To view the video, you need a modern browser that supports HTML5 video.

Prefabricated buildings made from metal structures have become very popular in modern construction. One of the frame elements of these structures is the beam. If welding technology is used in the production of metal beams, they are called welded. Those obtained by rolling are called rolled. And in terms of design features, the most in demand are products that belong to the category of I-beams.

I-beams welded

If you look at the cross-section of such a beam, it is easy to note its similarity to the letter H. The structure of the metal profile includes three elements: the wall and the shelves adjacent to both its ends. The main advantage of beams is their low specific weight, and therefore ease and speed of installation. Previously, when assembling frames, other, smaller elements were used, which had to be connected with fasteners. This complicated the process, and the structures turned out to be fragile. The production of steel beams helped solve this problem.

Manufacturing of beams

A rolling type header is made from a single piece of metal on special equipment - a rolling mill.

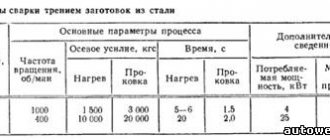

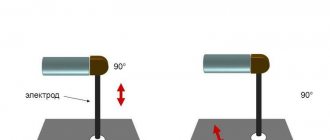

Consistently passing through a chain of lashes, the ingot gradually acquires the required shape. When producing a welded beam, its three components—the flanges and the wall—are welded to each other, forming a single structure. Despite the fact that the product looks very simple and without frills, the process of its manufacture is quite complicated. It is important for specialists to take into account the characteristics of the alloy: they affect strength, corrosion properties, rigidity, density and other nuances. Production of welded beams Particularly labor-intensive, although the welded beam is in demand. Its production begins not in the workshop, but in the technological department, where the load on the product is determined taking into account the physical and mechanical characteristics. The shelves and the wall, in fact, are elements of steel strips of different thicknesses, so the next preparatory stage in the manufacture of welded beams is cutting the strip into blanks of a given length and width. After this operation, the end sections are milled. The most critical stage, where errors often occur, is the assembly of the future beam. Its cross-section must have a perfectly regular shape; any violation of geometric accuracy is unacceptable. Today, manual assembly, in which the human factor can play a negative role, is increasingly giving way to automatic assembly. Modern mechanical engineering even offers special equipment - mills that assemble beams with millimeter precision. The procedure for both manual and automatic assembly takes place in the same sequence: first, a T-shaped product is formed from the wall and shelf, then the second shelf is attached. No less important in the production of a welded beam is the welding itself. It can be carried out in two ways: with an inclined electrode or a “boat”. The first method takes less time, but does not guarantee a deep seam. The second one is longer and more labor-intensive, but the seam is much more reliable. Even if all specifications are met, the finished welded beam may require adjustments. Therefore, the final stages of its production are measuring and editing. The straightening process is carried out on another specific equipment - a leveling mill.

Calculation and production of welded I-beam

High-quality welding of I-beams for floors will require a lot of attention and responsibility from you. You will need to calculate all the upcoming loads on the structure in general and on the joints of the beams themselves.

Just designing and planning I-metal welded beams takes a lot of time. Therefore, we recommend that you focus on the dimensions and purposes of finished products from manufacturers.

The modern market offers a fairly large variety of sizes of finished I-beams with their own designations and types. The dimensions of the beam are determined by the number, which indicates the distance between the outer edges parallel to each other.

For example, the marking K denotes columns and beams that must withstand enormous loads. Keep in mind that there is also a certain type of beams that are not used for floors, but only for creating heavy equipment and machinery. Such beams have their own manufacturing standards and properties.

Wide-flange designs are suitable for lighter loads. And the strength of such beams will directly depend on the length, the formula of the transverse profile, the use of raw materials and manufacturing methods, i.e. metal rolling technologies. Here is a standard welded beam for private housing construction:

Here are the parameters of welded steel I-beams for the manufacture of such beams:

How to weld a beam yourself?

If you already have some experience working with this material and you want to make welded beams for building your house yourself, you will need an alloy steel sheet as a base. The hot-rolled method of manufacturing at home is quite complicated, so welding is really better for you. This is a responsible task, so if you have the opportunity, it is more rational to immediately invite an experienced welder.

After the individual elements are ready, assemble the structure using the selected welding method. First you will need to install a vertical wall and secure the stiffeners and press everything down with clamps. The finished beam must be protected with a special coating so that it does not corrode in an aggressive environment.

How to avoid deformation?

If you make mistakes during the manufacturing process, you may encounter such unpleasant deformations of the beam, which in the future will significantly complicate the installation process:

Let us explain in more detail. Your main task when making welded beams is to then join the parts so that the seam does not work in tension.

You also take into account this important fact that the welding itself puts some stress in the beam, and this is not always noticeable to the eye. Therefore, it is advisable not to immediately weld the next part to it. Just push the seam back slightly and the beam will be level.

Comparisons: in order to avoid any deformation of the beam, especially for arranging an interfloor floor, it is subjected to special processing in the factory:

If you undertake making such a beam yourself, the following steps will help you figure it out:

Advantages of welded I-beams

Despite the labor intensity of manufacturing welded beams, it is no coincidence that customers and manufacturers prefer them. Rentals can only be obtained by “hot” method. After heat treatment and deformation, they significantly lose strength and rigidity. Welded ones, despite the presence of two longitudinal seams, retain mechanical properties. An important factor is lower steel consumption. Finally, the production of welded products is more universal and tailored to broad needs. For example, you can make beams of asymmetrical shape - with different widths of the shelves.

Characteristics of welded I-beam

Beams perform a responsible mission: the integrity of the structure and the lives of people depend on their quality. Therefore, the production of beams must be carried out strictly in accordance with GOST. The more general standard 8239-89 defines the following features of these products:

- maximum slope of internal faces;

- moment of inertia;

- maximum wall deflection;

- moment of resistance, as well as many other nuances.

The production of hot-rolled metal beams is regulated by a special standard - GOST 19425-74. In particular, he identifies special types of these products according to their intended purpose. Hot rolled beams can be used in such specific applications as installation of overhead tracks and reinforcement of mine shafts.

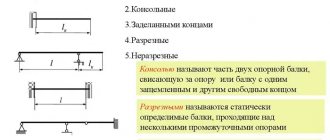

Range of welded I-beams

Based on the width of the flanges, welded I-beams are divided into normal, wide-flange and column. Column shelves have the greatest width and wall thickness. The higher these indicators, the more critical structures can be used rolled steel. Based on standard sizes, beams are divided into varieties, designated by the Latin letters H, h, S, t and B. The assortment tables also provide data on cross-sectional area, weight and reference values for the axes. All this data helps to produce a welded beam strictly in accordance with GOST standards.

Prices for I-beams

For all sheet metal, upon customer request, we provide a certificate of conformity and product quality. The cost of a ton of I-beams varies due to variable prices for raw materials and consists of the cost of manufacturing metal products and the metal itself.

The cost of manufacturing a profile with truncation, flange connections, perforations, bimetal, and with stiffeners is determined individually. To order, the ends of the beams are processed, shot blasted and primed.

Is there a welded beam according to GOST 26020-83 dimensions?

In our practice, there are cases when a customer asks to produce a welded beam for him, mentioning GOST 26020-83. The formulation of the question in this case is incorrect, because this standard is devoted to the production of hot-rolled beams. Their weight starts from 8 kg and reaches more than three hundred. The cross-sectional area of these products reaches 400 sq.cm. However, we can produce for you welded products of dimensions similar to those of rolled beams in accordance with GOST 26020-83, but with a significantly lower specific gravity.

How to weld I-beams

The design of the assembly equipment used to manufacture welded beams having an I-section is determined by the welding method used to form the waist seams. The choice of such equipment also depends on what devices are planned to be used in the production process. At modern enterprises, automatic submerged arc welding is most often used to form long belt seams of I-beams. This method allows us to obtain welds of high quality and reliability along their entire length.

Beam welding as a stage of its manufacture

The use of automated equipment for welding under a layer of liquid flux to produce I-beams allows not only to reduce the cost of the finished product, but also to ensure its high quality and reliability. The operating principle of such equipment provides that the unmelted flux protecting the welding zone is under pressure. Thanks to this, the splashing of liquid metal from the welding zone is minimized, which allows this operation to be performed efficiently even at high current values (up to 4 thousand Amperes). In addition, the flux protects the molten metal from rapid cooling, which facilitates more efficient removal of gas from it.

Meanwhile, the welded beam can be produced using manual arc and semi-automatic welding. In such cases, special conductors with clamping elements, or ordinary tacks and clamps are used to assemble them. However, it should be borne in mind that in this case you will have to deal with large losses of molten metal, which will occur due to its splashing and waste. Such losses can reach up to 30%.

Recumbent beams

In addition to the production of metal beams, many enterprises today offer so-called aged steel. These are products that were released at one time, but never found a buyer. On the one hand, they were not used and therefore were not subject to wear. On the other hand, the long wait left its marks on them: for example, in the form of corrosion. Of course, it is not worth using such a beam for capital and monolithic construction. But it can find dozens of ways of application in other, less critical structures. In addition, modern cleaning methods - shot blasting or sandblasting - will help return these products to their former appearance.

Where is the best place to buy welded beams?

You probably know that the best prices can be found at metal warehouses. However, a distinction must be made between a warehouse that directly produces steel beams and a commercial structure that buys rolled steel from a manufacturer and then resells it at a large markup. If you want to save money and not doubt the quality of the product, we advise you to contact the warehouse of our workshop. There you will find the main standard sizes of beams. And if you need something special or a large batch of rentals, we will work on your project.

production cost

In the “Cost” section on the same page you will find a price list for the production of welded beams in our workshop. We have indicated the average prices for services in the table. They consist of a fairly simple form: the cost of the metal plus the cost of the work of our specialists. However, they may be adjusted depending on the circumstances. Fulfilling an urgent order within an extremely short period of time requires an extra charge, while a large serial project requires a good discount per ton.

Features of using a beam of variable section

A beam of variable cross-section is often used for the construction of prefabricated buildings as a load-bearing frame, as well as for the purpose of installing floors between floors.

Beams of variable cross-section are very effective for creating the internal volume of a room. Their use also helps reduce operating costs. What is the current price per meter today, you can find out from our consultant.

This type of beam has also found its application in the form of crane tracks. The highest quality of production allows installation to be carried out using bolts and the use of special equipment. Today in Russia, and in particular in Moscow, there are a large number of manufacturers of I-beams.