Original German autobuffers Power Guard

Mirror-video recorder FUGICAR FC8

Sun blinds Trokot with magnets!!!

Compressor oil is a special type of fuel and lubricant, specially designed for use in moving components and assemblies of compressor equipment. There are several types of compressor oils, each having its own area of application and differing in operational and technical characteristics.

Description and features

In terms of their area of use and technical characteristics, compressor oils are classified as motor oils. They are operated under similar conditions - they are exposed to elevated temperatures and sudden changes in operating conditions.

Like other oils used to lubricate internal combustion engines, compressor lubricants are created on a mineral, synthetic or semi-synthetic basis.

The cost of fuels and lubricants depends on this - synthetics, which are more durable and have better performance properties, will accordingly cost the buyer more.

Another important technical indicator is the degree of viscosity, which determines the fluidity of the oil. The higher this indicator, the more easily the lubricant penetrates into the smallest gaps of moving parts inside the mechanism. The low viscosity coefficient of the oil facilitates the operation of the compressor unit, reducing friction and preventing the formation of harmful deposits in the gaps - soot, corrosion and oxides.

The peculiarity of using lubricants for compressors lies in their technical design.

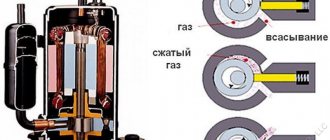

The compressor operates like a conventional internal combustion engine, but in reverse mode. If in an internal combustion engine the torque from the piston group is transmitted to the crankshaft via the connecting rod shaft, then in compressors it is the other way around - from the crankshaft the torque goes to the piston group, which pumps air into the receiver or supplies it directly to the consumer. In the case of a car engine, oil that gets into the piston chamber will simply burn along with the fuel.

In a compressor, the lubricant that gets into the piston group will inevitably end up in the receiver chamber or in the environment into which the compressed air is supplied. Such contamination by fuel particles can lead to negative consequences, therefore special technical requirements are imposed on compressor oils.

Lubricant selection

To minimize the risk of various kinds of troubles, it is necessary to carefully select a lubricant. Initially, the following factors will depend on the quality of the product: stability of operation and service life of the mechanism. If the oil used is of high quality, then the performance of the mechanism will be quite stable without the appearance of various unpleasant surprises.

For piston compressors, you need to use compressor oil that is recommended directly by the manufacturer - air units have high requirements for the liquids poured inside.

- Oil viscosity . A special indicator, its minimum value is seven units. It is necessary to take into account that thanks to it, most parts are lubricated, so it should fit well on them.

- Working temperature . First of all, it depends on the seasonality of oil use and directly on the characteristics of the compressor used. Typically, product replacement occurs with the onset of a new season. When choosing a universal product, a new one is poured during maintenance at the end of the specified engine performance.

Composition and performance characteristics

To ensure trouble-free operation and long service life of the mechanisms, the lubricant must meet the following requirements:

- Ensure temperature stability by effectively cooling the moving internal components of the compressor;

- Prevent the formation of coke-like deposits during oil heating;

- Have a stable viscosity indicator over a wide range of operating temperatures;

- Maintain the tightness of the joints of the parts, filling all the gaps;

- It is good to lubricate rubbing parts to avoid abrasion and overheating.

To achieve the above requirements, compressor oils have the following performance and technical characteristics:

- The viscosity coefficient at t = 100ºC varies in the range from 7 to 30 centistokes;

- Low degree of evaporation, including at elevated operating temperatures;

- Ability to perform its functions at high temperatures of mechanism components and pumped substances. According to the requirements of technical standards, the ignition temperature of compressor lubricant should be from 190 to 270ºC;

- Chemical neutrality. It must not react with the pumped gases. When used in refrigeration units, compressor oil must be inert towards refrigerants.

Based on their composition, compressor oils are divided into mineral-based varieties. These are either pure mineral oils or have a certain percentage of additives that provide anti-corrosion properties, oxidative stability, and increase the service life of fuels and lubricants.

In recent years, synthetic and semi-synthetic oils made from hydrotreated or essential oils have become widespread. Their main advantage compared to mineral oil is their improved technical characteristics. This concerns the fluidity rate, the lower solidification threshold, and the ability to work for a long time in particularly difficult conditions.

Is it possible to fill the compressor with motor oil?

Traditional oils are not suitable for several reasons:

- Compressor oil has higher environmental standards. Air can enter the operator's respiratory tract, even if he is a mechanic using pneumatic tools.

- The composition must ensure fire safety. That is, lubricant vapors, if mixed with air, should not pose a risk of ignition. And in such temperature conditions the risk is very high.

- The viscosity characteristics are fundamentally different.

- The compressor can run longer than the car engine (other terms for replacing used oil).

An amateur's experience or what will happen if you pour engine oil into a compressor - video

In addition, uniform standards have been established for oils that can be poured into the compressor. Each manufacturer (of equipment) sets its own requirements, but the approach remains the same.

- Minimum coke number. This means that during thermal decomposition of the lubricant (if it occurs), the amount of solid precipitation should tend to zero.

- Requires high thermal conductivity not available with traditional motor oil.

- When temperature and pressure increase (normal conditions for an air piston compressor), the physico-chemical properties should not change. This is especially true for the parameters of dripping, melting, solidification and flash. Although for this type of oil it is more correct to use the term “discharge temperature”.

Classification of compressor oils and their scope

All modern compressors are divided into two main types, differing in their design and operating features. These include:

- Volumetric. In such equipment, the distilled gaseous substance is sucked into the working chamber, compressed and thrown out under pressure by the forward-return movement of the piston system;

- Dynamic. The compression of the medium they distill is carried out using turbine mechanisms. The intake gas is accelerated by the turbine rotors, after which it suddenly slows down, causing it to be dynamically compressed.

In volumetric piston compressors, oil provides lubrication of moving parts - piston group, valves, bearings. Traditionally, such models use mineral oil that meets international certificates DIN-51506-VGL, VDL. The viscosity class for them corresponds to ISO/VG standards from 68 to 150. In positive displacement rotary or screw compressors, the moving parts are lubricated using an oil bath. As a result, the oil is constantly mixed with the forced air, heating to a temperature of about 90-100ºC.

At the outlet of the compressor chamber, a filter device is installed that separates the oil from the gaseous substance. Therefore, for use in rotary and screw compressors, oils with increased deaeration and demulsification characteristics are used.

Special requirements are also imposed on increased anti-corrosion properties and the maximum amount of deposits during operation. Most manufacturers of such equipment provide instructions in the accompanying instructions regarding the selection of a suitable lubricant.

In dynamic modifications of compressor units, lubrication is provided through a forced supply circuit: gears, shaft seals, bearings. It is recommended to use the same type of oil for the compressor operating mechanism and its drive system. It is recommended to use special turbine oils of the following grades in dynamic installations that comply with the ISO/DP-6521 standard:

- DIN-51-515 TDL-32;

- TDL-46;

- TDL-68;

- TDL-EP with extreme pressure additives.

Conventional motor oils are classified according to their flash point.

Compressor lubricants are divided, unlike motor lubricants, according to the temperature of the pumped substance.

In Russia, along with the international classification of compressor oils, the domestic classification adopted by Gostekhnadzor back in Soviet times is still often used.

According to it, all compressor oils are divided into 4 groups:

- Lubricant intended for operation under moderate loads. The temperature of the discharge gas does not exceed 160ºC.

- The second group is intended for operation under moderate loads, but with a discharge gas temperature of up to 180 degrees.

- Compressor lubricant of the third group is designed for mechanisms operating under increased loads and temperatures up to 200ºC.

- The last group includes oils intended for operation in extremely difficult conditions, with increased pressure and temperatures up to 200ºC.

Each group has a special list of operational and technical properties that must be taken into account when choosing the type of oil for the compressor.

It should be noted that foreign manufacturers have not developed a unified classification for operating temperature, and each large company uses its own standards.

Functionality of compressor lubrication

To achieve stable operation of the device, it is necessary to find out exactly what kind of oil to pour into the piston air compressor. This fluid must perform various functions that ensure stable operation of the device during normal maintenance. Failure to perform any function will reduce the performance of the device and may even cause it to fail. The most important properties of a piston compressor fluid are:

- Protection of parts from increased wear.

- Excellent heat dissipation.

- Reducing engine knock.

- Sealing of the working compression chamber.

Instructions for use

In order for compressor oil to provide effective protection of the mechanism, you must follow the main rules for its use:

- To select the correct class and type of oil, you must carefully read the technical instructions before filling. Manufacturers of compressor equipment always indicate the recommended lubricant in the specification;

- When filling, half of the required volume of lubricant is poured directly into the compressor mechanism, and the second half into the oil tank (receiver). In this case, the oil will be evenly distributed throughout the entire volume of the mechanism, ensuring the most complete filling of the gaps between the rubbing parts;

- When starting a compressor with freshly filled oil, there is a high probability of water hammer occurring, which can damage internal components and parts of the equipment. To avoid this problem, it is necessary to rotate the shaft manually several times to evenly distribute the lubricant;

- After filling, do not immediately turn on the compressor. It is necessary to wait about an hour, allowing the compressor oil to settle and fill all internal gaps;

- The oil must be changed in accordance with the manufacturer's technical recommendations, after a certain number of operating hours. If the operating hours during operation of the compressor are not calculated, then the optimal option would be the oil change range - twice a year.

Correct use of oils will increase the service life of compressor equipment, reducing wear of its units and components.

It is prohibited to mix different types of oil when filling, and when changing oil, the oil system of the mechanism must be flushed.

How to replace compressor oil?

If you adhere to the technical requirements, replacement is not provided. That is, there is no alternative among other types of lubricants. However, based on experience in using low-power compressors, it is possible to fill in engine oil for diesel engines with a viscosity of SAE 15W40.

This may not be profitable from an economic point of view: branded compressor oil is cheaper. And given the availability of these materials, there is no point in experimenting with the equipment.

I have one friend who is not friendly with technology at all. At the same time, he has to work with the units constantly. Either he and his wife will go to the dacha, or something needs to be done around the house. One day we got to talking, and I was surprised to learn that he had an air piston compressor, but my friend didn’t even know that it needed some kind of oil.

So, my friends. Air piston compressor oil is essential. Without this composition, the equipment will not work fully, it will quickly break down and you will only have to throw it away. I will tell you about choosing the right oil for a compressor in this review.

Advantages

Compressor oils differ from conventional motor oils in a number of advantages that allow them to be used in particularly difficult conditions.

- Compressor lubricant has a high degree of resistance to aging. During operation, when interacting with air and under the influence of high temperatures, a relatively small amount of coke-like residues is formed in them;

- The additives used in their composition increase their anti-corrosion properties and ability to resist oxidation;

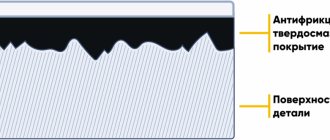

- Due to their high fluidity coefficient, compressor oils are able to lubricate the smallest gaps between contacting parts. This achieves a reduction in friction and increases the wear resistance of compressor equipment parts.

- Ability to work at elevated ambient temperatures reaching 200ºC.

How to select oil for a compressor?

Manufacturers are trying to produce lubricants that meet the requirements. As a result of testing, the product receives a quality certificate and approval for use. The instructions for the equipment can help in choosing the appropriate composition. The document often states which lubricant will be optimal for the unit.

Sometimes people wonder whether it is possible to replace the oil with a different composition. There are no such options. Other types of lubricants can significantly harm equipment and even damage it.

Special formulations

What kind of oil should I pour into the compressor? A piston air compressor has special requirements. The lubricant must be in close contact with the highly heated compressed gas. Thus, the product must be safe even when heated to temperatures of 170°, 180°C and more. It should include only high-quality additives that eliminate the risk of carbon deposits on moving parts. Also, the substance must have high resistance to temperature oxidation, otherwise the likelihood of compressor failure increases.

Due to long-term use, its density increases as the liquid evaporates and contamination increases. Because of this, a fire is possible, so the oil in the air compressor must be changed regularly.

Types of compressor equipment

This technique is classified mainly by the way the cylinders are arranged. There are:

- Machines with vertical installation of cylinders. Obviously, in this case the main elements are located in the vertical plane.

- Horizontal devices. This group of units, in turn, is divided into versions with unilateral installation of cylinders relative to the crankshaft and with double-sided installation.

- Corner machines. This option involves both horizontal and vertical arrangement of cylindrical elements. In addition, this group includes equipment with V, W-shaped installation of cylinders.

There is another division of similar equipment: an oil-free piston compressor and an oil analogue. As you can guess from the name, in the first case no lubricant is used. This may be necessary in a number of cases when for production it is necessary to obtain a clean gaseous medium, without additional impurities. In earlier times, the oil-free version was a special kind of design, when the sealing of the working moving element (piston) was carried out by cutting grooves on it.

But the prevalence of such devices decreased over time, and subsequently they were replaced by an oil-free piston compressor of a different type with a seal of a different type. This option assumes the presence of piston sealing rings. They are usually made from composite materials. The peculiarity of this design is its ability to function for a much longer period of time. This property distinguishes such equipment from a number of existing analogues, including piston oil compressors.

Let's watch the video, types of units and their features:

Another division of such devices is by the number of compression stages.

There are:

- Single stage;

- Two-stage;

- Multi-stage.

The advantage of the last of these options is that oil compressors of this type are able to regulate the temperature of the working environment precisely due to a multi-stage compression system.

An increase in the temperature of the compressed air occurs due to the formation of oil deposits, which accumulate in excess on various surfaces of the working elements. This is perhaps the main drawback of devices such as piston oil compressors.

Brief descriptions of products from various manufacturers

Compressor oil is a specific material used exclusively for narrow-profile applications. Manufacturers insist on using high-quality and certified material to obtain maximum performance. Among the inexpensive, but at the same time high-quality liquids, the following stand out.

- Ariane K-12 . It is mineral and is used in medium or high pressure units, in various mechanisms that require the use of a product with a minimum amount of sulfur (0.3). Viscosity 11 - 14, thickening temperature approximately - 25 degrees.

- Oil B. P. Enersyn GCS-180 . It is an exclusive synthetic product and cannot be combined with mineral products. It was developed exclusively for piston units with direct gas contact. This product contains various oxidation inhibitors, giving it not only high temperature stability, but also the ability to suppress corrosion of the components of the mechanism.

- Ariane KS-19 is mineral and is used in high or medium pressure piston units. Produced from paraffinic sulfur oil using a selective purification method. Viscosity ranges from 18 to 22, and the thickening temperature is 15 degrees.

- Mobil Rarus 429 is ideal for a variety of air compressors. The high level of purification guarantees low viscosity and flash point. This product has minimal coke formation. Therefore, the parts retain high performance for a long period.

- Ariane K-28 can be used in various air units. It is mineral and made from petroleum with a small amount of sulfur. Viscosity is approximately 26−30, complete absence of various additives, but thickens at a temperature of approximately -10 degrees.

- VDL 100 Fubag is designed for air piston units and is compatible with units from other companies. The composition includes a variety of additives that prevent oxidation at operating temperature and the formation of soot on the components of the mechanism.

- KM100 Enkor 40612 is a semi-synthetic product and is used only in a piston-type air unit. A low level of evaporation guarantees good savings in product consumption. High performance indicators allow you to work at a fairly low degree (-30). During overload of the unit, the components of the mechanism are preserved without any damage.

- REZOIL COMPRESSOR Rezer is used for stable operation of various air compressors. Special additives included in the composition minimize the formation of carbon deposits on mechanism parts.

The use of equipment entails material costs to maintain it in working condition. And you need to use not only high-quality oil, but also monitor its level and top up on time. Not least important is compliance with fire safety, and this directly depends on what product will be poured inside the mechanism. In order to minimize various unforeseen situations in work, it is necessary to use only proven, certified materials.

Mineral or synthetic

Opinions are divided on what kind of oil to pour into the compressor: some praise mineral oil, while others say synthetic oil is better. Mineral is cheaper and is usually used when the compressor is used infrequently. In this case, there is a temperature limit - no more than 90 °C. Higher temperatures may cause ignition or detonation. The oil service life is short - 2-4 thousand hours, depending on the brand and manufacturer.

Synthetic oil has different properties:

- High viscosity allows its use for any screw compressors.

- Heating to 180−200 °C does not disrupt the structure of the substance and does not lead to detonation. Therefore, it is considered universal.

- It performed well when working in low temperatures: it can be used outdoors in winter.

- Service life is up to 8000 hours, which is 2-4 times longer than mineral.

Synthetic oil is more expensive than mineral oil, and they prefer to buy it when the compressor is used frequently and actively.

Correct selection of liquid

In order for the device to show high performance, you need to select compressor oil for piston compressors, and all its parameters must necessarily meet the individual requirements of the device.

The most important indicators of such a liquid are:

- Viscosity degree.

- Thermal-oxidative parameters.

Consumption depends on operating temperature.

It increases as it increases. This is what causes frequent lubricant changes. What oil to pour into a piston air compressor to reduce heat transfer performance is usually decided taking into account the brand of liquid and the manufacturer’s recommendations. Professionals advise using only fluids intended for a specific model. The oil brand is indicated in the technical description of the device. The manufacturer indicates the best option. Today the most popular lubricants are:

The last type differs from others in its properties. Its kinematic viscosity is affected by the operating temperature. If it is 40 degrees, the viscosity value approaches 150 sq. mm/s. If the temperature reaches 100 degrees, the viscosity begins to decrease. Its value becomes equal to 10.6 square meters. mm/s. If a problem arises about what kind of oil to fill into an air compressor, Eco mak brand, Shell Corena P 150 liquid can be considered the ideal option.

Selecting the right type

It is not always possible to immediately select the right type of lubricant for pouring into a piston compressor. The most important parameter in the classification is its viscosity. For screw motor devices, sealing properties are considered the main ones. The permissible viscosity value is 7 mm2/s, at an ignition temperature of +180 degrees.

Which is better: mineral water or synthetic water?

This problem occurs quite often. Some people prefer synthetic products, while others consider mineral lubricants to be of better quality. It all depends on the frequency of use of the device. If the compressor turns on rarely, it is better to fill in mineral water, especially since it costs much less. In addition, its operating temperature is +80 - +90 degrees. Mineral liquid has a short service life.

The properties of a synthetic product are much better. High viscosity makes it possible to fill the lubricant into any compressor. Even when the temperature reaches its maximum values (+200 degrees), the structure of the liquid remains unchanged and the engine does not detonate. Therefore, this product belongs to the universal group.

Synthetics allow you to work at low temperatures. The service life of such a liquid is several times longer. Of course, the cost of synthetics is much higher, but the quality of such oil compensates for all costs. The liquid is actively used in workshops where the compressor operates constantly.

Review of popular oils

Of course, compressor lubricant can be called a specific material.

It is designed for a specific job. Manufacturers recommend using only certified, high-quality products. They can be replaced with other materials, of which several types are considered the most popular. The most popular of them is “Arian K-12”. Mineral water designed for the operation of a piston compressor. Oil hardens when the temperature drops below - 25 degrees. Viscosity ranges from 11 to 14 mm2/s.

BP Enersyn GCS 180. Synthetics. Can be used at high temperatures. Thanks to special oxidation inhibitors, it protects parts from corrosion.

Mobil Rarus 429. Refers to universal products.

Can be used in any compressor. It has excellent viscosity and ignites at high temperatures. The lubricant is designed for a long service life. "Arian K-28". Universal mineral oil. The degree of viscosity is in the range of 26-30 mm2/s. The liquid contains virtually no sulfur. Due to the absence of various mechanical impurities, the liquid can be used at a temperature of -10 degrees.

"VDL 100 Fubag". Special product for filling into piston compressors. Thanks to special additives, the lubricant protects parts from oxidation when temperatures reach high values. The liquid prevents the appearance of burning on the surface of parts.

Explanation of markings

In Russia, a special designation for lubricant is used. To choose the right type of oil, you need to know what the designation means.

Very often, KS-19P brand liquid with the following designations is used to fill the compressor:

- “K” - compressor;

- “C” - made from sour crude oil;

- “p” - it contains special additives;

- 19 is the viscosity value when the temperature reaches 100 degrees.

Recommendations from professionals

It is advisable to fill the device with lubricant specified by the manufacturer. It provides maximum performance and fully complies with the characteristics of the device.

The oil level must exceed the required volume. These devices do not have a separate lubrication system. Oil enters directly into the system after the connecting rod captures lubricant from the crankcase.

Compressor oil is a complex synthetic or mineral composition that simultaneously performs different functions. Labeling is important, since each brand has its own characteristics necessary for a specific situation. For example, if the required viscosity is not present, the filled oil can cause rapid equipment failure.

Selection by characteristics

Read the labeling carefully. The main thing is to have heat resistance and high thermal-oxidative stability. Moving parts become hot during high temperature operation and the use of a low-quality product may cause a fire. These characteristics must be indicated on the container.

In the case of screw models, it is especially important to create tight gaps, so the use of oil with a viscosity of less than 7 mm²/s is unacceptable. In this case, the operating temperature is not so important, but it is still not recommended to use brands in which this indicator is 90 °C. Otherwise, the oil will have to be changed much more often than indicated in the passport in order to increase the service life of the compressor.

When studying the markings, pay attention to the designations. As a rule, the options are standard: SAE 20, SAE 40, SAE 60, etc. You can also find the following markings: SAE 20W, SAE 30W. Here the letter W indicates that the oil can be used in the cold season. At temperatures of -20 °C or -30 °C, the viscosity will ensure high-quality pumping.

What is a compressor?

Before you start choosing oil, you need to understand in more detail what a car compressor is, what features it has that should be taken into account when choosing a lubricant.

Every automaker strives to increase engine power as seriously as possible, and at the moment there are only 2 main methods to do this. One of these methods is to use an internal combustion engine of as large a volume as possible; in this case, the engine becomes much more productive, but is difficult to maintain and expensive. Another method is to use special equipment, that is, a compressor, whose task is to increase the air supply to the combustion chamber of the internal combustion engine, which allows, without increasing the size of the engine, to achieve maximum productivity.

It is the second method that most automakers use nowadays, so a piston compressor is an indispensable part of any car, and the productivity of both the engine itself and the entire car largely depends on its operation.

Why are compressors needed?

What do compressors do, why are they necessary? Compressors in operating condition increase the pressure of air or any other gaseous mixture.

The gas pressure level increases several times, and its energy in the system increases. Considering that the volume of the entire substance is limited, due to the impact on it, its temperature and density sharply increase.

The device of a piston compressor.

There are only 2 types of compressors - dynamic and positive displacement. About the latter, we can say that volumetric devices ensure that the gaseous mixture is simply sucked into the chamber, compressed to a small size and squeezed out using a piston, which uses the possibility of reciprocating motion for this purpose. The operating principle of dynamic devices is slightly different. With this method, the turbine wheels quickly accelerate the medium to a certain limit, after which it sharply slows down.

Over the past 20 to 30 years, piston engines have been increasing power in a variety of ways. But preference was given to rotary and screw devices. Today, the share of screw and winged devices on the market is very large. If you go to any branded store and look at the assortment, then most of the products offered will have exactly this principle of operation.

The other part is the air piston compressors themselves. We will talk about them. The operating system of a piston-based air compressor is different from a rotary or screw system.

Return to contents