- hot and cold cracks during welding

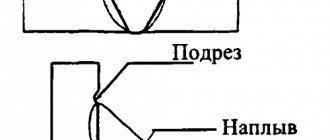

- Undercuts

- Lack of penetration of edges, roots

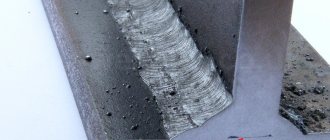

- Surges

- Cavities (gas cavities, fistulas)

- Pores

- Solid inclusions

- Non-fusion

- Violations of the connection form

- Metal splashes

- Random arc

Any welding process must be carried out strictly according to the rules and regulations. Any defect is a consequence of violating these rules. There are large cracks that are visible to the naked eye. And there are microcracks that are noticeable only at fifty times magnification. Despite their small size, they are just as dangerous as large ones.

Cracks are divided into hot and cold depending on the welding temperature. If the seam was cooked at a temperature of more than a thousand degrees, then they will be called hot. If the cooking temperature was lower - cold.

Both cold and hot cracks are irreparable defects. If they are present, the product will be considered defective and cannot be used.

What types of cracks are there?

Hot and cold welding cracks can also be classified on other grounds. They can be transverse, longitudinal, radial and so on.

Hot ones are intercrystalline fractures that occur in the weld itself or near it, in the so-called heat-affected zone. They look like a discontinuity or a cut. They appear when the metal crystallizes or after the compound cools. They are dark in color and curved in shape.

Cold ones represent local destruction and are formed when the metal cools if welding was carried out at temperatures up to 200 degrees. A cold crack appears near the weld and has a light tint at the fracture. Such defects occur during arc welding of steel products of large thickness.

Hot cracks that appear near the seam, in turn, are divided into four types:

- Liquidation

- Appearing due to low elongation

- Crystallization

- Appearing for other reasons

The first type of defect appears very often when working with structural steel. It contains many different inclusions, most often sulfides. When melting, some of them dissolve in the thermally affected region and turn into a film. It is located at the grain boundary and reduces the cohesive strength of the product, causing hot cracks to appear. The appearance of these defects when working with low-alloy steel is caused by the presence of alloying elements such as titanium and niobium. Liquidation defects are quite long, without branches, and more open.

Defects resulting from low elongation occur only when welding austenitic steels.

Crystallization defects are short microcracks. Most typical for cylinder head.

Weld joint cracks

The reliability, performance and efficiency of welded structures largely depend on the quality of welded joints and the presence of defects in them. When deciding the important question of the admissibility of detected defects, the following important factors should be taken into account;

- design features, dimensions and shape of the structure itself and its welded components;

- the stressed state resulting from its manufacture, as well as after heat treatment;

- the nature of the defects, their number and location;

- operating conditions of the structure, etc.

Defects in welded joints can be classified

- according to their location,

- reasons for education

- according to configuration and size.

The formation of cracks, pores, and slag inclusions is largely determined by the chemical composition of the welding materials used and welding technology, while lack of penetration, undercuts, sagging, and burns is determined by a violation of the technological process, equipment malfunction, and low production standards.

Defects such as macro- or microcracks can be divided into the following groups depending on the temperature range of their formation:

- hot, arising during the cooling process at high temperatures corresponding approximately to the interval from the temperature above the solidus point to 1000°C;

- hot, formed in the temperature range 1000...600°C;

- formed after welding as a result of tempering of welded joints;

- cold, which appear after welding at temperatures below 250...200°C;

- lamellar, occurring in the HAZ of a welded joint. They can nucleate at elevated temperatures and spread when cold.

Hot cracks.

They form when, during the cooling process, the deformation of the metal exceeds its ability to deform. As the metal cools, its ductility and rate of deformation change. The degree of metal deformation in the temperature range of brittleness (TIH) depends on the temperature coefficient of linear expansion, the rigidity of the welded product and the welding mode.

Alloying elements and impurities (carbon, sulfur, boron, etc.) present in the liquid metal of the weld pool, having a small distribution coefficient, accumulate between growing cells (dendrites), cause a significant decrease in the solidification temperature of sections of the liquid metal located between the cells, and promote expansion two-phase region - crystallization temperature interval (TIC). In this regard, the difference in the mechanical properties (ductility and strength) of the metal layer between the cells, which solidifies at a lower temperature compared to the previously crystallized axes of the cells, increases.

When the metal cools as a result of shrinkage, the amount of deformation and its concentration in the metal layers, which have a lower solidification temperature, and, consequently, strength and ductility, increase. The exhaustion of ductility leads to the formation of cracks when the deformation capacity of the metal is less than the deformation caused by shrinkage.

The smaller the TIC, the higher the plastic properties of the metal, since the difference in the mechanical properties of the crystallite axes and their boundaries decreases. The thermal cycle of welding influences the nature of primary crystallization, the size of crystallites and the degree of chemical heterogeneity over the cross section of crystallites, the direction of growth of crystallites, the shape and dimensions of the weld pool. As the size of crystallites increases, the degree of chemical heterogeneity over their cross section and the tendency of the metal to form hot cracks along the boundaries of crystallites increase. With a narrow and deep weld pool, when crystal growth occurs from opposite edges towards each other, as a result of the accumulation of alloying elements and impurities in front of the crystallization front, causing a decrease in the solidification temperature, the danger of cracks in the middle part of the weld increases. Thus, the resistance of the metal against the formation of crystallization cracks is influenced by the shape of the penetration and the weld shape coefficient.

Metallurgical and technological recommendations for increasing the resistance of weld metal against their formation are basically the same. Metallurgical recommendations boil down to the use of welding materials with a low content of harmful impurities (sulfur, phosphorus) and surfactants (tin, antimony). If sulfur is present, it is necessary to bind it into refractory sulfides of manganese and rare earth elements (cerium, yttrium, etc.). Technological recommendations consist in the use of welding methods and modes that make it possible to obtain the optimal shape of the weld pool, to ensure refinement of the primary structure, which helps to reduce the degree of chemical heterogeneity and TIC, as well as to increase the deformability of the hardening metal, which can be adjusted by changing the parameters of the welding mode, the rigidity of structures and in some cases - due to preheating.

Hot cracks in the HAZ. In the temperature range of approximately 1400…1000ºС, intensive grain growth and migration of grain boundaries are observed in the HAZ. The accumulation of alloying elements and impurities at grain boundaries contributes to the formation of hot cracks.

The resistance of the HAZ against the appearance of hot cracks is largely determined by the purity of the structural steel and the content of non-metallic inclusions in it (for example, sulfides). The high heating temperature of the HAZ causes the melting of such inclusions located both inside the grains and along their boundaries. During cooling in the HAZ, as a result of an increase in temporary stresses, conditions may arise that promote the formation of hot cracks.

Evaluation of the resistance of welded joints against hot cracking. The essence of hot crack test methods is high-temperature deformation of the metal during the welding process under the influence of external forces created by a testing machine (machine testing methods), or under the influence of internal forces from weld shrinkage (technological testing methods). Among the machine methods, it should be noted: LTP-1-6, “Werenstrain”, “Transverenstrain”, the method of forced deformation of the weld metal, etc.

To qualitatively assess the resistance of weld metal against the formation of hot cracks, technological methods of testing samples are used, which are typical welded joints (assemblies, structures), the welding technology of which causes an increased rate of high-temperature deformations leading to the appearance of cracks.

To study the tendency of the HAZ to form hot cracks or determine the TIC of the metal, the method of modeling the thermal deformation cycles of the HAZ metal can be used. Such tests can be carried out on IMET, Termorestor, and Glibl systems.

Hot cracks that form in the temperature range in the low-temperature brittleness range (LTBR) (600...1000ºС) occur in multilayer welds in the HAZ created in the previous layer when applying a subsequent layer, in the HAZ of the base metal, subjected to repeated heating during multilayer welding, in welded connections of structures during their heat treatment. One of the main reasons for the formation of hot cracks in NTICH is the segregation of impurities at grain boundaries as a result of reheating.

As measures to increase the resistance of the metal against the formation of cracks, NTICH recommends: reducing the sulfur and oxygen content in the metal, refinement of the structure of the weld metal and HAZ, increasing the deformation rate, reducing the residence time of the metal in this interval and specific energy, etc.

Leave cracks. During heat treatment of welded products made from low-alloy steels, as well as from nickel, austenitic chromium-nickel steels, undertaken to reduce the level of residual stresses, cracks initiate in the low-temperature range (200...300ºС) when the welded product is heated to the tempering temperature and at tempering temperatures. The reason for the appearance of cracks of the first type may be the high heating rate of the product. High-level thermal stresses, interacting with residual stresses, can cause the formation of microcracks, the growth of which continues with further heating. Defects in welded joints (hot, cold cracks) resulting from welding can increase significantly when the product is reheated.

The formation of tempering cracks can be prevented by reducing the heating rate of the product during heat treatment, as well as by cooling after welding before planting in the furnace at a level of 150…300ºС.

As the cooling rate decreases, the sensitivity of steel to the formation of tempering cracks increases. Tempering cracks that occur at higher temperatures can be caused by the precipitation of finely dispersed carbides from the solid solution inside the grains, which causes their dispersion strengthening. In this case, the relaxation of residual stresses during tempering should proceed through the mechanism of creep along grain boundaries. When the plastic properties are exhausted, cracks appear at the grain boundaries.

The presence of surface-active elements in steel, as well as some alloying elements (chromium, molybdenum, vanadium), has an unfavorable effect.

Cold cracks. They are typical defects in welded joints made of medium-alloyed high-strength steels of the pearlitic and martensitic classes and most often affect the heat-affected zone.

Longitudinal cracks located in the HAZ are called spalls. If they occur in the fusion zone on the seam side, they are called tears. Transverse and longitudinal can pass from the HAZ to the seam. They may or may not extend to the surface of the welded joint (external or internal).

The resistance of welded joints against the appearance of cold cracks is determined by the structure of the metal, the hydrogen content in it, the level of stresses of the first kind, as well as the presence in the metal of small quantities (traces) of impurities such as sulfur, phosphorus, lead, tin, etc., which can cause formation of hot cracks or microtears at grain boundaries, developing into cold cracks during the cooling process.

The resistance of a metal against the formation of cold cracks is significantly influenced by the presence of local peak microstresses that arise in freshly quenched martensite as a result of phase transformations. From this perspective, the kinetics of phase transformations in the HAZ, which is determined by the composition of the weld metal and the temperature range of phase transformations, becomes important. When a welded joint is loaded with an external load, the stress level increases in areas in which local microstresses coincide in direction with the external load. In such places, microcurrents are created even at low external load values. If residual microstresses are small, then large external stresses are required for microdeformations to occur.

As a result of microplastic deformation, relaxation of local microstresses occurs. In the case of sufficient mobility of dislocations (due to a reduced carbon content or increased temperature of the metal during loading), a path is implemented that leads to a more uniform distribution of residual microstresses under load. In the same way, obviously, relaxation of microstresses occurs during rest of hardened steel, leading to a decrease in local stress peaks, as a result of which the steel’s resistance to delayed fracture increases. Under conditions of limited mobility of dislocations (due to increased carbon content or low temperature of the metal during loading), relaxation occurs due to the formation of defects (microcracks), which, when subsequently loaded, serve as stress concentrators and increase the risk of brittle fracture.

In places of local microstresses, areas of volumetric expansion of the crystal lattice can appear - traps for hydrogen, which causes its non-uniform distribution. Hydrogen in freshly quenched martensite is located mainly at the tops of large martensite needles and at grain boundaries, and after rest it is distributed more evenly both at the boundaries and inside the grains. An increase in the hydrogen content in freshly quenched martensite and its accumulation in areas of volumetric expansion can reduce the resistance of steel to delayed fracture.

The chemical composition of the weld metal has a great influence on the resistance of the HAZ metal to delayed fracture. The main factor influencing the resistance of the HAZ of welded joints against delayed destruction is the temporary stresses that are formed in the weld metal and HAZ as a result of their shrinkage during the cooling process. The interaction of temporary stresses with stresses caused by phase transformations promotes the relaxation of microstresses through microscopic shifts. The higher level of temporary stresses in the weld metal and HAZ when welding with austanite wires compared to ferrite-pearlite wires determines the higher resistance of the HAZ of welded joints made of bainitic and martensitic steels against delayed destruction.

The resistance of the HAZ against delayed and brittle fracture depends on the cooling rate of the welded joints. As it increases, more stressed structures with limited relaxation of microstresses through microplastic shears are formed in the HAZ.

The simplest and most effective way to prevent cold cracks is to regulate the thermal cycle of welding, as well as the use of preheating when necessary. Optimal thermal cycles for welding thick metal with preheating can be achieved by using two- or multi-arc welding.

Tests for cold cracking susceptibility can be divided into the following groups:

1) involving the use of a real welding process for rigid samples (tests using Tekken, STS, cross, RRC samples with forced rigidity, etc.);

2) mechanical using LTP-2, LTP2-3 installations, the “Implant” method;

3) with a simulated thermal deformation welding cycle based on the Termorestor, Glibl, LTPZ-6, etc. installations.

Lamellar cracks. The sources of occurrence of lamellar cracks mainly in the HAZ or in the base metal when it is loaded in the direction perpendicular to the thickness of the sheet (along the z axis) can be considered to be non-metallic inclusions in a significant amount and unevenly distributed in the steel, which are arranged in layers along the thickness of the rolled product. Lamellar fracture most often occurs when welding structures made of sheets of significant thickness made of structural and austenitic steels. In austenitic steels, the centers for the formation of cracks (delaminations) can be lines (interlayers) along the thickness of the sheet made of carbides and oxides.

These cracks are classified as cold crack type defects, although their formation may be associated with processes occurring in the high-temperature HAZ region. The most effective measure to prevent the formation of lamellar cracks is to select steel with good plastic properties in the z-axis direction.

When welding steels prone to the formation of lamellar cracks, in some cases, preliminary lining of the edges is used before welding. An important condition for preventing the occurrence of lamellar cracks is the choice of a rational design of welded joints in order to reduce the level of stress along the thickness.

Ultrasonic testing makes it possible to determine the accumulation of inclusions, which are potential sources of crack formation during welding. The plastic properties of sheets are most often assessed in the thickness direction. The evaluation criterion when using this test method is the amount of transverse narrowing. The ductility of critical structures must be at least 30%.

The noted patterns of crack occurrence during welding and heat treatment make it possible to interpret them from the general positions of metallurgy and strength as a manifestation of brittle fracture under relaxation (creep) conditions. They arise when the margin of ductility during intergranular fracture of the corresponding section of the welded joint is less than the creep strain accumulated during welding (hot cracks), holding after it (cold cracks) or during tempering (cracks during heat treatment). The physical laws of the process of formation and development of cracks at the microstructural level may be different for each type of fracture, but their common features allow the use of unified phenomenological approaches developed for conditions of intergranular fracture during creep.

Measures to prevent cold cracking

- Electrodes and fluxes must be calcined.

- All parts used in the welding process must be preheated to 250-450 degrees.

- It is necessary to unconditionally comply with all the requirements, rules and regulations of a particular type of welding, and select the most optimal heating temperature.

- It is necessary to use the type of weld that is necessary in a particular case.

- Cooling of the product should occur slowly and evenly.

- After completion of the work, softening annealing is carried out in the elements in order to relieve stress.

The causes of defects in the form of hot cracks are external and internal. External causes include segregation of elements and oxides. These elements are not part of the metal being welded, but appear due to the use of auxiliary impurities. Internal causes of occurrence are characterized by the influence of filler materials.

The segregating elements do not have to be molten to cause a hot crack. They can cause the formation of a thin film, which will contribute to a decrease in grain boundary strength.

Everyone has at least once encountered such an unpleasant phenomenon as the formation of a crack in the tongue. Moreover, very often it seems that the tongue has cracked for no apparent reason, on its own. Small cracks may not bother you at all for a long time, while deep cracks cause discomfort and acute pain to the patient. However, plaque and cracks should not be ignored, since over time even the smallest cracks, if left untreated, can increase in size and begin to hurt. We will tell you why they appear and what they mean, as well as whether congenital fissures are dangerous and how to treat them.

What it is

Officially, painful cracks on the tongue and along the edge of the tongue are called glossalgia. This is a fairly common neurosomatic disease.

Most common symptoms:

- dryness in the tongue area;

- itching and burning;

- swelling;

- soreness.

The insidiousness of glossalgia is that it does not go away on its own; without appropriate treatment it is impossible to get rid of a crack in the tongue.

At an early stage of the disease, the doctor may not notice pronounced cracks in the tongue, since they are microscopic and mainly manifest themselves as burning and pain. If you do not respond to this symptom in a timely manner, over time a crack may form at the tip or in the middle of the tongue, longitudinally, as well as cracks under the tongue and on the sides. In this case, the doctor also notes swelling and swelling of the tongue, atrophy of the salivary glands and filiform papillae on the surface of the tongue. The sooner you start treatment, the easier it is to get rid of glossalgia, so if you have cracks in your tongue, you should immediately consult a doctor.

Congenital fissures

It happens that a patient has cracks in the tongue since birth or childhood, which practically do not cause him any concern. Such cracks are usually transverse and are caused by the development and formation of the tongue.

Some patients have a so-called folded tongue, a congenital feature of tongue development. It is usually considered normal and does not require any treatment. The exception is red cracks in the tongue, which form at the bottom of the folds and cause pain to the patient. This happens with insufficient oral hygiene, so those with a folded tongue must carefully clean not only their teeth and gums, but also their tongue from plaque. If the owner of a folded tongue has developed cracks, treatment should be prescribed by a doctor, taking into account the design features of the patient’s tongue. To prevent the formation of folds in the depths, more attention should be paid to the sanitation of the oral cavity.

How do they look

Small cracks in the tongue can be completely invisible to the naked eye; only an experienced doctor can examine them using special instruments. The larger ones are clearly visible to the naked eye; they resemble longitudinal or transverse grooves on the tongue. Deep cracks look like crevices; sometimes the tongue appears to be cracked or split into two parts. If you notice such a problem, consult a doctor, even if nothing is bothering you at the moment. If an infection gets into the crack, the course of the disease may be complicated by the inflammatory process.

Reasons for appearance

Reasons for education:

- lack of nutrients, iron and vitamin PP in the patient’s body;

- anemia;

- lack of B vitamins;

- allergic reaction to toothpaste or medications;

- chronic fatigue and constant nervous tension;

- mechanical damage to the tongue (nervous biting, chewing);

- disruption of capillary blood flow in the tongue;

- the patient has diseases such as gastritis, enterocolitis, hepatitis, cholecystitis;

- wearing uncomfortable dentures.

The main reason why the tongue is cracked is mechanical injuries due to a lack of vitamins and microelements in the patient’s body. In this case, it is enough to bite your tongue while chewing food so that a painful crack forms at its tip.

Another fairly common reason why a patient’s tongue is cracked is a malfunction in the patient’s central nervous system, which is caused by chronic fatigue, frequent stress, and lack of sleep. This is a reason to suspect a problem with the hypothalamus.

It happens that patients are perplexed: why there are cracks on the tongue, there seems to be no visible reason for their appearance. In this case, the answer to the question of why cracks appear can only be given by an experienced doctor, after a thorough diagnosis. It is necessary to do a detailed blood test to determine which microelements and vitamins are missing in the patient’s body. Quite often, correction of the nutritional system helps get rid of the disease.

Many people are probably interested in the question of what cracks mean. After all, the tongue, as is known, signals the presence of many diseases and pathological conditions of the human body. Cracks in the tongue are a sign of a lack of vitamins and microelements in the body. Quite often, cracks are caused by worms, as they deplete the human body, causing anemia and iron deficiency. They also indicate a diseased liver, since with this disease the human body does not receive many microelements important for health.

Cracks in the tongue on the side can be a sign of thyroid disease; in this case, it swells and is injured at the edges by the patient’s teeth.

Treatment

The main question that worries patients with glossalgia is how to cure cracks in the tongue. In fact, everything is not so difficult. The treatment method depends on the cause of glossalgia.

- First, it is necessary to eliminate the dental causes of tongue cracks - correct an incorrect bite, replace defective fillings, repair a prosthesis. Next, the patient should be carefully examined by a therapist, neurologist, and, if necessary, by an endocrinologist and gastroenterologist. And only after this should treatment for glossalgia be prescribed.

- Typically, treatment for fissures consists of drug therapy and physiotherapeutic procedures. Treatment with medications is to improve blood circulation in the tissues of the oral cavity, as well as to improve general cerebral circulation. For this purpose, drugs such as trental, cavinton, nicotinic acid, and vitamin C are prescribed.

- The tone of the autonomic nervous system should also be improved; for this purpose, sedatives are prescribed - tincture of valerian, motherwort, persen.

- Additionally, the doctor may prescribe procedures such as electrical neurostimulation using a TENS device. A good effect is achieved by using electrophoresis, as well as iontophoresis of novocaine.

- If the tongue is severely painful, the doctor may prescribe local painkillers - lidocaine, dicaine.

- If the patient has cracks in the tongue, plaque and burning, it is necessary to adjust the diet. During treatment, you should completely exclude from the diet foods that irritate the surface of the tongue - such as sour juices, vegetables, pickles and marinades. You should not consume large amounts of spices, especially pepper and salt. It is advisable to quit smoking.

- After each meal, be sure to brush your teeth and rinse your mouth with salted water or a decoction of medicinal herbs. Oak bark, sage, propolis, and honey have a healing effect.

How to reduce the likelihood of hot cracks?

- Monitor metallurgical processes when the metal is molten.

- Ensure optimal metal deoxidation process.

- When working with sulfur, you need to keep in mind that it can cause the appearance of sulfide films. Therefore, it is better for her to interact with manganese.

- To prevent sulfur from having a negative impact on emerging defects, the welder must be very careful when crystallizing the weld. The sulfur should pass to the left of the peritectic point. In this situation, delta ferrite is released, which dissolves it better.

How does an anal fissure appear?

The main symptom is pain, so it is difficult to ignore an anal fissure. Painful sensations can be of varying intensity, most often intensify during defecation, and gradually subside after it. The pain can be so severe that it makes you afraid to go to the toilet. Sometimes people with an anal fissure stop eating food because of this fear, hoping that this will delay the moment of defecation. This tactic often backfires.

In some situations, if you do not contact a coloproctologist for treatment for a long time, the intensity of the pain becomes so severe that it becomes painful to sit and walk. Most often this happens if an infection occurs.

There may be a feeling of “stiffness” in the anus, a foreign body in the anus.

Another equally frightening symptom is bleeding. Blood from an anal fissure is often bright red in color, may come out in drops or simply leave red marks on toilet paper. Sometimes traces of such blood can even be seen on underwear.

The appearance of blood, pain and any other unpleasant sensations in the anus should alert you. If you have the complaints noted above, you should immediately contact a specialist, since the sooner treatment is started, the faster it will be possible to get rid of the anal fissure completely.

Reasons for the formation of hot cracks

- Presence of liquid layers.

- Deformations that occur when a part is shortened.

- Rigid fixation of parts during operation. This prevents the element from being able to be moved to cool properly. As a result, tension appears.

- Cooking with metals such as tungsten, titanium, molybdenum and vanadium can cause chemical bonds to break down.

- The presence of “harmful” impurities in the mass of the metal being welded: phosphorus, sulfur.

The highest probability of deformation in the form of cracks is present when the metal is in a liquid state. It is at this moment that impurities in the metal mass migrate and the space between the grains becomes contaminated. During cooling, there is also a risk of stress occurring when the seam shrinks unevenly. This is the basis for the appearance of transverse hot cracks.

Any crack is the result of inattention, non-compliance with the welding process technology, and lack of awareness regarding the composition of the materials to be welded.

What may be secondary changes in chronic anal fissure?

— sentinel tubercle (shown in the photo)

— skin fold (shown in the photo)

- fistula (shown in the photo)

Rice. 3. Anal fissure with the formation of a fibrous polyp similar to the hypertrophic anal papilla

Rice. 4. Progression of an anal fissure with the formation of a skin fold

Rice. 5. Anal fissure with the formation of a secondary fistula tract

If an anal fissure develops in a patient due to dense stools, frequent loose stools, anal sex or the use of sex toys, then it will be classified as a primary anal fissure. And if an anal fissure occurs in a patient who suffers from other diseases, such as anal cancer, cicatricial stricture of the anus, Crohn's disease, ulcerative colitis, HIV, then we will classify it as a secondary anal fissure.

Based on location, cracks are divided into three types:

Rice. 6.

Ways to prevent their occurrence

To ensure that neither hot nor cold cracks appear during operation or after cooling, certain actions must be taken:

- Ensure that the elements are not rigidly fixed during operation.

- Select the correct seam size depending on the pipe wall thickness. If the joint area is too small in relation to the thickness of the product, then the likelihood of cracks occurring is very high.

- Select the desired welding mode for a specific type of material, taking into account all the nuances and features.

- Cook strictly in accordance with established standards, including observing the angle of the tip.

- All parts must be properly prepared before welding.

- Choose electrodes that match the type and temperature of welding; do not purchase cheap electrodes.

- Avoid overheating by using a welding current higher than that recommended for a particular type of welding.

Thus, to avoid the appearance of defects in the form of stresses and cracks, you need to:

- Take into account all the features of working with a specific metal.

- Increase the width of the connection with a significant thickness of the product.

- Avoid the appearance of narrow rollers.

- Make continuous seams.

Prevention of cracks

There are certain measures that reduce the likelihood of various types of cracks:

- Reducing the rigidity of the connection of welded parts.

- Select the width of the weld commensurate with the thickness of the parts.

- The value of the welding current must correspond to the recommended type of connection. Exceeding will result in overheating.

- Select welding wire with low sulfur and carbon content.

- Observe the angle of inclination of the electrode.

- The seam should not be too narrow.

- Application of a multi-pass welding method. Single pass seams are less durable.

It would be a good idea to preheat the parts to be welded.

Welding cracks

- In addition to standards for the welding process, there are also standards for eliminating defects. They are established in GOSTs 5264 and 1153.

- Cracks must be prepared before welding. Preparation includes inspection and determination of their endings. This occurs when heated with a gas burner to a temperature of 100-150 degrees.

- The ends of the crack need to be drilled out. When working with a drill, the center of the hole should coincide with the end of the crack, or deviate from it by about 3-5 mm.

- If it is impossible to drill out a crack, it is burned with a gas torch.

- Before welding cracks that do not extend beyond the edges of the pipe, it is better to slightly heat the areas located behind the ends of the cracks with a torch.

- Cracks larger than 300 mm are welded using a reverse-step method.

Thus, there is a certain list of reasons for the formation of hot cracks during welding. To avoid their appearance, you need to know all the features of the material with which you have to work. Melting of metal from the moment of preparation until the finished product cools must be carried out strictly in accordance with the standards established by GOSTs. Not all defects can be corrected, so it is better to be aware in advance of all the rules and nuances of working with a particular material.

Weld inspection

Visually detectable cold cracks that appear in welding areas cannot be ignored and special methods applied to them aimed at eliminating them and strengthening welded joints. But the greatest danger is the appearance of cold cracks deep in the metal. They are not visible and seem to be absent, but they greatly weaken the seam, creating the danger of its destruction.

To combat this phenomenon, scientists and designers have developed a number of methods for monitoring welded joints:

- radiation flaw detection;

- magnetic control;

- ultrasonic flaw detection;

- penetrant flaw detection;

- permeability control.

During radiation flaw detection, the process involves scanning the joint with X-rays or gamma rays and fixing the image on special plates. This is the most reliable method of control, but, due to its high cost and health hazard, it is used only on the most critical products.

Magnetic control is carried out by special magnetic field sources. The magnetic flux created by them is directed to the connection and is distorted in areas of uneven density. The result is recorded either with magnetic powder or with a special magnetic tape. The method is very specific and is used extremely rarely.

Ultrasonic flaw detection is a very convenient, inexpensive and widely used method. Ultrasound, created by a special convenient and compact device, is directed to the seam and reflected from the boundaries of different media. The reflected signal is received by the sensor and displayed on the instrument display. This method could become universal if not for some restrictions on the list of controlled metals.