product, fairly rigid adhesion, which can, under certain conditions, lead to the destruction of the connection;

- impossibility of use for some types of fabric, PVC; when working with plaster and concrete.

How to use hot glue

To use hot glue, you must first clean, degrease and dry the surfaces to be glued. Smooth elements can be treated with sandpaper for better adhesion; cold - warm to room temperature so that the composition does not harden too quickly. Then you need to insert the rod into the glue gun, turn on the device, wait 3-5 minutes until it heats up. After this you can start working. Press the trigger, apply glue, firmly press the parts together, fixing them in this position for several minutes.

When working with the molten composition there is a risk of getting burned, so it is important to be careful and use gloves if necessary.

What are the rods made of?

The main component of hot glue is a thermoplastic polymer (up to 50% of the total mass), the rest is made up of resins and plasticizers. Depending on the type of polymer, the following types of rods exist.

- Ethyl vinyl acetate (EVA) - melt at a fairly low temperature, have high adhesion and low strength. The seam is not exposed to water and a number of chemicals.

- Polyamide - characterized by a high melting point, high rigidity, and seam strength. However, with frequent contact with moisture, the connection may lose its strength.

- Polyolefins are the most refractory. The seam is very hard, with low adhesion.

- Polyester - have good resistance to atmospheric conditions, very high adhesion. This means can reliably glue dissimilar materials together.

- Hot melt adhesive based on modified silicone works at low temperatures. The seam is distinguished by its plasticity, transparency, and resistance to stress.

- Rods based on synthetic rubber are characterized by high elasticity, heat and moisture resistance.

- Hot glue, which contains reactive polyurethane, when cooled, forms a durable elastic layer on the surface of the parts that is not exposed to either high or low temperatures. The difference between this type of hot-melt adhesive is its long polymerization (hardening), up to 2 days.

We recommend: Quelyd non-woven wallpaper adhesive

Types of hot melt adhesive rods

Glue gun refills differ in their characteristics. To make it easier for the buyer to navigate the properties of the adhesive, color coding was adopted. That is, you can choose a composition suitable for working with certain materials only by the color of the cartridge.

Colorless Transparent Glue Sticks

The transparent, colorless composition is a universal adhesive that is suitable for gluing almost any surface and forms a fairly soft, highly adhesion, elastic seam.

Clear glue sticks

Yellow transparent rods

These hot-melt cartridges are used when working with paper, cardboard or wood, and are also used with some types of plastics and metals. The yellow transparent composition is characterized by low adhesion and the ability to absorb moisture.

Yellow clear glue sticks

Opaque white rods

Thermoplastic adhesive in the form of matte white rods is used for gluing glass and metal parts. But if necessary, it can also fix wood, plastic, and textiles.

White opaque glue sticks

Opaque multi-colored rods

Colored opaque adhesives are also made on the basis of EVA. Their properties are almost no different from universal ones. But at the same time, they have one undeniable advantage - the ability to make the seam minimally noticeable by matching the color of the rod to the surfaces being glued.

Black and gray hot melt adhesive

Two types of specialized hot glue are produced under this color marking:

- for sealing and sealing seams between fastened parts;

- for insulating electrical contacts.

Black glue sticks

Decorative rods for arts and crafts

Hot melt adhesive is an indispensable thing in many types of needlework. In addition to colored cartridges, decorative rods with glitter sparkles are especially in demand among craftswomen.

Due to their safety, such compositions are also used in children's creativity.

Multi-colored glue sticks for creativity

Melting point of hot melt adhesive

Depending on the composition, glue cartridges differ in melting temperature. For example, hot melt adhesive based on ethylene vinyl acetate begins to melt already at 80°C, the operating temperature is 120 – 150°C. This is a low-temperature glue for which household heat guns are designed.

Polyamides and some thermoplastic polyolefins are characterized by a softening point of 150°C. Their operating temperature is 180 – 200 °C. Such compositions are used mainly with professional devices, the heating temperature of which reaches 500°C.

For gluing parts subject to heating to significant temperatures, special high-temperature compounds are used that do not collapse even in such conditions.

Conversely, when working with materials that can be damaged by too high temperatures, craftsmen use low-temperature glue guns and adhesives.

Glue gun refill sizes

Another important parameter of glue gun cartridges is their size: diameter and length. The most popular rods are 7 and 11 mm in diameter. They are suitable for solving many household problems and are used in heat guns with low power, small dimensions and weight. They are convenient for gluing light parts, temporarily fixing elements, and minor repairs. For professional tools, glue sticks with a diameter of 12, 15, 43 mm are produced.

As for the length of the rod, it can be from 4 to 30 cm and affects the duration of use of one cartridge. Therefore, when choosing, you should focus on the parameters of your gun, as well as the amount of work performed.

How to remove hot glue from clothes

When working with hot melt adhesive, a drop of melt may get on your clothing. In this case, you need to know that there are several ways to remove the adhesive from the fabric.

- Place the soiled item in the freezer for several hours. When the hot melt glue freezes, it will become brittle and can be chipped off or carefully removed from the fabric with a blunt object.

- Iron the stain with a hot iron, after covering it with a clean natural cloth or wax paper, for 10-20 seconds. Repeat the procedure until the melted glue is completely absorbed into the flap.

- You can also get rid of stains if you know how to dissolve frozen hot-melt adhesive. Any organic solvent, such as acetone, is suitable for this. When using this method, you must first check the resistance of the fabric to the effects of the product in an inconspicuous area.

We recommend: How to use the “Kreps reinforced” adhesive solution

How to use hot glue

To use hot glue, you must first clean, degrease and dry the surfaces to be glued. Smooth elements can be treated with sandpaper for better adhesion; cold - warm to room temperature so that the composition does not harden too quickly. Then you need to insert the rod into the glue gun, turn on the device, wait 3-5 minutes until it heats up. After this you can start working. Press the trigger, apply glue, firmly press the parts together, fixing them in this position for several minutes.

When working with the molten composition there is a risk of getting burned, so it is important to be careful and use gloves if necessary.

What are the rods made of?

The main component of hot glue is a thermoplastic polymer (up to 50% of the total mass), the rest is made up of resins and plasticizers. Depending on the type of polymer, the following types of rods exist.

- Ethyl vinyl acetate (EVA) - melt at a fairly low temperature, have high adhesion and low strength. The seam is not exposed to water and a number of chemicals.

- Polyamide - characterized by a high melting point, high rigidity, and seam strength. However, with frequent contact with moisture, the connection may lose its strength.

- Polyolefins are the most refractory. The seam is very hard, with low adhesion.

- Polyester - have good resistance to atmospheric conditions, very high adhesion. This means can reliably glue dissimilar materials together.

- Hot melt adhesive based on modified silicone works at low temperatures. The seam is distinguished by its plasticity, transparency, and resistance to stress.

- Rods based on synthetic rubber are characterized by high elasticity, heat and moisture resistance.

- Hot glue, which contains reactive polyurethane, when cooled, forms a durable elastic layer on the surface of the parts that is not exposed to either high or low temperatures. The difference between this type of hot-melt adhesive is its long polymerization (hardening), up to 2 days.

What are glue sticks made of?

To make the principle of hot melt bonding more universal, manufacturers produce several main types of glue sticks:

- Ethylene vinyl acetate polymer has high fluidity and very high adhesion; it adheres well to any porous surface. The melting point is only 78-80°C, so EVA is used only in low-temperature glue guns. The color of the ethylene vinyl acetate thermal rod is whitish, translucent;

- Polyamide plastic is characterized by an increased melting point of 150-155 ° C, the adhesive melt is very viscous and viscous, but after the glue hardens, a seam is formed that is 40-50% stiffer and stronger than EVA. Most often, PAP is used in the industrial assembly of cladding and upholstery for automobiles and household appliances;

- Polyolefin material is the most refractory of all hot melt adhesives, the melt formation temperature is 180°C. The seam is very rigid, with low adhesion, so it is used mainly for spot gluing packaging;

- Modified silicone, the most plastic and fusible, has a melting point of up to 100 ° C, has high transparency, the frozen seam perfectly withstands tearing and shearing loads. A silicone stick for a glue gun is used for gluing fabrics, linoleum and in handicrafts.

High- and low-density polyethylenes also have very similar technological characteristics; often the cheapest adhesive sticks are made from granulated polyethylene. The quality of the seam is poor; when working on cheap machines, an oily smell may appear in the air.

Types of hot melt adhesive rods

Glue gun refills differ in their characteristics. To make it easier for the buyer to navigate the properties of the adhesive, color coding was adopted. That is, you can choose a composition suitable for working with certain materials only by the color of the cartridge.

Colorless Transparent Glue Sticks

The transparent, colorless composition is a universal adhesive that is suitable for gluing almost any surface and forms a fairly soft, highly adhesion, elastic seam.

Clear glue sticks

Yellow transparent rods

These hot-melt cartridges are used when working with paper, cardboard or wood, and are also used with some types of plastics and metals. The yellow transparent composition is characterized by low adhesion and the ability to absorb moisture.

Yellow clear glue sticks

Opaque white rods

Thermoplastic adhesive in the form of matte white rods is used for gluing glass and metal parts. But if necessary, it can also fix wood, plastic, and textiles.

White opaque glue sticks

Opaque multi-colored rods

Colored opaque adhesives are also made on the basis of EVA. Their properties are almost no different from universal ones. But at the same time, they have one undeniable advantage - the ability to make the seam minimally noticeable by matching the color of the rod to the surfaces being glued.

Black and gray hot melt adhesive

Two types of specialized hot glue are produced under this color marking:

- for sealing and sealing seams between fastened parts;

- for insulating electrical contacts.

Black glue sticks

Decorative rods for arts and crafts

Hot melt adhesive is an indispensable thing in many types of needlework. In addition to colored cartridges, decorative rods with glitter sparkles are especially in demand among craftswomen.

Due to their safety, such compositions are also used in children's creativity.

Multi-colored glue sticks for creativity

Characteristics of hot-melt adhesive and features of use

First of all, I would like to talk about the device for which the glue sticks are actually intended. This is a glue gun that greatly simplifies the task of gluing surfaces. It is a device dependent on the electrical network, into which the same rods are inserted. The end of the rod enters the rubber receiver and then into the heating chamber. When you press the trigger, the glue comes out of the tip of the gun and is applied in an even layer to the surface.

After applying the mass, the surfaces to be glued must be fixed to each other until the adhesive has hardened.

Sometimes you can see the name “hot-melt glue”, which means the same thing as a glue stick. But not all stores and catalogs can find hot-melt adhesive, since it goes under a second name. Names such as “heat gun cartridges,” “hot glue,” or “sticker” are also used.

As mentioned earlier, a glue gun can glue almost any material in different combinations. If you start listing, the list can turn out to be endless; it includes plastic, tile, wood, metal, cardboard, fabric, paper and other materials. It would be better to indicate those materials that he is not able to glue. These are concrete, plaster, some types of fabrics and polyvinyl chloride.

If there are no additional requirements for the work, then gluing is carried out using guns with standard sizes. Typically, they use rods with a diameter of 7 and 11 mm, which are relatively inexpensive. They differ in the following characteristics:

- Transparency of the material upon visual inspection.

- The difference is in length, the maximum of which is 30 cm.

- The material is not brittle due to its bending strength.

- Simple storage conditions - at room temperature.

- Unlimited shelf life subject to storage rules.

- These rods are completely universal and suitable for most materials. In some cases, black rods can be used to make the seam invisible.

Melting point of hot melt adhesive

Depending on the composition, glue cartridges differ in melting temperature. For example, hot melt adhesive based on ethylene vinyl acetate begins to melt already at 80°C, the operating temperature is 120 – 150°C. This is a low-temperature glue for which household heat guns are designed.

Polyamides and some thermoplastic polyolefins are characterized by a softening point of 150°C. Their operating temperature is 180 – 200 °C. Such compositions are used mainly with professional devices, the heating temperature of which reaches 500°C.

For gluing parts subject to heating to significant temperatures, special high-temperature compounds are used that do not collapse even in such conditions.

Conversely, when working with materials that can be damaged by too high temperatures, craftsmen use low-temperature glue guns and adhesives.

Glue gun refill sizes

Another important parameter of glue gun cartridges is their size: diameter and length. The most popular rods are 7 and 11 mm in diameter. They are suitable for solving many household problems and are used in heat guns with low power, small dimensions and weight. They are convenient for gluing light parts, temporarily fixing elements, and minor repairs. For professional tools, glue sticks with a diameter of 12, 15, 43 mm are produced.

As for the length of the rod, it can be from 4 to 30 cm and affects the duration of use of one cartridge. Therefore, when choosing, you should focus on the parameters of your gun, as well as the amount of work performed.

Choosing glue gun refills

Diameter and overall dimensions are the main requirements for rods. In most cases, material with a thickness of 11 mm or 7 mm is suitable for solving typical problems. The length of the rod is determined by the parameters of the gun. Rods are available for sale, the length of which varies from 40 to 300 millimeters. Accordingly, the price of the material increases depending on the size of the rod.

If special requirements are placed on the quality of the connection, the material is selected accordingly. Black rods are used when it is necessary to achieve maximum seam identity with the surface. Special compositions are used for increased requirements for structural rigidity. Bonding dissimilar materials is also possible when using special brands of glue.

When choosing glue, color marking is taken into account. The opaque composition is universal and intended for use in most cases. Translucent material having a certain shade has a special purpose. White and black glue gun refills are also universal and designed for general use.

Cylinders of white color and opaque consistency are used for gluing glass and metal. Translucent materials are suitable for working with wood, paper and combinations thereof. Black rods are characterized by insulating and sealing properties, therefore they are used for processing stressed elements, as well as for strengthening seams.

When working with materials that heat up significantly during operation, special adhesive compositions are used. Such rods are high-temperature and do not lose their characteristics when heated significantly. As a rule, cylinders with a melting temperature of about 100 or 150 degrees are presented on the market. The choice of one or another rod is determined by current needs.

The choice of cylinders with a diameter of 11 mm or 7 mm is made based on the characteristics of the hot glue gun used. Diameter, melting point, fluidity of the material and its melting rate are the main criteria for selection.

How to remove hot glue from clothes

When working with hot melt adhesive, a drop of melt may get on your clothing. In this case, you need to know that there are several ways to remove the adhesive from the fabric.

- Place the soiled item in the freezer for several hours. When the hot melt glue freezes, it will become brittle and can be chipped off or carefully removed from the fabric with a blunt object.

- Iron the stain with a hot iron, after covering it with a clean natural cloth or wax paper, for 10-20 seconds. Repeat the procedure until the melted glue is completely absorbed into the flap.

- You can also get rid of stains if you know how to dissolve frozen hot-melt adhesive. Any organic solvent, such as acetone, is suitable for this. When using this method, you must first check the resistance of the fabric to the effects of the product in an inconspicuous area.

Still undecided? Let's sum it up

So, when choosing hot glue, you should focus on the characteristics of the hot glue gun you have, as well as the material and structure of the surfaces you plan to work with. First of all, you should pay attention to the size (diameter and length) of the adhesive cartridge, temperature, melting rate, as well as color markings that determine the properties of the composition.

The most popular brands of hot-melt adhesive are those based on EVA, as they are universal, suitable for household glue guns, and have a relatively low cost.

If there are special requirements for joining parts, you should purchase special hot glue compositions that are suitable in terms of characteristics and properties.

To avoid mistakes when choosing, it is recommended to read the technical information posted on the material packaging, as well as get advice from a specialist.

Glue guns are now used everywhere. This is due to their versatility and excellent technical characteristics of the resulting adhesion of the bonded surfaces. But for such a device it is necessary to choose the right consumables, since the quality of the work depends on the glue sticks.

Criteria for choosing a glue stick

So, let's move on to the list of criteria by which glue sticks are selected:

- Diameter. It was previously stated that the standard stick diameter is 7 and 11 mm. But there are those that are thinner or thicker than those named. The choice depends on the size that fits a particular model of glue gun. That is why the device itself is purchased first, and only then the consumables for it. Usually the universal size of 11 mm is chosen.

- Rod length. After determining the diameter, it is worth thinking about the length of the rod. It can vary from 4 to 20 cm. The purchased glue gun model will also help in this matter - it will let you know what length of the rod is suitable.

- Adhesive sticker color. This is, one might say, one of the main criteria on which the choice depends. For a better understanding, it is necessary to consider the entire range of colors of glue sticks currently presented. We'll talk about this a little later.

- Temperature operating conditions. For some stickers, 100 degrees is enough to become liquid, others need 150. It is clear that when gluing those surfaces that can heat up during use, you will need glue that can withstand such a load. The main thing is not to buy a sticker whose melting point will be higher than that for which the heat gun is designed.

Intuitively, you can understand that the higher the melting temperature, the higher the performance of the hot-air gun model. In household devices with a rod size of 11 mm, the heating temperature is usually set from 105 to 120 degrees; such limits are due to the fact that many materials are quite sensitive to the effects of too high a temperature. Usually all guns have a temperature regulator, so you can choose the indicator that is suitable for a particular sticker.

If it is necessary to process a large area, it is better to choose the version of the glue stick that will melt and be applied as quickly as possible, so that the previously applied layer does not have time to harden. This is necessary because the material usually hardens within 1 - 2 minutes, and complete curing occurs in less than 10 minutes.

What is a glue stick

Consumables for a glue gun are flexible polymer rods up to 20 cm long and 7 mm or 11 mm in diameter. Thinner rods are usually used for soldering with low-power home soldering guns. Hot-melt glue rods with a diameter of 11-12 mm are used for more powerful and productive guns, most often professional and semi-professional types.

The material is elastic and at the same time durable, it is very difficult to tear the glue stick with your hands, you can slightly bend it, and some brands can even be rolled into a donut.

Anyone who regularly uses a hot glue gun at home or in professional activities notes some features of the consumable:

The material of the rods is not thermosetting; when reheated, it can be melted, but due to the increase in viscosity, it is almost impossible to squeeze it through the nozzle of the melting chamber; a very large force will be required.

Glue stick depending on color

The construction market now offers a lot of shades of glue gun refills. Each type differs from the previous one in composition and technical features. So, let's look at the glue gun refills depending on the color.

Transparent universal type stickers that are suitable for gluing any surfaces. For doing crafts or some household needs, such a rod will be quite sufficient. They are most often produced in diameter 11 mm.

Colors, except black, are also universal. Their main advantage is the ability to adjust the color of the seam to the surface being designed. For example, when repairing a red plastic part, a rod of the same shade is used, and the seam becomes invisible. They will be very useful for those who do needlework professionally.

In addition to colored ones, opaque white consumables are also produced. They can be universal or designed for glass and metal. When purchasing, be sure to look at the labeling. Color in this case will play the role of a marker. This glue can also be used to fasten plastic, but it is still more intended for glass and metal.

Yellow transparent stickers. To perform work on wood, cardboard or paper, purchase a yellow transparent rod, which is intended specifically for these materials. It should not be confused with opaque yellow, which is used as a universal one for hiding the seam.

Black or gray glue can work in two ways: as a sealant or an insulating material. With such rods you can easily insulate conductors or seal small seams.

We have given the main types of glue for hot-melt guns by color. When choosing, it is best to pay attention to the packaging, which contains all the information regarding the scope of application of a particular rod and its technical characteristics, including diameter.

Working principle of a glue gun

The heat gun was invented in 1949, and since then the principle of its operation has not undergone significant changes. This tool functions as follows:

- The device is connected to the network (some models run on batteries) and warms up for some time.

- Hot-melt adhesive for a gun (available in rods, one of the most popular diameters is 11 mm) is inserted into the corresponding hole, from where, after pressing the trigger, it enters the melting chamber.

- In the melting chamber, the adhesive is heated to a temperature of 100–200 °C and melts, turning into a thick liquid.

- This liquid comes out through a nozzle and is applied to the surfaces to be fastened, where it hardens, connecting them.

- After finishing work and turning off the gun, it takes some time to cool down. It should be taken into account that during cooling, glue residues may flow out of the nozzle (some models are equipped with special shut-off valves that prevent this undesirable phenomenon).

The heat gun can only be “charged” with glue rods (sticks) of the appropriate diameter. Do not twist them or pull them out of the tool. Failure to comply with these rules may result in damage to the device.

The range of pistols is very wide: there are both simple household tools with a power of up to 15 W, and professional industrial tools whose power reaches 1000 W.

Materials for making glue sticks

Despite the name, heat gun stickers do not contain any adhesive. They consist of a special thermoplastic polymer that hardens after cooling. Now such glue guns can work with two types of rods.

- Ethylene vinyl acetate rods melt at temperatures above 80 degrees. This polymer belongs to the category of light and plastic, with low strength. When heated, the material becomes viscous and sticky. The seam made with this substance is resistant to moisture and chemical influences.

- Polyamide rods have greater rigidity and strength. Because of this, they melt at a temperature of more than 150 degrees, so you need to choose a gun for them that can provide such a temperature.

When purchasing glue gun refills, you need to pay attention to the characteristics, as mentioned earlier. You also need to purchase material with at least a few pieces in reserve to avoid a situation where the glue runs out at the most inopportune moment.

Materials for production

Contrary to their name, glue cylinders do not contain adhesives. The cylinders are made from a thermoplastic polymer that melts when heated and hardens when cooled. Classic guns operate with 2 types of glue cylinders.

Ethylene vinyl acetate rods melt at a temperature of approximately 80 degrees. This polymer is very elastic and lightweight. When heated, the substance has great stickiness and fluidity. The use of such a composition guarantees the resistance of the seam to chemically active substances and moisture.

Polyamide cylinders - hot melt adhesive for guns - are characterized by higher rigidity and strength. Such materials begin to melt at a temperature of approximately 150 degrees. Therefore, guns that provide sufficient heating temperature may be suitable for the application of rods. This type of composition has only one flaw. With prolonged contact with moisture, its strength begins to decrease.

When buying cylinders for a glue gun , you should take into account the fundamental characteristics of this material. In addition, it is recommended to purchase material with a reserve. The total price will hardly change, but the refill for the hot-melt device will not run out at the most unexpected moment. Materials of various parameters, shades and compositions are available on the market, and this guarantees a wide range of uses for glue guns.

When purchasing this tool for work, it is recommended that you read the technical information presented on the packaging. Most often, it contains detailed information about the composition of the cylinders and methods of its application. Familiarization with the specified information from the manufacturer and consultation with the manager will protect the consumer from miscalculations in the choice. In this case, using a glue gun will not cause any problems during use.