Cold cracks during welding can form either at the end of the welding process or during surfacing of an additional layer of metal. The formation of cold cracks occurs at low temperatures not exceeding 200-250°C, in contrast to hot cracks during welding, which form at high temperatures.

The figure shows the types of cold cracks. They are longitudinal - 1, transverse - 2 (with a large thickness of the weld). The most common places for cracks to begin to form is at the root of the weld, or at the junction of the weld bead and the base metal. There are cracks formed in the heat-affected zone - 3.

Cold cracks do not always appear on the surface of the metal. They may well form inside and be small in extent. Internal cold cracks are difficult to detect because the penetrating chemicals used to inspect welds are not sensitive to such weld defects.

If hot cracks during welding turn out to be quite branched, then the main difference between cold cracks and hot ones is that they are not so branched and open. Surface cracks exposed to air remain unoxidized and acquire a brown or blue color. Such cracks are formed mainly during welding of high-strength steels.

Types of cold cracks during welding

Based on the place of formation, cold defects are divided into external and internal subtypes. Based on the direction relative to the joint, the types of cold cracks are given the following names:

- spalling - longitudinal in areas near the joint;

- separation - directed along the seam;

- palisade - formed across a seam or in a heat-affected zone perpendicular to the joint.

Types of cold cracks during welding

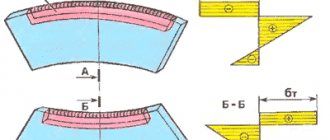

At complex joints, cold cracks can form:

- between seams during double-sided welding;

- at the boundary between the seam and the metal of the part;

- on the underside of the connection under the bead.

Casting defects

Cold cracks.

When cooling steel castings below the temperature range of 620-650′ C and cast iron below 400-650 C, elastic properties predominate in their material. Cracks that form in castings during the period when elastic properties predominate in their material are called cold. The division of cracks into hot and cold is arbitrary, since the formation mechanism of cold cracks is almost no different from hot ones.

Cold cracks are called weakly noticeable violations of the integrity of the casting, mostly with a light, grainy fracture surface. Cold cracks usually have regular outlines, since when they form, destruction occurs along the grains, and not along their boundaries. Their width is usually insignificant, since the plasticity of the alloys during the period of their formation is small and the possibilities for deformation of the casting are limited.

Cold cracks form in the zone of tensile stresses and are located mainly in sharp corners and other places of stress concentration. The reason for the formation of cold cracks is the residual stresses that arise in the casting during its cooling. In addition, temporary stresses also influence the formation of cold cracks.

Cold cracks caused by residual stresses appear when castings are operated under loads significantly lower than the design ones. In practice, they can occur even without the influence of external forces - during cleaning, transportation or mechanical processing.

The probability of the formation of cold cracks depends on the nature of the loading of the casting, the magnitude of the residual stresses acting in it, and the plastic and strength properties of the alloys. Thus, depending on the loading conditions, the formation of cold cracks is more likely, the lower the strength or ductility of the material.

Let us consider the conditions for the formation of a cold crack using the example of a casting pulley with a small-section rim and large-diameter spokes. Such castings are often obtained with distorted dimensions, high stresses and cracks. When manufacturing pulleys from carbon steel, they experience predominantly temperature stresses rather than phase stresses. Immediately after pouring, the cooling rate of the rim will be significantly higher than that of more massive spokes and hubs. Since the spokes and the rim are connected into one system, the spokes will have a certain average length. In this case, the spokes will be compressed (shortened), and the stresses arising in them will be extinguished by plastic deformations. Some elongation of the rim in this case can be neglected. As the pulley cools further, there will come a point when elastic properties begin to dominate in the spokes. After this, the system acquires greater rigidity and a reduction in the size of any of its elements should cause corresponding elastic deformations and stresses in the neighboring one.

If the spokes were now cooled separately from the rim, then, since their temperature is higher than the rim, the absolute amount of shrinkage would be greater and a gap would form between them and the rim. However, since the casting is a single system, after the final cooling of the casting the spokes will be elastically stretched and tensile stresses will act in them, and compressive stresses will act in the rim. If the pulley rim is not rigid enough, it may bend, which will lead to defective warping. If the rim has sufficient rigidity, then the stresses in the spokes may exceed the permissible value and cold cracks will appear in the casting along the spokes.

As another example, consider the cooling conditions and cold crack initiation in a ductile iron casting of a passenger car hub. It consists of two parts - a hub, a massive bushing and a small-section disk. Due to the fact that during the first cooling period of the casting the disk cools faster than the bushing, by the time the cast iron of the entire casting transitions to an elastic state, the temperature difference between the bushing and the disk is 80°. As a result, after the casting has completely cooled, thermal residual stresses arise, tensile in the bushing and compressive in the disk and leading to the formation of cold cracks.

The formation of cold cracks can also be influenced by temporary temperature stresses. So, for example, in this case the hub would have been knocked out 2.5 minutes after its bushing had cooled. In this case, due to the acceleration of cooling of the casting after pouring, the temperature difference between the sleeve and the disk would increase to 135°. The temperature difference of 135° - 80° = 55° would be caused by the accelerated cooling of the disk and would lead to the emergence of temporary thermal compressive stresses in the bushing and tensile stresses in the disk. In this case, residual and temporary stresses have opposite signs. Since temperature stresses are directly proportional to the temperature difference, the residual stresses in the part will be 1.3 times greater than the temporary ones. In addition, the higher the elastic modulus of the material, the greater the stress.

One should strive to create non-rigid, uncoupled structures in which, as a result of local deformations, residual stresses do not reach dangerous values. For the same purpose, sometimes large castings are divided into several parts. For example, the casting of a large flywheel is divided into two half rings. After machining, they are connected with bolts. The stresses and distortions of each half ring are less than those of the whole ring.

As indicated, the probability of crack formation is greater, the lower the ductility and strength of the alloys. Therefore, with equal residual temperature stresses in castings made of steel, gray and white cast iron, the greatest danger of cold cracks is in the less ductile white cast iron.

Measures to prevent cold cracks.

Measures to prevent the formation of cold cracks are reduced to appropriate measures to prevent the occurrence of significant residual stresses. Good results can be obtained by increasing the strength and plastic properties of the cast metal. In steels, elements such as carbon, chromium, manganese, etc., reducing ductility, contribute to the formation of cold cracks; steels with a reduced content of carbon and alloying elements are less prone to the formation of such defects.

To prevent the occurrence of cold cracks, it is especially important that the casting does not have walls of different thicknesses.

Thus, reducing the rigidity of castings by replacing tensile deformation with bending deformation helps to reduce residual stresses and eliminate cold cracks. In this case, some parts of the castings may warp.

However, it is not always advisable to use flexible casting structures with bending ribs, disks or spokes, since their large bending can cause stress concentration. Thus, in the upper ribs of the white cast iron roller (Fig. 58, a) cold cracks were observed, sometimes turning into a disk. These cracks arose as a result of a significant stress concentration when the disk was bent under the influence of residual temperature stresses. The lower ribs, subject to compression, had no cracks. When the top ribs are removed, the stress concentration disappears and cracks do not form. However, in this case the rigidity of the upper half of the roller is unacceptably reduced.

In foundry practice, one of the most common ways to reduce residual stresses in castings is their heat treatment. Castings are heated to temperatures at which the plasticity of their material increases significantly, the yield strength decreases, plastic deformation occurs and stresses decrease. With further cooling of the casting from high temperatures, temperature and phase stresses may again arise in them. Therefore, during heat treatment carried out to reduce internal stresses, it is necessary to equalize the temperature across the sections of the casting during holding and subsequent cooling.

In the production of steel castings, heat treatment is a mandatory technological operation carried out to improve their crystalline structure and physical and mechanical properties, but at the same time internal stresses are reduced. For steel containing 0.2 - 0.3% carbon, the heat treatment temperature is 880-900″ C. At this temperature, the yield strength of steel is quite low and residual stresses are almost completely removed. A similar phenomenon occurs when annealing white cast iron castings.

Low-temperature annealing (artificial aging) of gray cast iron castings consists of heating them, holding them at a temperature of 400-600 ° C and slow cooling with the furnace. Loading of castings is carried out both in a cold and heated to a temperature of 200-300 ° C furnace. The rate of increase in furnace temperature is 50-150 degrees until the holding temperature is reached. The higher the temperature and the longer the olives are kept in the oven, the lower the magnitude of the residual stresses. The temperature of low-temperature annealing of gray cast iron should ensure sufficient ductility of the metal base, reduction of residual stresses in places of their concentration and sufficient stabilization of residual stresses,

preserved in the casting. In this case, the initial hardness of the metal should not decrease significantly.

After the end of the holding period, the castings are cooled slowly, at a rate of 10 - 30 degrees, together with the furnace to a temperature of 350 ° C in order to avoid the appearance of new temperature (thermal) stresses. After all areas of the casting reach a temperature of 350 C, the cooling rate can be increased to 60 degrees. Unloading of castings from the furnace should be done at a temperature not exceeding 100-150″ C.

Reasons for education

The highest probability of cold cracks appearing after welding is in high-carbon and alloy steel grades, titanium and aluminum alloys. A cold defect occurs if:

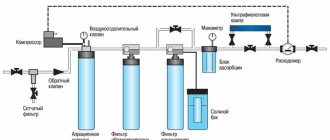

- The structure of the seam and workpieces is sensitive to the action of hydrogen. Hardenable steel grades have this property even when cold.

- The welded zone contains a sufficient amount of hydrogen, which penetrates from the seam.

- There is a tensile stress inside the joint.

Scientists have found that the main reason for the formation of cold cracks during welding is the negative effect of hydrogen on the structure of steel. Its source can be electrode coating, flux, or moisture from the air. Hydrogen can enter the molten metal from contaminants on workpieces and filler material or as part of a shielding gas. If the edges of the workpieces are not cleaned of rust before welding, when heated, it will begin to actively saturate the seam with gas.

Mechanism of cold crack formation

The effect of hydrogen on a welded joint can be temporary or permanent. Temporary influence appears when the welded joint is tested immediately after welding is completed, or shortly after it. In such cases, certain difficulties may arise, especially when monitoring and assessing the plastic properties of the connection. Samples, even at small bend angles, may already have surface cracks.

Such cracks appear due to the diffusion of hydrogen into places where pores or slag inclusions are formed, as well as in the case of the transformation of atomic hydrogen into molecular hydrogen. After hydrogen transforms into a molecular state, high gas pressure arises in places where it accumulates, and this causes the appearance of shiny pores in the metal.

The transition of hydrogen to the molecular state occurs at low temperatures, less than 200°C. At elevated temperatures, hydrogen in welded joints is in an atomic state.

The permanent influence of hydrogen includes its effect on the formation of cold cracks. The tendency of a metal to form cracks is primarily due to its hardenability or embrittlement, which is the result of structural transformations.

Zones along the boundaries of primary grains can be damaged as a result of various processes, not necessarily due to exposure to hydrogen. This can occur when some of the sulfides or carbides dissolve and, as a consequence, the precipitation of sulfides and carbides from solid phases. This process reduces the strength at the grain boundaries. And when transitioning to a molecular state, hydrogen exerts strong pressure on these zones, which can cause the formation of cold cracks.