A cold-rolled profiled metal beam with a U-shaped cross-section is called a bent channel. Products of this type are a universal material, without which not a single sphere of the national economy can do. Whether this is actually true will be helped by a detailed acquaintance with the technical characteristics and features of specialized products in demand in industrial and civil construction.

Advantages of bent profile products

The cold-formed bent channel has a clear geometry, rounded outer corners and uniform wall thickness. This guarantees perfect compatibility of products and facilitates installation.

Advantages:

- Low weight and high rigidity compared to straight hot-rolled beams.

- A wide range of sizes and thicknesses allows you to select a material that meets the required operating conditions.

- Assembly of structures can be carried out without welding using bolted fastening.

- Ease of installation increases the speed and productivity of work.

- High degree of resistance to axial loads and bending pressure.

- Reducing the metal consumption of structures while maintaining strength reduces construction costs.

- Possibility to give the profile the shape and dimensions according to the customer’s requirements.

- The channel is easy to weld and machine.

- Exact dimensions, do not require straightening or additional adjustment.

- The light weight of the beams allows you to lift large volumes and carry out work at heights.

The thermal effect that is exerted on the profile during the production process leads to changes in the crystal lattice of the steel. Due to annealing, its internal stress decreases and ductility increases. The result of this process is the production of a wear-resistant material that is resistant to negative environmental factors during its operation.

Capabilities of the company's plant for the production of channels

We offer our clients the production of bent channels in accordance with the provisions of the following standards:

- 8278-83. Taking into account the requirements of this GOST, equal-flange channels are produced;

- 8281-80. This GOST regulates the requirements that our unequal-shelf products meet.

At the request of clients, we manufacture bent channel bars , the parameters of which, among other things, are similar to products that are currently not produced by profile metal rolling plants. For example, those whose characteristics correspond to channels No. 33, 36 and 40.

The consumer is offered products whose thickness can range from 2.0 mm to 8.0 mm, and length - from 1.0 m to 12.0 m.

Application of bent channel

Main areas of application:

- Carrying out reconstruction of buildings and repair and construction activities.

- Assembly and installation of metal structures of various shapes.

- Reconstruction of old buildings. Light profile weight reduces the load on the foundation.

- Assembly of wall frames and facades for industrial and civil buildings.

- Creation of lathing for applying facing material.

- Carrying out roofing work.

- Laying hollows for water during the construction of communication networks.

- Construction of partitions and shelving in warehouses.

- Installation of frames for greenhouses, sales tents, billboards.

- Manufacturing of canopies, trailers, body parts for vehicles.

- Production of non-standard equipment.

- Reinforcement of walls and ceilings.

- Creation of architectural objects of non-standard or complex shapes.

- Use as a fastening element for beams of industrial cranes.

A bent channel provides a significant reduction in construction costs and ensures the reliability of structures and structures. The combination of all the advantages increases its popularity and makes it a competitive representative of metal profile products.

How does a bent channel differ from a hot-rolled one?

The presence on the market of different types of rolled metal of the same type raises questions among many consumers; in particular, they are interested in the difference between bent and hot-rolled channels. We will give an answer to this question in three aspects, which relate to the appearance, production method and assortment of this rolled metal. We have summarized the most significant differences in the following table:

| Index | Hot rolled channel | Bent channel |

| Thickness of walls and shelves | The angle of the channels is different (the shelves are always thicker). | For bent products, it is the same throughout the entire section of the channel. |

| Shaperib | Clearly rectangular | Round |

| Range of sizes, which is determined by the height of the wall | By number, each unit of which is equal to 10 mm seriesU, P and E – 5–40 seriesL – 12–30 series C – 8–30 | Wall height in mm for equal-flange channels – 25–410 for unequal-flange channels – 32–300 |

| Shelf width range | SeriesU, P and E – 32–115 mm seriesL – 30–65 series C – 45–100 For each standard size of channel, with rare exceptions, there is only one option for the width of the shelves | 26–160 mm for equal-flange channels 12–90 on the smaller shelf and 22–180 on the larger shelf for unequal shelf items. For each standard size of bent channels, the presence of several options for shelf widths is the rule. |

| Metal structure | Homogeneous throughout the channel body | Broken along the bending lines, which negatively affects the strength of the product |

Hot-rolled and bent channel: external and manufacturing differences

In appearance, they are easily distinguished by the shape of the ribs. Hot-rolled steel with parallel flange edges of the L and S series has the maximum external resemblance to bent products. However, unlike a conventional bent channel, it has a wider assortment, which provides consumers with a variety of choices. Now let's move on to answering the question posed from the point of view of the production of both types of rolled products.

Production of bent and hot-rolled channels

A hot-rolled channel is manufactured by passing a heated billet through the stands of a rolling mill to obtain products of the required standard size with a given wall and flange thickness. The bent channel is made on profile bending mills from strips . Strips are blanks made from cold-rolled and hot-rolled sheets, which are cut into strips of the required width. It must be sufficient to bend a product with a given wall height and shelf width.

Both types of rolled products are made from the same grades of steel, so the differences between them are mainly due to the methods of their production. For example, bending technology makes it possible to produce small-gauge channels - less than No. 5, that is, with a wall height of less than 50 mm. In addition, the range of bent equal-flange channels is much larger than that of hot-rolled products, even when all series are combined into one. This provides consumers with the optimal choice of channels according to their characteristics.

Such a big difference in the range of bent and hot-rolled channels is due to the fact that the production of rolled products using traditional technologies is much more complicated. To switch to a new standard size of hot-rolled products, a serious readjustment of rolling equipment is required. To produce a different standard size of bent channels, it is enough to change the width of the workpiece and perform the minimum settings of the roll forming mill. Therefore, rolled metal products are cheaper than their hot-rolled counterparts.

Properties of bent and hot-rolled channels

Channels are intended for the manufacture of load-bearing structures, so their main characteristic is bending strength (resistance to vertical loads). It will not be possible to compare the properties of both types of channels head-on, since in their entire assortment there are no identical products in terms of wall and shelf thickness. To illustrate this fact, we give an example of comparison of hot-rolled channel No. 5E and equal-flange bent products with a height of 50 mm. The following table contains basic information about them:

| Index | No. 5E | Bent channel h 50 mm |

| Wall thickness in mm | 4,2 | 2–6(4) |

| Shelf thickness | 7 | 2–6(4) |

| Moment of resistance to vertical load: for the wall for shelves | 9.17 units 3.05 units | 3.25–10.65 units (7.12) 0.9–5.51 units (2.89) |

| Weight of 1 mshweller in kg | 4,79 | 1,61–5,73(3,62) |

For a single standard size of hot-rolled product No. 5E, there are 11 options for bent channels with a wall height of 50 mm. The table in parentheses shows the characteristics of the closest standard size, based on the wall thickness. Comparison of these indicators with the characteristics of channel No. 5E suggests that hot-rolled products are significantly superior to the nearest bent analogues in strength (by 28.8% for the wall and 5.5% for the shelves). The price for the advantage in strength is a 32.3% increase in weight.

We will not go into the nuances of the theory of strength strength, according to which the required strength of load-bearing structures is calculated and, accordingly, suitable standard sizes of rolled products are selected. However, the obvious fact is that bent channels provide greater freedom of choice and savings on material. Let us remind you that rolled metal is sold by weight and lighter products will cost the consumer less.

This is interesting: Shut-off control valves: practical application

Storage, transportation

The safety of rolled metal and its operational characteristics is ensured by compliance with storage conditions. To store channels of any type, a covered room is required, the humidity level of which does not exceed 70%. Before being sent to the warehouse, the channels are bundled. Profiles of the same size are grouped and fastened with wire or special tape. A marking in the form of a stamp is applied to the surface of each product.

Transportation of channels is carried out by trucks with an open or closed body. During transportation, bent beams can be packaged in two ways.

- Piece by piece. To protect against mechanical damage, each unit of rolled metal is packaged in oiled paper or special film. It is used for long-distance transportation and is relevant for transportation by sea.

- In bundles. The most common type of transportation, characterized by fast loading. Pre-packaged products do not require additional work to connect several units of products and package them, which reduces transportation and storage costs.

When transported in a car with an open body, the products are covered with a waterproof awning.

Features of work

Channels are very durable structures that are quite difficult to bend at home, since they are practically not amenable to this operation. To carry out such work, special high-pressure machines are used, which make it possible to perform the deformation of this type of rolled metal.

There are only three main ways to bend a channel:

- on the shelves;

- along the wall with shelves outward;

- along the wall with shelves inward.

This is due to the fact that the shape of this structure is asymmetrical, which does not allow its deformation in other planes. Please note that if the channel is large enough, then it is very difficult to deform, but still possible.

Varieties

According to the manufacturing method, there are several types of bent channels:

- rolled under high temperature conditions;

- rolled under low temperature conditions

- special and general purpose;

- bent equal flange;

- bent unequal.

Hot-rolled products are produced in two versions: with parallel flanges and with their edges inclined from the inside. They can also be divided into 2 categories:

- A – high accuracy;

- B – normal accuracy.

Hot-rolled products can also be divided by numbers - each of them indicates the exact distance between the outer edges of the walls.

Special channels are used mainly in the carriage building and automotive industry.

Such products are manufactured in special mills. The manufacturing material is standard rolled fabric of normal quality, as well as carbon high-quality structural steel. The average height of the profile structure is between 50 and 400 mm, and the width is between 32 and 115 mm.

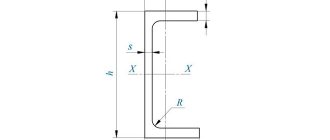

Equal flange channels have the same flange width, while unequal flange channels have a correspondingly different flange width. The GOST tables indicate the exact dimensions of products according to the generally accepted designation system:

- h – value of the height of the product;

- b – flange width value;

- S – flange depth value;

- R – value of the radius of curvature.

Also, bent steel profiles are usually divided into 4 categories depending on the shape of its structure:

- U - the edges of the shelves inside are inclined;

- P – both shelves are parallel to each other;

- L – light products with parallel shelves;

- C – special purpose profile.

The use of bent channel allows consumers to reduce the overall weight of the structure and save up to 30% of the metal used compared to alternative metal products.

According to GOST, a bent channel profile can have different lengths:

- from 3 to 11.8 m (equal flange);

- from 4 to 11.8 m (unequal).

Separately, companies often produce bent profiles of non-standard sizes. Moreover, for products whose length is more than 6 m, the maximum permissible deviation in length can be +40 mm, and for a high-strength model - no more than +30 mm. Distortion is allowed no more than 0.1% of the total length, and for a high-precision bent profile - no more than 0.05% of the entire length. The waviness of the edges can be 2 mm per 1 m, with a minimum wavelength of 50 cm.

Manufacturing of bent steel channel.

The bent steel channel is manufactured using special roll forming equipment.

To produce this rolled metal product, a variety of types of steel can be used:

- hot rolled steel coils;

- cold rolled steel coils;

- structural steel;

- low alloy steel;

- carbon steel.

The production of steel profile channels is carried out in accordance with current state standards. And the range of resulting products is quite large: it includes different types of channels (equal and unequal), as well as various sizes in width and length.

Execution options

The most popular material in the metal rolling industry is bent channel. The main purpose of this product is to give the structure the necessary level of stability and strength. The specificity of the channel is that it not only tolerates the load applied to it well, but also redistributes it evenly. Depending on the size and shape, several types of channel can be found on sale:

- With parallel edges of all shelves.

- With a slight slope of the edges of the shelves.

- Universal copies.

Depending on the manufacturing method, they are usually divided into unequal-flange and equal-flange channels. As for the last type of product, the main process of its manufacture is not considered difficult, since a pipe machine is used in the work process. Standard quality steel coils and high quality carbon structural steel are used as blanks. Bent steel unequal-flange channel is produced using universal roll forming mills.

It is also worth considering that the galvanized type of bent channel, due to its strength and specific gravity, has found its application not only on large-scale construction sites, but also in mechanical engineering, machine tool building, automotive industry, carriage building and many other areas. The manufacturing process of this type of rolled metal consists of two main stages:

- A product of the desired shape and size is produced from the blank.

- The finished part is covered with a galvanized coating, which serves as reliable protection against the negative effects of corrosion.

The stainless steel type of channel can be either bent (not coated with zinc) or hot-rolled. During the period of active operation of such products, it is necessary to carefully monitor its strength characteristics, since it participated in the creation of metal structures and the quality and safety of the entire facility depends on it.