A resident or owner of a country house must have a good welding inverter. Without it, you can’t repair a car, you can’t put up a fence, you can’t weld an arch for grapes or a trailed implement for cultivating a plot. Before purchasing, a problem arises: you need to decide which inverter to choose for your home, when preference should be given to arc welding, and when to argon welding, what parameters should be taken into account? We’ll tell you everything in order, and don’t forget to mention reliable manufacturers.

When choosing a welding inverter, you need to know the basic rule - the current value affects the maximum diameter of the electrode , in turn, the diameter of the electrode affects the maximum thickness of the material being welded (axiom for manual arc welding). For example, for a profile with a thickness of 3-4 mm, it is necessary to use an electrode D = 3 mm, and the current strength should be 80-130A. The relationship is direct: the smaller the electrode, the less current . Amps, in turn, affect the power of the inverter. Our rating has selected the best inverters with electrodes with a diameter of up to 5 mm for manual arc welding. In addition, the best semi-automatic and universal welding inverters (TIG, MIG/MAG, MMA) have been identified.

Go straight to the rating of inverters =>

For novice welders , inverters are the best choice, since these devices have very useful functions on board that facilitate the welding process: forced arc, hot start, anti-sticking. In addition, be sure to use a protective mask, overalls and gloves (gaiters).

Based on the fact that welding machines were selected for household needs in the TOP manufacturers, we did not include the famous brands EWM, Kemppi due to the very high price, although these companies are certainly leaders in the production of welding equipment.

Semi-automatic inverters

4. In 1st place among semi-automatic devices and in 4th place in the overall rating is the device of the Russian-Chinese assembly Aurora OVERMAN 180. This equipment is widely used in our country and enjoys considerable success.

With a maximum current of 175 A (power consumption of only 4.7 kW), the semi-automatic machine shows excellent welding properties for both thick and thin metal. The presence of manual adjustment of inductance allows you to perform work with maximum accuracy.

The only thing that spoils the positive impression is the inability to adjust the wire drawing speed.

5. Svarog EASY MIG 160 (N219), characterized by high reliability, is widely used in private workshops. Both regular and flux-cored wire are suitable for the job, and even a beginner can make a good weld.

With all its positive qualities, the high cost of the inverter does not allow it to rise above 5th place in the rating.

6. Elitech IC 190P performs high-quality work even with severe voltage drops (up to 160V). Providing a current of 150 A, the device has an enviable useful time coefficient of 80% and extremely low power consumption, not exceeding 4.2 kW. Very easy to use.

But the standard sleeve supplied in the kit is quite short, and due to the design features, long-term work with millimeter wire is impossible. Well-deserved 6th place out of 10.

The best inverters for manual MMA welding

This section presents inverter machines for the simplest type of welding - coated electrodes.

Eurolux IWM190 - budget option

4.9

★★★★★ editorial assessment

89% of buyers recommend this product

See review

One of the most inexpensive inverters provides comfortable welding work due to its light weight (3.7 kg), wide current range from 10 to 190 A and Hot Start function.

The device can operate without loss of efficiency with an input voltage from 140 to 260 V. The permissible diameter of the electrodes is 1.6-5 mm. The front panel of the device contains a current regulator and indicators of the current state of the inverter.

Advantages:

- Overload protection;

- Wide range of welding currents;

- High duty cycle coefficient 70% at maximum;

- Arc Force;

- The cost is slightly higher than 4 thousand rubles.

Flaws:

- Short complete cables (2 and 1.5 m);

- Demanding on the quality of electrodes.

Eurolux is an entry-level inverter for small volumes of welding work. It will be an excellent assistant for a summer resident and will be useful in a private home and garage.

Fubag IQ200 – compact and powerful model

4.8

★★★★★ editorial assessment

88% of buyers recommend this product

See review

A new product in the range of welding inverters from a German manufacturer is suitable for most household welding work. The device has a wide current adjustment range from 20 to 200 A, has a built-in cooling system and overload protection.

It’s nice to see a full range of useful functions in a “home” inverter: afterburner, anti-sticking, hot start. Thanks to them, you can comfortably work with any 1.6-5 mm electrodes.

Advantages:

- Good set of functions;

- Compact and lightweight (3 kg);

- Stable operation at low input voltage from 150 V;

- High efficiency due to the use of IGBT transistors.

Flaws:

- Relatively low PV coefficient of 40%;

- You cannot approach the current regulator with work gloves.

Thanks to its good functionality and honest characteristics, the IQ200 can be recommended to both professionals and beginners. But the device itself is designed only for short-term work with long breaks.

Resanta SAI-220 – the most functional of the “handbrake”

4.7

★★★★★ editorial assessment

87% of buyers recommend this product

See review

Resanta MMA inverters can be called the best in terms of price, functionality and quality.

Hot start, anti-sticking of the electrode and an increased threshold value of the welding current of 220 A allow you to make high-quality seams and metal cutting. At the same time, long-term continuous operation remains possible, and arc stability is maintained even at low input voltage.

Resanta SAI-220 is the simplest model in the line and is only suitable for learning welding. But it has a compact analogue 220K, differing only in smaller dimensions and weight, as well as a more advanced variation labeled “PN”.

This device already has a display with large and bright numbers, and its settings will be easier to understand.

Advantages:

- Sturdy case with IP21 protection;

- Wide range of current settings (from 10 A);

- Stable operation at a voltage of 140 V;

- High PV – 70%.

- Case included.

Flaws:

- Lack of afterburner function;

- Does not tolerate hypothermia well.

Resanta SAI-220 is suitable for both novice welders and experienced welders - just choose the appropriate modification.

Spark MIG-305SP – 2-in-1 hybrid

4.6

★★★★★ editorial assessment

86% of buyers recommend this product

The features of this unit are its relatively low power (6.4 kW), as well as separate adjustment of arc voltage and welding current within the range of 20-305 A, which is very atypical for models in the budget price category. And most importantly, we have a full-fledged semi-automatic hybrid with the possibility of manual welding.

The manufacturer decided to save money on additional functionality. Iskra received only the essentials for solving standard tasks: a quick wire threading button, an overload indication and the ability to change polarity in semi-automatic mode.

Advantages:

- Ability to work without a gas environment in MMA mode;

- Rich equipment including a shield and knee pads;

- Continuous operation – 60%;

- Low cost for a semi-automatic machine.

Flaws:

Lack of quick release torch connection.

“Iskra” is a simple but reliable inverter that is suitable for occasional use in the country or in the garage. Moreover, it can be used both as a semi-automatic MIG and as a regular MMA device.

Torus 200c Super

Moskovskaya produces truly reliable welding machines. They are widely known among professional and novice welders because they work even with the most careless operation and are inexpensive. This model costs only $270 and will not give you headaches even after the warranty period. The semi-automatic 200c Super produces 200A and allows you to work with electrodes up to 5 mm in diameter. The minimum current value is 20A, which will allow you to work with the thinnest metals.

Many devices are certified by NAKS, confirming the decent quality of the products. Weld seams are smooth and strong even for a novice welder. This is due to an improved microprocessor circuit that generates current. Even with a strong voltage drop, you can continue welding at the same set parameters without loss of quality.

It is very easy to light an arc using this model. It is stable and can be conveniently operated both in gas welding mode and using an electrode. The only drawback: devices with NAKS certification are more expensive than devices without certification, but the difference in price is insignificant.

The best machines for manual arc welding from Aliexpress

Arc welding is designed to work with predominantly thick metals; thin sheet materials begin to melt upon contact with the electrode. The main advantage of such a device is the ability to qualitatively weld the joints of channels, angles, rails and other things. They are usually used to create highly loaded structures. The best in their niche are 4 models.

Deko DKA-200Y 200A 4.1 KVA

I really liked the compact device (238x109x163 mm) Deko DKA-200Y 200A 4.1 KVA. The device is pleasant to work with thin metals, which is facilitated by a successful power regulator with the correct information on the screen. I can almost with my eyes closed make a smooth, even and clean seam on car doors, pillars or roofs. High quality is confirmed by over 900 highest possible ratings in the Aliexpress store.

Advantages:

- Weighs only 3 kg;

- Cooks under constant current;

- The kit includes a holder and a ground cable with a clamp;

- The screen correctly displays the actual current values;

- Possibility of welding with reverse polarity;

- Rated output power 4.1 kW.

Flaws:

- Low PV – 60%;

- The ground cable is not the best quality.

It is reasonable to take Deko DKA-200Y 200A 4.1 KVA only for welding thin metals, and it does its job perfectly. With this device, an experienced welder can perfectly weld a 1 mm seam without damaging the workpiece.

Forgelo 2 in 1 ARC/TIG IGBT 220V 250A MMA

The semi-professional welding machine on Aliexpress 2 in 1 ARC/TIG IGBT MMA is interesting because it allows you to switch between arc and argon types of work. Advanced IGBT inverter technology ensures a stable arc and long-lasting welding capability. The hot start function reduces the number of stickings after the device starts. Thanks to its high power (maximum 7 kW), this model is suitable for high-quality welding of even thick metals (up to 8 mm). The ability to adjust the current from 10 to 250 A allows you to create a neat arc, including on very thin products.

Advantages:

- Color display;

- Possibility of separate adjustment of power and current;

- 2 in 1 design: for argon and arc welding;

- IP21 moisture protection technology and insulation class F;

- High idle voltage (59 V), allowing the electrode to heat up faster.

Flaws:

You will have to purchase an additional power plug and ground holder yourself.

I got a double impression about the 2 in 1 ARC/TIG IGBT MMA welding machine. On the one hand, the tool is really good and worth the money, on the other hand, there are often cases when the declared values in the device do not correspond to reality, so after receiving the device it is worth checking everything carefully.

Yeswelder ARC-200 220V MMA

Inexpensive and productive welding Yeswelder ARC-200 is suitable for installing all popular electrodes: 7018, 6010, 6014. The easy arc start system allows you to create seams of various diameters and sizes without the need to frequently stop the process, even at a maximum current of 200 A. Duration of activation of the tool the standard is 60%, and for compact devices this is a good value. This model is distinguished by the presence of smart mode switches; it is not necessary to set the current manually; you can set the thickness of the electrode and metal; the device itself will select the appropriate characteristics.

Advantages:

- Ease of creating seams;

- The kit includes a ground cable, an electrode holder and a metal brush;

- Easy to start welding with no-load voltage 63 V;

- High-quality power board design and reliable soldering;

- Long power cord.

Flaws:

- Low maximum current – 200 A;

- Cooler noise during operation.

Which welding inverter is better to choose?

Welding inverters have good efficiency and allow you to save on scarce electrical materials. They also differ in that they have mode adjustment over a wide range. Values can range from a few amps to values in the hundreds and thousands. The welding process is carried out using coated conductors. When choosing, the welding method and the stability of the arc ignition are selected. To expand the scope of application, it is worth choosing models that allow you to join difficult-to-weld steels and alloys.

Inverter devices have a more substantial price than transformer devices, but are used without problems to solve a huge number of problems. When choosing, focus on the static current-voltage characteristic; the functionality of the device depends on it. Universal machines allow operation in different modes and have an extended input voltage range.

When choosing, pay attention to the class, where each one corresponds to certain tasks, quality, volume and productivity. Sometimes a welder's mask and shield are included.

SavingsFavoritesDelete 4

Back

15 best hair straighteners (flat irons) – 2021 rating

MORE

MMA manual arc welding machines

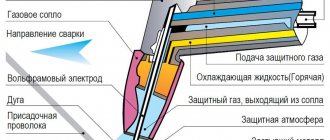

Manual Metal Arc technology is traditional; it involves the use of flux-coated electrodes. The essence of the welding process:

- the power supplied from the mains changes in the converter: the voltage decreases, the current increases;

- the electrical circuit is created by attaching contacts to the workpiece to be welded and the electrode (current is supplied to the holder);

- when the circuit is closed, an electric arc is created, it heats the metal to the required temperature, and a weld pool is formed;

- the electrode rod, melting, forms a seam;

- flux or coating creates a protective “coat” that protects the hot metal from corrosion (slag).

Direct and alternating current are suitable for manual MMA welding. The length of the arc depends on the type of electrode, the quality of the seam depends on the length of the arc. When working with direct current, the contacts are connected using direct or reverse polarity; for alternating current this is not important. When choosing an electric welding machine, this must be taken into account.

Beginners learn to weld metal using MMA technology.

Welding transformers

These are the most traditional and simple high-power devices for welding ferrous metals. They convert the AC voltage supplied from the mains to the parameters required for the welding process. The current is adjusted by moving one winding relative to the other. The disadvantages of transformers are:

- heavy weight, on average 16 kg - windings are made of copper busbars;

- dimensions;

- it is more difficult to maintain constant heating of the electrode;

- large splashing in the bath area;

- sensitivity to voltage drops in the network;

- poor seam quality.

Advantages:

- affordable price;

- durability, designed for a large number of electric weldings.

Welding transformer

Welding inverters

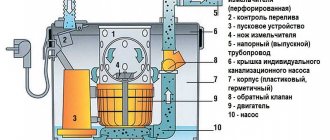

Semiconductor current converter of a new generation. The inverter consists of a transformer, a rectifier and a frequency converter. Equipped with a microprocessor - semiconductor control with a large adjustment range.

Main characteristics of inverters:

- the type of current at the output is of two types, constant is designated DC (Direct current), alternating AC (alternating current);

- starting current is the main parameter for selecting electrodes;

- current change interval;

- range of electrodes with a diameter of up to 5 mm;

- the voltage in the network to which the inverter is connected is 380 or 220 volts;

- open circuit voltage characterizes the speed of ignition of the electrode.

The dimensions of the inverter are proportional to the strength of the converted current; small devices cannot be considered universal; they are not suitable for welding thick-walled elements.

Inverters are suitable for welding low-carbon and alloy steels, non-ferrous metals. Electrodes of all types are used with them; the inverter apparatus has high efficiency.

Welding inverter

Welding rectifiers

Essentially it is a transformer, supplemented with a diode converter of alternating current to direct current. The capabilities of the rectifier are wider than those of the transformer; it is suitable for welding black metal, alloyed stainless steel, aluminum and non-ferrous metals. The straightener allows you to make a high-quality seam; it is more convenient for beginners to use: direct current produces less spatter and reduces the risk of electrode fading.

Which is better: transformer or inverter

When choosing a device for home use, they are guided by a number of parameters.

Advantages of inverters:

- inverter weight within 4 kg;

- small dimensions, several times smaller than those of transformers;

- high-quality seam due to automatic adjustment of current strength;

- does not overload the power grid;

- has additional functions;

- versatility - inverters are suitable for any metal.

The inverter can be damaged by condensation; it must be periodically cleaned of dirt and dust.

Advantages of transformers:

- strength;

- reliability;

- simplicity of design.

The disadvantage is that it is heavy and difficult to transport alone.

Now it is easier to determine what is better for domestic purposes: an inverter or a transformer.

What to look for when choosing a welding inverter

The inverter type welding device is divided into:

- for industrial purposes;

- performing professional tasks;

- solving everyday problems.

The first type is intended for continuous use throughout the day. Such a device has a significant price, can withstand significant loads, and allows you to weld massive metal structures.

The second type is relevant for repairing pipes and metal frames. It is used by professionals, but in a situation where it is possible to give the device a rest. The current reaches 200-300 A. These often include universal inverters, suitable for solving several problems at once.

The household option is ideal for welding small areas; it requires periodic breaks to prevent overheating. Such inverters are ideal for small-volume and rare repairs and have an affordable price. In them, the welding current is almost always below 200 A.

When purchasing a welding inverter, emphasis is placed on the following indicators:

- availability of modes;

- welding current;

- open circuit voltage;

- time of continuous activity;

- diameter of conductors;

- thickness of metal elements;

- dimensions and weight.

One of the important parameters before purchasing is the welding current adjustment range. To solve household and economic problems you need 16-200 amperes. The indicator depends on the thickness of the workpieces used and the diameter of the conductor. Therefore, this indicator must be adjusted.

The simplicity and stability of the arc is affected by the voltage between the two terminals of the electrical circuit. Beginners should focus on models with 60-90 V data; masters will need a device with a wider range.

Duration of activation is another important parameter. If switched on continuously and at high currents, the unit may overheat. In this situation, it usually turns off to cool down further. For example, with a duty cycle of 30%, keeping the arc at maximum current is permissible for 3 minutes out of 10. The device will need to rest for the remaining seven minutes.

Some inverters have additional protection against dust and moisture. The protection class is often IP21, less often IP23, but in any case, welding in the rain is not recommended. Metal dust is also dangerous, so you should not turn on the angle grinder near a functioning inverter.

back to menu ↑

Fast and Furious-161

Photo: https://beru.ru

The welding inverter produced by the Ryazan Instrument Plant, although it does not impress with the declared characteristics or ultra-modern design, will give the professional exactly what he needs - reliability and accuracy of the formation of the current-voltage characteristic of the welding current in the MMA and TIG modes. In both cases, the maximum welding current is 160A, but continuous operation is possible with a current of no more than 100A. Consequently, this inverter is most suitable for working with fairly thin metal that does not require deep penetration at high current. Among the advantages of the device is the ability to work with strong voltage drops - the manufacturer’s declared performance at 140V in a socket is perfectly confirmed in practice. A “soft” arc is easy to ignite and burns without much metal spattering. The automatic fan control used in the inverter based on a signal from a temperature sensor significantly reduces the amount of dust sucked into the housing, accordingly making the need to clean the output stage radiators less frequent.

Welding machine 161 (TIG, MMA)

Advantages:

- stability of characteristics during voltage sags

- high reliability

- automatic activation of “anti-stick” is convenient for novice welders

Features of Russian-made inverters

The first reason why domestic inverters have stable popularity is their reliability, due to a more thoughtful design .

First of all, this applies to the most loaded node of the inverter - the output stage of the converter.

The figure below is a schematic diagram of the power part of a typical Chinese inverter:

This is the simplest circuit of a pulse converter, where there is only one transistor switch in each arm. Its failure means a sharp loss of converter power - it will no longer be possible to cook with such an inverter. The circuit shown uses IRF830 field-effect transistors with a typical drain-to-source resistance (on-state resistance) of 0.83 ohms. At high currents, this will lead to a noticeable loss of power due to heating of the transistor, and during prolonged operation - to its overheating. Their current reserve is also small: the low rated continuous current forces the manufacturer to reduce the arc voltage, hence problems when igniting and working with contaminated parts (in this case, 160 A in the secondary circuit of the converter can only be obtained by significantly reducing the voltage).

The best semi-automatic welding (MIG/MAG)

Welding equipment of this group is distinguished by more substantial dimensions compared to manual arc welding machines. However, they have advantages in performance and can weld non-ferrous and ferrous metal products of different thicknesses. This type also positively characterizes the high-quality seam formed during welding and the ability to work with thin metals. Semi-automatic machines are actively used in the repair of various equipment, including car body parts.

RESANTA SAIPA-165

The device from Latvian manufacturers has a power of 6.6 kW. The diameter of the wire used in the work is 0.6-0.9 mm, the maximum possible current: 160 A, operating voltage: 26 V. Device weight: 11.5 kg, packaged dimensions: 531x289x389 mm.

Advantages of the welding machine:

- Easy setup.

- Reliable connection of cables and device eliminates current losses.

- Automatic blocking against overheating.

- Convenient handle for transportation.

- A durable metal case protects the product from possible mechanical shocks.

Disadvantages of the welding machine:

- Short burner cord.

- Increased sensitivity of the regulators, they move at the slightest touch.

- Problem with spare parts.

Aurora OVERMAN 180

The production of equipment at Chinese enterprises will now surprise no one. This allows the brand owner to declare a competitive price for the product. This inverter from a Russian company is also produced in China. Its power: 4.7 kW, arc voltage: 16-22.5 V, working wire diameter: 0.6-1 mm. It is supplied from a coil installed in the internal space of the housing at a speed of 2-15 m/min.

Advantages of the welding machine:

- Convenient control using switches.

- Quick connection of cables to connectors using bayonet connections.

- The presence of ventilation holes protects the device from overheating.

- Wire feed speed adjustment.

- The ability to adjust arc rigidity, welding depth, and bead shape by adjusting the inductance.

- Stable arc burning, no spatter.

Disadvantages of the welding machine:

- High price of the product.

RESANTA SAIPA-200

This is a universal welding inverter that can perform manual arc and semi-automatic welding. Machine power: 5.5 kW, MMA welding current: 15-200 A, Mig/Mag: 30-200 A, product weight: 9.3 kg. The work uses wire with a diameter of 0.8-1.0 mm.

Advantages of the welding machine:

- There is a convenient handle for carrying.

- There is protection against overheating.

- Relatively small dimensions for a welding machine of this class: 544x364x342 mm.

- Convenient location of control knobs.

- Removable burner type.

- Long operating time – 70%.

- Nice product design.

Disadvantages of the welding machine:

- Occasionally, owners come across defective products.

Preferred Models

Based on the above, we can draw the following conclusion: a welding machine for the home based on an inverter circuit and planned for use in the country, in the garage, at home, must meet the following parameters:

- small overall and weight parameters;

- low price;

- ease of operation and maintenance;

- stability of operation when voltage changes, this is especially true for those devices that will be used as a summer assistant;

To this we can add the fact that, as a rule, people who do not have special training work on household machines, and therefore the machine must forgive them some mistakes, while ensuring decent welding quality.

According to many constantly conducted surveys and sales ratings, Resanta devices can be put in first place - they are a good welding inverter. On our market there are three basic models SAI-160, 190, 220 and of course their modifications. The number in the name indicates the maximum welding current. The SAI 160 machine can weld with a 4 mm electrode, models 190 and 220 can weld with a 5 mm electrode.

All models of this brand are equipped with anti-stick options and protection against overheating and power surges. The kit includes cables and electrode holders. There were no obvious shortcomings noted. These models are produced in China, at a serial plant. Therefore, the build quality is not satisfactory.

Another model from Chinese manufacturers is FUBAG IR 160. Like most inventory devices, it has low weight and small dimensions. The shoulder strap makes it easy to carry within the workplace.

The front panel has an indication of power supply and thermal protection. It works easily with electrodes with a diameter of 4 mm. Like most devices intended for household use, it is equipped with anti-stick protection. Unfortunately, the manufacturer saves some money on wires.

Among the many inverter-type welding machines, one can highlight such a brand as PATON VDI-160E DC MMA. Welders of this family are used for domestic needs. It was designed with two goals: maximum environmental friendliness and high efficiency. During its operation, resources are saved due to reduced use of materials and low energy consumption. Being lightweight, these devices can work even if the voltage is reduced to 160 V. Of course, this device is equipped with an anti-stick option. The high quality of work performed is achieved through the use of high-quality components and total control over the assembly of the product.

The Russian-made welding machine REAL ARC 160 (Z240) - Svarog, has the ability to operate at reduced voltage (160 V). The classic control system installed on it does not create difficulties when working on it for a non-professional welder. This system has a built-in Antistick option, which turns off the power when the electrode gets stuck. It should be noted that Russian-made devices are adapted for use in our country.

To complete the rating, we can put the WESTER IWT200 - this is a device that was designed only for beginners in welding. This device generates an operating current of 200 A, the minimum voltage at which it remains operational at a network voltage of 170 V. The range of electrodes used is from 1.6 to 5 mm.

You must understand that this rating is conditional. All devices that are intended for domestic use are equipped with an overheating protection function and some other functions that are useful for beginners.

Which inverter is better should be decided by the consumer himself, after consulting with friends in the store and being guided by the rating of this equipment.

Additional functions of inverter welding machines

The presence or absence of service functions is not critical, but it makes life a lot easier, especially for a beginner. Their set is usually standard:

- “Hot start” HOT START - affects the ignition of the arc. When igniting, an additional impulse is given, which makes it easy to start welding.

- “Arc Force” - ARC FORCE - when the electrode suddenly approaches the metal, the welding current automatically increases. This prevents the electrode from sticking.

- “Anti-stick” - ANTI STICK - turns off the power when the electrode gets stuck, turns it on after it comes off. A convenient function, especially relevant for novice welders.

There are some other useful features. For example, indication and automatic shutdown when overheating. This is a useful addition - it is not always possible to keep track of the time or the overheating indicator. Automatic shutdown saves you from burnout and expensive repairs.

A welding machine for manual electric arc welding allows you to weld almost all metals, except non-ferrous ones

Pay attention to the package: in addition to the welding machine, there is usually a power cable (sometimes it is removable, sometimes it is stationary), two welding cables - one with a clamp for attaching to the part, the second with an electrode holder. It is better if the cables are light, flexible and long. But such luxury is not always available. More often, working cables are about 2 meters long, which is not always convenient. When looking at the cables, pay attention to how they are terminated, soldered (preferably) or clamped/rolled.

Pay attention to the warranty period, as well as how close the nearest service center is to your home/dacha. The lack of a service network is an alarming sign. This means that even if there is a warranty breakdown, you will have to repair it yourself, for money. You won’t send your device for repairs across half of our rather large country...

How to choose a device

Svarog produces and sells welding machines for work using the technologies listed above. You need to choose the type of welding inverter based on your tasks. For example, if you need welding for a service station, then argon arc welding is best suited in terms of cost and versatility in the field.

Using argon, it will be possible to weld together those metals that are used in cars - steel, aluminum, titanium, etc., which is a necessary condition when working with cars, since conventional electric arc welding does not cover all the problems and tasks that arise in in this case.

First of all, you need to decide on the type of work for which welding will be used. It is also worth taking into account the qualifications of the specialist who will work with it - not every welder will be able to work with plasma or argon, so the human factor must be taken into account.

Next, you need to look at your budget - Svarog has welding machines for one technology, but they differ in cost. An inverter is selected based on the budget and required functionality.

Do you have a Svarog welding machine in your workshop?

Yes No, but it will be!

Svarog ARC 205 (J96)

The model from is more expensive (about $130) than our previous contender for the title of best welding machine, but it also offers more features. It can be used for manual MMA arc welding and for light argon welding (TIG). But keep in mind that it will not replace full-fledged argon arc welding machines, since it does not allow working with alternating current.

The maximum possible current supplied by this model is 180 amperes, but the operating time is much longer than that of most competitors. It doesn't need to be refrigerated as often. There is also a hot start and anti-stick function. The main disadvantage is increased sensitivity to unstable voltage.

Cedar MIG-160GDM

Photo: https://beru.ru

The most versatile device in the review - it allows its owner to work both with welding wire in the MIG/MAG mode, and with stick electrodes and an argon torch (though, exclusively in the TIG DC mode - it cannot be used for welding aluminum alloys). This inverter belongs to the family of welding machines with microprocessor synergetic control: it has only two controls - a touch mode selection button and a multifunctional regulator. Most arc burning parameters are set automatically depending on the selected mode. This is convenient for beginners, but a professional welder would rather choose a machine with a large number of manual settings. In addition, full operation at high currents is limited by the low PV value: long-term welding with an electrode can only be done with a diameter of up to 3 mm, which, taking into account the high price of the inverter itself, led to a noticeable decrease in the score in the rating of the best welding machines.

Welding machine MIG-160GDM (MIG/MAG, MMA)

Wester MMA-VRD 200

Photo: https://beru.ru

This compact welding inverter is very attractive in terms of its characteristics: with a maximum welding current of 200 A, continuous operation is already possible at 126 A, that is, in most cases it will not require breaks for cooling: you don’t constantly weld massive structures with five-millimeter electrodes? All the functions that a modern inverter for MMA welding is “supposed” to have are also present here – “anti-stick”, “hot start”, and arc afterburner. Since the no-load voltage here is 65 V, for safe operation in high humidity, the manufacturer has introduced a VRD circuit into the circuit, which automatically reduces the voltage at the terminals when welding is not in progress, but the device is not turned off.

Welding machine MMA-VRD 200 (MMA)

Advantages:

- functionality

- possibility of continuous operation at currents up to 126 A

Flaws:

- short standard wires