Types of aluminum frying pans

The classic design of the product does not require special care if the kitchenware is used correctly. Its weight is light, and its price compares favorably with expensive products with diamond, titanium or marble coating. The listed qualities of aluminum products make them a sought-after product in the consumer market. The price difference depends on the product model, which can last a long time.

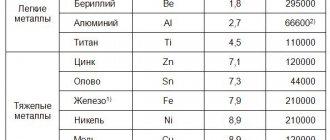

Since aluminum is a lightweight metal with good thermal conductivity, such a frying pan is lightweight and the food in such a frying pan heats up quickly.

Which is better - cast iron or aluminum frying pan? Steel and cast iron can be called durable goods. Aluminum is not inferior to them in these qualities and is cheaper.

Important! It should be remembered that containers made of this metal tend to burn. Then getting rid of the problem that has arisen is not easy. Falling from a height is an additional risk of damage to such products.

The range of models to choose from for such products is impressive. When purchasing, it is important to evaluate three qualities of a product: practicality, price and its impact on human health.

These pans are very convenient to use, they are easy to clean and are perfect for frying any food.

Various metals are used as the basis for such utensils. However, each of them has its own characteristics. Not everyone knows the difference between cast and forged aluminum.

Non-stick cookware for frying and stewing should be selected taking into account the following factors.

- Bottom. Its maximum thickness guarantees long service life of the frying pan. You need to pay attention to the multi-layer non-stick coating. Plasma spraying can raise the price of a product, which will serve as its additional guarantor.

- Risk when saving. Roller knurling is not the best purchase option if you want to use the product for more than a year. Aluminum cookware is not an unaffordable product. It is better to buy a more expensive frying pan so that it lasts longer.

- Prudence. You can’t skimp on quality cookware. However, when purchasing consumer goods, the risk of using a pseudo-aluminum frying pan a couple of times increases. If you have a small family budget, you should pay attention to domestic brands with excellent products at affordable prices.

The cookware is suitable for any stove: induction, electric, gas.

Each company producing such goods focuses on the use of a specific material.

- Ballarini.

The Italian company specializes in the production of ceramic-coated frying utensils. Buyers also noted the stylishness of the product, which implies its elegance and high strength. Ballarini offers to purchase aluminum containers in the form of frying pans, saucepans, and lids for these utensils. Do you want to buy a quality frying pan? Then pay attention to the Ballarini brand. - Kukmara.

A foreign word implies a domestic manufacturer. With a removable handle, the cookware can be used in the oven. The kit includes a pair of handles, which make the model itself a practical purchase. Kukmara frying pans are in great demand among customers. - Tefal.

A well-known company offers aluminum frying pans with high quality non-stick coating. Environmentally friendly materials allow you to prepare food for the benefit of your body. When choosing a cast aluminum frying pan, you can end your search with the Tefal model 04081100. French cookware with a non-stick coating. - Rondell.

The German manufacturer offers examples with a three-layer coating at a price acceptable to domestic consumers. The silicone handle is not exposed to heat, so there is no need to be afraid of burns. Rondell - models are reinforced with a fused bottom, which improves the thermal conductivity of the product and speeds up the cooking process. - Neva metal dishes. Again, we will talk about a domestic manufacturer. A company from St. Petersburg offers products for use in the form of cast aluminum structures.

Fluoropolymers and sometimes marble composite are used as non-stick coatings.

The kitchen is an important area of the home, and you should not skimp on its improvement. Its equipment should imply the presence of at least one aluminum frying pan in the housewife’s arsenal.

According to restaurant chefs, the most suitable for professional cooking is a cast iron frying pan. It is heavy, but absolutely not subject to deformation and is ideal for cooking meat and baking pancakes. Cast iron can be easily washed without fear of damaging the bottom of the frying pan with a hard brush or brush, and food cooked in a cast iron frying pan always turns out to be as tasty as possible and evenly fried.

Cast iron pans don’t need to be washed at all - just periodically heat them over a fire and rinse them under cold running water.

You can also give the chef a titanium frying pan, which is resistant to wear and deformation when heated. In addition, a titanium frying pan has a very presentable appearance and is a more rational investment than purchasing a simple aluminum frying pan. It is generally better not to skimp on such a gift, since a frying pan for a cook is one of the most important tools in his work and the taste of the food he prepares, and, consequently, customer reviews, depends on its quality.

Just twenty years ago, uncoated aluminum pans were the most popular cookware in home kitchens and food service establishments.

Products made of cast aluminum are recognizable at a higher cost compared to analogues, because in most cases manual labor is used. Such products are durable and have uniform thermal conductivity. Here the material is poured into special molds; the technique does not provide for deformation of the structure of the raw material.

Compared to forged and stamped products, cast products are heavier and have thick walls. The product range includes parts for the engineering industry, household items, and dishes.

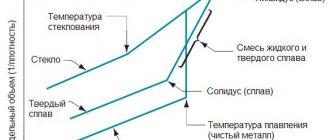

The process can be hot or cold. The first method is relevant for alloys that contain zinc. The mold is systematically filled with molten metal, working manipulations are automated in production conditions.

During cold casting, liquid metal enters the mold under high pressure conditions. The result is high-precision parts that do not require additional processing. Such products have the following properties:

- complex configuration,

- minimal roughness,

- high density,

- exact dimensions.

Aluminum alloys with the addition of:

- silicon, iron, copper - for shaped casting of products that require high strength;

- silumin and magnesium - for the manufacture of parts that will be used under light loads. The material may shrink slightly;

- nickel, copper, zinc, silicon - for the production of especially durable models.

The plastic material makes it possible to produce complex products with various configurations.

Aluminum

This material is often called “winged” because it is used in aircraft construction. But can frying pans made from it be considered high-quality? There is no yes or no answer here.

The undoubted advantage of such cookware is its lightness, high level of thermal conductivity and quite reasonable cost. At the same time, not everything can be fried in an aluminum frying pan; for example, cutlets will simply burn. It is also not suitable for use in the oven - again, the dish will simply “burn”, and the frying pan itself will take a long time to wash afterwards.

Another disadvantage of cast iron frying pans is their “dislike” for various alkalis and acids. In addition, due to the relative softness of this metal, it is quite easy to scratch it.

Aluminum pans should not be overheated. Otherwise, especially if there is a stamped bottom, they may change their shape. The risk of this increases significantly when using such cookware on an electric stove.

If an aluminum frying pan has an internal non-stick coating (usually Teflon), then damage to it as a result of overheating can cause deformation of the pan and it will be almost impossible to cook in it - the food will burn.

Therefore, in order for an aluminum frying pan to last as long as possible, it is worth purchasing a cast product rather than a stamped one. Such frying pans usually have a bottom that is at least 6 mm thick, and most importantly, they can be used on electric stoves.

Cast iron

Cast iron kitchen utensils have come to us from time immemorial. Today, many housewives prefer cast iron frying pans rather than more modern materials. And this is not surprising, such pans are ideal for products that need to be cooked for quite a long time. Cast iron heats up very strongly and quickly - just what you need for high-quality frying.

In addition, during the cooking process there is virtually no need to stir food. Cast iron is a porous metal, so a natural non-stick film of fat forms on the bottom and inner walls of such a frying pan. In this case, you don’t have to be afraid to use lemon juice or vinegar, since cast iron products are resistant to such acids.

If we talk about the disadvantages of cast iron frying pans, there are several of them: the possibility of rust forming on its surface (as a result of improper care, long-term storage of cooked food, etc.), quite large weight, as well as fragility (if such a frying pan is for some reason falls on the floor for some reason, it can easily break).

Cast iron products are difficult to confuse with any other products. It has an impressive weight and is considered a product for long-term use. Aluminum has much less weight, which is the main focus.

For the entire period of operation, subject to proper care, cast iron cookware is able to maintain a decent, presentable appearance.

Both metals have a tendency to burn food on it without stirring. However, cast iron is more resistant to cleaning than aluminum. For this reason, it can serve its owner for an unlimited number of years.

Important! The difference in weight will be the main criterion for such a comparison. In addition, the color of aluminum is difficult to beat. Counterfeits of this metal are rare, which is why it is not an expensive material.

Features of copper forging

Copper is very easy to work with because the metal has a wide operating temperature range. Using scrap and waste non-ferrous metals for work, the master can make large parts. Copper is a malleable metal, so it is suitable for stamping and bending. There is no need to pre-anneal it, since it has no hardening.

Copper should be heated until it turns red. Even if you use a large piece, no additional heating will be required. A mixture of gases is used to weld individual elements during forging.

Health benefits and harms of aluminum frying pans

When cooking, it is important to get dishes that are tasty and safe for the body. A frying pan and saucepan made of aluminum have caused controversy among experts about the advisability of its use. Some of them consider metal entering the body to be dangerous. A category of skeptical doctors argue about the cumulative effect of the negative impact of such a factor on health.

The aluminum frying pan heats up very quickly, the heat is evenly distributed from the bottom to the walls, so the food is evenly fried on all sides.

In contrast to this opinion, most scientists believe that aluminum in microdoses cannot cause damage to the body. Conclusion - the harm of the sounded metal to health has not been proven by laboratory studies.

Additional Information! Aluminum cookware does not mean cooking sour dishes in it. If desired, you can transfer such food to an enamel container, since the harmfulness of metal lies in its rapid oxidation.

Aluminum cookware: types and technological features of production

Very often we are asked the question: what is the difference between cookware made of aluminum?

What kind of aluminum is there? Which aluminum cookware is best to choose? This question is very logical, because on store windows we see a huge selection of aluminum cookware and it is quite difficult for an unenlightened person to understand this entire assortment.

The popularity of aluminum in the production of cookware is not surprising and is determined by the excellent technical characteristics of the metal: it conducts heat well, is lightweight, safe, and food in aluminum cookware cooks quite quickly.

It’s no wonder that manufacturers willingly use it to produce a wide variety of types of cookware. These include pots, frying pans, ladles, cutlery, etc.

So, what technological features are typical for the manufacturing process of aluminum cookware? Aluminum stamped, cast, forged - what is this set of words incomprehensible to the average housewife? What is the difference, what are the main advantages and disadvantages of such dishes? Let's talk about all this in this article.

One of the most popular types of aluminum cookware today is extruded aluminum cookware . This is partly explained by the fact that it is, as a rule, the cheapest, and therefore is readily purchased by housewives.

The technology for producing such utensils is that manufacturers use ready-made aluminum sheets, from which certain items of kitchen utensils are subsequently stamped. That is, the shape of stamped dishes is given by mechanical processing.

The method in which cookware is produced by extruding aluminum from a single sheet is called embossing. This technology is simple and cheap, which explains the relatively low cost of the resulting dishes.

During the minting process, a change in the structure of the metal occurs, which somewhat worsens its thermal conductivity properties and reduces its resistance to deformation when heated. Manufacturers compensate for these shortcomings by increasing the thickness of the bottom and walls of the dishes or by inserting an anti-deformation disk into the bottom.

Characteristics of a good frying pan

During production, dishes are cast from aluminum, like plaster figures. The metal is melted and poured into the prepared mold.

A quality product has a thickness of 5-10 mm. These utensils can be used daily. After cooking, you need to transfer the food to a storage container.

Made from cast aluminum:

- Pots of different sizes.

- Any types of frying pans (ladle, pancake pan, etc.).

- Braziers.

Most frying pans have a non-stick coating. During operation, it is permissible to use any type of stove.

Care instructions:

- Before using a new product, it is advisable to wash the surface with warm water and detergent.

- If a dark coating has formed, the dishes must be treated with vinegar, or the solution must be boiled in it for 10 minutes (add 0.5 tsp of citric acid to 1 liter of water).

- It is prohibited to store various pickles: cabbage, cucumbers, mushrooms, etc.

- When cleaning, do not use chemicals with a high alkali content.

Before choosing a gift, you need to pay attention to some characteristics of the frying pan, which are very important for cooking. First of all, the bottom of the frying pan should be smooth from the inside, without the slightest gaps or tubercles that indicate poor quality of the product. To avoid this, it is better to purchase a frying pan from a store that has a quality certificate for its products. In addition, it is advisable to choose a frying pan with an ornamented or ribbed bottom (bottom groove).

A ribbed or ornamented bottom allows the cookware to heat up evenly and maintain a high temperature for a long time.

The wall of the frying pan chosen as a gift to the cook must be very thick - at least four millimeters in thickness and no more than three centimeters in height. This is an important condition for “meat” frying pans, while the parameters of the walls of pancake frying pans should be two millimeters in thickness and one centimeter in height.

Pan coating

A good quality frying pan today is the ultimate dream of any housewife. And if the choice fell on an aluminum frying pan, you should know something about it. If you buy a product without special coating, you can save a lot. These pans are made from light alloys. But their durability is a big question. Today there are two coating options for aluminum frying pans being considered on the market:

Aluminum frying pan with ceramic coating

Using advanced technologies, ceramic-coated frying pans began to be produced. Aluminum products are covered with a special film. This contributed to the fact that food in such a frying pan cooks much faster and does not burn. Ceramics can handle mechanical stress and avoid any damage. But it is still recommended to use spoons, forks and spatulas that are not sharp, even metal ones.

Food cooks much faster in such a frying pan and does not burn.

During the production process, each product is sprayed with a special layer. Therefore, in the future you will rarely be able to see cracks or scratches on your frying pan. Temperature limit - up to 400 degrees. The material is environmentally friendly. It is considered impossible to interact with acids or alkalis.

Aluminum non-stick frying pan

Today, several subtypes of this option are offered. In general, pans are coated with a layer that is based on Teflon. Now it means heat resistance, environmental safety, and neutrality towards acids.

The further service life depends on the thickness of the non-stick coating.

The further service life depends on the thickness of the non-stick coating (the higher the thickness, the better for the consumer). A high level of strength is observed in the titanium-ceramic coating.

Shape and size

The dimensions of the frying pan depend on its purpose. The round shape of the dishes remains traditional. If you wish, you can choose parameters with more creative lines. Functionality is important in cookware, which is worth remembering. A square-shaped aluminum frying pan will look impressive, but if you want to turn food over the fire, this format will create problems for the cook.

Aluminum in air is instantly covered with an oxide film - oxidized. As a result, aluminum products are completely rust-free.

The dimensions of the product depend on the number of people living in the family. With a diameter of 28 cm, this frying pan is ideal for cooking for all people living in the house.

Advantages of forged aluminum wheels

- Forged wheels are typically about 25% lighter than alloy wheels.

- Although casting is a cheaper process, cast wheels exhibit significantly lower mechanical properties than forged wheels.

- Composite forged wheels consist of two or more parts that are connected to each other in various ways. Some composite discs use bolted connections, others use welding or even adhesive materials. In either case, the joints in the composite wheel rims act as stress concentrators and a point of initiation for fatigue cracks. Bolted connections may vibrate or become loose.

- Forged aluminum wheels are superior to cast aluminum wheels, especially in terms of impact and fatigue resistance. Forged wheels generally do not fail during impact tests, whereas impact tests are a problem for alloy wheels.

- The increased fatigue strength of forged wheels gives designers the opportunity to further reduce their weight, while at the same time remaining comparable in fatigue strength to cast wheels.

Figure 2 - Forged wheels: variety of design options

Accessories for aluminum frying pan

It is difficult to imagine dishes that do not have additional elements. Their presence/absence often affects the functionality of the product.

In this case, we are talking about removable and non-removable components of the frying pan design. Its choice depends on the need to use the dishes in the oven and directly on the gas stove. Often it can be purchased as an additional accessory to the frying pan.

Cast aluminum is much stronger due to the thickness of the walls and bottom, and due to the structure of the metal. Accordingly, the material is not afraid of mechanical damage.

The handle can be made of plastic, which does not make this material less functional. You cannot get burned when using it, because modern models of frying pans do not involve heating the handle.

Lid

Quite often this accessory is not provided for the frying pan. You can buy it in a separate set. Ideally, the lid should be made of aluminum. Stainless steel or high-quality silicone will also work in this case.

Cast aluminum does not wear out or deform over time.

The lid can be matched to any model that matches it in diameter. Its sizes usually vary from 18 to 28 cm.

Features of aluminum pans

The classic design of the product does not require special care if the kitchenware is used correctly. Its weight is light, and its price compares favorably with expensive products with diamond, titanium or marble coating. The listed qualities of aluminum products make them a sought-after product in the consumer market. The price difference depends on the product model, which can last a long time.

Since aluminum is a lightweight metal with good thermal conductivity, such a frying pan is lightweight and the food in such a frying pan heats up quickly.

Which is better - cast iron or aluminum frying pan? Steel and cast iron can be called durable goods. Aluminum is not inferior to them in these qualities and is cheaper.

Important! It should be remembered that containers made of this metal tend to burn. Then getting rid of the problem that has arisen is not easy. Falling from a height is an additional risk of damage to such products.

Introduction to aluminum pans

Not only pots are made from aluminum, but also other kitchen utensils: frying pans, ladles, colanders, ladles, spoons and much more. Even inexperienced housewives distinguish aluminum cookware from steel and cast iron by appearance.

The list of properties includes both beneficial and harmful ones. Aluminum is not prone to corrosion, is not afraid of temperature changes, scratches, or dents. A huge plus is the lightness of the metal. Thin aluminum pans are very light, which allows you to produce dishes with a volume of 20, 30, 40 liters or more.

Giants are in demand in dining rooms and professional kitchens, as well as in the homes of housewives making home preparations for the winter. Large aluminum pans can be tall or wide. The choice depends on the purpose.

The thermal conductivity of aluminum is higher than that of cast iron and steel, so water boils faster, which is important if you need to boil an egg or cook rice in a bag. The metal is not afraid of contact with flame, so it is suitable not only for gas burners and ovens, but also for open fire. Aluminum camping utensils help out during picnics and fishing.

Contact with aluminum may leave stains on the glass-ceramic hob. There is a way out - use products with an external protective coating. Aluminum pans are not suitable for the microwave. For an induction cooker, there is a ruler with a multi-layer bottom that includes a magnetic disk.

The metal in question is inert to many substances, but actively reacts with some acids and alkalis, and when heated, with salts. Hence the restrictions on prepared dishes and the ban on storing prepared food.

For the production of kitchen items, pure food grade aluminum A5 (primary) is used; it is characterized by high thermal conductivity and low heat capacity. The metal itself is quite soft, so alloys with other elements safe for health are also used for pots and pans. According to GOST, these are brands AK7, AK12, AK9, AK5M2.

Aluminum cast iron deserves attention - an alloy that inherits the heat capacity of cast iron and the corrosion resistance of aluminum. Thick-walled stewpans, cauldrons, kettles, and ducklings are made from this alloy. They are lighter than cast iron, but their properties are practically not inferior to them.

For stamping pots, ladles, stewpans, teapots and coffee pots, bimetallic sheets of aluminum and steel are used. Such products inherit the advantages of two metals. The surface is less porous and not so susceptible to oxidation.

Aluminum reserves on the planet are still encouraging, and its extraction is not very expensive. The metal can be easily formed; production does not require complex expensive equipment. Hence the low price of the products.

It is not recommended to cook beets, tomatoes, and fish in aluminum pans. You cannot cook food with a high acid content: cabbage soup, berry compotes, jelly, marinades. You should not use an aluminum milk jug to prepare baby food. Here it is better to choose stainless steel.

Aluminum and alloy pans are ideal for cooking pasta, dumplings, dumplings, lean meat, eggs, potatoes, carrots and other neutral, low-acid vegetables.

You cannot store cooked food in aluminum containers. Leftover food should be immediately transferred to storage containers and the pan should be washed. For washing, do not use hard sponges or caustic solutions. If food sticks, soak the dishes in water or boil them.

Nuances of operation

During use, aluminum cookware becomes covered with scale, becomes dull, dark, and rough. It is unlikely that you will want to use the methods of the last century and clean burnt porridge with sand, soda or ammonia. Buy a special product in the store and restore its former shine and cleanliness in a few minutes.

To prevent food from sticking or burning to a forged or cast frying pan, prepare it before using it for the first time using one of the methods described on our website. The new cooking container should be boiled by adding two tablespoons of salt per liter of water to the water.

Aluminum has turned from a housewife's favorite into a pariah, due to myths about the dangers of aluminum cookware for health. There are opinions that this metal, entering the body, causes cancer and other irreversible diseases.

However, the ingress of metal particles into food is extremely small, and if you refuse to prepare acidic foods, then it is generally negligible. Pots sold in stores comply with state standards and strict certification requirements, according to which all household aluminum products are covered with special protective films. If you follow the instructions for use and care, there is nothing to be afraid of.

Different types of pans are made from aluminum - classic, pressure cookers, pasta cookers, pressure cookers, deep fryers. Explore your options and decide on your goals and objectives.

When purchasing, it is important to compare all the criteria:

- Volume. This parameter depends on the dishes you plan to cook, the number of eaters and habits (cook for once or for two days). For example, for boiling eggs and potatoes for a salad, a liter or one and a half is enough, for porridge for a family you need a capacity of two to three liters, and for dumplings or pasta - from three to five.

- Bottom diameter. It’s easier for owners of gas stoves; just focus on your favorite recipes. The universal diameter is 20-24 cm. If we are talking about an electric stove, then the diameter should correspond to the burner. A bottom that is too large will slow down cooking, while a bottom that is too small will waste energy.

- Thickness of the bottom and walls. Thin stamped pans are suitable for short-term cooking. They heat up quickly, are lightweight and easy to maintain. For frying, simmering, stewing and baking, forged or cast ones are needed.

- Presence of non-stick coating. If you plan to cook cereals, pasta and salad ingredients, or boil water and milk, you don’t need it. Do you want to cook borscht, soups, sauces and stews? Then buy it.

- Lid. Most often, the kit includes an aluminum lid of the same thickness as the pan. In cast dishes, the lids are also cast, which is due to the need for a heavy and well-fitting lid for stewing and simmering. Sometimes the lids are made of glass. It is advisable to have a hole for steam to escape. Otherwise, you will have to keep the pan slightly open the old fashioned way.

- Pens. In cheap stamped models, handles made of the same thin aluminum are attached to the body using fasteners or solder. These are not afraid of heat, but you will have to lift them from the stove using oven mitts. Bakelite handles are more comfortable; they do not heat up.

- The lid should also have a comfortable handle. The simplest option is a bracket, into which sometimes cork or wood is inserted. There are also screw-on plastic handles.

- There should be no dents on the body, and the bottom should be even and smooth if the house has an electric stove.

When purchasing a non-stick pan made of aluminum alloys, carefully inspect the integrity of the coating. The surface must be smooth and uniform. Some coatings are rough, but in this case there should still be no unevenness or burrs.

When studying the assortment of online stores, use the comparison function to see in detail the differences between models from different manufacturers. Don’t overpay for the brand; prices for aluminum pans from less well-known manufacturers are significantly lower. Russian companies do not let you down in quality, pay attention to domestic goods.

How to choose a high-quality and durable pan

Different types of pans are made from aluminum - classic, pressure cookers, pasta cookers, pressure cookers, deep fryers. Explore your options and decide on your goals and objectives.

When purchasing, it is important to compare all the criteria:

- Volume. This parameter depends on the dishes you plan to cook, the number of eaters and habits (cook for once or for two days). For example, for boiling eggs and potatoes for a salad, a liter or one and a half is enough, for porridge for a family you need a capacity of two to three liters, and for dumplings or pasta - from three to five.

- Bottom diameter. It’s easier for owners of gas stoves; just focus on your favorite recipes. The universal diameter is 20-24 cm. If we are talking about an electric stove, then the diameter should correspond to the burner. A bottom that is too large will slow down cooking, while a bottom that is too small will waste energy.

- Thickness of the bottom and walls . Thin stamped pans are suitable for short-term cooking. They heat up quickly, are lightweight and easy to maintain. For frying, simmering, stewing and baking, forged or cast ones are needed.

- Presence of non-stick coating. If you plan to cook cereals, pasta and salad ingredients, or boil water and milk, you don’t need it. Do you want to cook borscht, soups, sauces and stews? Then buy it.

- Lid. Most often, the kit includes an aluminum lid of the same thickness as the pan. In cast dishes, the lids are also cast, which is due to the need for a heavy and well-fitting lid for stewing and simmering. Sometimes the lids are made of glass. It is advisable to have a hole for steam to escape. Otherwise, you will have to keep the pan slightly open the old fashioned way.

How to heat an aluminum frying pan without burning it

Frying utensils will not cause any trouble if they are initially properly prepared for use.

Our ancestors did not like to spoil the taste of products that they already got with hard work. When purchasing an aluminum frying pan, you must initially pour salt on the bottom. In this case, any variety will do. Next, you need to heat the salt for 10-15 minutes. The used material should be removed and the pan greased with vegetable oil. In a couple of days it will be ready to eat.

Information about the dangers of aluminum has no basis.

You can do without this organic substance. First you need to boil water in an aluminum container for five minutes. The hot liquid must be drained and the frying pan itself must be left to dry for half an hour. Then you need to lubricate the inner walls of the dish with any vegetable oil. A fatty base in the form of lard will not work. In a day, the aluminum frying pan will be ready for use.

Metal has no pores, so it is very easy to clean pans from any type of dirt.

In this case, we are talking about calcining the salt together with an oily liquid. The recipe for preparing an aluminum frying pan in this way is simple.

- Use of oil. It must be evenly distributed over the entire bottom of the frying pan.

- Adding salt. 1 tsp is enough. of this substance to mix it with vegetable oil.

- The final stage. The container needs to stand for a couple of hours, after which it can be used.

You cannot store the finished dish in an aluminum frying pan.

The best frying pan for a chef

According to restaurant chefs, the most suitable for professional cooking is a cast iron frying pan. It is heavy, but absolutely not subject to deformation and is ideal for cooking meat and baking pancakes. Cast iron can be easily washed without fear of damaging the bottom of the frying pan with a hard brush or brush, and food cooked in a cast iron frying pan always turns out to be as tasty as possible and evenly fried.

Cast iron pans do not need to be washed at all - just periodically heat them over a fire and rinse them under cold running water.

You can also give the chef a titanium frying pan, which is resistant to wear and deformation when heated. In addition, a titanium frying pan has a very presentable appearance and is a more rational investment than purchasing a simple aluminum frying pan. It is generally better not to skimp on such a gift, since a frying pan for a cook is one of the most important tools in his work and the taste of the food he prepares, and, consequently, customer reviews, depends on its quality.

How to distinguish a cast iron frying pan from an aluminum one

Cast dishes are made by hand die casting. Thickened walls and bottom allow uniform heating of the pan; deformation of the pan during heating and peeling of the non-stick coating are also eliminated. Such dishes retain heat for a long time, which allows you to cook at low heat and save energy.

Stamped cookware is made by bending sheets of aluminum and forming them into bodies using special dies. Thanks to this technology, the dishes are light and thin. Cold-formed metal is damaged at the molecular level, so stamped cookware can easily become deformed by heat and mechanical shock.

The service life of stamped pans depends on the thickness of the metal sheet from which they are made. Stamped ware has a thickness of 1.5 to 2.5 mm. The thinner the walls, the more susceptible they are to deformation. Although such pans are the most inexpensive, they do not last long.

Stamped cookware is very thin and is only recommended for heating food. It is better to use such cookware on gas stoves, because... on other types of slabs it quickly deforms. More popular and more expensive is cast aluminum cookware. Cookware ™ KUKMARA is made from high-quality food-grade aluminum by pouring it into a pre-made mold - a mold.

The main difference between the process technology and stamping is that no deformation of the metal structure occurs. Therefore, aluminum does not lose its thermal conductivity or deformation-resistant properties. Thickened walls of the cookware up to 3-4 mm and a bottom 5-6 mm promote uniform heat distribution during cooking and reduce the likelihood of burning or sticking.

Cookware made from cast aluminum is heavier in weight and can last longer. Now let's compare the difference - on a stamped product, the non-stick layer is applied by rolling the coating onto aluminum blanks - flat metal disks. When molding products, the integrity of the non-stick coating at the molecular level is disrupted, and therefore the cookware quickly loses its non-stick properties.

Non-stick coatings are applied to cast cookware ™ KUKMARA by spraying: a liquid non-stick composition is applied to the already formed body with a spray gun, followed by drying and sintering. Cast cookware undergoes special surface treatment for better adhesion of coatings to the body. The spray coating method is evenly applied to the body of the product; the thickness of the coating is much higher due to technological features, so the cookware retains its non-stick properties for a long time. The choice is yours.

Difference Between Cast and Forged Aluminum Alloys

The main difference between Cast and Forged aluminum alloys is that Cast aluminum alloys have many internal and external defects, whereas Forged aluminum alloys generally do not have internal and external defects.

Aluminum alloys are alloys of aluminum that contain aluminum as the predominant metal along with one or more alloying elements such as copper, magnesium, silicon and tin. There are two main forms of aluminum alloys: cast and forged.

Content

- Overview and main differences

- What are Cast Aluminum Alloys

- What is Forged Aluminum Alloy

- What is the difference between cast and forged aluminum alloys

- Conclusion

What are Cast Aluminum Alloys?

Cast aluminum alloys are alloys containing aluminum as the predominant metal and some other alloying elements. This group of alloys is divided into two types: heat-treatable and non-heat-treatable. The tensile strength of cast aluminum alloys is comparatively lower, but from an economic point of view they are more beneficial. This is due to their low melting point. The most commonly used aluminum-silicon cast alloy. In this alloy, the high level of silicon provides excellent casting characteristics.

The advantages of cast aluminum alloys include the following:

- Low melting point

- Good fluidity

- Ability to control grain structure

- Good surface treatment

- Low solubility of gases in the alloy

- Possibility of strengthening by heat treatment

However, there are also some unfavorable properties. For example, these alloys exhibit high shrinkage and are susceptible to shrinkage defects. Moreover, these alloys have high solubility of hydrogen gas. They are also susceptible to hot cracking and have low ductility.

What are Forged Aluminum Alloys?

Wrought aluminum alloys are aluminum alloys containing aluminum as the predominant metal. These alloys are used in forming processes such as rolling, forging and extrusion. In addition, they are divided into two main groups: heat-treatable and non-heat-treatable alloys. About 85% of aluminum alloys are wrought alloys. They have relatively high tensile strength.

Heat treatable forged alloys can be strengthened by heat treating processes. This is due to the fact that the solubility of alloying elements depends on temperature. The initial strength of these alloys depends on alloying elements such as copper, silicon, magnesium and zinc. On the other hand, non-heat-treatable wrought alloys cannot be strengthened by heat treatment. Their initial strength is due to alloying elements such as manganese, silicon and magnesium. Since they are not heat treatable, cold working or strain hardening can be used to strengthen them. In addition, these alloys are ductile and moderately strong.

What is the difference between cast and forged aluminum alloys?

Cast aluminum alloy is a form of aluminum-containing alloy that has the characteristics of casting, while wrought aluminum alloy is a form of aluminum-containing alloy that is used for forming processes. The main difference between cast and forged aluminum alloys is that cast aluminum alloys have many internal and external defects, while forged aluminum alloys generally do not have internal and external defects. Moreover, the difference between cast and forged aluminum alloys based on properties is that cast aluminum alloys have a low melting point, hence their profitability is high, while forged aluminum alloys have a high melting point, thus their profitability is low.

Apart from this, there is also a difference between cast and forged aluminum alloys depending on their tensile strength. The tensile strength of cast alloy is lower than that of wrought alloy.

Conclusion – Cast vs. Forged Aluminum Alloys

There are two main types of aluminum alloys: cast and forged aluminum alloys. The main difference between cast and forged aluminum alloys is that cast aluminum alloys have many internal and external defects, while forged aluminum alloys generally do not have internal and external defects.

Comparison of manufacturing methods

The essence of the sheet method is that products are stamped from a sheet of aluminum, subjecting it to mechanical processing - embossing or forging. The surface, depending on the finishing treatment, is matte or polished.

Embossing is the cheapest technology, during which containers are extruded from sheets. Sheet blanks are placed in a machine with a rotating blank. During the minting process, the structure of the metal changes, thermal conductivity deteriorates and its strength decreases. This is how thin-walled products with low weight are most often made. To improve performance, the bottom of the pans is supplemented with an anti-deformation disc.

Forging is a more expensive method of producing stamped aluminum cookware. During the forging process, aluminum becomes stronger and its thermal conductivity increases. Forged aluminum pans are resistant to deformation, especially if there is a thickening of the bottom. They cost more, but the durability justifies the cost.

The most expensive dishes are made by casting - pouring molten raw materials into molds. With this production method, the metal does not change its structure, which has a positive effect on thermal conductivity and resistance to deformation.

Cast aluminum pans are thicker and heavier than stamped ones; they look like cast iron ones. And if they are made of an alloy with cast iron, then in terms of properties they are not inferior to it in many ways. Cast aluminum retains heat longer and heats up evenly. In this way, frying pans, stewpans, cauldrons and kettles are made.

Please note that complex shapes can only be achieved by stamping. Casting produces only dishes with a simple configuration, otherwise it will not be possible to remove the blank. Analyze by studying the characteristics specified by the manufacturer.

Which aluminum pan should you choose – cast or stamped? The answer depends on the tasks. Light stamped ones are suitable for cooking pasta, eggs, vegetables, boiling water and milk. That is, for quick cooking. For long-term heat treatment, forged or cast dishes are needed.

The multilayer bottom of the pan is a “sandwich” of different types of metal. Most often, this design is used for steel cookware, sealing aluminum between two steel plates. Aluminum in the “pie” accelerates heating and distributes heat over the entire surface of the bottom.

In aluminum cookware, a double or triple bottom is obtained due to a thicker aluminum plate. Such a bottom is found in forged groups with thick walls, more often in pots and cauldrons. An additional plate protects against deformation and burnout on the stove.

Also, cookware for induction cookers has a multi-layer bottom, where an additional layer is a plate made of a ferromagnetic copper-based alloy. In this case, the packaging must have a symbol indicating compatibility with an induction hob.

Why does an aluminum pan need a non-stick coating if you only plan to cook in it? Don't rush to jump to conclusions. The non-stick coating prevents metal from contacting food, which means you can cook almost any dish, including sour compotes and borscht. In a non-stick pan, milk and porridge will not burn, and pasta and dumplings will not stick to the walls.

The protective layer is applied using two methods – rolling and spraying:

- Rolling is used for stamped cookware; in this case, a non-stick composition is applied to a sheet of metal before stamping. But during the formation process, microcracks may appear.

- Spraying is the processing of finished dishes, a more reliable and high-quality technology. This method is more expensive and is used for cast and forged dishes. The more layers of non-stick substance applied, the better.

When choosing a non-stick aluminum pan, pay attention to the type of coating:

- Ceramic does not like prolonged contact with water, so it is inconvenient for first courses - the remainder will have to be poured into a tureen for storage.

- Teflon is very capricious and is afraid of contact with metal - you need to abandon metal ladles, skimmers and spoons.

- Stone coating is more practical, but only if it actually contains minerals.

Some manufacturers do not classify their developments as any type and come up with their own trademarks. It is important to understand here that any coating makes an aluminum pan safer and more convenient, but it is no longer easy to maintain and store. All types of coatings are vulnerable to temperature changes - do not pour cold broth or water into a heated vessel.

If you need a simple pan for pasta, dumplings or eggs, boiling water and other quick tasks, don't pay extra for the cover.

The cheapest aluminum pans are not coated with anything on the outside. They are sanded, polished or left matte. New dishes in the store shine, but after a week of active use the purchase becomes pale.

A decorative outer coating protects the surface and makes it attractive. It comes in different types:

- enameling – application of enamel;

- varnishing – coating with durable colored varnish;

- anodizing;

- application of porcelain suspension followed by firing.

Such aluminum cookware is more attractive and no longer looks simple and cheap. But the external coating is used only for the more expensive segment, most often in a line with non-stick coating inside.

Pan weight and wall thickness

The aluminum alloy frying pan is quite lightweight and easy to use. Accordingly, the less materials used to make it, the less you will have to pay. But due to the thinness of the aluminum frying pan, the shelf life of the cookware comes very quickly.

To avoid throwing money away, buy a frying pan with a thick bottom (at least 5 mm). Moreover, kitchen utensils with a thin bottom cannot be used on an electric stove, since the heating level there is much higher than that of a standard stove. The length of the sides is determined depending on your needs. If you are going to fry pancakes, the sides should be minimal. But for fish and meat, respectively, higher and wider, so that heat is better distributed.