How to increase the power of a gas generator

When buying a gas generator, you often don’t think about the fact that you will have to connect equipment with much greater power than the generator is capable of producing. Or you initially plan to use a gas generator for one piece of equipment, but then suddenly there is a need to connect another, but there is no time or money to buy a new gas generator. Therefore, the gas generator often operates in extreme conditions.

Basic add-ons for generators

Some of these items aren't cheap, but don't try to cut costs by buying an alternative of questionable quality. Choosing a low budget option instead of a reliable option is never a good idea when it comes to portable generators.

The truth is that when you are looking for a portable generator, you also need to budget for spare parts and installation costs.

Here are the generator parts and add-ons that should not be overlooked.

Restrictions

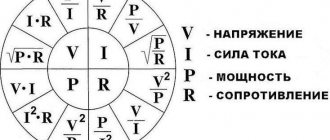

The question of how to increase the power of a gas generator arises when the equipment simply does not start, although the generator is working at full capacity. Of course, you will find a lot of advice about how to rewind the rotor winding with a larger diameter wire with fewer turns, or even some innovative developments for which they offer to pay a certain amount. But let's be honest - in nature there is a law of conservation of energy. If the engine of your generator is not capable of producing more power, then all rewinding efforts will turn out to be a failure. Moreover, they will affect the change in the parameters of the output current and voltage curve, which may adversely affect the operation of the connected equipment.

Heavy duty extension cords

For safety reasons, we recommend using heavy duty extension cords that can withstand extreme weather conditions. You don't want the connection to be interrupted when the main power is out due to bad weather.

Another requirement is that the extension cords have the same amperage as the generator. You can usually find the amplifiers you need at the output of the generator.

Please note that most portable generators have multiple AC outputs. Additionally, the extension cord should have two different plugs, one that fits into the portable generator socket and the other into the transfer switch socket.

Finally, the extension cord should also be long enough, so calculate the distance you need. Also consider how the length and thickness of the extension cord affects resistance.

Maintenance kit

Although maintenance for portable generators is minimal, some maintenance is required to ensure that everything continues to run smoothly. Where you bought your portable generator also sells maintenance kits.

Modernization of gasoline generators

increasing power, increasing speed stability, and other issues

and so I start the topic. modernization of gasoline generators. It is known that generators with contactless excitation of the machine dynamo and a four-stroke single-cylinder engine are very sensitive to the connection of the load; the generator begins to slow down the engine, strain and over-gas. And why, firstly, the dynamo of the car does not have a power reserve, that is, it is easy to burn it or overheat, and secondly, the engines do not have ignition timing or throttle control. I propose to start by considering the option of increasing the power of the dynamo of the machine, the diagram of which I will post later but will describe a little in a few words. we have a unit with a self-loaded rotor without external excitation and three stator windings, one, so to speak, is the working one, the voltage removed from it is supplied to the socket through a thermal fuse, the second winding is similar to the first but is unloaded and is shunted by a capacitor, the so-called ballast winding is needed to stabilize the frequency by dividing the angle rotor revolutions, and a third twelve-volt one, which you wouldn’t mind giving up. And so it is proposed to increase the reliability of the dynamo (generator) by increasing the cross-section of the wire of the main winding, which will reduce the rotor braking effect by adding a choke equivalent to a third of the voltage and equal in maximum power, which will take part of the load on itself, reducing by an order of magnitude the effect of a short-term circuit (this effect is clearly expressed when the tool is turned on almost equal to the generator power) which will further reduce the braking effect. there is no need to change the third winding; only for those who need a voltage of 12V, you can install a step-down transformer on the third winding, but its power is equal to half the power of this winding. that is, if the generator is 1 kilowatt, then a 500-watt trans will work without problems, I mean that with such trans power, the thermal coefficient of the generator winding will be more stable. Removing the 12V winding will provide additional space to increase the cross-section of the main winding. you can also increase the number of revolutions of the motor, which will give a little power and a little more linear operation (for example, not 800 revolutions but 1000 revolutions), not so much but significantly, and if you increase the number of revolutions, the number of turns of the stator windings must be reduced, otherwise the voltage will be too high. You can sew the windings relative to the revolutions like this, we set the speed we need. The voltmeter on the generator can go off scale, so there is no load, measure the voltage with a circuit and when disassembling, sew the number of turns on the winding, then divide the resulting number of turns by the measured voltage, we get a turn per volt and multiply this turn per volt by 230 volts we get the required number of turns. True, in practice this is only two or three turns less than the factory installation, but these two or three turns increase the cross-section by 0.2 mm and this is not bad, do not forget about the remote 12V winding because it is still 0.15 mm and in total 0.35 mm, that is, if the old winding is wound with 0.85 wire mm, then the new 1.2mm and this is 600 watt more reliable, that is, a 1000 watt generator will give you 1400 watt (we will not consider the maximum power as this is a mockery of the generator. The extra revolutions will give additional power and linearity will reduce the sensitivity of the motor to generator braking and will reduce the inconsistency of throttling, if not be greedy on fuel consumption because it is about 7.5%. The circuit of the converted generator is not very different from the original. If anyone has circuits, please share them for comparison and discussion in the topic, perhaps they will help create an optimally efficient device. Also share your thoughts and useful links.

How to choose a gas generator

A gasoline generator (or fuel energy generator) is an autonomous portable power station that is used in construction, welding and installation work, and in everyday life as the main and additional power source. Depending on the model, the unit allows you to connect one or more electrical appliances at the same time. In this article you will learn how to choose a gas generator for welding, power supply to your home, workshop or workshop, and which brands are most popular among Russian users.

Depending on the model, from 2 to 4 sockets with a voltage of 12, 220 or 380 V can be installed on the generator body for connecting various electrical appliances. Not all generators can be connected to any device. Welding electrical equipment requires a special gas generator for welding. It differs from the usual one in higher power and low voltage, which is important for welding inverters and plasma cutting machines.

Popular generator manufacturers

Decided to buy a gasoline generator - which brand is better to choose? This is one of the first and important questions facing the buyer. Today, there are a large number of domestic and foreign brands of European and Asian origin on the special equipment market. The most popular brands:

Is it possible to increase the power of a gas generator from 50 to 500 W?

Greetings! I have a question for you.

I work at a construction site, we often go to sites that are just under construction, so there is no talk about normal power supply to such areas. We constantly connected lighting equipment from a conventional 50W gas generator. Now more responsibilities have arisen and the power needs to be increased almost 10 times. Tell me, is it possible to somehow convert an existing generator so that it produces 500 W?

Comments and reviews

It won't be possible to change it. These are two very different electric cars both in terms of gas drive and electrical parts.

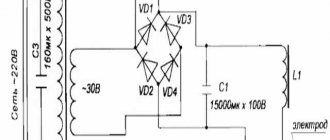

I'm afraid you won't be able to carry out such an upgrade on a gasoline generator. Now I’ll try to explain why, look at the circuit diagram of a standard gasoline generator:

As you can see, any gasoline generator works on the following principle: fuel is poured into the tank, which then enters the internal combustion engine (ICE), and it, in turn, drives an electric generator that gives you 50W of power. If you want to increase the power to 500W, then you will need to install a new 500W electric generator in the same device. And its size, in comparison with the current one, is also 10 times larger. And the old internal combustion engine is not enough to rotate such a generator, so both it and the tank for the new engine will also have to be replaced.

The new filling will no longer fit into the old frame or body, so there is simply no point in making such a replacement; you can try to purchase all the spare parts separately, but it is unlikely that you will be able to organize their coordinated work. Therefore, it is much more cost-effective to immediately purchase a new gasoline generator with the necessary parameters.

What kind of gasoline to pour into a gas generator

In most cases, A92 fuel is best suited for gasoline generators. In practice, gasoline with a higher octane number does not provide any great benefits, and its cost is significantly higher. When using a four-stroke gas generator, fuel must be poured into the tank in its pure form, while to refuel a station with a two-stroke engine you will need to mix gasoline and engine oil. This procedure is performed to ensure reliable and stable operation of the engine, extending the operating period and reducing fuel consumption. It should be noted that gasoline generators with two-stroke engines have much more toxic emissions than four-stroke engines. When choosing oil for a generator, it is necessary to take into account that they can be summer and winter, as well as mineral or synthetic, which affects their viscosity and fluidity under different conditions. Before purchasing and using oil, be sure to read the recommendations and advice of your power plant manufacturer.

In most cases, gasoline and oil for refueling two-stroke engines are pre-mixed, outside the equipment, but some models of gasoline generators are equipped with an automatic mixing system.

- Model:

EP 25000 TE in container with AVR - Power:

16 kW - RUB 1,079,740

- Model:

AB10-T400-VM111E in container - Power:

10 kW - RUB 291,690

- Model:

LT 3500 CL - Power:

2.5 kW - 19,600 rub.

How to increase on-board voltage

Where and how is a diode placed in the LV circuit on the generator in order to increase the voltage in the car network and better charge the battery? Here I propose a simple solution, raising the on-board voltage, without going anywhere in the car and its circuits.

I searched in my archives and did not find the material from which I read this decision. “Structurally, voltage regulators have an upper limit of 13.6V. This is due to the “old” connection diagram, from which the new one was copied and “successfully improved”. In it, the necessary voltage from the on-board network, supplied to the regulator for comparison, passed through a chain of wires. On them it dropped to normal. According to the new scheme, we have a chronic undercharge of the battery. Which, with the arrival of winter, makes starting the engine in the cold quite problematic. But if you install a pre-heater, starting the engine will be much easier.

It should also be noted that the battery begins to absorb energy (charge) only when its temperature is above zero. Therefore, in winter, if you make short runs and the battery does not have time to warm up under the hood to at least zero (plus charging time), it will be constantly discharged. And soon it will die... It is believed that after starting the engine, in order for the battery to recover, you need to drive for at least 20 minutes. Just go, and not stand in traffic jams! How to increase the voltage in the network?

Very simple! It is necessary to make the regulator “think” that we have low voltage in the network. Thus, the generator will give us the missing volts. A diode will help us do this. In a generator with a built-in voltage regulator, you need to place a diode in the circuit, as shown in the figure.

Do-it-yourself gasoline generator

There are several reasons to own a miniature power plant. These include frequent interruptions in the supply of electrical energy in rural areas, and new construction when electricity has not yet been supplied to the construction site. The best option is to purchase a ready-made structure. There is a large selection of gasoline and diesel power plants on the market in all possible power output ranges. The problem is their high cost.

Industrial gas generator

If you have the necessary parts and materials, as well as experience and desire, it is quite possible to assemble a homemade gas generator.

Selection of components

DIY wind generator from a car generator

How to make a gas generator with your own hands? The main parts are the engine and the generator. The engine can be any suitable gasoline engine from a chainsaw, motor cultivator, motorcycle or moped.

The motor power should slightly exceed that required at the output of the electric generator. A certain difficulty is the ratio of power expressed in kilowatts (characteristics of electric generators) and in horsepower, usually used for the characteristics of internal combustion engines. Various quantities are related to each other by the following relationship:

1 kW = 1.36 hp

Thus, a 2 hp chainsaw engine. translated into kilowatts it has 1.47 kW.

If you have a choice, it is better to go with a four-stroke engine, since a two-stroke engine has the following disadvantages:

- The need to use a mixture of gasoline and special oil as fuel;

- It is impossible to use a large fuel tank, since the fuel mixture tends to separate, and the viscous and heavier oil will end up at the bottom of the tank;

- Low efficiency.

An equally difficult task is choosing a generator. It is theoretically possible to use any electric motor as an electric generator, since these devices are reversible and can perform each other’s functions. It is tempting to use an AC motor so that the output immediately produces an alternating voltage with the necessary parameters. But in practice this is not feasible for a number of reasons:

- Impossibility of accurately stabilizing the rotation speed of an internal combustion engine. Thus, as the engine speed changes, the output voltage and frequency will change;

- High complexity of the control scheme.

In industrial gas generators, special windings loaded onto a capacitor are used. As the speed increases, the voltage frequency increases, accordingly, the capacitor resistance drops, and the load on the control winding increases.

That, creating additional magnetization, slows down the generator rotor, reducing the rotation speed. When the frequency decreases, the reverse process occurs.

In practice, this requires a complete change in the design of the motor, introducing additional winding into it, and is hardly feasible at home.

The only way out of the situation is to use a DC generator.

Car generators are best suited for a homemade gas generator because:

- It is possible to stabilize the output voltage by using the vehicle's standard voltage regulator;

- Possibility of connecting any generator to replace a failed one;

- Convert DC voltage by using an uninterruptible power supply.

We need to dwell on the last point in more detail. It is clear that a car generator produces a constant voltage. Its value is 12-14 V. But how to convert it to an alternating voltage of 220 V? The solution is simple - use an uninterruptible power supply unit, which has a car generator connected instead of a battery.

Uninterruptible power supply

It is quite possible that the uninterruptible power supply unit will be the most expensive part of a homemade home power station, since devices with a power of more than 500 W have a sharp increase in their cost. There are several options for increasing the permissible power:

- Conversion of an existing uninterruptible power supply to higher power values;

- Purchase of a faulty powerful one and its subsequent repair;

- Build your own design.

The first option requires great skill in repairing radio-electronic devices, since it requires:

- Replacing the standard transformer with a more powerful one;

- Replacing output transistor switches (possibly along with their wiring);

- Alteration or adjustment of current protection to a new output current range.

Making a completely homemade design requires no less knowledge, but there is no need to reproduce many unnecessary functions of an industrial device. Thus, the cost of a homemade converter may be lower than the other components of a homemade power plant.

Diode introduction

Observe polarity. There is no crime here, it’s just that if the polarity is not observed, charging will not happen. The diode must be designed for a current of at least 5 A. By the way, it will get very hot, so it is better to install it on a radiator. What should you consider when selecting the type of diode? Voltage drop on diodes: germanium - 0.3...0.7 V, silicon - 0.8...1.2 V. I.e. This is the voltage by which your on-board network will increase. Therefore, by selection we can achieve the “right” voltage in our network.”

On the generator

In the second picture you can see how the diode is installed, but with such a length of wiring it is not very convenient - everything is tight. It is better to make the length of the wire about 2 cm from the diode - this way, in my opinion, it will be easier to insert into the RN connector of the generator. As far as I remember, I have a K223 diode, i.e. it's silicon. Raises the voltage by about 1.3 V.

I’ll correct myself - I checked using reference data on the Internet what the K223 diode is - I must say that I was very mistaken in indicating exactly that name. In fact, there are diodes KD223 and D223, but their housings are completely different.

However, in the photos I provided, most likely diodes D214 or D242 are wrapped in electrical tape (there may be different letters after the numbers), here is the case (M6 thread):

Diode 242

I will briefly summarize the parameters here:

reverse voltage: from 50 to 100 V or higher forward current from 5 to 10A, with a voltage drop across the diode from 1 to 1.5 V.

Many motorists have encountered the concept of low voltage in the network. The culprit of the situation was the generator, which produced an insufficient amount of current. Is there any way to increase the voltage produced by the unit? How to increase the power of the generator without damaging the circuit and the overall system.

Diode in the circuit

ATTENTION! A completely simple way to reduce fuel consumption has been found! Don't believe me? An auto mechanic with 15 years of experience also didn’t believe it until he tried it. And now he saves 35,000 rubles a year on gasoline! Read more"

Installing a diode with a toggle switch is the easiest way to increase the voltage. There is no need to bother, look for a lot of information in books, etc. Everything is as accessible as possible, no special difficulties.

This option of increasing the voltage, despite its simplicity, gives the most reliable result. Ideally suited for domestic and VAZ car models.

The purpose of this method of increasing the voltage in the vehicle's on-board network is to deceive the regulator, which is located inside the generator. As you know, on old domestic car models (kopek, VAZ 2105, etc.) the voltage drop sometimes reaches critical values - sometimes it drops to 12.5 volts. The battery, of course, will not be charged at this voltage.

How to choose a generator for your home: power calculation, phases, engine type

Finally, you asked yourself this question - what will happen if the lights are turned off? There are a lot of unpleasant things - the house will defrost, information will disappear, production will lose power, a pump, machine will stop working, etc.

And... You decided to acquire your own independent source of electricity (generator, diesel generator, mini-electric power station, gas generator, etc.).

Do you want to fully provide yourself with electricity or only provide the most basic needs: lighting, refrigerator operation, heating and/or alarm system support, water pump, etc.?

Therefore, the first question will be the rated electrical power (PRP) of the generator (generator set) you are purchasing.

You must determine for yourself which consumers will be connected to the generator at the same time. It is best to check the power of consumers using their passport data.

To calculate the power of the selected generator, take triple the rated power of the electrical appliance with the largest electric motor, add to it the power of all other active consumers (lighting, electric stove, kettle, etc.).

The resulting power must be multiplied by the one-time use coefficient (or demand coefficient) equal to 0.6-0.8 - this is the power of the generator you need.

The second question that you need to decide: should your generator (diesel generator, gasoline generator) be 1-phase (230 V) or 3-phase (400 V)?

If you do not have 3-phase consumers at your site and a 1-phase network is connected to your house (dacha), then the choice here is clear: a 1-phase generator.

If you do not have 3-phase consumers, but a 3-phase network is connected to your house (dacha), then you still need a 1-phase power supply unit, since having purchased a 3-phase one, you will be forced to “parallelize” the output into three 1-phase ones. phase lines by analogy with the supply from the external network.

If you have a synchronous generator, then the difference in the load of each winding should not exceed 30%, if the generator is of an asynchronous type, then no more than 60%, which is better, but not entirely good, since it is a big inconvenience to constantly calculate, how many kilowatts and to which phase (generator winding) must still be connected or additionally loaded until an approximate uniformity of phase loading is observed.

And only in the case when there are 3-phase consumers, it is necessary to purchase a 3-phase PG.

The third question is, what engine should your generator be equipped with - diesel or gasoline?

They often ask: “Which is better?”, “What do you recommend?”

This question cannot be answered unequivocally. Each type of engine has its own advantages.

However, if we are talking about electrical power above 15 kVA, then it is impossible to find a generator with a gasoline engine on the power plant market, and diesel engines in this power range are mostly liquid cooled.

— The speed of rotation of the motor shaft is important. For gasoline engines, which are almost all air-cooled, it is 3000 rpm, as is the case for air-cooled diesel engines.

A diesel engine with liquid cooling (antifreeze) has an engine shaft rotation speed of 1500 rpm. Such engines are capable of operating around the clock.

And the noise from them is less than from the same, but spinning twice as fast, so-called “backup generator”, the resource of which is much shorter due to the high speed of rotation of the shaft.

By the way, all gasoline mini-power plants, as well as air-cooled diesel generators, are backup.

- Noise. There are no absolutely silent generators. The fight against noise is traditional - an enlarged muffler and a noise-proof casing. But at the same time, the price increases significantly, as well as the dimensions and weight.

But I want it to launch itself - is this possible?

Autostart. All generators with an electric starter can be equipped with an autostart system. Then human participation in the event of a power failure is reduced to monitoring the fuel.

NO momentary power loss.

Well, one more thing - if it is important that there is no loss of power supply even for seconds, then you need to additionally install a UPS (uninterruptible power supply or UPS).