What is this method, what is it for?

Experienced welders know about the negative impact of atmospheric air on the processes occurring in the weld pool. Fusion welding is a high-temperature process that is characterized by increased activity of the materials being melted . Interaction with chemical elements in the air leads to the formation of oxides, hydrides and nitrides, which impair the quality of work. Today, several methods are known to protect the weld seam from aggressive environmental influences:

- gas;

- slag;

- gas-slag;

- vacuum.

Slag protection (welding under a layer of flux) allows you to reduce the time required to complete work while increasing the quality characteristics of the weld. According to GOST 8713-79: “Submerged arc welding. Welded connections. Main types, structural elements and dimensions. There are two ways of performing work: mechanized (semi-automatic welding) and automatically (robotic automatic welding).”

Let's take a closer look at them.

Advantages of closed arc welding

There are several advantages:

- The magnitude of the current . When the arc is open, the current cannot exceed 600 amperes. If this indicator is exceeded, the metal begins to spatter very heavily and obtaining a high-quality weld becomes impossible. In the case of a closed arc, the current can be increased to 4000 amperes. Which, in turn, leads to a sharp increase in the quality of the weld and a significant increase in the speed of the entire process as a whole.

- Arc power . A closed arc has higher power. As a result, the metal being welded is melted to a greater depth during the welding process. This, in turn, allows you to avoid cutting edges for welding (one of the stages of preliminary preparation). An open arc is relatively low-power and without preliminary cutting of the edges it is impossible to obtain a good weld.

- Productivity . This term refers to the seam footage per hour of arc operation. The use of flux increases the productivity of the welding process by 10 times compared to traditional welding.

- Gas bubble . Forming a protective gas bubble from molten flux leads to a number of positive results. The loss of molten metal due to splashing and waste is significantly reduced. Which, in turn, leads to more economical consumption of electrode wire. At the same time, overall energy costs are reduced.

Semi-automatic

Widely used when welding curved surfaces. Area of application: small-scale production. The energy source can be either direct or alternating current.

To perform the work, a semi-automatic welding machine type PSh-54 is used. Working metal thickness is up to 30 mm. Semi-automatic welding allows you to carry out various types of work:

- with beveled edges;

- multi-pass fillet welds;

- welt seams;

- lap joints with through penetration;

- electric rivets.

The main difference from the robotic welding method is that the welder independently selects the voltage power, speed and angle of the electrode.

The main disadvantage of the semi-automatic method is the lack of control over the process of weld formation. When welding fillet welds, it is necessary to use a copying nozzle.

Semi-automatic welding

In the case of semi-automatic welding, only one process is mechanized: electrode supply. All other operations are performed manually by the operator. Welding wire in cassettes is used as an electrode. To protect the welding zone from contact with air, active (carbon dioxide) or inert gases (argon, helium) are used.

Performing semi-automatic welding

The process of using semi-automatic welding for industrial purposes was first developed by the Central Research Institute of Technology and Mechanical Engineering in the 50s of the twentieth century.

Advantages

Semi-automatic welding also has a number of advantages:

- It has a very small heat-affected zone, so it allows you to cook parts up to 0.5 mm thick without burns.

- The electrode and weld pool are visually accessible, so the necessary adjustments can be made in time during the welding process.

- Using semi-automatic machines it is possible to weld parts of different thicknesses.

- This method of joining metals is suitable for making seams in any spatial position, including hard-to-reach places.

- The productivity of semi-automatic welding is approximately three times higher than manual welding. At the same time, metal losses from splashing and evaporation are also minimal.

- Active or inert gases provide reliable protection of seams from exposure to air. The number of defects in them is minimal.

- This method of joining metals allows you to make butt welds for parts up to 8 mm thick and T-welds for parts up to 30 mm thick without bevelling edges.

- Carbon dioxide, the most popular for semi-automatic welding, is much cheaper than the flux used in automatic welding.

- During the work, no slag crust is formed, so there is no need to clean the seams. This is especially useful when welding multiple passes.

- The set of equipment for semi-automatic welding is more compact and simpler than for automatic welding.

Flaws

At the same time, certain disadvantages of semi-automatic welding should be highlighted:

- In this case, the arc is not hidden under a layer of flux, so the welder is exposed to intense radiation. It is impossible to carry out such work without protective equipment.

- The carbon dioxide used is heavier than air and can accumulate in the work area. Good ventilation is required for safe operation.

- When carbon dioxide is removed, metal spattering increases sharply.

- The use of semi-automatic welding is limited to enclosed spaces. It is not suitable for open air. In this case, the gas protection will be blown away, as a result of which the quality of the welds will suffer.

Scope of application

Semi-automatic welding is used to connect parts with a thickness of 0.5-100 mm. It can be used both in factories and in private households. The main difference between semi-automatic and automatic welding is the ability to weld seams of any geometric shape in all spatial positions. For this reason, it is in demand for small-scale and serial production of various complex metal structures.

Automatic welding in the welding world is like a racing car

Semi-automatic welding is like driving along a highway with a complex profile

Role

As mentioned above, the environment negatively affects the quality of welding work. The use of flux allows us to minimize harmful factors.

The essence of the method is to cover the melt zone with a layer of flux . As a result of the thermal effect of the electric arc, the metal, welding wire and flux melt in the welding zone. The molten flux forms an elastic capsule that protects against atmospheric influences.

The internal space is occupied by flux vapor, molten metal and welding gas. The internal pressure of the elements maintains a flux film that surrounds the welding area. The capsule significantly increases thermal efficiency, which provides high melting intensity compared to other welding methods. Therefore, submerged arc welding is considered a high-performance welding method .

As it cools, the flux turns into slag, which coats the weld. At the end of the work, the slag is removed mechanically without much effort. The remaining flux layer is suitable for further use.

Automatic submerged arc welding

The essence of the process is as follows. An electric arc burns between the workpiece being welded and the end of the welding wire. The welding wire melts. As melting occurs, new portions of welding wire are supplied to the welding site. The wire enters the welding zone either using a special mechanism, in which case we are dealing with automatic welding. Or manually, in which case the welding will be semi-automatic.

The electric arc itself is covered with a layer of flux and burns inside a gas cloud, which is formed as a result of the melting of this flux. As a result, there is no damaging factor for the eyes, as during conventional welding.

The metal being welded and the flux melt . In this case, the molten flux forms a protective liquid film, which prevents the metal being welded from coming into contact with the oxygen of the surrounding air. Inside the molten flux, not only the metal being welded melts, but also the welding wire.

All these molten metals are mixed in the so-called weld pool (a small space formed at the site of the parts being welded, directly under the electrode). As the electric arc moves further, the metal in the weld pool gradually cools and becomes hard. Thus, a weld seam is formed.

The molten flux is called slag. As this slag hardens, it forms a slag crust on the surface of the weld, which is easily removed with a metal brush.

Varieties

Welding fluxes are classified according to several parameters:

- Appearance. Depending on the area of application, granular, powder, crystalline, paste and gas fluxes are distinguished. In electric welding, granular or powder flux is used. When soldering, a paste or gas material is more often used. IMPORTANT! When performing electric welding work, the electrical conductivity of the material should be taken into account.

- Chemical composition. The main requirement is chemical inertness under high temperatures. Some fluxes may contain additives that improve the characteristics of the weld.

The percentage of chemical elements in the weld material when using various ceramic fluxes.

- Method of receipt. They are divided into melting and non-melting. The former are used when performing surfacing work. They are capable of transferring chemical elements, giving the metal various useful properties (for example, increasing resistance to corrosion). Non-melting fluxes are used to improve the mechanical parameters of the finished weld. Therefore, they are used for welding metals that are difficult to join under normal conditions: non-ferrous metals, high-carbon steel and others.

- Purpose. There are special fluxes, as well as general purpose fluxes. Special fluxes are developed for a specific type of work, for example, welding high-alloy steel. General purpose fluxes are universal. They can be used simultaneously in several jobs, both surfacing and welding.

It is possible to carry out classification by brand, which is determined by the developer. Electric Welding Institute named after. Paton labels its own fluxes with the abbreviation “AN” (Academy of Sciences), and the product of the Central Research Institute of Mechanical Engineering is designated “FC”. Production parameters are subject to state quality standards, but there is still no uniform marking of welding fluxes.

The principles that go into the operation of semi-automatic arc welding and its features

There are two types of arc welding: automatic and semi-automatic arc welding. The machine is perfect for mass or serial production. For small-scale production, it is best to use a semi-automatic machine. In individual cases, manual arc welding is used. The automatic process is not always suitable for items that need to be welded. For example, welds may be short, or have a fairly complex configuration, or may be awkwardly positioned. There are several options for semi-automatic arc welding:

- Welding, which is performed using a lying or inclined electrode.

- Hose welding.

Classification of arc welding.

In the first case, an electrode is used, which has a thick lubricant, and is placed on an object that is covered with writing paper. After this, a large pressure block is placed on it, which must be made of copper. This bar must have a groove that will allow the electrode to move. Welding current is supplied to the electrode. It is attached to the grease-free end, which is bent for convenience.

The arc is ignited by a special ignition rod, which is brought to the end of the electrode, which is adjacent to the product. After ignition, the arc temporarily becomes invisible as it crawls under the bar along the electrode, melting it. Thus, a weld bead is formed along it. The length of the electrode itself determines the length of the seam that needs to be welded. To change it, you just need to take an electrode of the required length. It can be up to 12 cm long and up to 0.8 cm in diameter.

If you use the second option, you can change the cross-section of the deposited metal depending on the change in angle. There are certain limits to this. In both the first and second variants, the electrode rests on the product, while the rod in both cases is isolated from the object thanks to a coating that acts as a so-called visor.

Basic modes

The final shape and size of the seam depends on the welding parameters. Let's arrange them in descending order of influence:

- Arc voltage.

- The magnitude of the current.

- Welding speed.

- Electrode wire diameter.

- Electrode inclination angle.

- Type and polarity of current.

- Flux type.

- The amount of electrode extension.

Welding work is possible provided the arc is maintained. Thus, the wire feed speed must correspond to the speed of its melting in the weld pool . A change in the value of one parameter must be accompanied by a change in the value of the second. With an equal current, a wire of smaller diameter must be fed at a higher speed. The influence of mode parameters on connection quality is studied by changing one of the parameters, leaving other parameters unchanged.

Selection of welding mode, choice of wire.

The depth of metal penetration can be increased by increasing the parameters of the welding current. The relationship between these parameters is almost linear. As the arc pressure increases, the molten metal is displaced more intensely. As a result, the level of interaction between the arc and the base metal increases. In this case, the width of the weld practically does not increase, since the arc goes deeper into the base metal.

Reducing the electrode diameter at constant current increases the welding current density. At the same time, the mobility of the arc decreases, the width of the seam decreases, and the depth of penetration increases.

Changing the shape and size of the seam can be achieved by giving the wire vibrations transverse to the direction of the seam. The amplitude and frequency are selected individually, depending on the desired result. The method is used in automatic installations.

The angle of the electrode has an effect similar to manual arc welding. To avoid splashing of molten flux, work with this method is performed only in the lower position. The angle of inclination of the product should not exceed 15°. Practical application - connecting circular pipe joints.

Working methods

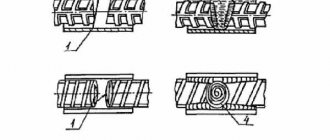

To make a connection using submerged arc welding, two methods are most common.

Connection using semi-automatic welding. To ensure optimal feed speed of flux-cored wire, the welder selects the appropriate operating mode on the machine, taking into account the thickness of the metal and the type of connection.

The arc is directed manually. At the same time, the wire feed speed, current strength and angle of inclination of the holder are the main factors affecting the quality of the work performed.

The automatic (robotic) welding scheme is designed for connecting butt and corner parts. In this case, the machine sets the direction of arc movement, wire feed speed and carriage travel. Such a device produces a high-quality seam at high welding speed.

One of the varieties of the automatic method allows you to weld with two electrodes at once - this is the tandem method. In this case, the electrodes run parallel to each other and are in the same plane, which makes it possible to increase the weld pool when the electric arc is instantly excited. The flux protects the seam from oxygen and ensures uniform cooling .

Cons and pros

Submerged arc welding technology has its advantages and disadvantages. Benefits include:

- High performance. The protective environment allows you to perform work with high current levels (up to 4000 amperes). This ensures deep penetration of the metal. The absence of splashes and waste eliminates possible loss of metal during work. The above factors, as well as automation of the welding process, have a positive impact on the speed of work.

- Quality of work. The protective film that the flux forms protects the melt zone from external influences. The low thermal conductivity of the film prevents rapid cooling of the welding zone. This was discussed above.

- Process automation. Expensive highly qualified specialists are not required to perform the work.

- Electric arc stability. Thanks to the protective gas bubble under the flux layer.

- Economical. Submerged arc welding allows you to increase the efficiency of thermal energy utilization. Energy savings, compared to other methods of work, are 20-40%. Electrode metal losses do not exceed 5%. For example: during manual arc welding, the average level of metal loss is 25-30%.

- Conditions for performing work. To remove harmful welding gases, it is enough to install a ventilation system. The flux hides the welding area. This eliminates the negative impact on the operator’s vision - there is no need to use a welding helmet.

The method has two disadvantages:

- Welding work must be carried out only in the lower position. The permissible level of inclination of the welding edges is 15°.

- The design features of welding machines make it difficult to use automatic technologies in installation conditions. Currently, design engineers at manufacturing enterprises are actively working to solve this problem.

Features and Benefits

The advantages of semi-automatic and automatic welding under a protective layer of flux allow this type of permanent connection to occupy one of the leading places.

High level of performance

According to this characteristic, the advantage over manual welding is at least 6 times, some experts believe that it is much more. But this is not the limit; by increasing the operating coefficient of the welding machine, the amount of labor productivity increases. Another reason for achieving such results is the use of high current values during welding.

A dense layer of flux material does not allow the metal to spread, while good weld formation occurs. At higher current values, this equipment can reliably provide penetration of even thick metal without extensive cutting of edges. Therefore, productivity increases even more. The time required to clean up splashes and heavy metal spreading is reduced.

Improved seam quality

The quality of the connection increases due to the fact that the molten metal is not exposed to oxygen and other atmospheric substances.

There is a wide choice of welding wire material available. By using the brand that is best suited for welding, you can obtain a weld with a homogeneous composition.

It becomes possible to give the seam an excellent shape, with the required seam leg. Thanks to the protective film that forms when the flux burns, there are no undercuts, lack of penetration, pores or cracks in the seams. Finally, there is no need to replace electrodes, so the seam is smooth and without tears.

Economical consumption of materials and improved working conditions for the welder

When welding with submerged arcs, wire consumption is reduced by up to 35%, when compared with welding with electrodes. The material is not wasted in the form of cinders and metal spattering.

With this method, carbon monoxide is released in smaller quantities; the specialist’s eyes and face are not exposed to strong ultraviolet radiation, as with electric welding.

Equipment

Welding equipment suppliers offer a wide range of submerged arc welding equipment. Let's look at several types.

Gantry installation

The gantry welding installation is designed to perform robotic welding work of various types. The basis of the design is the portal, which is characterized by high rigidity. Installed on rails. The main elements of the installation are:

- CNC system.

- Movement system. The drive is an electric motor with a gearbox.

- Welding flux recycling system.

- Welding rectifier.

- Welding installations moving system.

- Device for moving welding heads.

- Conduit.

It is used in enterprises producing metal structures.

Welding column

Welding columns are required to move the welding head along several axes. During submerged arc welding, the column is fixed.

The main structural elements are the drive platform and the vertical stand. A console is installed on the rack, capable of moving in the transverse direction and in height. There are two modes of movement - marching and welding. The process is controlled via a CNC system with a remote control.

Equipment and materials

The equipment of a submerged arc welding installation operating in automatic mode includes machines, mechanisms, and devices according to the diagram. The equipment also provides movement of the workpiece, collection of flux, and monitoring of the welding seam.

Installation diagram for submerged arc welding:

Submerged arc welding machines are structurally divided into:

- feeding a consumable electrode at a constant speed regardless of the voltage on the arc;

- with auto-regulation. They implement an algorithm for slowing down the electrode wire feed speed when the arc voltage increases and increasing the speed when the voltage decreases. This makes it possible to achieve a uniformly stable welding seam. The algorithm is implemented in a complex electronic circuit.

The most widely used units are those with a welding head that provides a constant electrode feed rate. They are structurally simpler and reliable in operation.

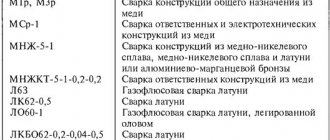

Electrode wire

An important condition for a high-quality weld is the correct selection of a consumable electrode: the characteristics of the weld are affected by its chemical composition. The choice of electrode wire is regulated by GOST 2246-70.

Welding fluxes

It is equally important to choose the right welding flux. The quality characteristics of the weld metal (structure, resistance to cracking) and the gas atmosphere in which the metal is welded depend on it. The composition of the gas affects the combustion of the arc and the resistance of the weld to the formation of pores. The chosen flux determines whether harmful gases will be released and in what quantities.

Below is a table with the most commonly welded steels and the welding wire and flux used for them:

| Types of steels | Wire grades | Flux brands |

| Low carbon steel 1, steel 2, steel 3, steel 4, steel 10, steel 20, steel 30, steel 40 | Sv-08 Sv-08A Sv-08GA Sv-10G2 | AN-348A OSC-45 |

| Low alloy 12GS, 15GF, 14G2, 14KhGS, 12KhSND, 12Kh1MF, 15Kh1M1F, 10KhSND | Sv-10G2 Sv-12GS Sv-18KhGS Sv-18KhMFA | OSC-45 AN-22 |

| High-alloyed 08Х12Н8К5М2Т, 08Х12Н7К7М4, 10Х17Н13М2Т, 08Х18Н10Т | Sv-08Х16Н8М2Т2Б2 Sv-06Х19Н10М3Т | ANF-16 ANF-1 |

Causes of pores

The process of crystallization of the weld may be accompanied by the formation of pores. These are gas-filled cavities of various shapes. There are no external signs. Detection is possible through the use of non-destructive testing methods. For structures that operate under conditions of increased load, pores are considered an unacceptable defect.

The main reason for the appearance of pores is the oversaturation of the weld pool melt with gases . In addition, the high rate of crystallization of the seam does not allow the welding gas to leave the joint zone. It has been experimentally established that high molecular weight gases have virtually no effect on the pore formation process. The main culprits are simple compounds - hydrogen, nitrogen and carbon monoxide.

Much depends on the materials being joined. When submerged arc welding of stainless steel, hydrogen is the cause of pore formation. Carbon has no effect on austenitic steels, and nitrogen practically does not cause pores.

The composition of the flux also affects the process. Scientists from the Institute of Electric Welding have found that lowering the acidity level of the flux promotes the formation of pores. And the use of ferritizers reduces the risk of pores appearing when welding conventional steel grades.

Welding mode selection

Depending on the thickness and metal of the parts being welded, the submerged arc welding mode is selected. Each mode has its own range of voltage, welding current and wire diameter. The speed of seam formation ranges from 6 to 100 meters per hour.

If the thickness of the parts to be welded is from 2 to 10 mm, then the welding mode is selected on a steel lining under the joint of the parts. The flux bed mode is suitable for welding parts with a thickness of 10-25 mm, and welding of parts with a thickness of 16-70 mm is performed in the mode of preliminary manual welding of the lower part of the seam.

With an increase in the thickness of the parts being welded, the diameter of the wire electrode and the welding current increase, but the speed of formation of the weld decreases.

The welding current (A) depends on the wire thickness (mm) as follows:

- 2 mm – 200-400 A;

- 3 mm – 300-600 A;

- 4 mm – 400-800 A;

- 5 mm – 700-1000 A;

- 6 mm – 700-1200 A.

The welding voltage increases significantly only when the thickness of the parts is over 25 mm.