Methods of welding polymers and plastics

Welding of polymers and plastics involves heating the edges to be welded to a plastic, viscous-flow state and joining them under some pressure. The following welding methods are used:

Fig.1

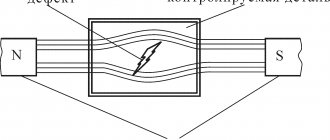

1. Welding with heated gas (Fig. 1). The welded edges of the part 4 and the filler material are heated to the welding temperature with a jet of hot air or gas. To heat the air (gas), electric heaters or gas burners 1 are used. The filler rod 2 is pressed into the weld groove 5; the heated layers of material stick together and the filler rod forms weld seam 3. When welding thick material, several heated filler rods are sequentially placed in the groove of the seam, as shown in Fig. 2.

Fig.2

Welding without beveled edges is used to join sheets less than 4 mm thick. For larger thicknesses, V- and X-shaped seam grooves are used at an angle of 60°. At the same time, X-shaped seams are more durable. During the welding process, as the surfaces of the welded edges and the filler rod soften, it is necessary to continuously press the rod into the base of the groove under slight but constant pressure. To obtain complete penetration, it is necessary to leave a gap of 0.4...0.5 mm at the root of the seam. When welding soft thermoplastics (polyethylene, etc.), the filler rod is inserted at an obtuse angle to ensure sufficient pressure on the edges being welded. When welding rigid thermoplastics (vinyl plastic, organic glass, etc.), the rod is inserted into the groove of the seam at almost an angle of 90° to the seam.

When welding, polyethylene and polystyrene are heated with hot gas or air to a temperature not higher than 160...180°. It is recommended to weld organic glass using a stream of air heated to 200...220°C. The filler material is rods with a cross-section of 7... 12 mm2. It is allowed to use welding rods made of vinyl plastic with a diameter of 3.0...5.0 mm. Viniplast is welded in a softened (viscous-flowing) state at a temperature of 220...240°C. The filler material is welding rods with a diameter of up to 5 mm made of plasticized vinyl plastic. The welding process is carried out by softening the rods and bonding them to the base material.

To weld materials with a thickness of 2...25 mm using this method, GGP-1-66 torches are used. The coolant is air mixed with combustion products of a propane-butane mixture. Burner weight: 0.6 kg. The GEP-1A-67 burner operates with electric heating of the coolant - gas (air, nitrogen, etc.). For this purpose, an electric spiral is installed in the path of gas movement in the burner body. Burner weight: 0.68 kg. The simplicity of the equipment and technology allows this method to be used for welding parts of any size and configuration.

It should be noted that polymers and plastics have a high coefficient of thermal expansion (4...6 times more than metals). This creates the risk of large internal stresses occurring in the weld, weakening the welded joint and causing warping of the parts being welded. To obtain a good weld, it is recommended to use a jet of heated gas with a small cross-section (jet diameter 3...5 mm), as well as various fixing devices.

2. Contact heating welding. With this method, the surfaces to be welded are heated using an electric heater; bring them to a viscous-flowing state; then the heating element is removed, and the surfaces to be welded are joined by compression. The films are overlapped, and the electric heater can be an electric iron or a special device with a roller or roller. This method welds films no more than 2 mm thick, since low thermal conductivity makes it difficult to heat plastics to the desired temperature.

This welding method is suitable for both soft and hard polymers and plastics. However, it requires a lot of time to heat up, adjust the temperature and cool the seam (under pressure) after welding.

3. Welding with high frequency currents. The parts to be welded are heated in a high-frequency electric field. After heating the edges to a plastic state, they are compressed to obtain a strong connection. This method is very economical and widely used in industry. High-frequency current welding of products made of polyvinyl chloride plastics is most widely used. For example, for welding vinyl plastic, currents with a frequency of 60...75 MHz are used. The thickness of the welded material is 0.5…2 mm; with a smaller thickness, the heat of the pressing electrodes is wasted. Welding productivity is 5... 10 times higher than the previously discussed methods.

For seam welding of films and tapes, welding machines LGS-02, MST-ZM, etc. are used. The material to be welded is rolled between two rotating electrode rollers, to which a high-frequency current is connected. Welding ensures a continuous, strong and airtight seam.

Lap joints can be welded without bevel and with edges beveled at an angle of 45°. Seam width 2…4 mm. Welding speed reaches 3 m/min.

4. Friction welding. The edges of the parts to be welded are heated to a plastic state by the heat released when the surfaces of these edges rub against each other. For welding, one part of the part is fixed in the chuck of a lathe or drilling machine and, after rotation, is pressed against the second part of the part, fixedly fixed in a special device. Since thermoplastics have poor thermal conductivity, the rubbing surfaces heat up quickly. The compression pressure, depending on the material, is 0.2…1 MPa.

Fig.3

This welding method does not require surface preparation, since film and dirt are displaced during welding. The advantage of this method is the speed of welding. In the friction zone, the temperature rises rapidly, ensuring instant welding, while the temperature of the material near the welding zone remains almost unchanged. However, this method can only weld parts such as bodies of rotation. In addition, the need to provide pressure for welding makes this method applicable only to rigid thermoplastics. In Fig. Figure 3 shows examples of welded joints made of solid (a) and hollow (b) materials.

5. Ultrasonic welding. Ultrasonic welding is the most versatile and promising method for welding polymers and plastics due to its wide technological capabilities. Local heat release in the welding zone and heating to a temperature close to the melting point eliminate overheating of the material observed with other methods. The design of the working tool (waveguide) allows welding in hard-to-reach places, and also makes it possible to obtain point, straight and closed welds of various contours (depending on the configuration of the working part of the waveguide). Welding is performed at frequencies of 17…45 kHz. Electrical vibrations generated by the generator using a transducer (magnetostrictive or piezoelectric) are converted into mechanical vibrations of the working tool (waveguide). The high-frequency mechanical vibrations that arise in the material are converted into heat, which is used to heat and weld the material.

In industry, the installation for semi-automatic welding UPSH-12 (with a generator GUF-28/40 with a power of 40 W, intended for welding synthetic fabrics with a thickness of 0...1 mm), UZAP-type equipment, etc. are used. For manual welding, RUSU-28 and RUSU-50

soedenimetall.ru

Other types of polymer welding

Extrusion welding. In this process, the welding material, preferably the same polymer as the part being welded, is fed into the welding area in molten form from a hand-held extruder. This small extruder or heated gun receives a continuous supply of filler material in the form of a rod from a coil.

Fig.3. Working with a manual extruder

Solvent welding. This method consists of a number of technological operations: wetting, a pause to wait for the polymer to swell, contact between surfaces, holding under load. This welding is used for polymers that are not resistant to solvents, usually amorphous thermoplastics.

Friction welding. A method that allows you to obtain a strong welded joint almost instantly and without much expense. Excellent for rotating bodies when connecting in a socket. Typically, one product is rigidly fixed, and the second is put on a mandrel, which is rotated by any drive. Then the second product is moved in the axial direction and connected to the fixed product in a socket. From the resulting friction energy, both parts melt, the rotation stops and the desired connection is formed in a matter of seconds.

Great Encyclopedia of Oil and Gas

Page 3

The mechanism of formation of welded joints when welding fluorine polymers, like other thermoplastics, depends on the welding temperature. At temperatures below the flow temperature of the polymer (when welding polymers such as fluoroplastic-4), the surfaces being welded are in a highly elastic state and the formation of welded joints is caused mainly by the diffusion of segments across the interface. The strength of welded joints in this case increases with increasing temperature and increasing welding duration. [31]

A stepped waveguide has the highest possible Ku, is easy to manufacture, but resonates in a narrow frequency range. Such waveguides are used in systems where a large amplitude of the welding tip is required, for example for welding polymers. In practice, it is rational to use it as the first stage of a two-half-wave concentrator. [32]

One of the main technological parameters of heated gas welding is the temperature of the gas stream at the exit from the heater tip. Air is most often used as a coolant gas, as it is the cheapest gas. When welding polymers (polyamides, polyethylene, polypropylene) subject to thermal-oxidative destruction, it is recommended to use inert gases such as nitrogen, argon, carbon dioxide. [34]

The difference in the melt index of the same materials practically affects the strength of their welded joint, since during the process of upsetting the joint during the rheological flow of such polymers, layers of materials with different melt viscosities will come into contact with each other. Materials with a low melt index have a lower melting rate Von than the same materials with a high melt index. In this regard, it is necessary to adjust the main parameters of the recommended polymer welding mode (temperature and pressure) taking into account their melt index. [35]

The discs are brought into contact, and pressure is applied to the stationary disc by means of a screw. In this case, a large amount of heat is released, the material melts from the surface and rapid welding occurs, not accompanied by a general heating of the plastic. Surfaces heated by friction are closed to air access, which is especially important when welding oxidizing polymers, such as polyethylene and polyamides. [36]

The installation for roller welding type LGS-02 consists of a lamp generator mounted in a separate cabinet and a welding machine with an adjustable electric drive. High frequency voltage is supplied to a working capacitor formed by two rollers, between which the polymer is welded. The drive roller is driven by a DC electric motor. [37]

Due to the low strength of polymer materials when crushed and sheared, threaded connections are excluded. Welded joints are not universal for polymer materials and can only be used for pipelines made of thermoplastics. However, with all welding methods there is a certain risk that can be avoided if it is clearly determined whether the developed polymer welding method guarantees the absence of residual stresses in the weld and in the adjacent areas. If it is necessary to guarantee reliable operation of a pipeline for 50 years, this issue becomes relevant when operating pipelines at an average temperature of 18 - 20 C, since the stress relaxation time at these temperatures for individual polymers ranges from one year to 50 years. [38]

However, both the amplitude and intensity of ferrite emitters are quite sufficient for their use in a variety of ultrasonic technological installations. The use of ferrite transducers is very promising in installations for the influence of ultrasound on galvanic processes, where an intensity of less than 1 W/cm2 is required and the corrosion resistance of ferrites is extremely useful. Ferrite emitters are proving to be quite suitable for a new, rapidly developing area of ultrasound application - ultrasonic welding. In installations for welding polymers, a tool vibration amplitude of 20 - 30 microns is required, and when welding elements of microelectronic technology, the tool amplitude is even smaller - about 5 - 10 microns. [39]

| Polymers are high molecular weight substances that consist of an infinite number of monomers (repeating structures). Various plastics are created on their basis. Today, polymers have taken pride of place in production and even in households. They are used almost everywhere: from water pipes to furniture. At the same time, they significantly reduce the cost of production and make the part much lighter in weight. Modern polymers can be in several physical states: glassy, viscous-flowing and highly elastic. Welding polymers involves heating the working surfaces to a viscous-fluid state and fusing them under pressure. Due to this, the polymers are mixed in the welding zone and the air is squeezed out. After cooling, a monolithic part is formed. However, there are polymers that are very difficult to weld or are completely incompatible with each other. For example, elastomers and thermosets cannot be welded at all, because... they do not melt with heat. It is also important to prepare the surfaces before starting work. The work area should be free of grease, outer plastic layer and any contaminants. In this case, cleaning must be carried out immediately before welding. To do this, use concentrated ethyl alcohol and any non-fibrous rags. The top plastic layer is removed with a special scraper. Cleanliness requirements also apply to the working tool itself. Welding of polymers is carried out in several ways: • Heated gas. In this case, the surfaces to be welded and the filler material itself are heated to the required welding temperature by supplying hot air or gas. The gas itself is heated by gas burners or electric heaters. The filler element is pressed into the weld groove. Sheets with a thickness of no more than 4 mm are welded without bevel of edges. During work, as the surfaces soften, the rod itself must be pressed under slight constant pressure into the base of the groove. • Welding with a heated tool. It is also called contact-thermal. This is one of the simplest methods for welding plastics and polymers. It is used for the manufacture of various containers, connecting pipes, various structures and even machine parts. Welding polymers in this case occurs in two stages: heating the surfaces with a tool and contacting them under a certain pressure. In this case, it is necessary to remove the heating tool in time to ensure optimal bond strength. • Extruder welding. This is welding with a special gun with a heater, through which a special filler rod is fed. At the same time, the temperature of this exiting composition should be 40-50 ºС. You can cook using both contact and non-contact methods. With the non-contact method, there is no need for additional pressure, because heat transfer is ensured directly from the tool itself to the parts being welded and heat losses are reduced. • Welding of polymers using special solvents. Typically this method is used to join parts made of amorphous thermoplastics. In this case, both surfaces are pressed against the sponge with a minimum amount of solvent. After swelling, they connect and remain under pressure for some time. To speed up drying and evaporation of the solvent, heating of the parts can be applied. The main disadvantage of this method is the particular harmfulness of the adhesives. Therefore, it is used only as a last resort. Polymers lend themselves well to welding. In addition, welding polymers does not require complex and expensive equipment, so it can be done even at home. |

| Orientation of fluoroplastic-4 in the workpiece. [40] |

Colloidal graphite expands negligibly at this temperature. The difference in thermal expansion of the two materials leads to the formation of cracks in the surface layer of colloidal graphite on each fluoroplastic-4 particle. In the presence of high pressure, the polymer is welded at the location of these cracks. [41]

Polymer materials are increasingly used in industry, construction and agriculture. The use of these materials reduces product weight, overall dimensions, operating costs and increases labor productivity. Due to the widespread use of polymers as structural materials, the problem of their connection has arisen. The industry uses several methods for welding polymers: coolants, ultrasound, infrared radiation, etc. Further work remains to improve methods for welding polymers and plastics. [42]

The issue of mutual solubility of polymers is closely related to the phenomenon of auto-adhesion, which plays an important role in the processes of their gluing, and to the welding of polymer materials. During gluing, the adhesive is applied in the form of a solution (almost all adhesives [10] are solutions of high molecular weight substances), and since polymer substrates are able to swell or dissolve in the adhesive solution, mutual diffusion of macromolecules from one phase to another occurs. As a result, the boundary between the phases disappears with the formation of a strong seam. This mutual diffusion of macromolecules is the essence of autoadhesion, which also manifests itself in the process of welding polymers. [43]

Polymer materials are increasingly used in industry, construction and agriculture. The use of these materials reduces product weight, overall dimensions, operating costs and increases labor productivity. Due to the widespread use of polymers as structural materials, the problem of their connection has arisen. The industry uses several methods for welding polymers: coolants, ultrasound, infrared radiation, etc. Further work remains to improve methods for welding polymers and plastics. [44]

The most important condition for ensuring the stability of the process of processing polymer masses (solutions, melts and plasticized polymers) is the absence of gas phase bubbles in them. If the latter appear during the manufacture of a polymer material or a product made from it, then it is necessary to eliminate the possibility of their release. If the pressure during processing is lower and the temperature is higher than when obtaining the polymer mass, or the processing temperature is higher than the boiling point of the volatile components contained in the polymer, then the melt or solution prepared for processing turns out to be supersaturated with dissolved gas. Such phenomena occur during the formation of films, fibers, rods from melts, plasticized polymers and solutions, during vacuum forming of products, during drying of polymer coatings, welding of polymers and in other processes of their processing. [45]

Pages: 1 2 3 4

www.ngpedia.ru

content .. 21 22 23Lecture No. 23.

Welding of plastics

23.1. Features of welding plastics.

According to their weldability, plastics, as already mentioned, can be divided into 2 groups: thermosetting, which are predominantly not weldable, and thermoplastic, which are easily welded.

Welding of plastics is the process of forming a permanent joint by bringing the surfaces to be joined to a viscous-flow state by applying pressure. As a result, the interface between the surfaces being joined partially or completely disappears, and the strength of the material at the joint, as well as other physical properties, are brought closer to the properties of the material being welded.

The process of welding thermoplastic materials is distinguished from the processes occurring during welding of metals by a number of features:

1) When welding plastics, a liquid bath does not form. This process can only occur under certain conditions. The main ones are: increased temperature at the welding site (temperature of the viscous-flow state of the material), the presence of close contact of the welded surfaces and a certain time for the process. Plastics are a large number of mutually dissolved polymers, built from the same units, but differing in molecular weight, so they do not have a pronounced melting point, and when heated, they gradually transform from a solid state to a highly elastic state and then to a viscous-flowing state when the material becomes sticky and individual parts under pressure can be firmly connected to each other, i.e. weld.

2) Thermoplastic masses begin to decompose at high temperatures. In this case, the degree of decomposition depends both on the temperature and on the duration of exposure to this temperature. Thus, when welding thermoplastics, heating of the material should be as short as possible, and the temperature should not exceed the decomposition temperature.

3) Plastics have a high coefficient of thermal expansion, several times greater than that of metals.

23.2. Physical basis of welding plastics.

Welding of polymer materials is carried out as a result of the ongoing mutual diffusion of polymer molecules in contacting surfaces or as a result of a chemical reaction of addition between the links of the molecules of the polymers being joined. Depending on the degree of ordering of individual sections of linear molecules, the polymer can be in a crystalline or amphoteric state.

In the process of welding crystalline polymers, as the polymer melts, the ordered decomposition of molecules in it is gradually disrupted and a transition from the crystalline phase to the amorphous phase begins. The temperature at which a polymer transitions from solid to liquid can be higher than the melting point of the crystalline phase in it and depends on the molecular weight of the polymer.

With a high molecular weight, a polymer heated above the melting point, having passed into the amorphous phase, still retains a solid state of aggregation and only with a further increase in temperature gradually transforms into a viscous-flow state.

The amorphous solid state of the polymer is characterized by a fixed but loose arrangement of macromolecules relative to each other and only limited mobility of the units. With increasing temperature, the energy of thermal motion of macromolecules increases. When this energy becomes sufficient to make the entire molecule flexible, the polymer enters a highly elastic state (glass transition temperature). The transition occurs gradually in the temperature range 15-25°C. In a highly elastic state, relatively small stresses cause the molecules to move and orient in the direction of the acting force. After the load is removed, the molecules gradually acquire a shape characteristic of the equilibrium state. With a further increase in temperature, the energy of thermal motion increases so much that the molecules acquire the ability to move relative to each other (viscous flow state).

The weldability of polymers due to diffusion is possible only in a zone allowing free movement of molecules, i.e. in the viscous-flow stage. The lower the temperature at which the polymer transitions to this stage and the higher its fluidity, the faster it is possible to achieve homogeneity of the material in the welded joint zone.

23.3. Basic methods of welding plastics.

Currently, a number of methods are used for welding plastics, carried out with and without heating the joint zone.

Methods for welding joints with heating, depending on the heating sources used, can be divided into 2 groups. The first group includes welding methods that use the energy of extraneous heat sources:

1) gas coolants;

2) extrudable additive;

3) heating elements.

In all of the above methods, heat is transferred to the plastic surfaces being welded due to convection, thermal conductivity and partial radiation.

The second group includes welding methods in which heat is generated inside the plastic by converting various types of energy. This uses energy:

1) high frequency currents;

2) ultrasonic vibrations;

3) friction;

4) infrared radiation;

5) chemical reactions;

6) laser radiation.

Solvent welding is performed without heating the joint area.

The classification of methods for welding plastics is shown in Fig. 23.1.

Rice. 23.1. Classification of plastic welding methods.

Welding with gas coolants is relatively simple and allows you to obtain a variety of products with minimal equipment costs. Heating of the welded edges is carried out due to heat transfer from the heated gas coming from the burner. Used in the manufacture of equipment for the chemical industry.

The extruded filler welding method gives good results both when welding films and when welding sheets of greater thickness. The method is based on supplying an additive in a viscous-flow state to the welding site.

Welding with a heated tool is used in the manufacture of pipes, packaging containers, covers and many other products. The heating source is heated bodies that transfer heat through direct contact with the plastic.

The high-frequency welding method is based on the ability of some plastics to heat up in a high-frequency electric field that occurs between electrodes, which simultaneously compress the surfaces being welded.

In friction welding, heating is carried out due to the heat generated in the process of friction of the welded surfaces when pressure is applied to them.

The ultrasonic welding method is based on the conversion of mechanical high-frequency vibrations excited in plastic into heat. The heat, which develops mainly on the surfaces being welded, softens the plastic and when pressure is applied, the parts are welded. Ultrasonic welding is especially suitable for welding products for which access to the joint is difficult, and the material being welded does not allow heating throughout the entire volume.

When welding plastics with infrared radiation, heating is carried out due to the heat source of infrared radiation obtained by incandescent quartz rod lamps and other sources. Used primarily for welding polymer films.

23.4. Chemical welding of plastics.

Chemical welding of plastics is used for welding thermosetting plastics (fiberglass, textolites, press powders, phenol-formaldehyde, epoxy, hardened polyester resins).

Chemical welding of plastics is carried out due to the chemical interaction of the materials being welded with a substance that is introduced into the weld, which in this case plays the role of a cross-linking additive. These substances react with active groups of molecular units located in the contact zone.

Figure 23.2. The mechanism of chemical welding of PET using diisocyanate.

The success of this welding method depends on many factors:

1) the polymer being welded must contain highly active functional groups of sufficient concentration so that the set of chemical bonds formed at the junction provides the necessary mechanical strength.

2) a low molecular weight substance acting as a bridge-forming substance should not evaporate at welding temperature.

3) the reaction rate must be high enough.

4) the reaction should not be accompanied by the release of a large amount of an easily evaporating by-product, which should not destroy the polymer or, by adsorbing in it, change its quality.

23.5. Welding plastics using solvents.

The essence of solvent welding of plastics is that the surfaces to be joined are wetted with solvent until they become sticky, then they are folded and held under pressure. Pressure facilitates the mutual diffusion of macromolecules in contacting surfaces at ordinary temperatures.

Solvent welding is used when the polymer is in an amorphous state (polymethyl methacrylate, polystyrene, polyvinyl chloride, etc.). Due to the flexibility of the molecules, continuously alternating intermolecular voids appear in them, in which the solvent diffuses. After filling the free spaces in the polymer, the solvent molecules begin to push the polymer molecules apart, making it easier for them to separate from each other. This stage of dissolution is called swelling. As soon as the intermolecular interaction decreases so much that the molecules become able to move, the second stage of dissolution begins - the diffusion of polymer molecules into the solvent.

Control questions:

What is the essence of the thermoplastic welding process?

What is the difference between the process of welding plastics and welding metals?

At what temperatures does the viscous flow state occur for most thermoplastics?

What methods are mainly used for welding plastics?

What is the essence of welding plastics with high frequency currents?

content .. 21 22 23

Welding of polymer materials

Many polymer materials, like metals, can be welded using gas welding. The welding technique is somewhat different from metal welding, since in this case there is no weld pool. That is, the plastic is heated not to a liquid state, but to a viscous-flowing state of the edges and filler material, in which they stick together, forming a welding seam. A characteristic feature of welding plastics is the fact that they are not processed with an open flame, like metals. The technology for welding plastic sheets is shown in Fig. 1. There are several methods for welding plastics, which differ from each other to a certain extent.

| Rice. 1. Welding plastic with heated gas with an additive: 1 - parts to be joined; 2 - filler rod; 3 - burner |

The most widely used method is heating the edges and filler material; hot gases. Hot gases are produced in special burners as a result of the combustion of flammable gas (for example, propane-butane) mixed with atmospheric air, or using electric spirals.

Welding is performed both with and without filler material. When welding without filler material, the edges of the parts being welded are heated to a viscous-sticky state and pressed together by pressure rollers. As a result, the edges stick together and, when cooled, form a welding seam. Welding with filler material is carried out in the following sequence. First, the edges of the parts are heated, and then the filler rod is placed between the edges with slight pressure. In this case, it is necessary to ensure that the heating of the edges and filler material is the same and sufficient for the plastic to transition to a viscous-fluid state.

Almost all types of plastics are subjected to hot gas welding, which, under the influence of elevated temperatures, become viscous and sticky. This can be vinyl plastic, from which pipelines and various containers for chemically aggressive substances are made, polyethylene, which is used in the manufacture of pipes, films and other products, and many other types of polymers. Each polymer has its own heat treatment modes, which are selected based on their characteristics. The material of the filler rod should be the same as in the edges being welded, but slightly more plasticized using various additives. Using this technique, one achieves a reduction in the temperature necessary to impart plasticity to the rod.

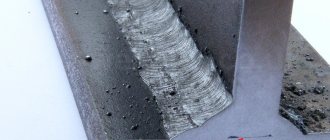

Plastics, like metals, are welded using butt corner and T joints. Options for cutting edges for these types of joints are shown in Fig. 2 and 3. To do this, the edges are thoroughly cleaned, degreased and processed mechanically at the desired angle. Depending on the thickness of the parts being welded and the edge cutting technique, the number of filler rods in the weld may vary. An approximate layout of filler rods when welding butt joints is shown in Fig. 4. The main parameters of butt joints made of vinyl plastic with heated gas are given in the table.

| Rice. 2. Edge cutting and welding of corner polymer joints |

| Rice. 3. Cutting edges of polymer T-joints |

| Rice. 4. The order of laying filler rods when welding butt joints, with V-shaped (A) and X-shaped edge preparation: 1 - 6 seam numbers (B) |

Vinyl plastic butt joints

| Thickness of welded edges | Diameter, mm | Cutting angle | Root weld gap | Number of stacked rods | Consumption of rods per 1m weld, G | Strength in relation to the base material, % | |

| Prutka | Tip holes | ||||||

| V-groove | |||||||

| 3-5 | 2,6 | 2,5 | 55-60 | 0,5-1,0 | 8-10 | 60-75 | 75 |

| 7-10 | 3,0 | 3,0 | 60-65 | 1,0-1,2 | 10-14 | 100-140 | 75 |

| 12-15 | 3,0 | 3,0 | 70 | 1,0-1,5 | 20-28 | 200-280 | 75 |

| 17-20 | 3,5 | 4,0 | 75-90 | 1,5 | 32-42 | 495-650 | 75 |

| X-shaped edge groove | |||||||

| 3-5 | 2,6 | 2,5 | 45-50 | — | 6-8 | 45-60 | 83 |

| 7-10 | 2,6 | 2,5 | 50 | — | 8-12 | 60-90 | 85 |

| 12-15 | 3,0 | 3,0 | 55-60 | — | 16-12 | 160-220 | 85 |

| 17-20 | 3,0 | 3,0 | 60-70 | — | 24-35 | 240-350 | 85 |

build.novosibdom.ru

Welding with a heated tool

» Articles » Welding with a heated tool

The welding method with heated tools (see Table 24) has several methods that differ in equipment and heating circuit. In order for heated surfaces to cool less when welding with a hot blade, the time from the moment the heater is removed until the surfaces are compressed should be minimal.