In the absence of a centralized water supply, drilling an artesian well (hereinafter referred to as AC) may be the only way to solve the problem. Let us consider in detail what this hydraulic structure is, a list of related works, as well as issues with documentation. The collection also contains other information related to technical issues, such as drilling depth and location. Considering the relevance of this topic, we will be glad if you share your practical experience in the comments, indicating the features of the site.

What does the term artesian well mean?

An artesian well (abbr. AS) is a system for extracting groundwater that lies at great depths between 2 impermeable layers of limestone rocks. When the upper one is opened, water under high pressure and with the help of a pump rushes upward to the surface of the earth. Other names for AS are “deep”, “limestone well”.

AS are of natural origin and artificially created by man (drilling). The former are formed naturally when faults and cracks occur in the earth's crust and form artesian basins (examples: Pechora, Volga-Kama, Azov-Kuban).

Thanks to the impermeable layers between which artesian waters are enclosed, they are protected from pollution from surface runoff. The main source feeding the well can be located tens or even hundreds of kilometers from the point where the artesian water comes to the surface.

Drilling work: stages

1. First you need to dig a hole or pit, the dimensions of which are 150 by 150 cm. To prevent the recess from crumbling, its walls are lined with plywood, boards, and pieces of chipboard. Another option is to dig a trunk with a diameter of 15-20 cm and a depth of 1 m with an ordinary drill. This is done so that the pipe is more stable in a vertical position.

2. A strong metal or wooden tripod (called a drilling derrick) is placed directly above the recess, securing a winch at the junction of its supports. Towers made of logs are more common. A drill string with one and a half meter (if drilling independently) rods hangs on a tripod. The rods are threaded together into one pipe and secured with a clamp. This design is used for lifting and lowering equipment.

The pump is selected in advance in order to determine the diameter of the future well and core pipe. The pump must pass freely into the pipe. That is why the difference between the diameter of the pump and the internal diameter of the pipe should be at least 5 mm.

The lowering and raising of drilling equipment is the drilling of a well. The rod is rotated while simultaneously hitting it from above with a chisel. It’s much more convenient for two people to do this: the first one turns the gas wrench, and the second one hits the bar from above, breaking through the rock. Using a winch simplifies the process: it makes lifting and lowering equipment into the well much easier. The rod is marked during drilling. Markings will be required for orientation. The markings help determine when it is time to pull out the rod and clean the drill. It is usually recommended to do this approximately every half meter.

3. To make it easier to overcome different layers of soil, special drills are used.

- spiral drill (otherwise, coil) - for clay soils;

- drill bit for loosening hard soils;

- drill spoons for sandy soil;

- The bailer helps lift the soil to the surface.

4. It is easier to go through the sand layer with a spoon drill, adding water while drilling. If the soil is hard, use a chisel. Drill bits come in cross and flat types. In any case, their purpose is to help loosen hard rocks. They overcome quicksand using the shock method.

For clayey soil, you will need a coil, a bailer and a spoon. Coils or spiral drills penetrate clay soils well because they have a design similar to a spiral, and the pitch of the spiral is equal to the diameter of the drill. The size of the lower base of the drill is from 45 to 85 mm, the blade is from 258-290 mm. Pebble layers containing gravel are pierced, alternating with a bailer and a bit, with casing pipes. Sometimes you can't do without pouring water into the hole. This can significantly simplify the task of drilling a well. The option of drilling a well using a pump is also worth considering.

Soil drilling process

5. If the rock brought to the surface has become important, then the aquifer is already close. You need to go a little deeper to cross the aquifer. Drilling will suddenly become noticeably easier, but you cannot stop. You need to find a waterproof layer with a drill.

Advantages and disadvantages

AC has its advantages and disadvantages.

Arguments in favor of choosing an artesian well for water:

- High water yield, ensuring uninterrupted production of large volumes of water. Artesian wells are practically inexhaustible. At the same time, productivity (3-10 m³/h) does not depend on the time of year. For comparison, a sand well can quickly become depleted if several other wells are located nearby or, for example, a pit or quarry is being dug nearby.

- The high quality of water, which does not contain any harmful impurities, is explained by its natural filtration through the limestone layer and its inaccessibility to groundwater, wastewater and surface contaminants.

- Durability - the service life of the speaker ranges from 25 to 50 years, and, unlike sand, it is not necessary to use it regularly.

Among the disadvantages of a well for limestone is the high cost of its creation compared to the construction of a simple well or sand well (from 1300-1500 rubles per 1 m of depth). It is also necessary to obtain a license before drilling to a depth of more than 80 m.

Another disadvantage of such a structure is that water from an artesian source contains a high concentration of minerals and requires additional purification with special filters for daily consumption.

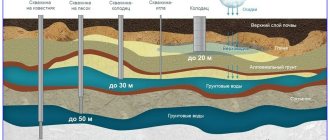

Types of wells and their features

Before drilling, the site area must be examined, determining the level of groundwater. The amount of work that will need to be done to make the well water-bearing will depend on this parameter. The type of well is chosen taking into account the depth of the water-containing formation.

If water is found at a depth of 3-12 m, choose the “Abyssinian well” type. At a depth of up to 50 m, a sand well is used, and an artesian well, if the water lies in the ground at least 200 m. Almost every summer resident can do the first two types manually, but an artesian well will require a drilling rig and professional drillers.

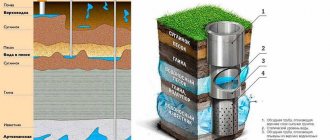

Well internal structure

How to determine the location for a future well

In theory, a deep well can be located anywhere. But in practice, there are a number of rules that must be followed when choosing a drilling site.

Requirements for the site of the proposed installation of the nuclear power plant:

- flat terrain and area from 30×30 m to 60×60 m;

- absence of electrical wires, including telephone lines, directly on the site and at a distance of 2 m around it;

- the possibility of free access for transport and the availability of an area for placing drilling equipment;

- at a distance of 200 m there should be no sewers, cesspools, or other sources of biological or other pollution;

- absence of any structures in the drilling area.

The future well should be located as close as possible to the point of water entry into the house or other premises. This will reduce the length of the pipeline, and with it the costs of constructing a well. The distance between two speakers should not be less than 100 m.

If the drilling and flushing method is used, it is important to provide a system for draining process water. The area where work is planned to be carried out is fenced and guarded in advance. Drilling service specialists can provide assistance in choosing the optimal location for an artesian well.

Organization of the “Abyssinian well” well

This is the simplest needle hole to make. It is shallow, so care must be taken to carefully select a place for it.

There should be no septic tanks, garbage heaps, cesspools or sewage pits nearby. Due to the shallow depth, harmful substances can seep into the source, polluting it.

If the ground does not contain pebbles or other hard rocks, drilling a well can be done in the area around the house or directly in the basement of the house. The well in the basement is convenient to use even in cold weather. The home well is equipped with a manual column and a pump so that water can be used regardless of the availability of electricity.

Artesian well design example

Types of structures

Classic (typical)

This type of construction is applicable in the absence of sand and clay in the limestone aquifer. The well uses 1 steel pipe of standard diameter 13.3 or 15.9 cm. It serves as both casing and production. It is installed before the beginning of the limestone layer. It is no longer required, since the layer is waterproof and is not washed away by water. The pump is placed above the limestone, at the end of the casing.

Double casing

This option is also called "pipe in pipe". It is similar to the previous one with the only difference that below, after the steel casing, a second pipe is installed to the entire depth of the upper limestone layer before the water begins. It is made of durable food-grade plastic that does not emit harmful substances, has a smaller diameter, is equipped with water intake holes, and a pump is installed in it.

To enhance the tightness, the space between the 2 casings is filled with compactonite clay. When in contact with water, it expands in volume, filling the smallest gaps.

With conductor

This design is necessary if the upper layers of the soil are saturated with water (quicksands) or have a heterogeneous structure (rocky layers in clay or sand, etc.). A conductor is a pipe with a diameter larger than that of the casing. It is installed in the upper layers to protect the casing from additional pressure and from surface waste contaminants entering the well.

Telescopic

This type of AS provides for the installation of 2-3 or more casing pipes up to the limestone layer. This design is the most expensive. It is advisable if the soil above the limestone is unstable (quicksands, heterogeneous composition). The name “telescopic” is due to the fact that the casings are nested into each other according to the principle of a telescope. But they are motionless, firmly fixed in the ground.

A typical example of a telescopic speaker:

- The upper steel casing has d=13-13.5 cm and ends at the level of the boulders.

- The middle one is slightly narrower, it is also metal and reaches the limestone layer or passes into the next one above the waterproof layer.

- The third, lower, narrowest, made of durable plastic, does not exceed d=12.5 cm and is installed in the presence of clay layers above the limestone.

First, the widest pipe is lowered into the well, then narrower pipes are pushed deeper through it one by one.

Drilling a sand well by hand

This type of source involves pumping water from a depth of up to 50 m. A sand well is called this because it “gives water” from a water-containing sandy layer of soil, the depth of which is usually just fifty meters. This depth does not guarantee the purity of the water, so it is recommended to periodically check the contents of the well at the sanitation station for the presence of organic and chemical compounds.

To organize a sand well, a classic scheme with a pump is used. And to purify water from suspended matter and debris, use a filter installed at depth. The filter needs to be cleaned regularly. The service life of a sand well is about 15 years.

Sand well drilling diagram

Documenting

The first step in legal preparation for the construction of a nuclear power plant is the collection of documents to obtain permission to drill a deep well. They are submitted to the Subsoil Use Department - the territorial licensing department in your region.

List of documents:

- certificate of ownership of the site where drilling is planned;

- design resolution, which is received from the Subsoil Monitoring Department;

- site plans - cadastral, general, situational;

- calculation of water consumption approved by the Federal Agency for the Protection of Water Resources;

- conclusion from Rospotrebnadzor on work on the site;

- documents of a legal entity, if you are one (certificate of registration, charter);

- conclusion of geological examination;

- certificate of tax registration of the site.

Before collecting and submitting documents, you must obtain permission from the Ministry of Natural Resources and Environment (MNRE). In addition, the Regional Committee for Water Resources must check and approve the design of the future well.

If the depth of the plant is 100 m or more, then in addition to collecting documentation, you must pay a tax fee. The total cost of the license and registration, excluding payment for drilling operations, is about 1 million rubles. This is not cheap, but at the same time, 1 deep-water well can supply several houses or even a small village with water.

Legal registration services are offered by drilling companies, which saves time. However, this does not reduce the final cost of the project. More detailed information about the rules and legal aspects of registration of AS can be found in the Law of the Russian Federation “On Subsoil”. The necessary information is contained in article 19.

Disadvantages and advantages of manual well drilling

Advantages: low cost; no need for bulky special equipment to enter the site; due to the relatively shallow depth, homemade wells are pumped faster and take less time to tighten; If there is no electricity, water can be obtained using a hand suction pump.

The main disadvantage of self-drilling is the limited depth and lack of specialists who can help maintain a homemade well. Thus, after reading this article, we hope that you will not have any questions about how to drill a well with your own hands.

List of drilling works

If you can dig a small well, if you have the knowledge and skills, with your own hands using several assistants and a minimum of equipment, then a well for limestone requires a professional approach. Preparation for the creation of a nuclear power plant involves drawing up a project and calculating the cost, geological studies to select the exact drilling location, and paperwork.

The further algorithm for constructing a deep well includes the following steps:

- Directly drilling to the limestone layer, under which artesian waters lie.

- Work to strengthen the well by cementing in the area around the casing pipe laying site.

- Measuring the depth of a future well.

- Creation and strengthening of casing.

- Installation of a hydraulic accumulator, pump, caisson and other equipment.

- Chemical analysis of water composition, assessment of its suitability for drinking.

- Pumping the well for cleaning purposes.

- Starting up equipment to check its proper operation.

- Connecting the well to the water supply system.

In their work, drillers use various equipment and machinery - a drilling rig for lifting pipes, a winch, a drill, rods, pumps for pumping out dirty water.

Drilling equipment and tools

When drilling artesian wells, professionals use drilling rigs. For smaller wells, a regular tripod with a winch is suitable. It will lower and raise the drilling tool, consisting of a core pipe, drill rods, a drill column, and a drill.

Special equipment, without which it is problematic to make a well, is a drilling tool that will help you go deeper into the ground (auger), a tripod and a winch. To drill a well with your own hands, you will need a metal auger. An ice screw, which is used for winter fishing, can act as an auger. The main thing is that the drill is made of high-strength steel. This is the cheapest option for drilling a well. In addition to the tripod, you will need pipes of different diameters (water pipes, hoses, casing), valves, caisson, filters, and a pump for the well.

The process of drilling an artesian well

Recommendations and operating rules

The service life of the well directly depends on compliance with the operating instructions, which are attached to the AS along with the passport. Please read it carefully before use. The main recommendations are as follows:

- Replace cleaning filters in a timely manner;

- carry out an annual analysis of the chemical composition of water, and if it changes, adjust the filter system;

- if the pressure decreases during water withdrawal, you need to call specialists without taking any independent measures;

- If an emergency occurs, contact the appropriate service to resolve the problem.

Work technology

Before starting construction work, you must obtain a permit and prepare the necessary documents:

- Title deeds and land plot plans. Among them should be situational, cadastral and general.

- Water consumption is calculated. The calculation must be agreed upon with the Water Resources Committee.

- In order to arrange a sanitary zone at the well construction site, the consent of Rospotrebnadzor is obtained.

- Permission must be obtained to carry out design work. These issues are dealt with by the Center for State Monitoring of Subsoil Conditions.

All received papers are sent to the Subsoil Use Department. Based on these documents, a license for the construction of nuclear power plants is issued.

The next stage is concluding an agreement with the design organization. When the construction and installation of the well is completed, the AS must be registered.

Stages of work

Construction work on the arrangement of an artesian spring can be divided into several stages:

- Determination of the depth of the aquifer.

- Search and preparation of a site for construction.

- Delivery of construction and drilling equipment to the site.

- Work on loosening the soil and its extraction.

- Pipe installation.

- Installation of pumping equipment.

- Connection of water main and equipment.

Technology selection

The main stage of NPP construction is drilling. It is performed using specialized equipment. Different operating principles can be used; soil extraction is carried out using the following technologies:

- Auger. This method is best suited for constructing a well on light sandy soils. In this case, the main working tool is a screw - an axis equipped with a solid helical surface. The advantages of this technology include the speed of work and relatively low cost. However, auger drilling can only be used to create shallow sources. If the artesian aquifer is located deep, then it is worth choosing a different technology.

- Rotary. The process takes place using a drill bit. Unlike an auger, this tool has increased strength and copes not only with loose soils, but also with any hard rocks, such as boulders. The disadvantage is the higher cost of performing the work.

Drilling

Drilling work is carried out in several stages:

- Drilling equipment is placed on the site.

- The rock is loosened according to the selected technology.

- Sludge is removed from the well - soil that was formed during the operation of special equipment.

- A casing pipe (or several pipes, depending on which design scheme was chosen) is inserted.

- Assembling equipment for an artesian well.

Well development

The work of installing a well is not limited to drilling; it is equally important to properly install the plant and start it up. This work is carried out in stages:

- Install the caisson. It can be made of steel, concrete or plastic.

- The submersible pump is being installed.

- Electrical wiring and additional equipment are being adjusted.

- Install the pump accumulator and automatic unit.

- The water intake points and the source are connected by a pipeline.

- Carry out decoration.

Calculators for calculation

Limestone wells are the most expensive. The cost is determined by several factors - the depth of drilling, the diameter of the casing pipes, the brand of pump, the volume of the hydraulic tank, the type of wellhead arrangement (caisson, adapter or simply reinforced concrete rings), the length of the trench before entering the house, transportation costs, etc. The estimated price per linear meter of drilling is from 2000 to 6000 rub.

You can calculate the cost of a deep well taking into account the above characteristics using a special calculator.

Despite the complexity and high cost of design and arrangement, an artesian well is a reliable source of clean, high-quality water for many years to come.

Tips for those who make a well themselves

Before starting work, it would be a good idea to ask your neighbors what the water level is in your area. If there are wells nearby, take a look there.

A water level above 5 m is good news, because the only tools needed for drilling are a garden auger.

A small-sized drilling rig or mechanical drilling device - “handbrake”, can be rented. This way you will have the opportunity to use convenient equipment and not pay a lot of money for it.

You cannot lower the water pipe into the well all the way to the bottom. It should not reach the deepest point by about half a meter. This way the water will go up better.

The pipe leading into the well must have ventilation holes on the surface, otherwise, without air access, the water will quickly become musty. It is convenient to equip the pipe with a hinged cover so that there is constant access to the well.

The most convenient way to equip a well is a solid plastic pipe.

After the well is operational, be sure to submit your water for examination. Water is recognized as drinking water if its transparency is at least 30 cm, the nitrate content is no more than 10 mg/l, there are less than 10 E. coli in 1 liter, and the maximum rating of smell and taste is 3 points.

Well construction and finishing

Drilling an artesian well

The choice of drilling method depends on several factors:

- well size – a small diameter well can be drilled manually.

- soil type;

- aquifer depth.

When drilling an artesian well yourself, a mechanical device with a tripod and a casing pipe with a special nozzle is used. To pass through soft soil, a screw-shaped auger is used, and for hard soil, a chisel is used. Strong rocks are usually drilled using percussion drilling using a metal projectile. The soil is removed from the aquifer using a bailer.

Casing design

How to drill a well on limestone with your own hands

- A hole is drilled using an auger.

- The pit must be equipped with a casing pipe. It is selected based on the soil layer: plastic or steel.

- Next, the casing is clogged. The casing should be one meter or more into the clay soil layer. This prevents the penetration of groundwater.

- To get into the limestone layer, drilling continues through the casing. The diameter of the pit in limestone will be smaller. You can use hydraulic drilling technology using a special hydraulic device or, for example, a pneumatic hammer, auger, etc. The main task is to penetrate the interlayer layer.

- When the required depth is reached, all rock should be removed from the pit.

- Next, a plastic pipe is lowered, which will protect the limestone walls from erosion. The result is a two-pipe well. The bottom of the pipe should be perforated so that liquid can penetrate through it.

After this, installation of ground equipment is carried out.

Tools for DIY digging

Equipment depends on soil type. For example, the rotary method is used for limestone. A special installation rotates the drilling elements.

A bit is used in the construction of a telescopic well. As the drill goes deeper, a smaller diameter bit is used.

A tripod is used if drilling is done with your own hands. An electric drive is installed on it to automate the process. In this case, a special rod with a drilling head is used. If the soil is relatively soft, a spoon drill is used.