We sell equipment for processing aluminum profiles: pneumatic and manual presses for processing facade, window and door systems Tatprof, Sial, New Tec, Agrisovgaz, Almo, Alusit, manual presses for processing sliding and swing systems Provedal. Machines for aluminum structures are sold from a warehouse 120 km from Moscow, delivery throughout Russia is possible.

You can see the price list for equipment here.

Pneumatic press SHOHAM

Pneumatic presses have been manufactured by SHOHAM MACHINERY LTD https://www.shoham-mach.co.il/ for more than 10 years. SHOHAM MACHINERY LTD equipment is very common in Russia and has proven itself to be of high quality, simple and reliable.

All presses are covered by the manufacturer's warranty - 2 years from the date of sale. In the event of a planned replacement/breakage of cutting knives, we will deliver them as soon as possible so that your production does not stand idle.

Simultaneous Punching System With Changeable Die Sets

Simultaneous punching system with replaceable dies

Multi-spindle indexing template

Model T-Pneumatic Unit for Series 5600

SHOHAM information booklet (pdf)

Pneumatic press PNZ8 for the NEW TEC 150 system

The PNZ8 pneumatic punching press is designed for technological processing of aluminum profiles of the NEW TEC 150 system. Price 3900 EUR.

| Specification | Meaning |

| Working temperature | 0 ÷ 40 |

| Storage temperature | -10 ÷ 50 |

| Maximum height | 2000 oil |

| Storage humidity | 80 @ 20° C RH % |

| Maximum humidity of working environment | 70 RH% |

| Operating pressure | Min 6 – Max 7 Bar |

| An effort | 1950 kg |

| Air flow | 1.6 Nl/cycle |

| Dimensions | 240x360x240 mm |

| Noise level | less than 70 dB |

PNZ8 press operating manual (pdf)

Installation and operating instructions for the PNZ 8 OEMME press (pdf)

Pneumatic press P-AGS150

Pneumatic small-sized punching press (pneumopress), designed for cold processing of profiles of the AGS150 system. Price 5,680 USD.

- List of technological operations:

- punching round holes in the crossbar for self-tapping screws 4 pcs.

- cutting out the back wall on a large crossbar

- cutting out the back wall on a small crossbar

- cutting three quarters on the crossbar

- punching a drainage hole in the clamping bar

- punching a hole for a self-tapping screw in the clamping bar

- punching holes to remove steam and condensate in the lid

- cutting a groove for the crossbar in the rack

| Cylinder (outer diameter) | 200 mm |

| Working temperature | 0-40 °C |

| Operating pressure | min 6 – max 8 bar |

| Developed force | 2500 kg |

| Air flow | 9 liters/cycle |

| dimensions | 530 x 300 x 440 mm |

| Weight | 90 kg |

Instructions for the press P-AGS150 (pdf)

Knives for press P-AGS150 (pdf)

Knife P-AGS150-K02-4

PNEUMATIC PRESS BS15800

The pneumatic punching press is designed for the technological processing of aluminum profiles of the AGS500 system. The price for the BS15800 press is available on request.

| vendor code | BS15800 |

| Types of processed profiles | AGS-500 |

| type of drive | Pneumatic, 4 tons |

| Operating pressure | Min – 6 bar, max – 8 bar |

| Temperature range of application | From -20 °C to +60 °C |

| Tool stroke | 23 mm |

| Dimensions (LxBxH) | 660x295x296 mm |

| Weight | 87 kg |

BS15800 Press Operating Manual (pdf)

Model P-AGS500-5 Station

Price 4,480 USD.

- List of technological operations:

- punching a hole for a self-tapping screw in the clamping bar

- cutting out the back wall on a large crossbar

- cutting out the back wall on a small crossbar

- cutting three quarters on the crossbar

- punching oval holes in the crossbar for self-tapping screws 4 pcs

- punching holes to remove steam and condensate in the lid

- punching an oval hole in the clamping bar for the drainage tray

- punching drainage holes in the clamping bar.

Manual P-AGS 500-5 Station (pdf)

Pneumatic press P-AGS500-8

Pneumatic small-sized punching press (pneumopress), designed for cold processing of profiles of the AGS500 system. Price 6,160 USD.

- List of technological operations:

- punching a hole for a self-tapping screw in the clamping bar

- cutting out the back wall on a large crossbar

- cutting out the back wall on a small crossbar

- cutting three quarters on the crossbar

- punching oval holes in the crossbar for self-tapping screws 4 pcs

- punching holes to remove steam and condensate in the lid

- punching an oval hole in the clamping bar for the drainage tray

- punching drainage holes in the clamping bar.

| Cylinder (outer diameter) | 200 mm |

| Working temperature | 0-40 °C |

| Operating pressure | min 6 – max 8 bar |

| Developed force | 2500 kg |

| Air flow | 9 liters/cycle |

| dimensions | 650 x 300 x 440 mm |

| Weight | Weight, kg |

Pneumatic press model ALUSIT FC50+ (pdf)

Pneumatic press ALUSIT FC50+ Shoham P 509100

The pneumatic small-sized punching press is designed for cold processing of profiles of the ALUSIT FC50+, AGS 500 facade system. Price RUB 430,300.

- List of technological operations:

- punching a hole for a self-tapping screw in the clamping bar

- cutting out the back wall on a large crossbar

- cutting out the back wall on a small crossbar

- cutting three quarters on the crossbar

- punching oval holes in the crossbar for self-tapping screws 4 pcs

- punching holes to remove steam and condensate in the lid

- punching an oval hole in the clamping bar for the drainage tray

- punching drainage holes in the clamping bar.

| Parameter | Values |

| Cylinder (outer diameter) | 200 mm |

| Working temperature | 0-40 °C |

| Operating pressure | min 6 – max 8 bar |

| Developed force | 2500 kg |

| Air flow | 9 liters/cycle |

| dimensions | 650 x 300 x 440 mm |

| Weight | 97 kg |

| Equipment and tools | Price |

| Press 509100 | RUB 410,800 VAT included |

| Knife ALS 50-K01-9 | 43.00 USD |

| Knife ALS 50-K02-4 | 250.00 USD |

| Knife ALS 50-K03-5 | $307.50 |

| Knife ALS 50-K04-7 with holder | 250.00 USD |

| Knife ALS 50-K05-5 | 77.50 USD |

| Knife ALS 50-K06-5 | 158.00 USD |

| Knife ALS 50-K07-6 set | 158.00 USD |

| Knife ALS 50-K08-4 | 204.00 USD |

Pneumatic press model ALUSIT FC50+ (pdf)

Knives for press ALS 509100 (pdf) Warranty for press ALS 509100 (pdf)

Shoham PMF50 for Alutech systems

The pneumatic small-sized punching press PFM50 is designed for cold processing of aluminum profiles of the ALTF50 system. The pneumatic press allows you to perform all the main operations for assembling the facade, which represent the sequence of the complete process of processing profiles (end processing of crossbars, punching drainage grooves in the clamping strip and decorative cover, punching holes for fasteners).

The pneumatic press is equipped with punching dies. It is possible to process crossbars at an angle of up to 10°. Price 6500 USD.

Pneumatic press Shoham PMF50 for Alutech systems (pdf)

Correct calculation of the force of punching holes in metal

Metal punching is characterized by the fact that when making holes, a rather complex pattern of loads arises with an increased concentration in the area of contact between the punch and the matrix.

The movement of the punch when entering the material does not occur with the entire end surface, but only with the outer annular surface. There is a response from the matrix. In addition, the pressure that appears in the area of interaction of such three components may be distributed unevenly.

In other words, during cutting, two forces arise, due to which a circular bending moment is formed with an effect aimed at bending the sheet blank. This bending force causes pressure to be exerted on the die and punch edges. It must also be taken into account that during the action of friction forces, tangential forces arise. From the above, we can conclude that during metal punching, a force field of a non-uniform nature arises. Therefore, to perform calculations, a conventional technical value such as shear resistance is used.

Based on the results of previous studies, it was found that resistance is influenced not only by the properties of the metal, but also by the following indicators: the level of hardening, the thickness of the material being cut out, the gaps between the matrix and the punch, as well as the speed of the punching process.

Pneumatic presses for processing window and door systems

For processing window and door series NS SY50-60-68/ AGS50-68, our company supplies pneumatic presses manufactured by COMALL. COMALL equipment has been known in Russia for a very long time and, thanks to its good technological development, relatively low cost and high reliability, is very popular among processors of aluminum structures.

Pneumatic press PNZ1

The system being processed is NEW TEC SY50-60-68/ AGS 50-68 produced by Alstokservis LLC and Agrisovgaz LLC. Price PNZ1 - 2,210 EUR.

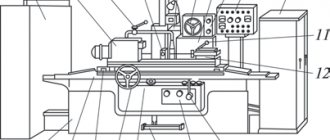

This machine is designed for cold punching of holes of a given shape in profiles made of aluminum or similar materials. Punching is done using punches or knives of appropriate shape and dies.

- List of technological operations:

- punching a hole and cutting a groove for a corner connection

- cutting a groove for attaching a handle with a center-to-center distance of 104 mm

- punching a hole for the T-connector

- punching a drainage groove

- cutting out a groove for the latch

- punching holes for handle and tip

Operating manual for pneumatic press PNZ-1 (pdf) Instruction COMALL PNZ1 ZPX 14035(pdf)

Instructions COMALL PNZ1 ZPX 14378 (pdf) Accessories, operations New Tec (pdf)

Press knife PNZ1

Pneumatic press PNZ1/3 manufactured by Comall

The system being processed is NEW TEC 50-52-68/ AGS 50-68 produced by Alstokservis LLC and Agrisovgaz LLC. Price PNZ1/3 - 3,068 EUR.

- List of technological operations:

- punching a hole and cutting a groove for a corner connection

- cutting a groove for attaching a handle with a center-to-center distance of 104 mm

- punching a hole for the T-connector

- punching a drainage groove

- cutting out a groove for the latch

- punching holes for handle and tip

- cutting holes for NT 31

| Cylinders | 200mm |

| Number of cameras | 1 |

| Cylinder stroke | 20mm |

| Minimum operating pressure | 6 bar |

| Force | 1740 kg |

| Dimensions | 690 x 280 mm H=360 |

| Weight | 71.6 kg |

Operating manual for pneumatic press PNZ1/3 Comall (pdf)

PNEUMATIC PRESS BS12000

The pneumatic punching press is designed for technological processing of aluminum profiles of the AGS50-68 system. The price for the BS12000 press is available on request.

| vendor code | BS12000 |

| Types of processed profiles | AGS-50, AGS-68 |

| type of drive | Pneumatic |

| Operating pressure | Min – 4 bar, max – 7 bar |

| Temperature range of application | From -20 °C to +60 °C |

| Tool stroke | 23 mm |

| Dimensions (LxBxH) | 615x285x296 mm |

| Weight | 55 kg |

Operating manual for BS12000 press (pdf)

Metal coordinate punching technology

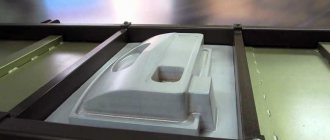

Coordinate punching and metal cutting are used in cases where it is necessary to create perforated parts with a wall thickness of about 6 mm. This technology cannot be used for processing brittle metals and alloys.

If it is necessary to produce a large number of similar holes on sheet metal at a certain distance from each other, special equipment is usually used - coordinate punching machines. In the modern industrial industry, this method of processing steel sheet material is distinguished by its excellent accuracy parameters and excellent quality.

Using a punching press, you can create holes of the required size and shape in a sheet of metal at any specific point. To perform the operation, the sheet blank must be placed and firmly secured on the working table of the pressing equipment using clamps. With the help of machine mechanisms, the grippers move simultaneously with the fixed sheet workpiece along a certain trajectory according to the part processing program entered into the equipment computer.

Manual punching presses for processing systems

PNEUMATIC PRESS BS13600

The BS13600 press (ПХ.09.465.007.000 according to the Tatprof catalog) is designed for processing the Provedal С640 and Tatprof EK-640 sliding series.

- List of technological operations:

- punching a hole in the frame for ventilation and condensation removal

- cutting in the sash sizes: 38.50, 51.50, 52.50, 86,100

- cutting for roller installation

- cutting for joining the vertical and horizontal parts of the frame

- punching holes for self-tapping screws

- punching holes for the corner latch.

Press price BS0 rub. without VAT.

| vendor code | BS13600 |

| Types of processed profiles | Provedal C640 and their analogues |

| type of drive | Manual |

| Tool stroke | 23 mm |

| Dimensions (LxBxH) | 480x380x180 mm |

| Weight | 32 kg |

BS13600 Press Operating Manual (pdf)

PRESS BS14200

The price for the BS14200 press is available on request.

PRESS BS 18200

Manual punching press for technological processing of aluminum profiles of the swing system EK-640 (Tatprof). Price 40,300 rub. without VAT.

Operating manual for press BS 18200 (pdf)