Materials for cutting tools

The cutting ability of a turning tool is determined by the physical and mechanical properties of the material from which it is made. The main properties that determine the performance of a tool include hardness, heat resistance, wear resistance, thermal conductivity and adhesiveness.

The hardness of the material from which the tool is made must exceed the hardness of the material being processed. Due to the fact that significant cutting forces act on the working part of the tool, creating bending deformations, the tool material must have strength. The hardness and strength of the tool material is significantly influenced by the ratio of alloying components and carbon included in their composition in the form of carbides. With an increase in the number of carbides and a decrease in their grain size, the hardness and wear resistance of the tool increases, and the strength decreases.

The heat resistance of a tool is determined by the temperature above which the hardness decreases and wear increases.

Tool wear resistance is characterized by the tool's resistance to abrasion under the influence of frictional forces arising in cutting processes.

The thermal conductivity of a tool is determined by its ability to remove heat generated during cutting processes from the cutting edges of the tool. The higher the thermal conductivity, the better the heat is removed from the cutting edges, thereby increasing the tool life.

The adhesive ability of the tool and the material being processed is characterized by the temperature at which the material being processed sticks to the cutting edges of the tool. It depends on the molecular forces that develop at high temperatures and pressures at the points of contact of the cutting tool with the machined surface. The higher the temperature at which the material being processed sticks to the tool, the higher the quality of the material from which the tool is made.

Tool steels.

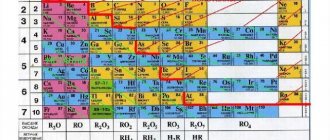

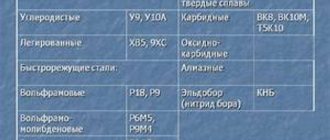

Tool steels are divided into:

- carbon;

- alloyed;

- high-speed.

Carbon tool steels.

In order to make cutting tools, carbon steel grades U10A, U11A, U12A and U13A are used. The letter U means that the steel is carbon tool steel. The number after the letter indicates approximately how much carbon in tenths of a percent is contained in this steel.

If there is a letter A at the end of the name of a steel grade, this indicates that the steel belongs to the high-quality group (U10A; U12A).

After quenching and tempering, the hardness of tools made from these steels is HRC 60–64. However, when heated to temperatures above 220-250°C, the hardness of the tool decreases sharply. Therefore, at present, such a tool is used on lathes only for work involving low cutting speeds (certain types of taps, countersinks and reamers).

Alloyed tool steels.

Alloyed tool steels are those into which special impurities (alloying elements) are introduced in order to increase their physical and mechanical properties.

With the introduction of chromium, molybdenum, tungsten, vanadium, titanium and manganese, the hardness of steel increases, since they form simple or complex compounds (carbides) with carbon, which have high hardness (especially tungsten and vanadium carbides). At the same time, the steel retains sufficient viscosity. Nickel, cobalt, aluminum, copper and silicon, dissolving in iron, strengthen steel.

With appropriate heat treatment, the tool has a hardness of HRC 62-64 and retains it when heated to a temperature of 250-300°C. Countersinks, reamers, taps, broaches are made from steel grades 9ХС, ХВГ and ХВ5.

High-speed tool steels.

High-speed tool steels are alloy steels with significant contents of tungsten, cobalt, vanadium and molybdenum. They retain the hardness HRC 62–64 obtained after heat treatment when heated to a temperature of 600°C, and some grades of complex alloy steels retain their hardness even when heated to a temperature of 700–720°C.

These qualities of high-speed steels make it possible to increase cutting speeds during processing by two to three times compared to tools made from carbon and conventional alloy tool steel.

All grades of high-speed steel are designated by the letter P (P9, P12, P18), the number placed after the letter P shows the average percentage of tungsten in this steel.

High-speed steels containing 3-5% molybdenum (R6M3, R6M5) are widely used These steels are superior in strength to P18 steel, although they have slightly lower heat resistance. They are usually used for tools operating under heavy-duty conditions.

When processing alloyed, heat-resistant and stainless alloys and steels, it is effective to use high-performance high-speed steels, which contain vanadium and cobalt (R10KF5, R18K5F2), or complex alloy steels (grades R18MZK25, R18M7K25 and R10M5K25). If the steel contains 10% or more cobalt, its hardness after heat treatment is 67–68 and is maintained up to a heating temperature of 640–720°C.

High-speed tool steels are used for the manufacture of cutters, drills, countersinks, reamers, taps, dies and other tools. .

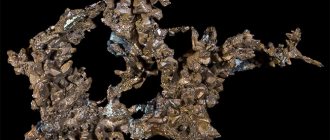

Hard alloys.

Hard alloys consist of carbides of refractory metals, which are evenly distributed in a cobalt binder. They are made by pressing and sintering. Hard alloys have high density and hardness, which does not decrease even when heated to 800–900°C. Based on their composition, hard alloys are divided into three groups:

- tungsten;

- titanium tungsten;

- titanium-tantalum-tungsten.

The main grades of tungsten group hard alloy used for the manufacture of cutting tools are VKZ, VKZM, VK4, VK4M, VK6 VK6M VK6V, VK8, VK8V, VK10. In the designation of the grade of hard alloy of this group, the letter B denotes the group, the letter K and the number following it indicate the percentage of cobalt, which is the binding metal. The letter M means that the structure of the alloy is fine-grained, and the letter B means that it is coarse-grained.

Hard alloys of the titanium-tungsten group.

Hard alloys of the titanium-tungsten group consist of grains of a solid solution of tungsten carbide in titanium carbide, excess grains of tungsten carbide and cobalt, which is a binder. The main alloy grades of this group are T5K10, T5K12, T14K8, T15K6. In the designation of alloys of this group, the number after the letter T indicates the percentage of titanium carbide, and the number after the letter K indicates the percentage of cobalt. The rest of the alloy is tungsten carbides.

Hard alloys of the titanium-tantalum tungsten group.

Hard alloys of the titanium-tantalum-tungsten group consist of grains of titanium, tantalum, tungsten carbides and a binder, which is also used as cobalt. The grades of this group of alloys are TT7K12, TT8K6, TT10K8B and TT20K9. In the designation of this group of alloys, the number after the letters TT indicates the content of titanium and tantalum carbides, and the number after the letter K indicates the cobalt content as a percentage.

Depending on the content of tungsten carbide, titanium carbide, tantalum carbide and cobalt, hard alloys have different properties. The more cobalt, the more tough the alloy and the better it resists impact. Therefore, for the manufacture of tools used for roughing work, alloys with a high cobalt content are used. When processing steel, hard alloys containing titanium carbide are used, since steel chips stick less to tools made from these alloys.

Tungsten-cobalt hard alloys.

According to GOST 3882 - 74, hard alloys of the VK group (tungsten-cobalt) are recommended for processing brittle materials (cast iron, bronze). Alloys of the TK group (titanium-tungsten-cobalt) are recommended for processing viscous materials (steel, brass). Alloys of the titanium-tantalum-tungsten group are used under unfavorable operating conditions for tools with shock loads, when processing steel castings and forgings.

Mineral ceramic materials.

Mineral-ceramic materials for cutting tools are made in the form of plates from aluminum oxide Al2O3 (alumina) by pressing under high pressure followed by sintering. They have high hardness, temperature resistance (up to 1200°C), wear resistance and sufficient compressive strength. The disadvantages of these materials include high fragility and low impact strength. Tools equipped with mineral ceramics are typically used in finishing machining operations where the load is constant and where there is no vibration.

Synthetic materials.

Synthetic diamond is characterized by high hardness and wear resistance, and is slightly chemically active. It has a low coefficient of friction and a low tendency for chips of the processed material to stick. The disadvantages of diamond are its fragility and relatively low temperature resistance (750-850°). Diamond cutters are used for finishing processing of non-ferrous metals, alloys and non-metallic materials.

Cubic boron nitride (CBN) is a synthetic superhard material (elbor, cubanite, hexanite) consisting of boron and nitrogen compounds. Its hardness is slightly lower than that of diamond, but its temperature resistance is much higher (1200 – 1300°C). It is chemically inert to materials containing carbon, therefore, when processing steels and cast irons, its wear resistance is significantly higher than the wear resistance of diamonds. CBN inserts are used to equip turning tools for machining hardened steel and high-strength cast iron.

TYPES OF INSTRUMENTAL MATERIALS AND AREAS OF THEIR APPLICATION

Carbon and alloy tool steels. The range of instrumental materials is varied. , carbon tool steels of grades U7, U7A...U13, U13A began to be used for the manufacture of cutting tools In addition to iron and carbon, these steels contain 0.2...0.4% manganese. Tools made of carbon steels have sufficient hardness at room temperature, but their heat resistance is low, since at relatively low temperatures (200...250 °C) their hardness sharply decreases.

Alloyed tool steels in their chemical composition differ from carbon steels in the increased content of silicon or manganese, or the presence of one or more alloying elements: chromium (increases the hardness, strength, corrosion resistance of the material, reduces its ductility); nickel (increases strength, ductility, impact strength, hardenability of the material); tungsten (increases the hardness and heat resistance of the material); vanadium (increases the hardness and strength of the material, promotes the formation of a fine-grained structure); cobalt (increases the impact strength and heat resistance of the material); molybdenum (increases elasticity, strength, heat resistance of the material). For cutting tools, low-alloy steels of grades 9ХФ, 11ХФ, 13Х, В2Ф, ХВ4, ХВСГ, ХВГ, 9ХС, etc. are used. These steels have higher technological properties—better hardenability and hardenability, less tendency to warp, but their heat resistance is almost equal to the heat resistance of carbon steels. steels 350...400 °C and therefore they are used for the manufacture of hand tools (reamers) or tools intended for processing on machines with low cutting speeds (small drills, reamers).

High-speed tool steels. From the group of high-alloy steels, high-speed steels with a high content of tungsten, molybdenum, cobalt, and vanadium are used for the manufacture of cutting tools. Modern high-speed steels can be divided into three groups.

Steels of normal heat resistance include tungsten R18, R12, R9 and tungsten-molybdenum R6M5, R6MZ, R8MZ (Table 6.1). These steels have a hardness in the hardened state of 63...66 HRSe, a bending strength of 2900...3400 MPa, an impact strength of 2.7...4.8 J/m2 and a heat resistance of 600...650 °C. These steel grades are most widely used in the manufacture of cutting tools. They are used in the processing of structural steels, cast irons, non-ferrous metals, and plastics. Sometimes high-speed steels are used, additionally alloyed with nitrogen (P6AM5, P18A, etc.), which are modifications of conventional high-speed steels. Alloying with nitrogen increases the cutting properties of the tool by 20...30%, hardness - by 1...2 HRSe units.

Steels with increased heat resistance are characterized by a high carbon content - 10Р8МЗ, 10Р6М5; vanadium - R12FZ, R2MZF8, R9F5; cobalt - R18F2K5, R6M5K5, R9K5, R9K10, R9M4K8F, 10R6M5F2K8, etc.

The hardness of steels in the hardened state reaches 66...70 HRSe, they have higher heat resistance (up to 620...670 °C). This makes it possible to use them for processing heat-resistant and stainless steels and alloys, as well as high-strength and hardened structural steels. The service life of tools made from such steels is 3...5 times higher than from steels R18, R6M5.

Table 3. Content of alloying elements in high-speed steels, %

High heat resistance steels are characterized by a low carbon content, but a very large amount of alloying elements - Bl1M7K23, V14M7K25, ZV20K20Kh4F. They have a hardness of 69...70 HRCE, and a heat resistance of 700...720 °C. The most rational area of their use is cutting difficult-to-cut materials and titanium alloys. In the latter case, the service life of tools is 30...80 times higher than that of steel R18, and 8...15 times higher than that of hard alloy VK8. When cutting structural steels and cast irons, the service life increases less significantly (3...8 times).

Due to the acute shortage of tungsten in the USSR and abroad, tungsten-free tool materials, including high-speed steels, are being developed.

These steels include low-tungsten steels R2M5 and RZMZF4K5. R2MZF8, A11RZMZF2 and tungsten-free 11M5F (see Table 6.1). The performance properties of these steels are close to the properties of traditional high-speed steels of the corresponding groups.

A promising direction in improving the quality of high-speed steels is their production by powder metallurgy methods. Steels R6M5K5-P (P - powder), R9M4K8-P, R12MZFZK10-P and others have a very uniform fine-grained structure, are well ground, are less deformed during heat treatment, and are characterized by stable performance properties. The service life of cutting tools made from such steels increases up to 1.5 times. Along with powder high-speed steels, so-called carbide steels have proven themselves well,

containing up to 20% TiC, which, in terms of performance characteristics, occupy an intermediate place between high-speed steels and hard alloys.

Hard alloys. These alloys are produced by powder metallurgy in the form of plates or crowns. The main components of such alloys are tungsten carbides WC, titanium TiC, tantalum TaC and niobium NbC, the smallest particles of which are connected through relatively soft and less refractory cobalt or nickel mixed with molybdenum (Tables 6.2, 6.3).

Hard alloys have high hardness -88... 92 HRA (72...76 HRCE) and heat resistance up to 850... 1000 °C. This allows you to work at cutting speeds 3...4 times higher than with tools made of high-speed steels.

Currently used hard alloys are divided into:

1) for tungsten alloys of the VK group: VKZ, VKZ-M, VK4, VK6, VK6-M, VK6-OM, VK8, etc. In the symbol, the number shows the percentage of cobalt. For example, the designation VK8 indicates that it contains 8% cobalt and 92% tungsten carbides. The letters M and OM indicate fine-grained and especially fine-grained structure;

2) for titanium-tungsten alloys of the TK group:

T5K10, T15K6, T14K8, TZOK4, T60K6, etc. In the symbol, the number after the letter T shows the percentage of titanium carbides, after the letter K - cobalt, the rest - tungsten carbides;

Table 4. Brands, chemical composition and properties of tungsten-containing hard alloys

Table 5. Brands, chemical composition and properties of tungsten-free hard alloys

3) for titanium-tantalum-tungsten alloys of the TTK group: TT7K12, TT8K6, TT20K9, etc. In the symbol, the numbers after the letter T show the percentage of titanium and tantalum carbides, after the letter K - cobalt, the rest - tungsten carbides;

4) for tungsten-free hard alloys TM-1, TM-3, TN-20, KNT-16, TS20KhN, the composition of which is given in table. 6.3. The designations of this group of hard alloys are conventional.

Carbide grades are produced in the form of standardized inserts that are soldered, glued or mechanically attached to structural steel holders. Tools are also produced, the working part of which is entirely made of hard alloy (monolithic).

The correct choice of carbide grade ensures efficient operation of cutting tools. For a specific processing case, the alloy is selected based on the optimal combination of its heat resistance and strength. For example, TK group alloys have higher heat resistance than VK alloys. Tools made from these alloys can be used at high cutting speeds, which is why they are widely used in the machining of steels.

Tools made from hard alloys of the VK group are used when processing parts made of structural steels under conditions of low rigidity of the AIDS system, during intermittent cutting, when working with impacts, as well as when processing brittle materials such as cast iron, which is due to the increased strength of this group of hard alloys and low temperatures in cutting zone.

Such alloys are also used in the processing of parts made of high-strength, heat-resistant and stainless steels, titanium alloys. This is explained by the fact that the presence of titanium in most of these materials causes increased adhesion to TK group alloys, which also contain titanium. In addition, alloys of the TK group have significantly worse thermal conductivity and lower strength than VK alloys.

The introduction of tantalum carbides or tantalum and niobium carbides (TT10K8-B) into the hard alloy increases its strength. Therefore, three- and four-carbide carbide alloys are used to equip tools that work with impacts and on contaminated crusts. However, the heat resistance temperature of these alloys is lower than that of dicarbide alloys. Of the hard alloys with a significantly improved structure, specially fine-grained ones should be noted, used for processing materials with high abrasive ability. OM alloys have a dense, particularly fine-grained structure, and also have a small (up to 0.5 μm) grain size of tungsten carbides. The latter circumstance allows tools made from them to be sharpened and finished with the smallest radii of cutting edges. Tools made from alloys of this group are used for finishing and semi-finishing of parts made of high-strength ductile steels with an increased tendency to work hardening.

A slight addition of tantalum and cobalt carbide to the alloys of the OM group helps to increase their heat resistance, which makes it possible to use these alloys in the manufacture of tools intended for roughing parts made of various steels. Replacing tantalum carbides with chromium . This ensures the production of alloys with a fine-grained, uniform structure and high wear resistance. A representative of such materials is the VK10-XOM .

Alloys with a low percentage of cobalt (TZOK4, VKZ, VK4) have lower viscosity and are used for the manufacture of tools that cut thin chips in finishing operations. On the contrary, alloys with a high cobalt content (VK8, T14K8, T5K10) are more tough and are used when removing large-section chips in roughing operations.

The performance of hard alloys increases significantly when wear-resistant coatings are applied to them.

Mineral ceramics. Among modern tool materials, mineral ceramics, which do not contain expensive and scarce elements, deserve attention. It is based on aluminum oxides AO3 with a small addition (0.5...1%) of magnesium oxide MgO. The high hardness of mineral ceramics, heat resistance up to 1200°C, chemical inertness to metals, and oxidation resistance largely exceed the same parameters of hard alloys. However, mineral ceramics are inferior to these alloys in thermal conductivity and have a lower bending strength.

Modern mineral ceramics, created in the USSR and abroad, are close in strength to the most wear-resistant hard alloys. Mineral ceramics based on aluminum oxide can be divided into three groups:

1) pure oxide ceramics (white), the basis of which is aluminum oxide with minor impurities (AlO3 - up to 99.7%);

2) ceramics, which is aluminum oxide with the addition of metals (titanium, niobium, etc.);

3) oxide-carbide (black) ceramics - aluminum oxide with the addition of refractory metal carbides (titanium, tungsten, molybdenum) to increase its strength properties and hardness.

The domestic industry currently produces oxide ceramics TsM-332, VO-13 and oxide-carbide ceramics VZ, VOK-60, VOK-63, which contain up to 40% titanium, tungsten and molybdenum carbides. Along with materials based on aluminum oxide, materials based on silicon nitride are produced - silinite-R and cortinite ONT-20 (with the addition of aluminum oxides and some other substances). The physical and mechanical properties of cutting mineral ceramics are given in table. 6.4.

The high cutting properties of tools made of mineral ceramics are manifested in high-speed machining of steels and high-strength cast irons, and finishing and semi-finish turning and milling increases the processing productivity of parts up to 2 times while simultaneously increasing tool life periods up to 5 times compared to machining with tools made of carbide.

Mineral ceramics are produced in the form of non-grindable plates, which significantly facilitates the conditions of its operation.

Table 6. Physical and mechanical properties of cutting mineral ceramics