05/17/2021 Author: VT-METALL

Issues discussed in the material:

- Basic principles of welding station equipment

- Equipment of welding stations for arc welding

- Welding station equipment for gas welding

Equipment for a welding station means preparing the welder’s workplace: installing the necessary equipment, purchasing consumables, providing comfortable conditions, as well as mandatory compliance with safety regulations.

Depending on the type of welding, how and what the welding station will be equipped with differs. From our material you will learn about the most important nuances of organizing a welder’s place of work.

Basic equipment

To fully equip a welding station, it is necessary to equip it with electrical equipment, additional equipment and auxiliary means:

- a current source for the formation of a welding arc, which is a welding transformer or inverter;

- current-carrying cables in a reliable braid that can withstand high current strength and constant mechanical stress.

- conductors must have appropriate fastening at the end for connection to terminals, electrode holders and ground;

- gas burners for working with gas welding equipment;

- fixtures and other tools for welding work: clamps, clamps, holders;

- welding table;

- protective equipment: heat-resistant suit, special gloves, welder’s mask, headdress with a lapel.

A distinctive feature of a mobile welding station is that it does not have any boundaries. This is explained by the fact that a specialist needs to constantly move to perform his duties within a certain area: construction site, welding shop, production site, etc.

It is worth paying attention to the fact that this classification relates exclusively to the organization of procedures, but does not in any way regulate the nature of the manipulations performed.

The most popular types of gas welding equipment include acetylene and propane stations. They are used in almost the same areas, the only difference is the lower combustion temperature of the oxygen-propane post. That is why it is actively used for gas-flame processing of thin metals, without the risk of causing damage to the structure. As for the acetylene station, it is more advisable to implement it for cutting channel bars, as well as materials of similar density that cannot reach a given temperature.

The type of gas mixture coordinates the best use case for the installation. In this case, an oxygen-propane station should be used to obtain various shapes and sizes of metal, since it is subject to strong oxidation. With the help of propane, the seam will be smoother and stronger. To connect structures to each other, it is better to use an acetylene post, which can be compared in terms of results with electric welding. In addition, it is quite economical to use.

A specific characteristic of both types of equipment is strict adherence to safety measures during transportation, storage and, of course, working with them. Before purchasing, it is important to make sure that the propane or acetylene post has the appropriate certificates and that the manufacturer provides a warranty. In our store you can get only the best, high-quality acetylene and oxygen-propane posts, which we sell at affordable prices.

Our assortment includes a propane station and other gas welding installations of any type. They can be used in both domestic and professional areas. Experienced specialists will help you decide which tool and equipment is best to study. A properly purchased oxygen-propane station will give you the opportunity to quickly and reliably dismantle various metal structures, and an acetylene station will qualitatively connect or restore parts.

Today, oxygen-propane stations are used quite widely. You can see this equipment in almost every production or construction area. Its functionality allows you to replace entire complexes of complex mechanisms, which significantly simplifies technological processes. In domestic use, acetylene or propane post will also play a significant role. Safe to use and useful if certain precautions are taken, they will significantly speed up any work related to metal structures.

If you are interested in purchasing this category of goods, you can always contact our company. Excellent prices and ease of use in our online store will please even the most demanding customer. You can place an order without leaving your home! To do this, you need to find the corresponding post in the menu and fill out an online application.

Workplace arrangement options

In practice, it is customary to distinguish between two types of welding stations. Stationary is mostly used for working with small-sized workpieces. The mobile one is in demand at large production sites, in the construction or laying of various types of pipelines.

Basic requirements for organizing a workplace for welding work:

- Good lighting should be provided in the area. The minimum value is 80 Lux. It is advisable to combine natural light and artificial light.

- All electrical equipment must be grounded.

- The base must be strong and solid. As a rule, this is concrete or brickwork.

- Work pockets should be provided at the workplace where documentation or graphic materials could be stored.

- Good ventilation must be provided.

- The working surface of the welding table must be made of steel or cast iron. Nearby there should be connectors for connecting the welding machine and additional equipment.

- There should be a rubber mat or a thick wooden shield under the specialist’s feet.

- To perform work in a sitting position, you need a dielectric chair made of non-flammable material.

If the workplace is set up outdoors, then you need a canopy that will well protect the welder and equipment from rain. In sunny weather, you can work in an open area, but protection from direct sunlight is often required. Then the canopy can be replaced with high shields.

What is a welding post

A welding station is essentially a makeshift welder's office. Yes, there are no comfortable chairs, tables or jugs of water, but there is everything necessary to perform a complex of welding work. In other words, a welding station is a workspace where a welder can work comfortably and safely, and he always has consumables and other necessary equipment at hand.

The welding station must be equipped in compliance with all safety and labor protection requirements. This is a mandatory condition that allows specialists to maintain their health and get the most out of them. When setting up the post, special attention is paid to fire safety. But in order to achieve all the necessary conditions, you should study the specifics of different welding posts.

Depending on the equipment used, welding stations can be:

- Gas welding . The main distinguishing principle is that the energy obtained as a result of gas combustion in a special burner is used to melt metal blanks. Due to the specific nature of gas welding, it is important to equip a good ventilation system for organizing a work office. The surface of the desktop and the space around it must be made of non-combustible materials.

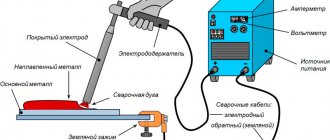

- Electric welding . Working with electric welding is no less dangerous than working with gas welding. In addition to good ventilation, effective protection of employees from electric shock is also necessary.

In any case, no matter what method of welding or cutting metal is used in a closed workspace, it is very important to carefully consider the arrangement of the ventilation system. In addition to the hood, supply systems are also installed for natural or forced supply of fresh air.

Depending on the needs, welding stations can be:

- Stationary . It is a limited space in a room, equipped specifically for welding metals. They are often equipped with rotary tables for convenience.

- Mobile . They are mobile structures that one person can carry or move within the work site. The best option in cases where welding of large structures is required. They can be located indoors (workshop, production site, shipbuilding dock, etc.) or in an open area (construction, creation of large-sized non-standard structures, etc.).

A stationary welding station is best suited for joining small and medium-sized metal workpieces. But for working with large-sized structures this is not the best option. A special cabin, which serves as the “walls” of such an area, is made of galvanized metal sheets. They are characterized by high resistance to high temperatures, as well as IR radiation.

A clear advantage of a mobile welding station is the fact that there is no need to create any special conditions for work. If necessary, protection from precipitation is provided by a canopy, and from wind - by side hard screens. If conditions permit, parts are welded without protection from the weather.

Tools and additional equipment are contained in the drawers of the tool cabinet, and artificial lighting (if required) is provided locally. In mobile posts, as in stationary ones, care should be taken to ground the equipment that is connected to the power supply network.

Basic principles of welding station equipment

A welding station is a workplace and space where a welder can easily perform his work in comfortable and safe conditions, and all the necessary working equipment and tools, as well as consumables, are always within reach.

When setting up a welding station, all rules and regulations of labor protection and fire safety must be met. Compliance with such conditions allows us to ensure the health of welding specialists and obtain maximum production efficiency. When setting up a post, special importance must be attached to compliance with fire safety requirements. To fulfill all these conditions in full, it is necessary to carefully study the specific features of different types of welding stations.

Based on the type of equipment, welding stations are divided into:

- Gas welding. Their main difference is that when melting the weld zone of metal workpieces, the energy generated by gas combustion in a special burner is used. Due to the specific nature of gas welding work, the welder’s office must be provided with local exhaust ventilation. All surfaces of the work table and objects located in the area adjacent to it must be made of non-combustible materials.

- Electric welding. Work associated with electric welding is no less dangerous than gas welding. When equipping a welding station workplace, in addition to a reliable air ventilation system, all conditions must be provided to protect the worker from electric shock.

It can be considered very important that no matter which of the above methods of welding or cutting metal is used, the closed workspace of the welder must be equipped with a room ventilation system. In addition to exhaust hood, the main equipment of the welding station must have a natural or forced supply of fresh air.

Depending on the purpose, welding stations can be:

- Stationary. They represent a limited space specially equipped for welding in a production facility. For convenience, a non-movable workplace is equipped with a table with a rotating mechanism or a stove, and is enclosed with screens. Suction units connected to exhaust ventilation are mounted above the table.

- Mobile (temporary). They are periodically portable structures that can be moved within the working area by one person. Widely used in welding large-sized structures. They can be used both indoors (production areas, workshops, shipbuilding docks, etc.) and in open areas (construction sites, when installing non-standard large-sized structures, etc.).

Stationary welding station equipment is most suitable for welding small and medium-sized metal workpieces. This type of post is not used to connect bulky structures. The welding cabin, which at the same time serves as the “walls” of this area, is made of galvanized metal sheet material. This type of fencing is very resistant to high temperatures and ultraviolet radiation.

The great advantage of equipping a mobile welding station is that there is no need to create any additional conditions for work. The canopy can protect from precipitation, and the side hard screens can protect from the wind. In good weather, parts can be welded without any protection.

Additional welding equipment and tools are placed in the drawers of the tool cabinet, and if artificial lighting is necessary, lighting fixtures are installed locally. Equipment of both stationary and mobile (temporary) posts that is connected to the electrical network must have reliable grounding.

Types of welding stations

Stationary post

The classic design of a stationary welding station involves the installation of a special protective cabin without a canopy.

Requirements for organizing a stationary workplace:

- The area of the room along the internal perimeter must be at least three square meters.

- The surface of the walls is finished with non-combustible materials.

- The cabin frame can only be made of metal.

- The height of the work table depends on the method of performing the work. For a sitting position it is 60 cm, and for a standing position it is 90 cm. Ideally, if the structure can be lowered or raised depending on the situation.

- A tarpaulin canopy is hung at the entrance.

- The minimum permissible cabin height is 2 meters.

- The lower part of the walls is raised above the floor level to improve ventilation. The gap should be at least 25 cm.

- The working surface requires a metal or cast iron sheet with a total area of at least one square meter.

- The inside of the cabin is treated with a special compound in a light gray shade. It has high fire-resistant characteristics and absorbs ultraviolet radiation. This is necessary to prevent accidental ignition of the surface of the walls of the room.

Gas welding station

To organize a gas welding station, you will first need the appropriate equipment: an acetylene generator, burners and hoses for gas supply, oxygen cylinders and reducers.

A portable gas welding station is a trolley on which cylinders, gearboxes and all the necessary equipment are located. The cart is most often made of pipes, and the wheel axle is located at the center of gravity to make it easier to move and hold.

The gas welding station equipment consists of the following elements:

- table with metal top;

- hood. It is usually installed above the table or slightly to the side;

- sources of light.

Gas cylinders are located slightly away from the workbench to prevent hot splashes from getting on the gearboxes. Gas is supplied to the work site through hoses. Large enterprises often provide for gas supply through centralized pipelines.

According to existing standards, for safety reasons, the distance between the work table and cylinders with acetylene and oxygen must be at least 10 meters. The same footage (no less!) must be maintained between cylinders and any sources of open fire. In cases where you have to work in narrow or hard-to-reach places, a supply of fresh air is required.

Mobile post

A mobile welding station is necessary when performing work with large-sized structures. Often, such a workplace is located outdoors. Therefore, it requires additional equipment for protection from sunlight, wind and precipitation. The protection consists of a hinged canopy and folding rigid shields (screens) from the wind. To accommodate consumables, additional tools and small equipment, the mobile workplace is equipped with metalwork carts with drawers.

During welding work, harmful volatile substances are released in large quantities. They pose a health hazard to the specialist. However, ventilation is not required: the mobile welding station is located in an open area and the gases quickly evaporate.

But a local lighting system may be required. In conditions of poor natural light, an additional light source will be required. It is placed directly above the table on stands. Good lighting reduces eye strain, improves working conditions, which helps increase specialist productivity. Electrical equipment, including the welding machine itself, must be grounded in order to minimize the likelihood of electric shock to the welder.

It is necessary to take into account that when installing enclosing structures, a gap of about 50 cm should be left between the panels. This is necessary to ensure a sufficient flow of fresh air. The welder must have protective equipment - a special suit, shoes, mask, mittens and headgear. It is imperative to always have a working main tool - a holder. It must be reliable and safe, protect the welder’s hand from a source of high temperature, hold well and quickly release the electrode.

Proper equipment of a mobile welding station gives the welder the opportunity to work without discomfort and in completely safe conditions. This in turn brings:

- good final result of the work;

- reducing the time required to complete welding work;

- reducing the likelihood of specialist illness.

Welding station equipment

Regardless of the functionality, be it a stationary or mobile welding station, the specialist’s place of work must fully comply with the following set of requirements:

- grounding of all energy-consuming devices is mandatory;

- good degree of illumination of the desktop. A combination of natural and artificial lighting is considered optimal;

- floors must be made of brick or concrete;

- the table top is made of cast iron or steel and is connected to ground;

- Drawers are provided for storing tools;

- in cases where sedentary work is required, a chair made of dielectric material is required;

- A rubber mat is spread under your feet.

When working in an open area, additional protection from sunlight, wind and precipitation will be required.

Stationary station equipment

A stationary workplace must meet a number of requirements:

- Such a workplace is made in the form of a cabin that does not have a roof. The total area of the allocated space should not be less than 3 square meters. The optimal height of the fences is 2 m. The entrance opening should be covered with a canopy made of fire-resistant tarpaulin.

- The lower part of the fence should be raised above the floor to a height of 25-30 cm.

- The material for the worktop tabletop can be steel or cast iron. The surface area is made no less than a square meter.

- It should be possible to adjust the height of the table so that the welder can change it to work while sitting (50-60 cm) or standing (90 cm).

- The perimeter walls are made of fire-resistant material. On the inside they are painted a light gray shade that absorbs ultraviolet radiation.

- It is necessary to provide a hood that would effectively remove combustion products. For effective air exchange, fresh ventilation will be required. According to safety requirements, the productivity of such a system is calculated to be no less than 40 cubic meters of air per hour.

- The standard lighting brightness is 60-80 lumens. It is ideal if it is possible to provide a combined illumination of the post: natural in combination with artificial.

All equipment connected to the power supply network must be grounded. In addition, one general switch is installed, which allows you to disconnect all equipment from the supply network at once.

Mobile post equipment

An excellent option for a production workshop or other large workspace, as well as when creating large-scale structures.

Primary requirements:

- Electric welding and additional equipment are combined on a mobile cart.

- The length of the power cable must be sufficient to move within the work area or facility.

- There is no need to install a ventilation system. On the street, combustion products of consumables are carried away as a result of the natural movement of air masses.

- The portable post is equipped with a canopy and protective shields that can be quickly assembled to protect from precipitation, wind or sun.

- In the same way, it is necessary to provide for the possibility of installing fences to protect bystanders from flashes of the welding arc.

- For ease of work, the welder must have a sufficient number of tool carts to store his equipment, additional equipment and equipment.

Equipment of welding stations for arc welding

When equipping a stationary or mobile welding station for electric arc welding, the following conditions must be met:

- connect the desktop and equipment housings to the grounding system;

- Provide desktop surfaces with good lighting (a combination of artificial and natural light is allowed);

- make flooring from fire-resistant material;

- make the table cover from cast iron or steel with a thickness of at least 20 mm, connect the ground cable to it;

- The welder’s table should be equipped with drawers or pockets for placing technical documentation, electrodes, working tools and equipment;

- to carry out welding while sitting, equip the workplace with a stool made of strong insulating material;

- Place a rubber mat under your feet.

When welding outdoors, to protect from rain, snow, and sun, the workplace must be equipped with a canopy (you can use an awning made of any waterproof material).

1. Equipment for a stationary welding station.

Such equipment is a cabin located above floor level with an open top. It is used for welding parts of medium and small sizes; it is not used for large-sized metal structures. Cabin walls are usually made of sheet metal, which are subsequently painted with zinc-containing paints or other types of coatings are chosen that are resistant to infrared radiation and high temperatures (for example, yellow chrome-lead paint, titanium-based white, or other modern preparations).

We recommend articles on metalworking

- Steel grades: classification and interpretation

- Aluminum grades and areas of their application

- Defects in metal products: causes and search methods

The floor must be made of concrete (or a screed must be used). The use of PVC coating, wooden boards or plywood on joists, as well as any flammable materials is not allowed. The entrance/exit opening must be covered with a tarpaulin, or for this purpose it is necessary to install metal double-leaf doors with corrugated glass.

There are also several requirements for arranging a welding cabin:

- The equipment of a stationary welding station must be provided with lighting necessary for comfortable work, a sufficient number of light sources to illuminate the table and the station as a whole, where all manipulations related to welding work are carried out.

- The area of the welding station must be at least 3 m2 with a height of metal fences from 1.8 to 2 m - such walls must be made raised above the floor level by 20–25 cm. Accordingly, the ceiling height of the room in which the cabin is installed must be more than 2 m to ensure air circulation.

- When working while sitting, the height of the metal table should be 50–60 cm. It would not be superfluous to install a copper sheet on the tabletop (including at the junction of the ground terminal). The material of the table cover can be either steel or cast iron up to 2.5 cm thick. The table must be provided with metal drawers to accommodate various tools, drawings, electrodes, fixtures and other necessary equipment.

- A special hood must be installed directly above the surface of the welding table.

If the post is used in a garage environment, then an exhaust fan can be built into one of the walls of the garage, but in this case it is necessary to provide for the presence of fresh air ventilation during the cold season. Recently, production shops often use point hoods, the flexible “trunks” of which can be brought directly to the welding site. According to regulatory documentation, the required air exchange rate in the room must be at least 40 m3/hour. It is important to remember that with reduced air exchange, toxic substances contained in welding fumes (aerosols) will enter and accumulate in the lungs of welders, which can lead over time to various occupational diseases. - When performing work, there should be a rotator (or manipulator) nearby, which can be equipped with a foot pedal for ease of control. The manipulator is used for welding cylindrical parts.

- For ease of work, you should use a rotating version of the welder’s work chair, which, in addition, must be made of heat-resistant dielectric material. The back and seat can be made of wood.

- All equipment at the welding station must be grounded (in some cases, an RCD is used for this purpose).

- A rubber mat should be placed under the welder's feet.

A switch for emergency shutdown of power to electrical equipment in the event of an emergency should be installed inside the welding cabin.

2. Mobile post equipment.

The equipment of mobile welding stations for manual welding does not provide for strict adherence to the dimensions of the workplace and provision of air exchange. However, all fire safety requirements that apply to stationary equipment must be strictly followed. The trolley for transporting equipment must be equipped with such wheels that the post can be moved with its help without much effort.

When carrying out welding work, a portable welding machine with a set of cables is used, which moves along with the unit along the object. To protect from bad weather, the mobile post must be equipped with shields for the location of the canopy. Cabinets and various fastenings are used to store electrodes and tools. In order to protect nearby people from light radiation, it is necessary to protect the workplace using portable shields. When installing long-distance pipelines, mobile welding stations are placed in small trailers with an autonomous electric generator - this type of workplace can be supplemented with car wheels.

Desktops

Considering that small metal parts are welded at stationary work stations, special tables are provided for convenience. Structurally, industrial workbenches are designed for work in a standing or sitting position. If the table is made independently, then you need to take into account that the optimal height for working while sitting is 60 cm, and for standing – 90 cm.

The table cover is made of sheet steel or cast iron 2 cm thick. The total surface area is at least 1 square meter. It is important that the table has drawers in which the welder can store electrodes and other consumables, tools and small equipment. If there are none, then you need to additionally acquire a special plumbing trolley.

Rubber mats should be placed under the table itself and along its perimeter to prevent electric shock to the welder. And one more small touch - a metal chair with a dielectric seat, which allows you to do part of the work in a sitting position.

Equipment for different types of welding

The organization of welding stations is associated, first of all, with the parameters of the equipment being used. The main ones are weight and requirements for the power supply network.

The welding station must be equipped not only with welding equipment and accessories for it. In addition, additional tools are required for trouble-free operation of welding machines, and, if necessary, minor repairs. For uninterrupted operation, you will also need a certain supply of consumables: various types of additives, flux in powder form or inert gas.

Technological maps, individual regulations, diagrams, drawings and other documentation will help you assemble a workstation more accurately. It is customary to distinguish two large groups of common equipment: electric and gas.

Stationary posts focused on the use of electrical equipment are often equipped with powerful AC or DC devices. Power supply often requires a connection to a three-phase network. The most popular additional equipment: AC transformers complete with or without rectifiers, generators, electric arc stabilizers.

When work is planned using gas (inert or active), the package includes cylinders containing hydrogen, argon, helium or other gas necessary for work. For gas welding, you will need cylinders with oxygen and working gas - acetylene or propane. The stationary gas welding station can be equipped with cylinders of different weights, starting from 10 liters.

The table can be very massive or small and compact. The only condition is that the area of the tabletop should not be less than 1 square meter. Vices and clamps will be its indispensable additions. In addition to this, additional equipment often includes various types of fasteners, pipe benders, rolling devices, etc. For mobile kits, small-sized equipment is used: gas welding machines with small cylinders, inverters and semi-automatic welding machines.

There are mobile installations located on the basis of automotive vehicles, including passenger cars. They are equipped with gasoline or diesel generators and are autonomous. Such posts are intended for field work. They are often found in natural disaster zones, on sections of highways after accidents; used in road and field work.

Gas welding station equipment

Regardless of what type of welding stations we are talking about, it will include:

- an oxygen cylinder with a reducer or a continuous oxygen supply system (the presence of the latter is typical for stationary gas welding stations);

- acetylene cylinder or generator with safety valves or gearboxes (for portable posts, generators with a capacity of up to 20 m3/hour are used, for stationary stations this power is increased to 160 m3/hour);

- rubber sleeves (hoses) for supplying oxygen and flammable gas to the burner or cutter;

- welding torches with a set of tips , for cutting - cutters with a set of mouthpieces and cutting devices;

- filler wire for welding, soldering, surfacing;

- fluxes , if they are necessary for welding a given metal;

- welding table and devices for its assembly and folding;

- protective equipment for the welder : glasses with dark lenses, sets of keys, hammer, chisel, metal brushes, ruler, square, etc.;

- ventilation system;

- fire fighting equipment;

- bucket of water for cooling burners;

- waste containers.

Basic requirements for arranging welding stations

Regardless of what equipment the post is equipped with, the fire safety requirements are almost the same. All their points are aimed at ensuring safe working conditions and making them as comfortable as possible. Primary requirements:

- The welder's place should be protected with shields or screens made of fireproof materials. the top should be left open;

- welding work using inert gases is allowed only in those booths where there is no top, the light opening between the fences and the base is 30 centimeters or more, and the walls of the fences are at least 2 meters;

- the inside of the post along the perimeter is sheathed with fireproof materials;

- The cabin area must be at least 4.5 square meters. This space is enough to accommodate welding equipment, accessories, various devices, systems for storing tools and consumables;

- when operating a plasma cutting machine, the height of the fences must be at least 2.2 meters, and the surface inside must be covered with fireproof materials;

- You should not install two welding machines inside one booth at once. And if this is really necessary, then a separating light-protective screen must be installed between them. It will prevent the possibility of a fire.

When arranging a welder’s workplace, the organization of a ventilation system is important. The production site foreman must check the ventilation performance of each station, since the safety of not only a specific welder, but also the work site as a whole directly depends on the efficiency of air exchange.

Practitioners advise:

- Ensure parallel operation of two exhaust systems at once: general and local.

- Local hoods are equipped with filters that purify the air from harmful aerosols and combustion products.

- When performing welding work in a protective environment, air is supplied dispersedly into the booth. In other cases, it may be pumped into the upper area of the cabin.

- It is desirable that the walls inside are matte. Then the welding glare will not be reflected.

If all the requirements for organizing the supply and exhaust ventilation system are met, then the workplace is ready for use. Before starting welding work, the specialist must wear protective clothing and a mask. Otherwise, he risks damaging his eyes and getting burns from hot metal drops.

Main types of gas welding stations

Currently, such posts are divided into two main types.

Stationary

A stationary station for gas welding work cannot be moved due to its size (in some cases, it can occupy several square meters in area).

The composition of such a post meets the main requirement - the ability to perform a large volume of welding work with high productivity. For this reason, such a gas welding station includes equipment designed for continuous operation.

The advantage of such a post is its high productivity compared to a portable post, as well as the ability to perform various types of welding work, including quite complex ones.

The disadvantages of this type of post are the impossibility of moving it, as well as the need for constant maintenance of the gas supply systems used in it.

Portable (portable and mobile)

Such posts are used primarily for repair and restoration work, as well as for domestic needs. The main difference from stationary posts is their relatively small dimensions, which make it possible to move such posts manually or using special equipment, but without labor costs that are critical in terms of volume. In addition, portable stations do not require a constant supply of gas.

The main disadvantage of such a post is that it will not be possible to complete a large amount of work with high productivity. This is due to the small capacity of gas cylinders or acetylene generators, which significantly limits the ability to perform welding work. However, this problem can be solved by installing additional cylinders or generators, which, despite the convenience of this solution, can significantly affect the overall weight and final mobility of the post.

Requirements for welding stations

General requirements

Requirements for the organization of welding stations are based on compliance with safety regulations and ensuring comfort in carrying out work. It is important to ensure that all energy consuming installations are grounded. To place them, it is highly advisable to make a base of concrete or brickwork. The post must have everything necessary to store not only tools, but also documentation.

Briefly about the basic requirements. Ventilation is required. The table is made of steel or cast iron. The welder must stand on a rubber mat while working.

For cases where the welder works while sitting, it is necessary to provide a special chair with a non-conductive seat. It should be durable, but light and small so that it can be moved with one hand if necessary. Naturally, the seat should be comfortable, since sometimes a specialist has to work for several hours without a break.

Productive work is impossible without adequate lighting. The brightness should not be excessive, but at the same time, even small details should be well illuminated. As practice shows, 80 Lumens are enough to work. The light source should be placed directly above the table. If this is not possible, then it is permissible to place the lighting device in close proximity to the workplace.

Even if we are talking about multi-station welding, you still need a switch, by turning which you can turn off the electricity supply in an instant. This may be needed in an emergency and to de-energize the area at the end of the working day.

Individual requirements

It is not surprising that there are significant differences in the organization of the workspace for manual arc welding from a similar process for semi-automatic welding. Depending on the technological aspects, distinctive requirements for the arrangement of the workplace are provided.

For example, if you plan to weld using an alternating current source, then an oscillator will be required. If you plan to use the post for cutting metal, then you need to provide a place for the cutting tool.

If a three-phase network is connected to the booth, then a contactor will be required. And if we are talking about gas welding work, then you need to allocate space for storing cylinders.

Welding station equipment for gas welding

Gas welding stations, as well as equipment for manual arc welding, depending on their dimensions and power, are divided into stationary and mobile. The latter, in turn, can be mobile and portable.

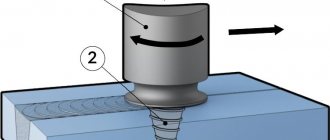

- Portable and mobile welding stations for gas welding.

The portable equipment of a gas welding station has the smallest dimensions and weight; it can be moved manually by one person without much difficulty. In the picture above you can see an example of a portable post. This type of welding equipment is widely used for repair and restoration welding work (plumbing repairs, replacement and restoration of pipes in heating or similar systems), for various household purposes and in many other cases when extensive work is not required.The advantage of equipping portable gas welding stations is that there is no need for a constant source of gas. In addition, thanks to their mobility, they can be delivered to the work site in a matter of minutes. Disadvantage - cylinders for flammable gas and oxygen have small volumes, so during long-term work they have to be constantly recharged, and this leads to loss of working time and, accordingly, a decrease in productivity.