Home / Devices

Back

Reading time: 2 min

0

3643

Nowadays, metal welding is performed using different techniques. Stores are overflowing with devices: transformers, inverters, rectifiers, semi-automatic devices and, of course, automatic machines.

They have serious differences. If any master can distinguish between a transformer and an inverter, then, without knowledge of the intricacies of these devices, the difference between a semi-automatic device and an automatic machine is not so clear.

Our publication will show in detail the difference between automatic and semi-automatic welding, and explain the superiority of the first over the second.

An automatic welding machine is a variation of a welding device; it is needed for automatic welding. No special skill is required here. It is enough to configure the equipment correctly, and it will do the rest itself.

An automatic welding machine is a complex technique, but be that as it may, it remains stable under significant loads. Fine adjustment affects the quality of the seams.

Since this method does not require direct participation in the welding procedure, the welder is called an operator.

An automatic welding machine performs several tasks simultaneously. They ignite the arc, make a seam, protect the welding space from exposure to oxygen (flux is used for this purpose), in addition, wire is fed into the welding bath.

- Advantages of automatic welding machine

- Difference between automatic and semi-automatic

- Why then use semi-automatic welding?

- conclusions

There are 4 types of devices:

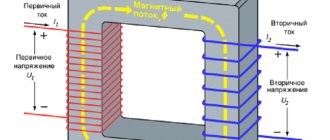

- Transformers are inexpensive and simple in design, but heavy and bulky devices. Welding is performed using alternating current. Due to this, only ferrous metals (cast iron, steel) can be welded.

- Rectifiers - also based on a transformer, but welding is carried out using direct current. Due to this, the strength and quality of the connection is higher, and the consumption of materials is lower. Usually used in industry.

- Inverters are compact and lightweight (from 3 kg) devices. The most convenient to use and recommended for beginner welders. They are characterized by a stable arc and can be used for welding non-ferrous metals and thin sheet metal.

- Semi-automatic machines are productive devices that are optimal for long-term operation. Capable of working with all types of metals. Widely used in car repair shops.

Advantages of welding inverters

The use of new generation welding equipment makes it possible to improve the quality of welding of metal structures and significantly simplifies the work of both professional welders and craftsmen working at home.

Compared to classic welding equipment, inverter-type semi-automatic welding machines have many advantages. The main ones:

- Compact dimensions and low weight greatly simplify the transportation and storage of welding and make inverters convenient to use.

- It is possible to use direct and alternating current electrodes, which allows you to obtain high-quality seams when working with products made of cast iron, aluminum, stainless steel, and heat-resistant steel grades.

- A large range of control of the input current allows the use of non-consumable electrodes for arc welding under gas protection.

- Availability of additional functions. “Hot start” ensures the supply of current of the optimal value necessary to ignite the electrode. "Anti-Sticking" reduces the current supply to a minimum when a short circuit occurs. “Arc Force” increases the current at the moment of drop separation, preventing sticking.

When choosing welding for home or work in a workshop, you need to focus on the time of continuous operation of the equipment. Professional welding inverters can work up to 8 hours without a break. After half an hour of operation, household-grade equipment will require 30 to 60 minutes to cool down.

Technical characteristics of inverters:

- Power. In the data sheet for the equipment, the manufacturer indicates the rated current value at which the device will not overheat.

- The abbreviation PN denotes the duration of the load, the temporary mode of use of the device.

- The abbreviation DPN denotes the range of supply voltage. It is especially important for welding work in unstable voltage conditions. Power surges of up to 20%-30% most often occur in gardening associations and dacha cooperatives.

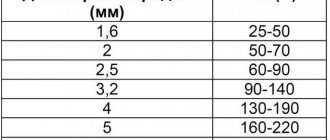

- Electrode diameter. The thickness of the metal depends on this indicator, as well as the ability to weld corners or channels. For steel thicknesses from 1.5 to 13 mm, it is recommended to use electrodes with a diameter of 1.6 to 5 mm.

ELITECH AIS 200

Photo: https://beru.ru

Although the marking of this welding inverter suggests that the maximum welding current here is 200 amperes, in fact the reality is a little more modest: it can only “squeeze” 180 A, and with a duty cycle of only 60%. Thus, the optimal choice for him is welding with 2-3 mm electrodes; with the “four”, planned smoke breaks will be required, if you do not try to test the safety margin of the welder in practice. As for the safety margin, here this term can be understood almost literally: in comparison with many representatives of its class, Elitech will seem like a real “brick”, because it weighs 8 kg - one and a half times more than many inverters with the same maximum current. Its circuit fully satisfies modern ideas about a welding inverter: arc forcing is provided, and current consumption is quite acceptable.

Welding machine AIS 200Prof (TIG, MMA)

Advantages:

- reliability

- quality cables included

- presence of arc forcing

Flaws:

- heavy weight

- large dimensions

- relatively low PV coefficient

Selecting a welding machine

In order to weld reinforcement for concrete, build a metal fence, or repair a burst pipe, you will definitely need an electric welding machine. Which welding to choose for home needs?

The main properties of a home welding machine

A home welding machine should be easy to use and safe. Modern welding equipment is small in size and weight compared to Soviet models. Welding machines are easy to transport to the place where welding needs to be done.

Before purchasing, you should decide for what purposes the welding equipment will be used. If the machine is needed for welding plastic pipes, then there is no point in spending money on equipment designed for welding or cutting metal.

To work with welding equipment, a constant, stable voltage is required. However, some models allow you to work with voltages that deviate from the norm by 15%.

Types and principle of operation of semi-automatic devices

Main components of the welding machine:

- control Panel;

- mechanism and sleeve for wire feeding;

- bay of consumables;

- burner;

- power supply cable;

- gas supply hose and reducer;

- gas cylinder;

- control system;

- rectifier and heater.

Such equipment is presented in a wide assortment, which is ordered by capabilities and ordered by type. According to the generally accepted classification, welding equipment is divided into manual, automatic and semi-automatic.

The simplest type - manual welding - is ideal for household use, workshops and other small industries. Automatic and semi-automatic machines are characterized by high productivity and processing accuracy. They are an integral part of production lines in large and medium-sized enterprises. In addition to speed of work, they provide high-quality connection of workpieces.

Helpful information

Inverter welding machines are widely used in everyday life and in production. Welding will help you weld a gate or barbecue at a dacha, and fasten water pipes or fittings at a construction site.

Inverters are popular because they have many advantages. Small size and weight of the structure. You can easily learn the job. Ability to adjust the welding current from tens to hundreds of amperes. A large model range allows you to easily select household inverters powered from a 220 V network with an electrode diameter from 1.5 to 4 mm or professional welding transformers for 380 V and an electrode from 2 to 6 mm.

Main settings

- Supply voltage 220 or 380 volts, as well as the ability to operate within the permissible range. For example, 160-240 Volts with unstable voltage.

- The power of the inverter affects the maximum thickness of metal that can be welded and electricity consumption. Not all wiring can withstand such power and starting currents must be taken into account.

- The welding current depends on the thickness of the parts being welded and the diameter of the electrode. Selected by maximum value.

- The PN load percentage shows the time intervals between work and rest at maximum current. The higher the value, the longer you can cook without interruption.

- MMA and TIG operating modes. Most often, household DC devices operate using the MMA method - manual arc welding. Most types of metals are welded. Some inverters also weld in TIG mode - manual argon arc welding with tungsten electrodes. Used in welding non-ferrous metals.

Characteristics and descriptions

- Welding current and electrode diameter determine the capabilities of the welding machine to work with metal of different widths. With a maximum current of 200 A, you can work with material no more than 5 mm thick.

- Supply voltage - inverters are divided into those operating in a single-phase or three-phase network.

- Weight of the device - with the same characteristics, a welding inverter from one manufacturer may be lighter than from another.

- The power of the welding machine should be chosen with a reserve for the future, since in the future you may need to weld metal of greater thickness.

Special functions to help you weld

- Arc Force automatically increases the current and reduces the likelihood of sticking when the electrode suddenly approaches the metal surface.

- Hot Start Hot Start provides easy ignition of the arc, which makes it easier to weld with poor electrodes or parts to be joined.

- Anti-stick Antistick is triggered when the electrode touches the part. Automatically reduces the current and prevents the electrode from sticking. If the adhesion is broken, the current is supplied again.

Cedar MIG-160GDM

Photo: https://beru.ru

The most versatile device in the review - it allows its owner to work both with welding wire in the MIG/MAG mode, and with stick electrodes and an argon torch (though, exclusively in the TIG DC mode - it cannot be used for welding aluminum alloys). This inverter belongs to the family of welding machines with microprocessor synergetic control: it has only two controls - a touch mode selection button and a multifunctional regulator. Most arc burning parameters are set automatically depending on the selected mode. This is convenient for beginners, but a professional welder would rather choose a machine with a large number of manual settings. In addition, full operation at high currents is limited by the low PV value: long-term welding with an electrode can only be done with a diameter of up to 3 mm, which, taking into account the high price of the inverter itself, led to a noticeable decrease in the score in the rating of the best welding machines. So if you are looking for a good inverter welding machine for production, then pay attention to this sample.

Welding machine MIG-160GDM (MIG/MAG, MMA)

Advantages:

- convenient for beginners

- multifunctional

Flaws:

- focus on low currents

- sensitivity to voltage sags

The most popular models:

- AURORA PRO OVERMAN 180 Mosfet

- WESTER MMA-VRD 200

- RESANTA SAI 220

Welding machine Eurolux IWM-160

| Welding type | MMA |

| Welding current strength | 10-160 Amps |

| Input voltage | 140-260 V |

| Duration of activation | 70% |

| Electrode diameter | 1.6 – 4 mm |

| Protection class | IP21 |

PROS

- Compactness

- Has a strap for easy carrying

- Shockproof housing

- Does not require special skills to operate

- Hot start - automatically increases the welding current at the beginning of work, which simplifies ignition of the arc

- Arc force – prevents sticking of the electrode, reduces metal spatter, and, if necessary, allows for deep penetration of the weld seam

- Anti-sticking - the device automatically reduces the welding current when the electrode gets stuck, making it easier to release it

- Quick connection

- Efficient cooling during operation

- Low price

MINUSES

- Short wires included

- No display

Welding inverter FUBAG IQ 160

| Welding type | MMA |

| Welding current strength | 20-160 Amps |

| Input voltage | 150-240 V |

| Duration of activation | 40% |

| Electrode diameter | 1.6 – 4 mm |

| Protection class | IP21S |

PROS

- Compactness

- Light weight (2.7 kg)

- Smooth adjustment of welding current

- Does not require special skills to operate

- Hot start

- Arc Fast and Furious

- Anti-stick

- Quick connection

- Improved cooling system

- Low price

MINUSES

- Short wires included

- No display

Inverter welding inverter RESANTA SAI 140

| Welding type | MMA |

| Welding current strength | 10-140 Amps |

| Input voltage | 220 V |

| Duration of activation | 70% |

| Electrode diameter | up to 3.2 mm |

| Protection class | IP21 |

PROS

- Compactness

- Light weight (4.3 kg)

- Has a strap for easy carrying

- Stable operation even at high current

- Hot start

- Arc Fast and Furious

- Quick connection

MINUSES

- The protective cover is rattling

- The wires included in the kit are short

Welding inverter FUBAG IN 176

| Welding type | MMA/TIG |

| Welding current strength | 10-160 Amps |

| Input voltage | 230 V |

| Duration of activation | 60% |

| Electrode diameter | 1.6 – 3.2 mm |

| The diameter of the wire | 1.6-4 mm |

| Protection class | IP21 |

PROS

- Compactness

- Multifunctionality

- The digital display and touch controls allow you to instantly set up the machine and control welding parameters without being distracted from your work.

- The electrode selection table is shown on the top panel.

- Stable operation at any voltage

- Hot start

- Anti-stick

- Arc force (only for MMA mode)

MINUSES

- Experience with TIG machines required

Welding inverter BlueWeld Prestige 186 PRO

| Welding type | MMA/TIG |

| Welding current strength | 20 – 160 Amps |

| Input voltage | 190-220 V |

| Duration of activation | 60% |

| Diameter of welding electrodes | 1.6 – 4 mm |

| Protection class | IP23 |

PROS

- Small dimensions

- Stable operation at any voltage

- Hot start

- Anti-stick

- Relatively inexpensive.

- Low power

- Convenient carrying handle

MINUSES

- Experience with TIG machines required

- Not suitable for welding aluminum.

- No argon burner.

Welding inverter Energolux WMI-200

| Welding type | MMA |

| Welding current strength | 10-200 Amps |

| Input voltage | 198-242 V |

| Duration of activation | 70% |

| Electrode diameter | up to 3.2 mm |

| Protection class | IP21 |

PROS

- Compactness

- Has a strap for easy carrying

- Smooth adjustment of welding current

- Hot start

- Arc Fast and Furious

- Anti-stick

MINUSES

- Short wires included

- No display

Fast and Furious-161

Photo: https://beru.ru

Our review of the welding equipment market in 2021 included the Forsazh-161 model. This welding inverter produced by the Ryazan Instrument Plant, although it does not impress with the declared characteristics or ultra-modern design, will give the professional exactly what he needs - reliability and accuracy of the formation of the current-voltage characteristic of the welding current in the MMA and TIG modes. In both cases, the maximum welding current is 160A, but continuous operation is possible with a current of no more than 100A. Consequently, this inverter is most suitable for working with fairly thin metal that does not require deep penetration at high current. Among the advantages of the device is the ability to work with strong voltage drops - the manufacturer’s declared performance at 140V in a socket is perfectly confirmed in practice. A “soft” arc is easy to ignite and burns without much metal spattering. The automatic fan control used in the inverter based on a signal from a temperature sensor significantly reduces the amount of dust sucked into the housing, accordingly making the need to clean the output stage radiators less frequent.

Welding machine 161 (TIG, MMA)

Advantages:

- stability of characteristics during voltage sags

- high reliability

- automatic activation of “anti-stick” is convenient for novice welders

Flaws:

- no wires included

- The device is designed to operate at low currents

Cost of welding equipment

Prices for welding machines are scattered over a wide range. The cost of the equipment depends on the country of origin, the functionality of the device and the availability of components for it. It is cheaper to buy a welding machine made in China. Japanese welding will cost more, but it may turn out that all the parts were made in China, and only assembly was carried out directly in Japan.

The price increases if the welding has a built-in power factor corrector. Such a device is necessary when the voltage range is too wide: 90–240 Volts.

Prices for welding machines

Welding machine name/Price

| Wert MIG 200 | from RUB 16,395 |

| Resanta SAI-190K 65/36 | from 4,825 rub. |

| Aurora PRO Overman 180 | from RUR 27,625 |

| Solaris MULTIMIG-227 | from 24,000 rub. |

| FUBAG IR 160 31401 | from 5,090 rub. |

Welding machines are divided into several types with their own specifics: welding transformer, rectifier, gas semi-automatic, inverter.

Transformers are the simplest and most inexpensive type of welding machines; moreover, they are reliable and unpretentious in operation. At the same time, the quality of the seam is relatively low, and working with a transformer requires certain skills. Yes, and such devices are suitable exclusively for ferrous metals. Therefore, a welding transformer is best suited for simple work (including at home) and for those who already have experience with welding.

Rectifiers differ from transformers in that they work not with alternating current, but with direct current. This improves the quality of the seam and allows you to weld both ferrous and non-ferrous metals. At the same time, rectifiers are more complex and consume significantly more energy than transformers, which requires appropriate quality electrical networks. Therefore, they are more designed for professional electric welding.

Gas semi-automatic machines are designed for welding in a special gas environment. They are reliable, easy to use and provide high quality welds, especially when welding non-ferrous metals - the gas protects the seam from moisture and oxidation. The disadvantages of semi-automatic machines are their high cost and some difficulties in use (for example, in addition to electrodes, gas mixtures for welding are also required). This type is considered optimal for auto repair shops; it can also be useful for domestic purposes. Inverters are considered the most modern type of welding machines. They provide good weld quality with high productivity, are resistant to low voltage, can weld both ferrous and non-ferrous metals, and are small in size and weight. Their disadvantages are their relatively high cost, as well as sensitivity to voltage surges.

Regardless of the type, when choosing, it is worth considering the voltage for which the device is designed. For domestic use, it is worth taking 220 V devices, and for workshops and production, where high power is required, 380 V models are produced. The main division into household and professional welding machines is based on current strength: devices up to 200 A belong to the first type, more than 200 A - to the second.

It is also worth choosing a device based on current strength depending on the thickness of the metal with which you will have to work. The thicker the metal, the higher the current should be; There are special tables that allow you to accurately select a device for specific needs.

What are the cheapest welding machines?

Top 3 inexpensive products from the Welding machines category:

- ✔ Inverter welding machine Resanta IWM160 Eurolux

- ✔ Inverter welding machine Pobeda AC 200, 200 A

- ✔ Inverter welding machine Resanta IWM190 Eurolux

What type of welding should I choose?

Manual arc (MMA)

The simplest type of welding, which is performed using an electric arc and a coated metal electrode. During operation, the electrode wire melts and lies in a layer on the parts being welded, turning into a seam. The quality of the seam in this case largely depends on the “direct hands” of the operator. This type is best suited for connecting steel and cast iron structures, and for rough work, for example, for welding embedded parts for floor slabs or making a metal fence frame.

One of the simpler models is Wester MINI 160T. Weighs only 3 kg, has a convenient carrying strap, and welding current range is 30-160 A.

Argon arc (TIG)

Unlike MMA, the argon-arc welding type makes the seam not from the electrode, but from the parts being welded. The electrode itself is made of non-consumable material. And to ensure that the seam does not collapse under the influence of oxygen, argon gas is supplied to it during operation. Thanks to this process, the seam is smoother than with MMA.

Argon-arc welding is excellent for joining non-ferrous metals and stainless steel. Also, in cases where it is necessary to avoid the presence of “humps” in the seam, for example, when it is necessary to weld heating pipes from the inside (welding “through the window”), an inverter with the TIG function is used. However, argon-arc welding will not allow welding very thin parts, for example, drain pipes with a thickness of 0.5-0.8 mm.

Among inexpensive models, we can recommend Hitachi EW3500 , which is included in many ratings of welding inverters 2021: a manual machine with the ability to work with gas.

Semi-automatic (MIG/MAG)

Semi-automatic welding is the standard choice for regular “shabats”. If there was a rating of welding inverters for home among welders, it would certainly include semi-automatic ones, since they allow you to weld all types of metals quite quickly. The filler material in it is wire with a cross section from 0.8 to 2 mm. The thicker the wire, the thicker the structural elements the inverter can weld. To protect the seam from oxygen, in this case, inert (MIG) and active (MAG) gases are used. Inert gas is used for working with non-ferrous metals, and active gas is used for welding steel products. It is worth noting that semi-automatic inverters provide a perfectly even seam and a relatively high speed of operation. For example, the Svarog REAL MIG 200 is capable of welding two steel plates 3 mm thick with a seam 5 cm long in just one minute.

Also, semi-automatic inverters allow you to work with both wire and electrodes (manual arc). If you often need to weld different types of metals for your home and part-time work, then a model with semi-automatic welding is your choice.

Spot (SPOT)

With this type of welding, the materials are joined at a point (similar to a rivet joint), which allows for the welding of fairly thin products. Most often, spot welding is used when repairing a car, for example, welding a body. Therefore, if you plan to weld and straighten your car yourself, then you cannot do without a spot welding device.