Every metal worker should know how to adjust a welding helmet. Correct adjustment prevents sparks and scale from getting into your eyes, and toxic fumes from burning metal and chemical components of the electrodes from getting into your lungs.

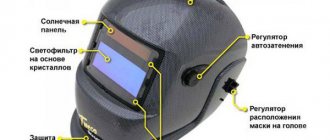

Location and name of the parts of the welder's mask.

Setting up a chameleon mask

Any welding mask is designed to protect the welder’s eyes from radiation, sparks, metal splashes, etc.

There are two types of masks: with fixed darkness and chameleon masks. The main difference between these masks is the light filter. The light filter of chameleon masks is capable of automatically changing the degree of darkness depending on the intensity of radiation. The filter owes this feature to its layered structure, which includes fireproof glass and layers of polymer crystals that change the transmission capacity.

This feature implies the ability to customize the chameleon mask, both for a specific job and for the individual characteristics of a person.

For an example of setting up a chameleon mask, let’s take a mask from TRUSONIX. Its settings panel looks like this:

There are 4 adjustment levers visible on the panel: MOD, SHADE, DELAY and SESITIVITY. Let's figure out what exactly each of them is responsible for in the settings of the chameleon mask.

This chameleon mask switch adjusts the amount of screen dimming. It has three positions:

- 9-13 din (used for working with high currents);

- 4-8 din (used for working with low currents);

- grind (used when working with an angle grinder).

Fine-tuned screen dimming. The switch has 5 possible positions and should be set in accordance with the MOD switch. There is a special table for this setting.

Fact. Incorrect setting of this switch may adversely affect your vision.

The position to which you need to set this chameleon mask setting depends on the amperage you will be working with. When working with low currents, a smaller value is used; when working with high currents, the value must be increased. This chameleon mask setting is not strict; if necessary, you can change it to suit yourself.

This chameleon mask setting is the delay time after which the filter will lighten. If you work with small details and you need constant control of your own actions, set a lower value. In the opposite case, when you are working with massive objects, the value of this switch needs to be increased. Otherwise, the radiation from such objects may harm your eyes.

The delay time at the maximum value is 2 seconds, at the minimum value – 0.2 seconds.

Fact. Flashing of the light filter after stopping operation indicates a low delay time. In this case, the setting value must be increased.

The sensitivity of the filter to sunlight.

Low values are used for outdoor work, and high values for indoor work. At maximum sensitivity, the filter reacts to almost any light and darkens. At the minimum value, the filter reacts only to bright flashes.

Fact. You can check this setting using a lighter. At the maximum value, the filter will react to both sparks and flames, and at the minimum value - only to sparks.

Source

Equipment and technical data

The operating instructions must also include the technical characteristics of the product.

For model SM-51

- automatic filter;

- cartridge with dimensions 110x90x8;

- convenient viewing window 98x35 mm;

- DIN 3 dimming mode;

- shade levels DIN 11;

- response time – 0.1, delay – 0.3;

- There is no photosensitivity adjustment;

- protection from IR, UV rays DIN 15;

- 2 sensors available;

- The power source is solar, lithium batteries;

- material for the mask body is special impact-resistant, fire-resistant plastic;

- operating temperatures – from 5°С to +55°С.

For model SM-101

Chameleon mask head mounting diagram.

- automatic filter;

- cartridge with dimensions 110x90x8;

- convenient viewing window 92x42 mm;

- DIN 4 dimming mode;

- shade levels DIN 9-13;

- response time – 0.2, delay – 0.15/0.8;

- There are 2 positions for adjusting photosensitivity;

- protection from IR, UV rays DIN 15;

- 2 sensors available;

- The power source is solar, lithium batteries;

- material for the mask body is special impact-resistant, fire-resistant plastic;

- operating temperatures from -5°C to +55°C.

How to set up a Chameleon mask for welding

Like all other welding helmets, the Chameleon protects the welder's eyes from infrared radiation. The automatically adjustable light filter operates in a convenient mode: the screen changes the degree of darkness depending on the illumination of the working field. When the Chameleon welding helmet does not darken, it is dangerous to work.

You need to figure out why the screen is not working. Sometimes it is enough to change the power supply elements and charge the battery. A dirty screen reacts worse to light; it may need to be wiped. If this does not help, it is better to turn to professionals.

Charging protective equipment

The method depends on what components are used in the device:

- batteries must be charged from an electric current network;

- solar cells - with targeted exposure to a source of artificial or natural light;

- disposable batteries need to be replaced;

- With combined power supply, the components are charged together.

We recommend reading: How to make your own welding table

Replacement of power supply elements.

Adjusting the Chameleon welding helmet

To understand how the Chameleon welding helmet works, you need to know the basic structural elements of the protective device. The overview screen has a layered structure:

- fireproof glass that does not transmit ultraviolet and infrared radiation;

- layers of polymer crystals that change transmission capacity;

- In order for the filters to darken, they are connected to a current source;

- light sensors (from 2 to 4, depending on the model);

- connection diagram to the power supply.

At the moment of welding, a spark appears, then a luminous flux. The radiation triggers the sensors, the crystals are polarized, and the screen darkens. The welder sees the junction of metals within the range acceptable to the eye. After turning off the light source (electrode or arc), the sensors are triggered again. The screen brightens.

The tuning system regulates:

- the degree of screen darkening, it is selected according to the instructions, depending on the type of welding;

- sensitivity to changes in light flux;

- shutter speed, that is, the time period for turning off the light protection.

The adjustment is made at the preparatory stage, when the serviceability of the Chameleon mask is checked before work.

How to properly prepare a welding helmet for work is written in the operating instructions. Setting up a chameleon mask includes several steps:

- a convenient distance from the face to the protective screen is set, this is done by loosening the clamps;

- The position of the filter is adjusted, the comfort of viewing the working area depends on this;

- the intensity regulator is installed: it is determined in what mode the Chameleon welding mask is used, the operating instructions must contain adjustment tables;

- depending on the current strength of the welding machine and the illumination of the workplace, the sensitivity mode is selected; high is indicated by the letter “H”, low – “L”, minimum – “L0”, it is selected experimentally, it is easy to adjust the Chameleon welder masks during work;

- the holding time depends on the type of welding; for spot welding, a minimum interval is enough; for electrode welding, when a melt pool is formed, it is necessary for the screen to remain darkened longer.

Possible faults

Regardless of the manufacturer and quality of the unit, any mask can break. The reasons for failure may be the following:

- Violation of operating temperature conditions.

- Mechanical damage.

- Use of low-quality components.

- End of natural lifespan.

If the operating rules are violated, first of all, they lead to malfunctions of the automatic light filter for the welding helmet. Before contacting official representatives, try to determine the cause of the problem . Some breakdowns can be easily fixed on your own, without the involvement of qualified specialists. Spare parts for repairs can be purchased at points of sale of welding equipment.

The simplicity of the mask design ensures no maintenance problems. A technologically complex device is more difficult to repair.

The mask can be powered either by a solar panel or by batteries. Failure of batteries is the main cause of problems with the chameleon . In this case, the solar cells may simply be discharged. To localize the cause, just leave the device under natural light and then check the functionality. Removable batteries need to be replaced. Replacing the power supply assembly will cost much more.

Problems with glass are visible to the naked eye - external defects in the structure will indicate this. In this case, the filter will not work properly. When replacing LCD glass, it is necessary to comply with the parameters of the element. This is the most expensive part of the assembly.

The biggest problems await the user in case of problems with the control board. In this case, independent repairs, without the involvement of service specialists, are impossible.

Possible malfunctions and methods for eliminating them

- The screen will not respond to light unless connected to a power supply. If the model is equipped with AAA alkaloid batteries or rechargeable batteries, charging indicators are displayed in the screen area. If the red light is on, it's time to replace the batteries. Solar panels are charged while welding. If the mask does not turn on, point it towards a light source for a few minutes.

- If the screen darkens unevenly, check the distance from it to both eyes. Perhaps while they were adjusting the mask and adjusting it to the head, the filter shifted. It should be parallel to the face. Loosen the clamps and align the casing.

- If the screen flickers during welding, it may be due to the outer glass. Sometimes it is enough to wash it. In case of mechanical damage (scratches, surface chips) it must be replaced. If the filter continues to act up, check the cleanliness of the sensor surface. When there are two operating modes (welding and grinding), check which position the switch is in. The screen may flicker when low-current welding in low sensitivity mode. The desired level can be established experimentally during operation.

- The filter does not darken immediately in the cold. Viewing screens quickly change the degree of darkness in the temperature range from +50 to -10°C; Chameleons are not intended for harsh winters.

- If the weld seam is difficult to see, there may be several reasons. Sometimes the film is forgotten on the protective glass. You can try cleaning it, switching the dimming control.

Operating rules

Instructions for using the chameleon welder mask include:

- Before setting up and working, the welder’s mask is carefully removed from the packaging, after which it must be inspected for damage. The protective plates are removed, the protective film is removed from them, after which the panel is put in place. It is important to check the cable.

- Installation and adjustment of the mask. Before starting work, it is necessary to adjust the raising/lowering of the mask using special locking nuts to ensure comfortable and safe work. The welder's mask should fit snugly, not wobble, or interfere with work. Next you need to adjust the angle of inclination. For this, a special limiter is used; the locking nut rotates clockwise, ensuring the mask is raised and lowered to achieve the required position.

- In order for the work to be safe, it is necessary to check the sensors of the light filters, for which the front side of the structure is directed towards a bright lamp. If the viewing window darkens, then the mask is in working condition. You cannot use a mask if the light filters do not work.

- The setup begins with setting the degree of darkness; a special regulator is used for this. The welder's mask can be used for any type of welding work, and only one filter is used; it is enough to set the appropriate degree. After this, the filter delay time is set. There are 2 positions in total, which are 0.15 seconds and 0.8. When setting indicators, you need to pay attention to the afterglow time of the working area.

How to test a Chameleon mask without welding

When you hold down the Test button for five seconds, the filter should darken. If there is no such configuration function, you need to check Chameleon in other ways. The sensors are triggered by a powerful light beam. The filter is turned towards the light source at least three times, the screen should darken in all cases. Light protection reacts to:

- radiation from the sun (the filter should darken and open after an exposure interval, because the flow is of constant intensity);

- red spirals of incandescent lamps (darkening persists throughout the entire period of being near the emitter; it operates at an alternating current frequency);

- a spark from a silicon lighter (the filter darkens sporadically when the wheel knocks out a spark);

- remote control for household appliances (sensors react to infrared radiation pulses, the light output of the remote control is uniform);

- smartphone screen during flash.

If the filter does not respond, check the power supply: change the batteries or batteries, charge the solar panels. The sensitivity of the filter is checked with an incandescent lamp. If the spiral is equally visible at different settings, the regulator does not work.

How to choose

Light filters for welding masks can be selected by marking. It has 4 digits. Each of them characterizes a certain indicator.

- Optical class number. Determines the clarity of the image through the filter.

- Level of light scattering. As the value of the number increases, the image received by the eyes deteriorates, the picture becomes cloudy. Best seen with marking value 1.

- The level of darkness and the uniformity of its distribution over all glass surfaces.

- Angular dependence of darkening, its degree when rotated by 15⁰.

Welding glass markings indicate how well the arc will be visible and the degree of eye protection while welding, including turning your head slightly.

Carrying out maintenance

Welders should inspect the Chameleon at least once a month. Dirt is removed with a soft rag or cotton cloth. Cleaning products with aggressive, oily and abrasive bases are not suitable for glass. It is important to remember that filters are fragile and cannot withstand shock loads. To get to the light sensors, the casing is dismantled. This is done when the power supply is turned off, just remove the batteries.

Step-by-step instructions for replacing the protective screen:

- The cartridge latches are moved to the center of the filter and opened.

- The damaged glass is removed along with the rubber gasket, and it is replaced with a new light filter of the Chameleon mask.

- The assembled cartridge is installed in its working position. It should fit tightly.

When replacing the filter, remove the regulator knob and potentiometer. Then the elements are assembled in the reverse order. Be sure to check the sensitivity lever; the delay time adjustment should work perfectly so as not to catch “bunnies”.

Brands and manufacturers

You know how to choose a chameleon mask for welding, but how to navigate among the mass of manufacturers? In reality, everything is not very difficult. There are trusted brands that always supply high-quality products and confirm their warranty obligations. Here are not very many of them:

Technical characteristics of the chameleon mask TECMEN DF-715S 9-13 TM8

- SPEEDGLAS from Sweden;

- OPTREL from Switzerland;

- BALDER from Slovenia;

- OTOS from South Korea;

- TECMEN from China (don't be surprised, the masks are really good).

Choosing a chameleon mask for home use is not easy. On the one hand, it needs to be of high quality, but obviously not everyone can afford to pay 15-20 thousand for it, and it’s not profitable. Therefore, we will have to forget about European manufacturers. At least they produce good masks, but their prices are no less than $70.

There are many Chinese masks on the market at very low cost. But buying them is risky. If you need a proven Chinese brand, this is TECMEN. They actually have certified chameleon masks of factory quality. The model range is quite wide, prices range from 3 thousand rubles to 13 thousand rubles. There are filters of the first class (1/1/1/2) and a little worse, with all the settings and adjustments. After the update, even the cheapest mask for 3,000 rubles (TECMEN DF-715S 9-13 TM8) has a replaceable battery, a clearing delay of 0.1 to 1 second, smooth adjustment and a “grinding” operating mode. The photo below shows its technical characteristics. It's hard to believe, but it costs only 2990 rubles.

Owners speak well of Resanta welding helmets. There are not very many models, but MS-1, MS-2 and MS-3 are a good choice for little money (from 2 thousand rubles to 3 thousand rubles).

Resanta welding helmet: MS-1, MS-2, MS-3 and MS-4

Resanta MS-1 and MS-3 masks have smooth adjustment, which is undoubtedly more convenient. But the chameleon MC-1 does not have sensitivity adjustments. They are unlikely to suit professionals, but are quite suitable for home use.

Technical characteristics of Resanta chameleon masks

The South Korean company OTOS produces very good masks. Its prices are slightly higher than those listed above, but there are two relatively inexpensive models: OTOS MACH II (W-21VW) for 8,700 rubles and ACE-W i45gw (Infotrack™) for 13,690 rubles.

Technical characteristics of OTOS MACH II W-21VW this chameleon mask is a worthy choice even for professional use

Safety precautions

Before putting it on, check the settings, operating mode switches, and battery charge. Always check to see if the filter is getting dark. If it turns off during welding, the protective glass protects the eye to a small extent from IR and UV rays. But it’s safer to stop working immediately. It is dangerous to use a faulty mask. If a defect is found or the filter does not respond, the malfunction is serious and welding cannot be continued.

It must be remembered when working that the powerful radiation of the arc and molten electrodes is destructive. In addition to discomfort, this threatens to damage the retina. To prevent loss of vision, it is necessary to correctly adjust the degree of darkening of the filter.

To preserve the mask, it is important to follow the storage regime: non-functioning filters and solar panels protect from exposure to light.

Setting based on welding mode

Diagram of the front glass of the chameleon mask.

The customizable chameleon welder mask involves the use of several operating modes. There is no need to change filters - you just need to set the required mode. The modes are designated as follows:

- MMA – manual arc welding;

- MIG/MAG – semi-automatic arc industrial welding, designed to work in a gas environment of argon or carbon dioxide;

- MIG (light) – semi-automatic gas arc welding;

- TIG, GTAW - arc welding, for which a non-consumable electrode is used;

- SAW – semi-automatic welding using flux;

- PAC – plasma arc welding.

The instructions also include information about possible breakdowns. In addition to breakdowns, troubleshooting methods are indicated. In case of complex breakdowns, it is best to contact a service center, since the equipment can be damaged, and its further repair will be expensive. If the filter darkens unevenly, you must contact a service center. The filter is out of order, and you can’t fix it with your own hands.

If flickering is observed or there is no darkening of the viewing window, then you need to carefully clean the plate from dirt . If this measure does not help, then it is best to replace the plate, since it is damaged and changing the settings will not help. If the darkening is uneven, it is necessary to remove the mask and inspect the condition of the sensors. It is important to make sure that the surface of the sensors is not blocked and that nothing prevents light from reaching them. The chameleon welder's mask should not have any stains of dirt or layers of dust on the surface.

Chameleon mask filter darkening selection table.

Damage to the sensors is indicated by the following:

- filter response is slow;

- the darkening does not go away after the arc goes out;

- flickering is observed, the viewing window does not darken.

In this case, you cannot repair the sensors yourself; you must immediately contact a technician at the service center.

Before starting work, you should always check the condition of the lithium batteries that power the equipment.

For many models, batteries can be easily replaced with your own hands. It is imperative to inspect the sensors, i.e. bring them to a bright light. This is required to ensure work safety, since the lack of darkening leads to eye injuries.

Sensors may be blocked if:

- the window begins to brighten when it is illuminated during operation;

- the dimming level does not correspond to the set mode;

- slow response;

- darkening is observed when there is no longer backlighting;

- flickering is observed.

It is easy to correct this situation: you need to clean the surface of the sensor itself and inspect the condition of the viewing window panel.

Contacting the service center

Additional options make repairs more difficult and increase the risk of mask failure. If the degree of darkening has decreased significantly, it is necessary to inspect the structure.

Some components cannot be repaired and require mandatory replacement. If you cannot do this yourself, you need to contact a service center. The guarantee is valid only for complete masks. If you managed to delve into it, you will have to pay for the service.

There is no point in undertaking repairs to the system board: this is a matter for professionals. It is better to contact the service center immediately. Unsuccessful DIY repairs can result in additional costs.

Rules for choosing filters

Before purchasing masks or glasses, you should understand the optical characteristics of light filters and the specifics of using the products.

Recommendations for choosing filters for welding

- If you regularly carry out welding work, you should choose the “Chameleon” mask.

- The size of the filter determines visibility and comfort during welding activities.

- The filter response time can vary from 0.03 to 0.0001 s.

- You should choose models with continuously adjustable dimming levels, which are more comfortable than stepped ones.

- It is recommended to use universal filters that have a shade of 9-13 DIN.

- The optical class of the filter determines the clarity and visibility of the image through glass (the best option has an indicator of 1).

Additional features

Additionally, you need to pay attention to: dispersion, homogeneity and angular dependence of the filters, what type of welding will be used, current indicators, risk of mechanical stress

When choosing protective devices, it is important to decide how the work will be carried out: indoors or outdoors

When choosing protective devices, it is important to decide how the work will be carried out: indoors or outdoors. The type of work carried out is indicated by markings: E – electric welding, G – gas welding,

The type of work carried out is indicated by markings: E – electric welding, G – gas welding,

B – auxiliary work, C – marking for “Chameleon” type filters.

Marking of different types of welding

To ensure uninterrupted operation of the filter, you should pay attention to:

- an adjustment unit, which can be accessed on the front side of the mask, which allows for correction without stopping work;

- on/off system that increases the longevity of the power supply and filter;

- availability of changing power sources;

- the number of sensors that determine the response time;

- possibility of adjusting parameters.

When choosing a model, it is recommended to choose filters marked 1/1/1/2, which determines the relationship to the optical class, uniformity and light dispersion.

When purchasing, it is important to study the product certificate, warranty period, and location of service centers. Explanation of the symbols on the welding mask

Explanation of the symbols on the welding mask

Welding helmet operating instructions

PLEASE READ THESE INSTRUCTIONS CAREFULLY BEFORE USING THE WELDING HELK.

A welding helmet with an automatic light filter protects the eyes and face from sparks, molten metal splashes and harmful radiation from the welding arc under normal welding conditions. The filter automatically switches from light to dark when the arc is ignited and returns to the light state when welding is completed. The welding helmet with automatic light filter is supplied fully assembled. Before use, you need to install two AAA batteries into the filter, adjust the mask according to your individual characteristics, select and set the required degree of darkness, sensitivity and delay time of the filter.

ATTENTION!

- This mask is not intended for gas and laser welding and cutting.

- Never place the mask and filter on a hot surface.

- Do not open the filter cartridge.

- This welding helmet is not intended to provide protection against severe impacts.

- Do not use this welding helmet while working with explosives or corrosive liquids.

- Do not make any changes to the filter or mask unless otherwise specified in these instructions. Use only spare parts specified in this manual. Making unauthorized modifications or using unauthorized parts will put the welder at risk and void your warranty.

- If the filter does not darken after igniting the arc, stop welding immediately and eliminate the possible causes of the malfunction. If you are unable to resolve the problem yourself, contact a technician or dealer.

- Do not immerse the filter in water.

- Do not use solvents when cleaning the filter and other parts of the mask.

- Use the mask only at temperatures between -10ºC and +55ºC.

- Store the mask and filter in a dry, cool, dark place when the mask is not in use for a long time. Storage temperature from -20ºC to +70ºC.

- Protect the filter from contact with liquid and dirt.

- Regularly clean the surface of the light filter from dust and dirt; do not use strong cleaning solutions. Use a clean, soft, lint-free cloth to clean optical sensors and solar cells.

- Replace the outer protective glass regularly if splashes of molten metal adhere to the surface, or if pitting, cracks, scratches, unevenness or clouding appear.

- The headband may cause an allergic reaction in sensitive people where the adjustment straps come into direct contact with the skin.

- To extend battery life, switch the filter to Grind mode after use. When the red “LOW BATTERY” LED on the inside of the filter lights up, replace the AA batteries.

- Before starting welding work, adjust the mask to your liking to achieve maximum comfort and protection, install two AAA batteries in the filter, select and set the required degree of darkness, sensitivity level and filter lightening delay time depending on the conditions and method of welding.

Preparing for head size

- The circumference of the headband can be increased or decreased by rotating the knob while pressing on the back of the headband (see “Y” in Fig. 1). This procedure is performed with the welding helmet on and allows you to obtain the tension necessary to securely fix the welding helmet on the head.

- If the headband sits too high or too low on your head, adjust the strap that goes over the top of your head. To do this, loosen the end of the belt by pushing the locking pin out of the hole in the belt. Move the two parts of the belt relative to each other to the required length and insert the locking pin into the nearest hole (see “W” in Fig. 1).

- Check the fit of the helmet by raising and lowering the welding helmet while it is on. If the headband feels loose, readjust until you get a secure fit.

Adjusting the distance from the eyes to the filter

- Loosen the locking nuts (see “T” in Fig. 1) and move the mask towards or away from your face. Make sure that the distance between both eyes and the filter is the same to avoid uneven darkening of the filter.

- After adjustment, tighten the locking nuts.

Adjusting the viewing angle of the mask

The viewing angle regulator is located on the right side of the mask (see Fig. 2). Loosen the right lock nut, push the lever pin out of the hole, turn to the required angle and tighten the lock nut.

Adjusting the degree of darkness (SHADE)

In the table “Degrees of darkness”, select the required level of darkness depending on the welding method and the value of the welding current. Set the darkening control located on the outside of the mask to the desired position. The degrees of darkness can be adjusted during welding using an external regulator.

Adjusting sensitivity (SENSITIVITY)

Sensitivity can be “H” (high) or “L” (low). Smooth adjustment of the filter sensitivity is carried out using the “SENSITIVITY” control knob located on the inside of the cartridge (see Fig. 3a). Medium-high sensitivity is recommended for most applications. Maximum sensitivity suitable for low amperage welding, TIG and other special applications. When working in the sun, in a brightly lit room, or near another welder, it is necessary to set the “SENSITIVITY” control knob to the “LO” (low) position (see Fig. 3b). To obtain the optimal effect, it is recommended to first set the sensitivity to high, and then gradually reduce it to a level where the filter begins to respond only to the welding arc, and not to ambient light (sun, bright indoor lighting, arc of another welder, etc.).

Principle of operation

The appearance of the mask is not very different from classic models. The design is as follows:

- A housing that protects the welder from splashes of molten metal and other harmful factors.

- Liquid crystal multilayer light filter with the function of automatic adjustment of the darkening level, depending on the intensity of work.

- Module for setting and controlling the light filter.

- Removable power supply.

A light filter is installed in the viewing glass. It is a device with several liquid crystals. In an inactive state, they do not show themselves in any way - the glass only protects from glare. But when the light sensors signal, the filter comes into operation, rearranging the arrangement of the crystals, darkening the glass. The reaction to the flash is almost instantaneous - about 0.0005 seconds.

The filter also reacts to the end of work with a delay, the level of which is set manually.

Please note that the design, thanks to built-in filters, provides protection from infrared and ultraviolet radiation even if it breaks.