Definition of the welding process

Various technologies are used to join parts in industry and construction. Welding holds the leading position. It is widely used in mechanical engineering and other industries, during construction and repair work. This popularity can be explained by the high reliability of the resulting structures and their strength. The technology is cost-effective and has high productivity.

Welding is a technological process that results in the formation of permanent joints of materials. Sometimes the concept is mistakenly attributed only to the technology of connecting metal elements. In fact, various types of welding make it possible to reliably fasten not only metal, but also glass, graphite, ceramics, and plastic. The connection occurs under the influence of temperature at the interatomic level, as a result of deformation, or by a combination of two methods.

At the physical level, during welding, the atoms and molecules of the surfaces being joined form strong bonds. For such connections to occur, certain conditions must be met:

- the surfaces to be welded must be cleaned of dirt, oxides, and foreign atoms;

- to facilitate the interaction of atoms with each other, their energy activation must occur;

- The workpieces to be welded must be placed at a distance that could be compared with the interatomic distance in the elements.

During the cooling process, a weld seam is formed at the joint.

Forward and reverse polarity

Melting of the metal for welding occurs under the influence of an arc. It, as noted above, is formed between the surface of the product and the electrode, since they are connected to opposite terminals of the device.

There are two main options for welding, differing from each other in the order of connection and called direct and reverse polarity.

In the first case, the rod is connected to the minus, and the part to the plus. In this case, an increased flow of heat occurs into the metal. As a result, a deep and narrow melting zone is formed.

Direct and reverse polarity.

With reverse polarity, the electrode is connected to the positive, and the product to the negative. In this case, the melting zone is wide and shallow.

The choice of polarity is entirely determined by the product you are working with. Welding can be performed with two types of polarity. When choosing, you should take into account the fact that the element connected to the positive is subject to greater heating.

For example, it is difficult to weld thin metal products due to possible overheating and burning. In this case, the part is connected to the minus. Currents are also selected according to the diameter of the electrode and the thickness of the metal. This data is taken from a special table.

Classification of welding types

Existing types of welding can be divided into three classes. These large groups are distinguished based on the following differences:

- specifics of technology;

- characteristics of the material being welded;

- Features of protecting the welding process from exposure to air.

The method of influencing parts is the main criterion, which allows us to distinguish the following three types of this process:

- Thermal welding. This is done using heat and using additional materials. The source of thermal energy for this type of welding can be a gas flame, plasma flow, or electric arc. Under the influence of high temperature, the filler metal melts, the resulting liquid fills the gaps between the elements. After cooling, a permanent connection is obtained.

- Mechanical welding. The main role in connecting elements is played by the external influence on the parts being welded. All types of mechanical welding involve deformation of surfaces, which leads to tight bonding at the molecular level. During physical impact, mechanical energy transforms into kinetic energy, which allows the elements to be heated to the desired temperature.

- Combined welding. Also known as thermomechanical, it consists of a combination of the above methods. This process uses pressure and thermal energy. For example, the metal can be preheated to the desired temperature, and then, using external influence, a permanent connection is formed.

Each of the listed classes includes several types of welding process. The main criterion for separation is the source of energy that acts on the surfaces being welded.

What is the basis for the reliability of welding: the basics of welding work

Strength is due to plastic deformation, which occurs at the molecular level, because the molecules mutually penetrate into the bodies being welded. This is achieved by heating metals using a welding arc. The classic production method to date is electric arc, when an electron and current are used. But now technologies using laser and ultrasonic radiation are becoming more and more relevant. They actually leave no seam behind. The devices mainly operate on the basis of an inverter, that is, a device that creates alternating voltage.

Thermal class of welding

The following welding methods are related to the formation of a weld pool during the process. Its formation occurs with the participation of two metals: base and filler. The filler metal in thermal welding can be a metal rod or electrode. The heat source is a welding arc, a flammable gas flame, a concentrated stream of rays, thermite. The heat source used determines what type of joint the parts are made of.

3.1 Arc

Arc welding is the most common. It does not require special devices or tools. Arc welding requires a powerful, stable discharge of electricity in an ionized gas atmosphere. During ignition of the arc, ionization of the arc gap occurs, which is maintained throughout the combustion.

Ignition of the arc is a process that occurs in three stages:

- Contact between the metal workpiece and the electrode causes a short circuit. It serves to achieve the temperature required for welding.

- Then the instrument is retracted a short distance (from 3 to 6 mm). This action provokes the onset of thermionic emission of electrons.

- The previous steps allow you to achieve a stable arc discharge. This occurs as the arc gap becomes electrically conductive.

This type of welding is divided into three subgroups based on the method of joining parts:

- manual - all actions with the electrode are performed by the welder manually, using electrodes with a special coating;

- semi-automatic - the wire acting as an electrode is automatically fed into the welding zone along with a protective inert or active gas and melts under the influence of current;

- automatic - the process is fully automated according to a given algorithm, human control is not required.

- Welding with a non-consumable electrode using a direct arc. A graphite or tungsten electrode is used; filler material is not always used.

- Welding with a consumable electrode using a direct arc. A metal electrode is used and the base metal is simultaneously melted.

- Indirect arc welding. As a rule, this method involves the use of two non-consumable electrodes.

- Three-phase arc welding. Arc burning with this method occurs between the electrodes, as well as between the base metal and each electrode.

The material, number of electrodes, as well as the method of their inclusion in the electric current circuit form another classification of arc welding into several subtypes:

3.2 Gas

In gas welding, the heat source is a flame. This makes this method suitable for use in field conditions and places where there is no access to electricity, since power from the mains is not required. Another characteristic difference between gas welding and arc welding is that the heating and cooling of the welded surfaces occurs quite slowly and smoothly. Therefore, the technology is suitable for joining thin-walled steel, non-ferrous metals, as well as for surfacing.

This type involves the melting of metal under the influence of a flame, which is formed as a result of the combustion of a mixture of flammable gases with oxygen. Usually acetylene or propane is used, less often - gasoline vapor or kerosene. Melting of the filler metal is involved in the formation of a seam at the junction of elements connected by welding.

3.3 Radial

The areas of application of beam welding are radio components, electronic circuits and other micro parts. The process itself occurs under the influence of a light beam. Unlike other types of welding, this one must take place in a special chamber with a vacuum environment. Otherwise, the beam will be scattered due to air density.

The ability to connect micro-parts is a distinctive advantage of this method, which cannot be achieved with any other method. The technology is widely used in the electronics industry.

Laser welding is distinguished by high precision seams. At the same time, heating of the surfaces is minimal, so even thin material does not deform as a result of the connection. This method allows you to direct energy using a prism to hard-to-reach places that could not be connected using other types of connections.

The source of energy can be not only a light beam, but also a stream of electrons from an electron gun.

3.4 Termite

Thermite, which is used for this type of joining of parts, is a special mixture for melting metal. It consists of aluminum, magnesium, and metal scale. The mixture in powder form is poured into a heat-resistant container and ignited using an electric arc, propastron or a special cord. The heat released when thermite burns melts the edges of the parts. The molten part, mixing with the metal of the parts being welded, forms a permanent connection - welding occurs.

The resulting connection is highly durable. This explains the demand and popularity of this type of welding when working with large-sized products. In particular, the method is used for joining pipes, rails, as well as for surfacing large-sized products.

3.5 Electroslag

No other of the above types is better suited for joining thick metal parts from 5 cm to 3 meters thick than electroslag. In this type of welding, vertically mounted workpieces are closed on both sides using movable water-cooled copper sliders. A layer of flux is poured onto the pan, which serves as a heat source, and an arc is ignited under it. The molten flux becomes conductive and melts the edges of the base metal and filler wire well.

Welding of this type is used to work with all types of steel, cast iron, and some non-ferrous metals. The industrial importance of the electroslag method is very great due to its economic benefits. The larger the surface area that can be welded, the more rational its use.

Hello student

Welding is the process of joining metal parts into one integral whole by heating the areas being welded; the heating temperature of the metal in the places being welded should ensure that it is brought to a plastic (dough-like) or liquid state. The pieces of metal connected by welding can either come into direct contact, or their connection is carried out using an intermediate metal, called filler material in welding practice.

During the welding process, a single metal mass is formed at the edges or surfaces being welded, the strength of which, determined by the interaction between ionized atoms and the electron gas, can be achieved the same everywhere.

Heating the metal being welded to a liquid or dough-like state is aimed at creating conditions for the possibility of close approach of elementary particles of the metal being welded and on a sufficiently large plane; Depending on the shape, purpose and material of the products being welded, various welding methods can be used, but they all boil down to creating this proximity of the elementary particles of the metals being welded.

The oldest welding method is forge welding, which dates back to ancient times. Currently, its specific importance is very small. Modern welding methods, the most important of which are electric and gas, arose at the end of the 19th century.

Modern welding methods make it possible in many cases to replace riveting and casting. In Russia, welding has become very widespread; In terms of the use of welding equipment, our country has taken first place in the world not only in terms of the volume of welding work, but also in the perfection of technological processes. Welding is widely used in new buildings in the manufacture of various types of steel structures, in machine-building plants, in boiler, ship, car and bridge construction.

Russia is the birthplace of the theory and practice of metal welding. In 1802, V.V. Petrov discovered and described the electric arc; this was 20 years earlier than the English physicist Davy observed it. V.V. Petrov described a number of properties of the electric arc and, in particular, its ability to instantly melt metal wire. Petrov's experiments were used by the Russian inventor Nikolai Nikolaevich Benardos, who in 1882 proposed using an electric arc for welding metals, using a carbon electrode to supply current. The Benardos method was first used in Russia on the Oryol-Vitebsk railway when repairing steam locomotives; it gained fame and distribution both in Russia and abroad.

In 1888, mining engineer N. G. Slavyanov replaced the carbon electrode with a metal one, which enormously expanded the scope of welding. N. G. Slavyanov’s method has gained worldwide fame and distribution; patents were issued in his name in many countries; in 1893, at the World Exhibition in Chicago, N. G. Slavyanov was awarded a gold medal. N. G. Slavyanov is responsible for the development of technological processes for electric welding; He used welding for a wide variety of jobs, the list of which amounts to more than one and a half thousand. Slavyanov wrote many works on electric welding; his works in translation are widely distributed abroad. After Slavyanov's death (1897), his work in the conditions of Tsarist Russia did not receive further development; Only after the Great October Revolution were welding issues given due attention. In the first Stalinist Five-Year Plan, welding began to be used in Russia not only for repair work, but also in the manufacture of new machines and metal products.

The development of welding in Russia was not limited only to the organization of production of welding machines and equipment; In Russia there are a number of welding research institutes, as well as special welding educational institutions.

The use of welding instead of riveting and casting in many cases results in metal savings of 15 to 50%; in addition, the transition to welding work in all cases is accompanied by savings in time and labor.

The development of the Stakhanov movement among welding workers led to an improvement in the welding process and was accompanied by an increase in labor productivity.

A great achievement of our welding technology is also the invention in 1927 by Stalin Prize laureate engineer. D. A. Dulchevsky, the method of submerged arc welding and the widespread introduction of automation into welding processes. The high-speed method of automatic electric welding under a layer of flux was developed under the leadership of Academician. E. O. Paton.

Gas welding of metals has become widespread since the 20s of the 20th century; its development is associated with the improvement of industrial methods for producing acetylene and oxygen. At a time when electric welding had not yet been sufficiently improved, gas welding was more common than electric welding. With the beginning of the use of high-quality electrodes with thick coating, gas welding is in some cases being replaced by electric welding. Automation of electric welding processes and the submerged arc welding method gave a powerful impetus to an even wider spread of electric welding. However, in the repair business, gas welding still retains its advantages in some cases.

Welding methods can be classified according to various criteria: 1) according to the type of energy used in the welding process; 2) according to the state of the metal in the place being welded; 3) by the nature of the technological process.

Depending on the energy source, welding is divided into chemical and electrical; The first includes forge, gas and thermite welding, the second includes all types of electric welding.

Depending on the degree of heating, the metal being welded can be either in a plastic (dough-like) or molten liquid state. In the first case, to carry out the welding process, it is necessary to apply a force to the product being welded, under the influence of which the particles of the material being welded begin to move, as a result of which the contact area of the pieces of metal being welded increases; This type of welding is called plastic welding. In the second case, the molten metal of the objects being welded and the filler metal form a common pool, after cooling of which the welding is carried out without the use of mechanical force; This type of welding is called fusion welding.

According to the nature of the technological process, welding can be divided into forge, gas, electric, thermite and gas-electric.

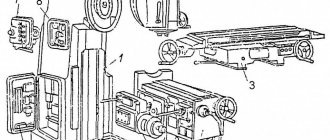

In fig. 319 shows a classification scheme for welding methods proposed by the Technical Terminology Commission; However, an addition has been made to this scheme - gas press welding has been added to the types of chemical-mechanical welding.

The closest to the terminology accepted in the practice of welding is a classification compiled depending on the nature of the welding process.

Download abstract: You do not have access to download files from our server. HOW TO DOWNLOAD HERE

Archive password: privetstudent.com

Thermo-mechanical welding class

Thermomechanical or combined types of welding joints are used when it is impossible to create an even seam in any other way. Most often, it is necessary to connect small elements in this way. In this class there are three types of welding:

- blacksmith's;

- contact;

- diffusion

Each of them involves a combination of thermal and mechanical effects on the parts being connected.

4.1. Kuznechnaya

The joining of iron blanks using a hammer and anvil was known long before the emergence of modern types of welding.

The quality of the connection directly depends on the skill of the blacksmith, as well as on how well the surfaces were cleaned of plaque before starting work. The master who welds using this method heats the workpieces in a forge and connects them with hammer blows, placing them on top of each other.

Only ductile metals can be connected in this way. Low productivity and insufficient reliability have led to low demand for forge welding. Sometimes a mechanized subtype is used: when heated workpieces are compressed by a press. The described method is called press welding.

4.2 Contact

The welded joint is formed during the process of plastic deformation. Resistance welding is so named because heating occurs due to the contact of the needle surface with the product. At the contact points, the maximum amount of heat is released, which helps to achieve a thermoplastic state or melting. Further compression provokes the formation of new points of contact. This, in turn, promotes the bringing together of surfaces at interatomic distances, that is, welding.

There are various classifications of this process according to the type of welded joint, the type of welding machine, and the type of current supplying the transformer. Depending on the type of welding joint, there are several types to solve different problems:

- butt - the entire contact area is heated;

- point - connections are formed in places of compression under the influence of current;

- suture - involves joining parts overlapping using roller electrodes;

- embossed - protrusions are pre-applied on the plane, which are smoothed out after applying current.

Resistance welding can easily connect small parts. It is highly productive and easy to automate. For this reason, such welding is used in mechanical engineering as part of robotic systems.

4.3 Diffusion

The technology is based on diffusion, that is, the mutual penetration of atoms of joined materials when pressed tightly against each other. Welding is carried out in a vacuum or inert gas environment. At the beginning of the process, the parts are placed in a special chamber, where they are fixed and begin to transmit force. Under the influence of electric current, the surface layers of the metal are heated to temperatures close to melting. This type of metal compound is facilitated by the high diffusion ability of atoms. More reliable fastening of parts can be achieved if they are left for some time under the influence of current.

This type of welding is used for poorly contrasting materials. The distribution of this method is not as wide as that of others in the group.

Features of semi-automatic welding

Semi-automatic welding is designated MIG/MAG. MIG is an abbreviation derived from Metal Inert Gas - welding, which is performed in an inert gas environment: helium, argon or its mixture with carbon dioxide. MAG is an abbreviation for Metal Active Gas, using active gas, most often carbon dioxide. The main difference between semi-automatic welding is the mechanization of the process of supplying the consumable electrode.

Power sources for semi-automatic welding

Transformer and inverter power supplies are used. They have the same pros and cons as electric arc welders.

Electrodes for semi-automatic welding

For semi-automatic welding, consumable electrodes are used in the form of wire placed in coils or cassettes. It can be with or without copper plating. The coating ensures uniform wire feeding and reduces its contact resistance, which leads to stable arc burning and low spattering of the electrode metal.

Another advantage of such electrodes is the minimum amount of impurities harmful to the welding seam. The fact is that non-copper-clad wire is coated with a technical lubricant containing fatty acids, alkali and water. They become suppliers of hydrogen to the weld metal and cause its porosity.

Set of equipment for semi-automatic welding

Advantages and disadvantages of semi-automatic welding

Advantages:

- a small heat-affected zone, which allows you to weld metal up to 0.5 mm thick without burns;

- high performance;

- the ability to cook elements of different thicknesses;

- high quality seams;

- the ability to carry out work in any spatial position;

- absence of slag crust and the need for mechanical modification of seams.

Flaws:

- welding work is carried out only in enclosed spaces, since the gas protection is blown off in the open air;

- mandatory presence of high-quality ventilation to remove carbon dioxide.

Application of semi-automatic welding

The scope of application of semi-automatic welding is the same as electric arc welding.

Mechanical welding class

The main feature of welding methods belonging to this class is the mechanical effect on the metal for the purpose of heating. The heat generated melts the metal and joins it. The methods by which welding is performed are friction, explosion, pressure, ultrasound.

5.1 Friction

The essence of the process: rotation and pressure are applied to the metal elements being welded. Friction welding technology is considered a promising development. In the process, either both workpieces or one of them can rotate, while the other is fixedly fixed.

Depending on the characteristics of the technology, the following welding is distinguished:

- Friction with stirring.

- Inertial.

- Oscillatory.

- With continuous drive.

- Radial.

- Orbital.

In all cases, the friction force heats the metal to its melting temperature, which makes welding of parts possible.

The main advantages of this method are its high quality and strength of the resulting structure, low energy consumption compared to other methods. Welding in this way can be used to join metals with different melting points. The process lends itself well to automation and is widely used for industrial purposes. Most often, such welding is used when working with rod structures and small-diameter pipes.

5.2 Cold

The use of this welding method involves connecting parts by pressure. A permanent fastening is formed when the elements are deformed and pressed into each other. The joining of parts becomes possible thanks to interatomic bonds.

Cold welding is divided into three categories:

- suture;

- butt;

- spot.

The technology is used to connect busbars, pipes or wires. To obtain a high-quality and durable connection by cold welding, it is necessary to carefully prepare the joint. The result also depends on the degree of compression and the nature of the impact - vibration or static.

5.3 Explosion

A detailed methodology for this welding method has not yet been developed; it is considered one of the rarest.

The explosion welding process begins with placing the workpiece to be welded above the base metal. Then a detonator is installed on the welded part. The most commonly used explosives are granulotol, ammonite, and hexogen.

After the explosion, the shock wave directs the moving part at high speed - it hits the bottom plate. The pressure at the point of contact significantly exceeds the strength of metals, at which they turn into a liquid state. In a fraction of a second, a molecular connection of two metal parts with a common crystal lattice occurs. That is, strong welding is ensured by synchronous plastic deformation of the two elements. In this case, diffusion occurs only in the upper layers of the metal due to the short duration of the process.

Explosion welding is used for industrial purposes to join dissimilar metals. With its help, large-sized workpieces and parts are manufactured, including bimetallic ones, and a wear-resistant layer up to 45 mm thick is applied to metal workpieces.

5.4 Ultrasonic

Ultrasonic welding is the joining of parts using ultrasonic waves. They create vibrations that bring the atoms of the workpieces being welded together to a distance that allows them to combine into a common structure. The high quality of connections makes ultrasonic welding quite popular, despite the high cost of equipment, in the production of small-sized electrical circuits and joining metals with non-metals. Welding can be used spot, contour or seam.

Before ultrasonic joining of parts, there is no need to pre-clean the surfaces, which saves time. When welding plastic elements, it is important to be able to control the temperature range to avoid overheating. Ultrasound heats the surface in a fraction of a second without emitting harmful vapors and gases.

Cherepovets Metal Structures Plant has many years of experience in the manufacture of bridge structures, canopies, decks, hydraulic structures and other metal structures. Welding and assembly takes place in compliance with technology and quality standards. Our clients receive products on time and at competitive prices.

Features of argon arc welding

Argon arc welding is abbreviated TIG. This is short for Tungstren Inert Gas. It is performed in a protective gas environment - argon. It is 35% heavier than air and easily displaces it from the welding zone. At the same time, argon does not react with other substances contained in air or metals. As a result, the number of defects in the seams is minimal. Argon can be replaced with helium or a mixture of argon and oxygen.

In argon arc welding, the electrode does not touch the surface of the metal. An oscillator is used to ignite the arc. It applies high-frequency, high-voltage pulses to the electrode, which ionize the air in the small gap between the electrode and the metal surface, and the arc is ignited when current is applied to the electrode.

TIG Welding Power Sources

For argon arc welding, both transformer and inverter power sources are used. According to the type of supply network, they are divided into single and three-phase. According to the supported operating modes, TIG devices are of two types:

- DC – work only on direct current;

- AC/DC – constant and variable.

Electrodes for argon arc welding

Argon arc welding is performed with non-consumable tungsten electrodes. Seams are formed by melting the edges of the elements being connected. For welding thick-walled parts, filler wire is additionally used. To operate on direct and alternating current, different tungsten electrodes are used. They are available in pure form or doped with special additives for different operating conditions.

The photo shows a diagram of argon arc welding

Advantages and disadvantages of argon arc welding

Advantages:

- absence of slag crust and the need for manual finishing of seams;

- minimum number of defects in welds;

- no metal spattering;

- possibility of joining dissimilar metals.

Flaws:

- low productivity;

- complex equipment setup and highly qualified welders.

Applications of argon arc welding

Optimal for thin-walled products and difficult-to-weld metals. It is suitable for working with any steel, including galvanized and stainless steel. With its help you can cook copper, cast iron, titanium and other non-ferrous metals. For connecting aluminum elements, argon arc welding is the most suitable option.

Purchasing consumables

In addition to equipment, it is necessary to purchase consumables. The main thing is the welder’s mask, which protects his face from possible damage. An attractive option is the “Chameleon”.

The lighting is adjusted automatically, which makes it unnecessary to remove the mask during short breaks in work in order to evaluate the result of work or replace a burnt electrode. The light filter reacts by darkening to changes in the brightness of the electric arc.

In addition to the mask, you need to take care of protecting the body, hands and head by purchasing or selecting a suit, mittens and a hat. Sturdy shoes must be worn. Nothing should be left unprotected.

You will need a hammer to knock down the scale. An ordinary hammer is of little use for this, since it weighs a lot and is inconvenient for beating off slag in hard-to-reach places. A slag hammer is a very useful tool for doing DIY welding work. With its help, you can easily clean the boiled layer before applying the next one on top of it.

To securely fix the parts to be welded, you may need a vice or clamps. A metal brush will help get rid of rust before you begin the actual process.

It is necessary to ensure that there is a container of water near the welding site in case of fire.

Tools and protective equipment

Uniforms and personal protective equipment include:

- welder's mask with a built-in light filter to protect the eyes from bright light and ultraviolet radiation from the arc;

- split-leaf gloves—gaiters to protect hands from splashes of hot metal;

- thick clothing made of non-flammable fabric;

- cap under the mask;

- durable shoes.

- a respirator to protect the respiratory system from generated gases and dust, especially when working with non-ferrous metals.

Tools, materials and equipment you will need:

- Angle grinder (grinder) for cutting workpieces and cleaning seams;

- A set of hand tools - hammers, chisels, pliers, etc.;

- Metal brush for cleaning workpieces;

- Clamps and clamps for connecting workpieces;

- Electrodes.

And finally, the inverter with the included cables and holder.