Among the variety of models of welding inverters of a well-known brand, the Resanta SAI-220 device is considered one of the most popular. In terms of technical characteristics and functionality, the inverter of this model can be classified as a device of both household and industrial type; it occupies an intermediate position between them.

Welding inverter Resanta SAI-220A and a convenient case for storage and transportation

It is thanks to these characteristics that this inverter can be equally successfully used both by professionals in their field to perform welding of increased complexity, and by novice welders taking their first steps in their profession.

Scope and technical characteristics

The Resanta SAI-220 welding inverter is a device operating from a single-phase electrical network with a voltage of 220 V. A direct current is generated at the output of the device, which is used to perform electric arc welding using consumable coated electrodes. If it is necessary to weld parts of small thickness, then such a device can even be connected to a regular household outlet (of course, provided that the electrical panel is equipped with machines that can withstand the current consumed by the device).

Using this inverter, you can not only effectively weld parts made of carbon steel, but also work with stainless steel and other alloy steels.

Although all Resanta brand inverters are manufactured in China, the circuits, construction and design of these devices were developed in Latvia. The brand name was also invented here, which today is well known to welders in many countries around the world. Among the technical characteristics of the welding machine in question, the following should be highlighted:

- welding current control range – 10–220 A;

- supply voltage value - 220 V (permissible deviations of the supply voltage can be 10% on the positive side (242 V), 30% on the negative side (154 V));

- the current consumed by the device at peak load is 30 A;

- open circuit voltage – 80 V;

- rated operating voltage – 28 V;

- ON duration (DS) when working at maximum welding current (220 A) – 70%, at welding current 10–140 A – 100%;

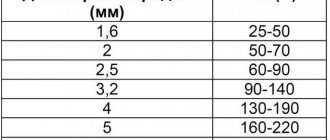

- the diameters of the electrodes used are 1.6–5 mm;

- protection class – IP 21;

- inverter weight – 4.9 kg.

The listed characteristics explain the large number of positive reviews about this inverter.

The required value of welding current for the SAI-220 machine is set in accordance with the diameter of the electrode

In addition to the inverter of the specified model, its modification is presented on the market - Resanta SAI-220 PN. The difference between the Resanta SAI-220 PN inverter and the base model is that it allows welding to be carried out efficiently even at an even lower voltage - 140 V. In addition, the design of the Resanta SAI-220 PN has a digital indicator of the welding current, which makes work at more convenient. Naturally, the cost of the Reasant SAI-220 PN welding machine is slightly higher than the price of the basic inverter.

Front panel of the Resanta SAI-220 inverter with a digital display and a transparent protective shield

It is worth dwelling in more detail on such a remarkable parameter of the device in question as the on-time period (OP), or the period of continuous operation (LOP - load duration). As mentioned above, for the inverter in question it is 70% when operating at maximum welding current and 100% at current in the range of 10–140 A. This means that if you are going to weld at maximum current, then for a period equal to 10 minutes, you will need to take a break for 3 minutes, and the remaining 7 you can work quietly.

Such a break is necessary so that the electronic circuit of the device, the elements of which are intensely heated during the welding process, cools down. Otherwise, the device may automatically turn off if the thermal protection is triggered, or simply burn out. If you use a current whose strength is in the range of 10–140 A, then there is no need to interrupt the operation of the equipment.

Flaws

- The ground wire does not have a very good design;

- Despite the high power of the fan, the blades are made of fragile material;

- The adjustment scale that the Resanta SAI 220 inverter welding machine has does not display the correct current value;

- The knobs rotate too easily, making settings easy to change with careless movements.

Technical characteristics of the welding machine Resanta SAI 220

The main thing that welders pay attention to when choosing equipment is the operating parameters. Here they look like this:

| Parameter | Parameter value |

| Operating voltage is allowed within, V | 140-260 |

| No-load voltage, V | 80 |

| Arc voltage, V | 28 |

| Current control range during welding, A | 10-220 |

| Duration of continuous load for 10 minutes, % | 70% at 220 A |

| Maximum diameter of consumables, mm | 5 |

| Protection class | IP21 |

| Weight, kg | 5 |

Welding machine diagram

The need to know the circuit diagram of the device arises in cases where it requires repair. Without knowing the exact location of each part, intervention can only cause harm. The circuit diagram of the SAI 220 welding inverter is as follows:

Scheme of welding machine Resanta SAI 220

Device

This model contains the following elements:

- Radiator transistors, in the amount of several pieces, which occupy about 20-25% of the entire circuit;

- The output rectifier radiator is the largest one, which ensures the operation of the secondary rectifier;

- Primary rectifier – converts the current coming from the network;

- Secondary rectifier – converts the current coming from the inverter;

- Cooler – cooling system devices;

- Current sensor – showing current parameters;

- Soft start relay – serves for easy start of the device;

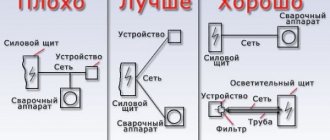

- Interference filter;

- Integral stabilizer - helps maintain parameters in one position, despite voltage surges.

Principle of operation

The design and operating principle of the welding inverter are interconnected. All processes occurring in the inverter are carried out in the following sequence:

- From the network, the current passes through the wires to the primary rectifier in the inverter. There it is converted from variable to constant.

- Next, the voltage decreases from standard 220 V to a lower value, which is set in the settings of the device itself. At this stage, the current turns back into alternating current. Its frequency increases significantly and it also becomes high-frequency.

- After this, electricity is supplied to the inverter transformer. Here the voltage again decreases to the state required at the output. This is required to increase the current strength, which affects the welding temperature.

- At the very end there is a secondary rectifier that converts the current to direct current. Here all the values already correspond to the specified parameters.

Resanta SAI-220 inverter circuits

Below are the electrical diagrams of the SAI-220 inverter welding machine. For ease of study, it is better to download the images to your computer in order to easily enlarge them to the desired size, since the sizes of some circuits will be too large for small monitors.

Electrical diagram No. 1 (click to enlarge)

Scheme No. 2

Scheme No. 3

Scheme No. 4

Advantages of using an inverter of this model

As with many models of modern inverter devices, this welding machine has a number of options that ensure high quality welded joints. Thanks to such options, a very important task is also solved - the influence of the welder’s qualifications on the quality of the joint being formed is minimized.

These options, which are familiar to many welders, include:

- automatic shutdown of the device if the elements of the circuit diagram overheat (this option is possible due to the presence of a special temperature sensor);

- “Hot start” is an option that ensures quick ignition of the welding arc due to the automatic supply of increased current to it;

- “Anti-sticking” is a function that automatically turns off the welding current at the moment when the tip of the electrode is welded to the surface of the parts;

- “Arc force” is an option that automatically increases the welding current when the arc length shortens and makes it possible to prevent sticking of the electrode.

The power of the device allows welding seams with electrodes up to 5 mm, but the current consumption is about 30 A

The welding inverter under consideration provides enhanced protection of the elements of the circuit diagram from overheating. This protection is provided by several design features:

- the presence of two fans at once, improving the cooling process of the device;

- high resistance of electronic circuits to overheating;

- the use of a temperature sensor that automatically turns off the equipment when it overheats.

The listed options are equally useful for both beginners and experienced welders, as they allow you to avoid many inverter malfunctions associated with overheating of the electronic filling, and also significantly expand the functionality and scope of use of the device.

The strong handle and fastened belt add convenience both when carrying the unit and during operation.

The indisputable advantages of the inverter of this model also include the following.

- The exceptional mobility of the inverter is ensured not only by its light weight, but also by the presence of a convenient shoulder strap, thanks to which the device can be carried to any place where welding needs to be carried out.

- The housing and other elements of the inverter are highly resistant to mechanical damage, which can be caused by impacts, falling or overturning of the equipment.

- The welding machine of this model is exceptionally compact (130x310x190 mm) and mobile.

- If desired, you can order an inverter package that includes a special suitcase with a handle, in which it is convenient to store and transport not only the device itself, but also all the necessary cables.

- The design of the inverter allows for its efficient operation even at fairly low ambient temperatures (down to –20). However, when welding at low temperatures, you should strictly monitor the heating and cooling conditions of the equipment.

The versatility of the Resanta model 202 inverter, ensured by its design features, is also a big plus. For example, this inverter can be used to connect parts made of different types of steel, including stainless steel.

Advantages and disadvantages

The SAIPA installation is worth purchasing for home use, as it is characterized by a large number of advantages:

- Thanks to the presence of the Hot Start function, an automatic supply of increased current to the welding arc is provided, which speeds up the process of its ignition.

- The device is characterized by the presence of an automatic shutdown function when overheating, which ensures its long service life.

- The installation has an Anti-stick function, thanks to which the welding current is automatically switched off during the period of welding the tip of the electrodes to the metal.

- The Arc Force function automatically increases the welding current as the arc decreases, so the electrodes do not stick.

Thanks to the presence of all the above functions, the possibility of inverter malfunctions is eliminated and its long service life is ensured.

Despite having many advantages, the installation has certain disadvantages. Reviews from device owners indicate that there is a high percentage of defects. That is why, when purchasing a device, it is recommended to check its functionality. If you work with metal with a thickness of more than 10 millimeters, the efficiency of the device decreases.

Disadvantages of the Resanta model 220 inverter

Many specialists and organizations involved in sales of welding equipment, judging by the reviews, complain that among the inverters of the model in question there is a fairly large percentage of defects. Thus, there is data according to which out of 10 Resanta model 202 welding machines, 1–2 are not completed until the end of the warranty period and fail.

Faulty parts causing overload

If you encounter a malfunction such as overheating of the inverter, you can fix it yourself or with the help of service specialists. Very often, overheating is associated with poor contacts between the elements of the electronic circuit and this problem can be eliminated by revising them. The situation is much more complicated when the electronic components of the inverter fail. In some cases, the cost of replacing such components can be comparable to the price of a new device.

The big disadvantage of inverters of this model is that the actual values of the welding current that they generate may diverge from the passport data by 15–20%. In most cases, this does not reduce the efficiency of using welding equipment, but nevertheless impairs its functionality.

Problems listed in the instructions for the welding machine

The Resanta model 202 inverter is not very effective when working with parts whose thickness exceeds 10 mm. In such cases (even using electrodes with a diameter of 5 mm), only surface melting of the metal is possible, and effective heating of the parts being connected does not occur over their entire thickness.

In general, reviews of the inverter of this model and the opinions of experienced specialists indicate that such a device is convenient and reliable in operation, and allows you to obtain high-quality and neat welded joints.

The ease of operation and maintenance of the device makes it easy to learn how to operate it, for which you can even use special videos. Of course, watching a video is best supported by theoretical knowledge that will help you thoroughly study the characteristics and capabilities of the equipment.

Welding machines for hire: varieties.

There are several types of these units. Transformer welding machines are quite heavy and of impressive size, but they are reliable and durable. They supply alternating or direct current through a transformer. Can be used when cutting ferrous and non-ferrous metals. A small inverter welding machine has been on the market in Krasnodar not so long ago. It works using electrodes and is little dependent on the input voltage. Used in professional activities, in cutting titanium, cast iron, stainless steel.

Semi-automatic welding machines are universal welding machines that work with inert gas. They will carry out high-quality welding of aluminum and iron. In most cases they are used at home. Generator welding machines are devices consisting of an engine running on gasoline or diesel fuel and an alternating current generator. These are indispensable assistants in welding various materials. At RosProkat23 you can rent any welding machine in Krasnodar at the lowest prices!

Reviews about the Resanta SAI-220 inverter from users

Reviews from those who have already evaluated it in practice, using it to perform welding work, say a lot about the quality and technical characteristics of the inverter of this model.

Sergey N. I use this welder for home work, in general there are no complaints, for not too thick metal it is the best option. It also handles thin stainless steel, which is nice. The convenient thing is that the device is lightweight and there are no problems carrying it around the site. Reliable, I accidentally dropped mine several times, nothing, it works. The wires in the kit are short - this is their problem, but this problem can be solved very easily with the help of an extension cord, for which it is better to use 1.5 wires and PVA. Overall, I’m happy with the device, I don’t know how it’s suitable for larger purposes, but it’s quite suitable for home use.

Ivan Sokolov had never done welding before, but when he bought a house, he realized that he had to learn. In your home and on your property, you always need to fix or weld something, but you don’t have enough money to call the experts with their own equipment. I spent a long time choosing which inverter was best to buy in order to quickly learn how to work with it; friends recommended the 220th Resanta. Of course, the first attempts to work on it did not make me very happy, the seams turned out so-so, and burns happened, but quickly enough everything began to work out. Its anti-sticking and fast arc ignition functions are very helpful when working on this machine for a novice welder. Now it’s been six months since I’ve been using this inverter, I’ve gained so much experience that even some neighbors started asking them to help when they need to weld something. In general, everyone is happy, especially me.

Vladimir, Tver I inherited this inverter from our disbanded construction team. For intensive use and for work on heavy and thick metal structures, it is better to choose a more serious welder. Although he never let us down at a construction site, sometimes it felt like he was working to the limit. But for the home - just right. I used this device for installing heating, and for making the frame of a greenhouse, and I installed a new fence with a gate - there are no complaints, with 3-4 electrodes it feels great, the arc does not go out, the electrode does not stick, the seams are of high quality. We are pleased with the compactness of this inverter, as well as its light weight, which is especially important if you have to constantly move it from place to place.

And finally, a short video that briefly but succinctly reveals the differences between the Resanta SAI-220 welding inverter with the PN attachment, designed for operation in a low-voltage network.

Modifications of SAI-220

Welding machine Resanta SAI-220

Resanta SAI 220 (Resanta 220A) is the penultimate model in the line of budget SAI inverters. Only the SAI-250 and the SAI-250PROF modification are more expensive. The Resanta SAI 220 device is intended for domestic use and welding using coated piece electrodes.

This inverter should not be taken as a professional welding machine. It is intended for study or simple repairs. But not for work in production or in a large repair shop. For such purposes, expensive powerful inverters like the LINCOLN ELECTRIC Invertec V350 PRO costing $10 thousand are usually used.

Let's return to the characteristics. The maximum declared current is 220 Amperes. In general, the names of inverters in the AIS line contain this characteristic right in the name. Hence “SAI 220”, which means “220 Amperes”. The device only needs 220V (+/- 20V) to operate. Plug in the inverter and you can start welding.

SAI 220 is very compact and lightweight. It can be hung on the shoulder using a belt and carried without any problems. This is really important if you have a large estate or have to travel long distances.