Lifting operations are classified as potentially hazardous. The norms and rules for the operation of slings concerning such important issues as the use and rejection of slings are prescribed in regulations PB 10-382-00, POT RM-007-98 (Inter-industry rules for labor protection during loading and unloading operations and placement of goods). Fire safety requirements are provided for each type of sling and are reflected in the relevant sections of RD 24-SZK-01-01, RD 10-33-93 and RD 11-07-2007. The documents indicate the terms and composition of the control, norms and conditions for rejecting slings and load-handling devices.

Sling inspection frequency

The condition of all elements is critical not only for the operation of lifting equipment and the safety of transported goods, but, above all, for the safety of personnel performing operations. All devices and equipment used during operations have special requirements for slings regarding their suitability for use. According to safety requirements, equipment must be inspected before use. It is necessary to ensure the presence of stamps or tags and the integrity of the devices. Persons responsible for the condition of lifting mechanisms and the safety of operations with lifting machines inspect removable lifting devices:

- slings - every 10 days;

- traverse, containers and gripping elements - monthly;

- rarely used lifting devices - before putting them into operation.

The procedure for inspecting slings is specified in the relevant instructions. Authorized persons carry out external and internal inspection, perform instrumental control, based on the results of which a conclusion is drawn up on compliance with the parameters given in the product data sheet. Inspection and rejection of equipment must be carried out by engineering and technical personnel who are responsible for the serviceability of the equipment and the safety of operations. When inspecting slings, you should pay attention to the condition of the following elements:

- ribbons,

- cables,

- chains,

- pendants,

- end elements,

- carbines and places for their fixation.

It is important to promptly discard slings that have unacceptable damage or defects. The results of checking the condition of the equipment must be recorded in a special inspection log. If defects or damage are found, information about their elimination must be provided. The journal must be filled out in accordance with the established form, indicating the following parameters:

- The name of the sling and its symbol;

- Serial number;

- Product passport numbers and manufacturer's name;

- Date, place and address of the recipient of the products;

- Date of the last survey;

- Conclusion on the possibility of using the product;

- Signature of the responsible person.

Requirements for the manufacture, testing and marking of slings

Periodic inspection of lifting devices and related equipment is stipulated by Russian legislation.

Slings must be manufactured exclusively on the territory of specialized enterprises (you cannot choose another manufacturing option):

- branch with links (corresponding elements) to ensure reliable attachment to the hook of a specialized crane and further connection of the load;

- ring in the form of a corresponding closed loop in order to ensure tying of the load.

Other features include:

- cargo rope slings must be made from special steel ropes, cargo chain slings must be made directly from round link chains. The owner of the enterprise can purchase equipment only from an accredited company specializing in the production of such equipment;

- design and manufacturing are carried out by a specialized engineering department of the manufacturer;

- locks are necessarily equipped with specialized high-quality safety locks to ensure an increased level of security;

- During manufacture, the equipment is tested under a load that exceeds 25% of the declared load capacity, and is subsequently recorded in the appropriate log.

Requirements must be met

All slings, without exception, must have a marking (appropriate tag), which indicates not only the manufacturer, but also additionally:

- inventory number;

- maximum permissible load capacity;

- date of the test.

Reference ! All indicators must be recorded in a specialized accounting and inspection journal.

Conditions for rejecting rope slings

Rope slings, the production of which is carried out in accordance with the requirements of GOST 25573-82 and RD-10-33-93, must undergo 3 stages of inspection:

- Outer;

- Interior;

- Instrumental.

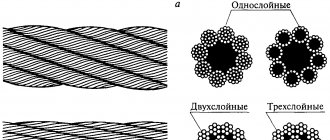

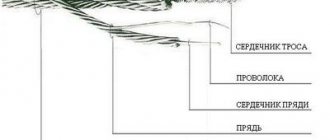

Inspection of rope products includes checking:

- Compliance of the type of ropes and markings of slings with the data contained in the product passport;

- The presence of defects/damage along the length of the product and their extent;

- Serviceability of loops at the ends of the rope;

- Condition of the internal strands and core of the sling.

What type of damage is the product subject to rejection? Signs and standards for rejecting slings:

- Broken rope strand;

- There are twists and knots, creases, kinks in the ropes, crushing, etc.;

- The tag with marking is damaged or missing, there is no passport for the product;

- The number of visible damage and breaks of the outer wires for a double lay rope is more than 3´d – 4, 6´d – 6, 30´d – 16;

- Due to corrosion, the rope diameter decreases by 7% or more;

- Due to corrosion or wear, the diameter of the outer wires of the rope has decreased by 40% or more;

- The core is damaged, resulting in a 10% reduction in rope diameter;

- Wear of outer wires up to 30% of the rope diameter;

- There is a strand break;

- Signs of rope displacement in the braid/sleeve were detected;

- The core has been extruded;

- Damage caused by temperature or electrical arcing;

- Crack in the crimp bushing, thimble deformation by more than 15%;

- Lack of safety locking elements on gripping parts;

- Deformation of the hook of the load-handling devices, there are cracks, tears in the hinged links;

- Unbending of the hook – as a result of residual deformations leading to a change in the size of the element by more than 5%;

- Dropping ends of braided wires.

The standards for rejecting steel rope slings must be strictly observed. Table 1. Rejection standards for steel ropes (slings) - according to the initial safety factor, according to the number of broken wires along the length of 1 pitch of the rope lay (the first number is a cross lay, the second is one-sided).

Table 2. Rejection standards for steel ropes

manufacturer's warranty

The sling was tested with a static load exceeding the load capacity by 1.25 times for 3 minutes. The sling is manufactured in accordance with the requirements of PB - 10-382-00, GOST 25573-82 and RD-10-33-93. The warranty period for the operation of the sling in accordance with GOST 25573-82 during single-shift operation is 3 (three) months for slings of the SKP and SKK types and 6 (six) months for other types, and according to RD-10-33-93 - during single-shift operation for 3 months for all types of slings, from the date of commissioning. During this period, the manufacturer undertakes to eliminate defects caused by his fault free of charge.

Signs of rejection of chain slings

The production of chain slings is carried out in accordance with GOST 30441-97, TU 3150-001-52466920-2005, RD 11-07-2007, PB-10-382-00. Products of this type have the longest service life, which is 1.5 years. During regular inspection of the product, the following is checked:

- The presence of tags and markings corresponding to the product passport;

- Serviceability of connecting end elements;

- Length and diameter of links, deviations of indicators in comparison with the original parameters.

Rejection of a chain sling link:

- In the presence of tears, cracks, metal delaminations in the chain elements, the presence of bending of 2 links;

- Reduction in link diameter as a result of wear and other mechanical damage by more than 10%.

- Chain slings are written off in the following cases:

- Missing/damaged product tag or passport;

- Absence/damage of markings on product elements;

- Elongation of links by more than 3%;

- The difference in the length of the sling branches with free slack is more than 15 mm;

- Reduction in the cross-sectional diameter of links due to wear – by more than 10%;

- Lack of safety elements on the sling grips.

Rejection of multi-leg slings is carried out if a difference in the length of the branches is detected.

Maximum permissible residual elongation for branches of different types of slings:

- Chain – 1%;

- Rope cars – 3%;

- Textile – 6%.

Fig.1. Signs of defective chain slings. Chain sling rejection percentage

1 - product damage; 2 — link bent; 3—tear of the product; 4 - crack; 5 - product wear; 6 - chain link extension

General inspection of lifting devices

When inspecting equipment for grasping loads (hooks, blocks, connecting devices), it is necessary to determine visually and using measuring equipment the presence of the following defects:

- compliance with the declared performance characteristics;

- state;

- cracks, chips, wear;

- performance.

Rejection of load-handling equipment is carried out in case of cracks, breaks, working wear of 10 percent, deformations (bending, change in fastening angle, defects in connections).

Based on the results of all stages of inspection of each sling (rope), a log of scheduled inspection of lifting equipment is filled out. Rejection is carried out (slings are not allowed for further use) or the equipment is allowed to be allowed to carry out lifting operations.

Routine inspection of slings, with recording of inspection data in a log, is a necessary safety requirement.

| № | Designation | Name | Quantity | Material | Weight 1 pc. | The mass of everyone | Notes | Signature |

| 1 | GOST 7667-80 | Steel rope 23.5 | 1 | 87 | 87 | No |

Norms for rejecting textile slings

Assessing the condition of textile slings consists of visually inspecting the product for compliance with the markings on the tag and the data in the passport. The serviceability of loops and seams, grips and connecting elements is checked. Products must be inspected using appropriate tools to identify defects and determine the size of elements. Textile slings are subject to rejection in the following cases:

- No markings or tags;

- Transverse tears, cuts of tapes;

- There are nodes on the supporting tapes, regardless of their size;

- When the threads on the tapes separate. Local delamination of the tape by more than 0.5 m, with a break of 3 or more lines. When delamination at the edge seal is more than 20 cm and edge deviations at the loop extend more than 10% of the stitching length;

- Longitudinal tears, cuts – more than 50 mm, total length – no more than 10% of the product branch;

- On through holes formed as a result of damage by sharp objects or burns with a diameter of more than 10% of the width of the textile sling. If there are 3 or more holes at a distance of less than 10% of the width of the tape;

- In case of chemical damage (acids, alkalis, solvents, etc.) and surface breaks of tapes, single damage exceeding 10% of the tape width;

- If more than half the length of the sling is contaminated with soils, resins, paints, cement, petroleum products, etc.

Conditions under which the use of textile tape slings is prohibited:

Rice. 1 - contamination of the textile sling Fig. 2 - total length of cuts, tears more than 10% of the total length Fig. 3 - more than three through holes Fig. 4 - surface breaks of the tape, bulging of threads - more than 10% of the thickness of the tape Fig. 5 – damage to the sling from exposure to chemicals Fig. 6 - no marking Fig. 7 - peeling of the edge of the tape or stitching of the product at the loop by more than 10% of the length of the stitching Fig. 8 - delamination in places where the edges of the textile sling are sealed

The rules for rejecting textile slings also apply to the structural elements of a textile sling (loops, brackets, pendants, links, etc.). The following damage to these structures is unacceptable:

- Deformation or wear of the surface, contributing to a decrease in the cross-sectional area of the element by 10% or more;

- Cracks of any size;

- Damage to an element that reduces its original size by more than 3%;

- Damage to threads and fastenings.

Slings made of polymer materials must not be stored on the floor, near sources of heat and UV radiation, or on surfaces damaged by corrosion. Rejected and suitable products cannot be stored together.

Crane rope rejection

Crane ropes should be rejected if examination shows that the deterioration of the rope has exceeded certain criteria. General rejection criteria require that any one of the factors listed below is sufficiently serious to cause negative consequences. However, the deterioration of the rope and the decision to remove it are almost always the result of the cumulative effect of a combination of these factors: - wire breaks; — reduction in diameter; - deformation; — corrosion.