Manufacturers offer a large selection of welders operating from a standard network. They are available in different capacities, sizes, and prices. Without knowing the fundamental differences between a semi-automatic welding machine and an inverter, which is better, it is impossible to say for sure. Each equipment has advantages, disadvantages, and a range of welding modes.

Operating principle and distinctive features

First, a few words about operating modes. Semi-automatic machines confidently support the following modes:

- MIG – carbon dioxide welding;

- MAG - an argon cloud is created above the weld pool;

- some have an MMA (manual arc welding with coated electrodes) mode.

Semi-automatic welders are purchased for TIG - argon arc welding using a non-consumable electrode. Leading manufacturers produce combined professional devices that support all modes. But now we are talking about household equipment.

The main difference between welding inverters and semi-automatic machines is the type of additive used. The latter feed welding wire into the working area at a certain speed. When working with an inverter, electrodes with various types of coating are more often used, creating a protective layer of slag on the melt pool. It is more difficult to make an even suture bead using an electrode. Semi-automatic welding is beyond the capabilities of beginners; experience is required.

An ordinary welding inverter is a universal power source with a compact transformer and semiconductor converters. Equipped with additional functions:

- limiting the no-load voltage, maintains a stable arc in conditions of high humidity;

- hot start (Hotstart), providing easy ignition of the arc;

- protection against sticking of the electrode (Antistick), in case of a short circuit the electrode is re-ignited drop by drop;

- arc force (ArcForce), ensures stable welding.

It is convenient for beginners to work with the inverter; the equipment has simple settings, convenient knobs for adjusting the welding current.

A semi-automatic device is a complex device consisting of three main parts:

- current converter;

- in the mechanism that feeds the filler wire, a special cassette with guide rollers is mounted;

- gas supply systems to the working area to protect the melt from oxidation.

Welding without inert gas

Semi-automatic welding without gas has distinctive features. The process can be carried out using gas or performed without gas using ordinary wire. A popular method of joining products is joining with a flux coating. But it is often used in industry because flux is an expensive material.

When welding without gas, high temperatures are used. It melts the powder, which leads to the appearance of a cloud of gas, which prevents oxidation of the weld pool. And the tap on the inert gas cylinder is closed at this time. The main advantage of flux-cored wire is that it allows welding even in strong winds. And in the case of gas supply, strong wind can become the main obstacle.

It is worth noting! Flux-cored wire has some restrictions on its use. It is not suitable for thin sheet metal and medium carbon steel. In these cases, there is a high probability of large hot cracks appearing.

Advantages and disadvantages

For ease of equipment evaluation, the main operational characteristics of semi-automatic devices and inverters are summarized in a table.

| View | pros | Cons according to experts |

| Inverter | low price; ease of use; small dimensions, weight - inverters are easy to transport; quick preparation; simple and clear setup; many models of different power; there are additional functions. | expensive repairs, you need to contact service centers; electronic filling is afraid of high humidity and dust; standard set of wires up to 2.5 meters, limits distance from the power grid; Unstable operation at low temperatures. |

| Semi-automatic | high quality of welded joints; the ability to perform complex work that requires a protective atmosphere; stability of the suture roller; high efficiency; welds any metals. | restrictions on dimensions, it is necessary to transport gas equipment and cylinders together with the device; the job requires skills; high price. |

Do-it-yourself semi-automatic welding practice

Scheme of a semi-automatic welding machine in shielding gas

The first step is to check and configure the equipment correctly.

- Based on the size of the base metal, select the current strength for welding. Keep in mind that the device copes worse with low current supply. Documents for a semi-automatic machine usually contain a table containing the necessary data for selecting modes.

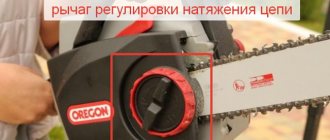

- Next, pay attention to the feed speed of the welding wire, again using the instructions. As a rule, special replaceable gears are included with the semi-automatic machine, with which the speed of movement of the electrode is adjusted.

- The next stage is to regulate the current and voltage

- After all the settings, it is best to weld a test seam, take into account all the shortcomings and adjust all the values. After which you should get a stable arc with little metal spatter and a sufficient amount of flux material.

- After checking all the characteristics and safety conditions, you can turn on the electrode supply mechanism through the burner.

- If there is flux, fill the funnel with the material.

- Then you should bring the torch tip directly into the weld pool area.

- Start striking the metal until an arc appears, opening the flux shutter at the same time. Next comes the welding process itself.

Semi-automatic aluminum welding

Criterias of choice

For your home or cottage, it is better to choose medium-power equipment for welding parts up to 4 mm. When deciding which is better: an inverter or a semi-automatic device, it is worth considering where you will have to work: indoors or outdoors. The semi-automatic device works stably only indoors; the inverter is universal in this regard.

The quality of the welded joint depends on the qualifications of the welder, the correct choice of additive, and the settings of the welding machine. The capabilities of a semi-automatic machine are wider; when using argon or carbon dioxide, the risk of defects in the weld is reduced. Coated electrodes may cause slag inclusions in the diffuse layer.

Pros and cons of semi-automatic machines

Positive traits:

- relatively small dependence on the level of corrosion of the base metal and its cleaned surface.

- comparatively cheap connection operation

- the equipment is even designed for welding thin sheet steel up to 0.5 mm, which increases the range of applications.

- you can use equipment for soldering with copper alloy wire.

Pros and cons

- in the absence of a protective gas jet, the spattering of metal from the weld pool increases significantly.

- This type of welding produces a brighter electric arc, so special attention should be paid to protection issues.

However, welding is often used in many manufacturing and repair applications.

Ferrous and stainless steel, as well as aluminum, are the most common metals that are processed with this type of welding. Carbon dioxide, argon, and helium are used to act as a protective jet. Various combinations of them are also used, however, most often the choice falls on carbon dioxide and the inert gas argon.

Semi-automatic welding video

For semi-automatic welding, a constant reverse electric current is used, where a negative charge is applied to the base. The following components are typical for any machine: a wire feed mechanism, a welding torch, and a power source for the machine.

Depending on the model, there are three types of wire feeding mechanisms

- pushing

- pulling

- mixed (universal).

Which device is better for home

When choosing welding equipment, the amount of work to be done is assessed. The final answer to the question of which welding machine is better for the home - an inverter or a semi-automatic machine - is obvious.

When there is a dacha, a country house, welders with experience and permission to work with gas equipment prefer to buy household semi-automatic devices of low power and light weight for personal use. This is an economical option, with it you can provide services to your neighbors: weld frames for greenhouses, doors, fencing bases, repair non-ferrous metal products. A break-in never hurts.

There is no need for beginners to purchase a semi-automatic device. For small household work with steel and aluminum, it is better to choose a small inverter power source with easy adjustment. It is not difficult to select the necessary electrodes; they are marked by type of coating and size.

Main types of welding

Electric welding is divided into 2 main classes: non-arc and arc.

Non-arc welding is more often called contact welding. In resistance welding, electrodes that supply current are applied directly to the metal being welded. A short but very powerful current discharge (thousands of amperes) is supplied through the metal located between the brought electrodes. In this case, fusion occurs only between the applied electrodes. If the electrodes are located directly opposite each other, then the welded joint is a spot weld. Although spot welding is not the only type of contact welding, it is the most common. Therefore, the concepts of “spot welding” and “resistance welding” are often used as synonyms. Spot welding voltage is a few volts. Therefore, resistance welding is used primarily for fastening thin sheet metal. For example, in the automotive industry.

In construction, electric arc welding has become much more widespread. In electric arc welding, there is a small gap between the current source (electrode) and the metal being welded, which is filled with an electric arc. It is a mistake to assume that this is an air gap. This is a gap of ionized gas that conducts current. Arc welding, as we imagine it today, is impossible without gas. The gas can simply be supplied from a separate cylinder, or it can be formed as a result of burning of the electrode coating.

The most common technologies in construction are the following:

- MMA (in the domestic classification - manual arc welding, or MMA)

- TIG (argon arc)

- MIG-MAG (semi-automatic, wire).

The popularity of this type of welding is predetermined precisely by the absence of the need to carry a gas cylinder with you. The coating of the electrode is the “frozen” gas cloud. As soon as the electrode touches the metal and the resulting short circuit current melts the metal of the electrode, the coating around it will also melt. The resulting gas cloud will provide a conductive ionized environment for the arc and protect the molten metal from oxygen.

Electrodes are selected according to the type of metal and diameter. The type of metal is important, since during operation the metal of the electrode rod flows drop by drop into the metal being welded and fuses with it. For a strong connection, the metal of the electrode rod and the metal being welded must be identical. The packaging of electrodes always indicates which metals these electrodes are suitable for.

Once you have decided on the type of electrode, you need to decide on its thickness. Newbie question: why do we need electrodes of different diameters? It's simple. The thicker the electrode, the greater the current that can melt it. The same goes for the edges of the metal being welded. Therefore, the thickness of the electrode is selected to match the thickness of the metal being welded. For ferrous metals it is recommended:

MMA technology allows you to work with most common metals, with the exception of aluminum and alloys based on it. Although theoretically this is also possible with an assistant, if you ensure that the cleaned aluminum surfaces do not have time to be covered with a film before melting. But it is more correct, of course, to simply use welding technologies suitable for this.

Consumers of TIG welding are entirely professionals and advanced users, and almost all of them are not in the construction sector. TIG produces cleaner seams, but is far inferior to MMA in performance and ease of use.

For example, many “amateurs”, having honed their skills on MMA machines, are frustrated by failures during their first experience with TIG. It turns out that, unlike MMA, it is not easy to strike an arc with a TIG machine unless it is equipped with a device such as an oscillator. (And almost all “2 in 1” devices are not equipped, of course). The welder strikes with a tungsten electrode - there is a spark, but the arc cannot be raised. But an experienced welder places a piece of coal under the electrode - and the arc starts without problems. It is no coincidence that specialized TIG devices rarely exceed a 1% share of retail store sales.

In TIG welding, devices with the ability to switch to alternating current mode, the so-called, deserve special mention. AC/DC. These devices are the main equipment for welding aluminum. It is they who predominantly make up this very 1% of TIG in retail sales of welding equipment.

MIG-MAG

Semi-automatic wire welding is mainly used for welding sheet metal. Therefore, traditionally its main area of application is body repair, as well as the construction of structures made of black sheet metal. Using wire instead of replaceable electrodes greatly improves productivity. Household devices use coils with a capacity of 1 and 5 kg, and professional ones use 5 or 15 kg.

The wire can be used both regular (without coating) and with coating (so-called flux). In the first case, it is necessary to use a gas cylinder (GAS mode). In the second, a cylinder is not required (NO GAS). Despite the fact that it is more convenient to work without a cylinder, uncoated wire is the leader in sales by a large margin. The reason is simple: it is much cheaper than flux. In addition, many professionals believe that the accuracy of the seams in the gas environment from the cylinder is higher.

Despite the fact that this type of welding also belongs to electric arc welding, the principle of the MIG-MAG device is fundamentally different from the principles of MMA and TIG. In MMA and TIG it is important to maintain current stability despite electrode fluctuations, in MIG-MAG it is important to maintain arc voltage stability. And the strength of the welding current in MIG-MAG machines is a conditional indicator (although, according to the habit developed in MMA, most people focus on it). The strength of the welding current in MIG-MAG will depend on the set voltage, the diameter of the wire used, the gas used and the wire feed speed. So, making a semi-automatic MIG-MAG out of an MMA device by attaching a wire feed unit and a torch will not work.

Conclusion

For professionals, when choosing a welding machine, the main criterion is the quality of the seam and the strength of the welded joints. Auto repair shops and small repair companies often purchase semi-automatic machines; they are suitable for joining thin and thick-walled steel workpieces and welding non-ferrous metals. The seams are smooth, strong, and sealed.

Beginners who have no experience will not be able to cook with semi-automatic machines. It will take a long time to achieve good seams, the metal will be damaged, and the wire will be wasted. For beginners, an inverter is a good option.