The great popularity enjoyed by the welding machine model Resanta SAI-160 among home craftsmen is explained by the high reliability of this equipment, as well as the ease of its operation and maintenance. Thanks to this, even a person without special training can use such welding equipment. The fact that using this inverter is very simple and convenient is also evidenced by the reviews of those who have already purchased it.

Appearance of the Resanta SAI-160 inverter

Advantages of Resant SAI-160

The compact dimensions and light weight of the inverter model Resanta SAI-160 are explained by the thoughtfulness of its design, where there is nothing superfluous. Such characteristics allow this equipment to be used as a mobile device that is easy and convenient to carry when performing welding work over a large area.

The welding inverter model SAI-160, in addition to its compact dimensions and low weight, has enviable technical characteristics. The modes on such a device are set very simply and are distinguished by their stability during the welding process. In addition, the device is characterized by a wide range of adjustment of operating parameters, which makes it possible for people who have low qualifications or have never even encountered the need to perform welding operations to successfully work on it.

Possible problems and troubleshooting

The Resanta SAI-160 model is convenient to use as a training device, on which you can easily and quickly learn the basics of the welding profession. The process of such training, as well as work on the inverter of this model, is simplified by two options that it has:

- facilitating the process of igniting the welding arc (“Hot start”);

- minimizing the risk of electrode sticking during the welding process.

This inverter has another remarkable advantage: high efficiency. Thanks to this characteristic, the use of this device allows you to significantly save energy.

It is very important that even a weak electrical network can withstand the maximum power that this equipment can generate. In addition, such an inverter can also operate from a mobile generator.

General description of the model

One of the undoubted advantages of the Resanta SAI 160 inverter welding machines is a wide range of current strength. At the same time, the wizard can set the required value manually. Thanks to this feature of the device, it can be used both for delicate welding using thin electrodes and, for example, for cutting thick metal.

The housing of the Resanta 160 welding machine is equipped with fans. These elements perfectly complement the natural air cooling of the device. If desired, models 160 can be used in low power networks. It is also possible to connect them through generators.

Of course, this model has all the functions that distinguish modern inverters from previously produced less advanced and convenient devices:

- preventing sticking;

- hot start.

If the electrode sticks to the surface being welded, the current in the machine automatically decreases. And this, in turn, reduces heating. As a result, the electrode easily comes off the metal.

At the very beginning of operation of the Resanta 160 inverter, the current increases sharply. This leads to rapid heating in the place where the electrode contacts the metal surface. Therefore, a welder using this equipment never has problems with electrode sticking at the beginning of work.

Specifications

The Resanta inverter model SAI-160 has the following technical characteristics.

- The maximum current consumption is 22 A.

- The voltage required for the device to operate is 220 V. The inverter of this model is capable of operating stably with voltage surges from -30 to +10 percent. With even more significant voltage drops, a modernized model of this device - Resanta SAI-160 PN - can operate.

- The duration of time under load at the maximum value of the welding current is 70 percent for this device.

- The welding current can be adjusted in the range of 10–160 A.

- The voltage when the welding arc is burning and when the equipment is idling is 26 and 80 V, respectively.

- Equipment weight - 4.5 kg.

Technical characteristics of Resanta inverters, including SAI-160

Protection class SAI-160 according to the international classification is IP21; for working on such equipment it is allowed to use electrodes whose diameter does not exceed 4 mm. Operating this inverter, as indicated in its data sheet, is permitted at ambient temperatures from -10 to +40 degrees.

As is clear from the characteristics of the equipment of this model, it is preferable to use it for semi-professional welding work; its properties will not be enough for use in industrial conditions.

Compact Resanta SAI-160K

Cheap model from the Resanta-160 line. The K in the name means “compact”. This is an advantage of the device for those who often need to travel to the welding site, including by public transport. You can’t easily take previous models with you.

The inverter weighs three kilograms, and SAI-160 weighs 4. It is so small that it can be carried in a backpack without purchasing a special bag. This is relevant for those who are just starting to learn how to cook and often make house calls.

The dimensions of the device are what distinguishes this model from others; in other characteristics it is completely similar to them.

It requires electrodes with a diameter of no more than four millimeters. This is enough to weld pipes. SAI-160 operates from the home network and can withstand voltage drops down to 10 V.

Principle of operation

The neat and compact body of this equipment is made of metal; on its front panel there are power connectors to which welding cables are connected. In addition, on the front panel there is a knob for adjusting the current strength, as well as two indicators: “Network” and “Overheat”. To ensure forced ventilation of the internal elements of the inverter, there are special openings in its housing, which in no case should be blocked to prevent overheating.

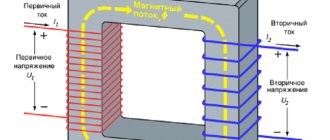

The operation of the inverter is ensured by its electrical circuit, in which several transformations of the electric current coming from the regular network occur. First, the alternating current supplied to such a circuit is converted into direct current, which also happens to the voltage. Then, in the second stage, both voltage and current again turn into variables, but their frequency increases significantly (current - from 20 to 50 kHz). Reducing the voltage, which also occurs in the second stage, makes it possible to obtain a high-frequency welding current of the required strength.

Resanta SAI-160 PN - inverter version for reduced network voltage

Who releases

is a Latvian company SIA RESANTA. This company began its activities in 1993. Initially, it was engaged only in the production of voltage stabilizers. These company products are also well known throughout the former USSR.

The quality of the devices is really quite good. And therefore it has always enjoyed enormous popularity among consumers. Thanks to this, by 2008 the company was able to increase its production volumes 10 times compared to 1993.

Today, in addition to voltage stabilizers, the company produces compressors, multimeters, thermal equipment, testers, etc. And of course, this company also supplies high-quality inverters to the market.

Correct connection of the inverter

Connecting the inverter of this model and fully preparing it for operation is not particularly difficult. This is evidenced by the reviews of its owners. Depending on what electrodes you are going to work with and what welding work to perform, you select a scheme (direct or reverse) for connecting the cable with a holder and a grounding cable. These cables are connected to the power terminals located on the front of the device. After connecting the cables, check whether the power switch is turned off, only after that the inverter is connected to the electrical network using a socket.

The cost of SAI-160 on the company’s official website is 7,300 rubles

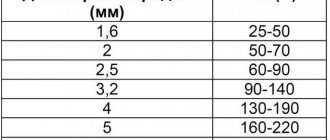

Before pressing the power switch, you must set the welding current regulator to the minimum value and move the power switch to the “On” position. After turning on the device, you can already set the welding current to the required value. In this regard, you can be guided by the following recommended values: when welding with electrodes with a maximum permissible diameter of 4 mm, choose a maximum current of 160 A, when welding with electrodes Ø 3.2 mm - 140 A, and so on.

Turning off the machine after completing welding work is performed in the reverse order: turn the current regulator to its minimum value, turn the power switch to the “Off” position, disconnect the inverter from the electrical network, and disconnect the power cables.

It is very important to adhere to exactly this algorithm for turning on and off the equipment: this will allow you to keep it in working condition for a long time.

Reviews

Alexey N. An excellent compact inverter, ideal for small household work. Already helped out many times. I often need it for small jobs, to weld something somewhere. Previously, I constantly ran in search of welders, who then had to pay at least a little, and also had to wait forever for them when they had time. Now I do it all myself. Easy to use. Of the minuses: the wires are a bit short.

Vladimir Tver At first I was afraid to buy, I thought that I wouldn’t be able to cook properly myself. But after a short practice on improvised hardware, it became clear that there is nothing overly complicated in working with such inverters. My verdict: SAI-160 is a good device for the home handyman.

Ivan 34 For your money - an excellent option. I spent it once, but then saved on welders, and in the end it was a clear plus, although I can’t say that I use it very often. It is not suitable for serious work; it will heat up quickly and will take a long time to cool down afterwards. If you have a private house or cottage and want to do something there, there is often a need to “grab it here, weld it there,” as a result, welding is needed infrequently, but regularly. This is where your own welder helps.

Sergey, Rostov If you don’t expect any significant performance from this model and don’t try to weld thick sheets of steel using it on a conveyor production line, then most likely the SAI-160 will not disappoint. A normal device for this price. All the shortcomings stem from the fact that some owners want from this inverter something that it was not originally designed for, or simply use it incorrectly.

Mains voltage and electrode diameter

The technical characteristics of the welding machine "Resanta 160" are really quite good. The ease of use, and therefore the popularity among consumers of this model, is explained, of course, primarily by the thoughtfulness of its design. In everyday life, the use of 160 devices became possible due to the fact that they operate from a 220 V network. For industrial equipment of this type, as is known, 380 V is required. Previously produced welding machines were designed to operate from precisely such networks.

The maximum current of this model, as can be judged by its name, is 160 A (with a minimum of 10 A). If necessary, welding can be performed with the Resanata 160 machine using fairly thick electrodes. The maximum diameter of the latter for this model is 4 mm. The minimum electrode diameter for the device is 1.6 mm.

Open circuit voltage

This figure for the model is 85 V. This figure, in comparison with many other modern devices, is quite large. This no-load voltage makes it very easy to ignite the arc in Resanta 160 devices. However, at the same time, the high value of 85 V, unfortunately, somewhat reduces the safety of use (discharge from accidental contact can cause harm to health) of this equipment. However, model 160, like most other modern ones, is equipped with a special function of protection against electric shock to the master.

Reviews about the model

The opinion of consumers on the Resanta 160 welding machines, as already mentioned, is simply excellent. The undoubted advantages of this model include, of course, the ability to work at unstable or low voltage, as well as compactness and low weight. Another advantage of this inverter is its relatively low cost. The price for Resanta 160 devices is approximately 7,000 rubles. That is, this equipment costs much less than much other similar modern equipment.

The 160 inverter rarely requires repairs. The equipment is quite reliable and durable. However, if it breaks, it will not be particularly difficult to repair it. Service points specializing in this brand are available in many cities of the country.

Thus, this model has many advantages. This is a really good welding machine. But this inverter, of course, according to consumers, also has some disadvantages. Masters include, first of all, as already mentioned, short cables. Also, some consumers note the fact that defects are sometimes found in batches of Resanta 160. In this case, the device must be repaired or replaced with a new one.