What is A1 fittings?

This type of reinforcement has a smooth surface. It is usually supplied from the factory in the form of coils or rods. The diameter of the A1 reinforcement can be 6-40 mm. The fact that A1 is a material with a smooth surface determines the relatively low stability of its adhesion to concrete, and therefore it is not always possible to use it as the main material for reinforcement in reinforced concrete structures.

A1 fittings

The type of reinforcement under consideration is most often produced from carbon steels of the following types:

- St3kp (or boiling);

- St3ps (or semi-calm);

- St3sp (or calm).

Reinforcement made from the first type of steel is used in structures that do not require large external loads. The most durable material is the one made using St3sp steel.

The main regulatory document defining the characteristics of type A1 fittings is GOST 5781-82.

The material in question is most often used in monolithic buildings, as well as in the production of various reinforced concrete products. The use of A1 fittings is also widespread in industry.

It can be noted that the corresponding material is characterized by high resistance to aggressive environments, and, what is especially important, to low, high air temperatures, as well as their sudden changes.

Other important advantages of the fittings in question include a relatively low price. Therefore, its use where possible from the point of view of production technologies can significantly reduce the project budget.

Another important characteristic of A1 reinforcement is good weldability. This increases the versatility of using the respective material.

Key features of class A1 fittings

In accordance with approved standards, reinforcement bars are classified into groups based on mechanical characteristics. A distinctive feature of the metal products is their smooth cross-section, the release form is in coils or in rods (products with a cross-section of more than 12 mm are supplied exclusively in rods).

It is worth noting that reinforcing steel A1, used for the manufacture of hardware by the hot-rolled method, is also designated by the marker A240 (the number is the yield strength). In the production of this category of rolled metal, the alloy St3 ps/sp is used, which has good weldability properties. The range of fittings includes products with a cross-sectional diameter from 6 to 40 mm.

What is A3 fittings?

This type of fittings is made of hot-rolled steel. Most often, A3 material is used in the construction of various structures - residential, industrial. Unlike smooth A1, the reinforcement in question is corrugated. There is a special pattern on its surface - in the form of 2 longitudinally located ribs, as well as many transverse ones, which are located at a short distance from each other.

A3 fittings

The noted feature characterizing the surface of the reinforcement makes it possible to increase its adhesion to concrete in the corresponding building structures. Therefore, type A3 material can be used as the main material for reinforcing reinforced concrete structures.

In addition, A3 fittings are in many cases produced from high-alloy steels - with admixtures of chromium, manganese, titanium, and silicon. This determines the very high strength of the corresponding material.

A3 fittings can have a diameter of 6-80 mm. It is customary to classify it into 3 main types:

- hot rolled;

- strengthened by hardening;

- strengthened by stretching.

The main advantage of A3 reinforcement is its ability to significantly improve the performance properties of building structures in the structure of which it may be present. Reinforced concrete structures with A3 reinforcement acquire exceptionally high resistance to various mechanical and, in many respects, atmospheric influences.

Like material type A1, the reinforcement in question is well welded. It is also characterized by resistance to many aggressive environments - in particular, it has excellent resistance to oxidation. But from the point of view of resistance to high and low air temperatures, as well as their differences, A3 reinforcement, as many experts believe, is inferior to material of type A1.

Area of application AI

Relatively low weight, strength, ductility, and optimal price make class AI reinforcement universal and explain its demand in various fields:

- monolithic, low-rise and road construction, reinforcement of reinforced concrete products and structures (mainly for the manufacture of loop and connecting elements, when pouring concrete into corners and transitions, for the manufacture of reinforcing meshes and frames);

- mining and extractive industries;

- construction of main pipelines.

You can also:

- “Hot-rolled steel for reinforcement of reinforced concrete structures”;

- “Rolling of periodic profiles from reinforcing steel”;

- find out prices and buy A1 fittings

Comparison

The main difference between A1 and A3 reinforcement is that the first material is smooth, made from carbon steel. The second is corrugated, produced in many cases from high-alloy steels. This property determines a significant difference between the reinforcements under consideration in terms of:

- adhesion to concrete;

- strength;

- versatility.

According to the first criterion, the A3 reinforcement wins - due to the corrugated surface. In terms of strength, material A3 is also superior to A1.

But from the point of view of versatility, as many experts believe, A1 fittings have advantages. This is due to its higher resistance to aggressive environments, and above all to high and low temperatures and their differences. Thus, in the conditions of the Far North, A1 reinforcement may be indispensable, since A3 material is not always resistant to low temperatures.

Having determined what the difference is between reinforcement A1 and A3, we record the conclusions in the table.

What is rolled reinforcing metal A1?

According to GOST 5781, A1 reinforcement is designated differently - reinforcement (reinforcing steel - hereinafter AC) AI (A240). This is a more correct name for this rolled metal and is used by all its manufacturers and professional consumers. In the technical language of GOST 5781, which classifies all types of reinforcing steel produced according to it for the reinforcement of conventional as well as prestressed various reinforced concrete structures, this designation stands for “class A1 reinforcement.”

The division into classes in this GOST is made according to one of the mechanical characteristics of the speakers - the yield strength. Its conditional value for product A1 is indicated in parentheses after the index A - the number 240. This is the value of the yield strength in kgf/mm2, but multiplied by 10. Thus, reinforcement A1 has a yield strength of 24 kgf/mm2 (corresponds to 235 N/mm2 ).

According to GOST 5781, AI speakers are manufactured only with a smooth profile - without corrugation of the surface of a regular round cross-section. Externally, depending on the nominal thickness, it looks like steel wire or rod.

Fittings without corrugation

AC A240 is produced hot-rolled and only from carbon steel. In this case, according to standard 5781, only brands St3sp, St3kp and St3ps are used. It is precisely because of this that A1 reinforcement, in contrast to smooth AC of other classes of GOST 5781 and produced in accordance with GOST 10884, is most in demand and is used both for reinforcement and as ordinary rolled metal - for the manufacture of various steel parts and structures. After all, St3 is the most flexible, ductile of all carbon and, especially, low-alloy grades and is better weldable than all alloys. Its chemical composition for finished AI fittings must meet the requirements listed in GOST 380.

The range of production of smooth AI speakers includes 14 standard sizes in diameter in the range of 6–40 mm. Products with a thickness of 6–12 mm are produced in rods or in the form of coils, and larger diameter A1 reinforcement is supplied only in rods. AS A240 rods are manufactured in lengths of 6–12 m. They are available in measured or unmeasured lengths. Together with the measured ones, unmeasured rods with a length of at least 2 m and in an amount equal to a maximum of 15% of the mass of the released batch can be supplied. The consumer can order the option he needs, and by agreement with the manufacturer, it is also possible to produce rods of 5–25 m.

Production of A1 fittings

There are 3 types of A1 rods, differing in production technology:

- hot rolled reinforcement;

- marked T - strengthened during heat treatment, hardening;

- marked B - cold-rolled, strengthened by drawing.

The material is produced in rolling mills using the method of deforming steel blocks. Source material - standard structural steel St3kp, St3ps or St3sp:

- low-carbon - for non-stressed reinforcement;

- high-carbon - for intense.

The characteristics of rods (strength, geometry, ratio of weight and cross-sectional diameter) are regulated by GOST 5781-82, GOST 2590-2006, DSTU 3760-98, as well as other current regulatory documents. The permissible deviation of the actual parameters of the finished product is 3...9%.

Standard sizes of fittings A1

Products are classified according to two basic indicators:

- Length - 6-12 m for measured products or arbitrary for non-measured fittings. The length of the measuring rod is determined by the diameter (the reference parameter is 10 mm).

- Cross-sectional diameter - 6-40 mm. The production step is 2-3 mm.

Class A1 materials are supplied in the form of rods or coils (coils) weighing from 1.5 tons. Wire with a diameter of up to 10 mm is rolled into coils.

Features and Benefits

A1 reinforcement forms contact with concrete in a number of ways:

- during adhesion (for example, when concreting a steel element into a block);

- during compression (for example, with reinforced concrete after concrete shrinkage);

- in shear bond zones;

- during friction;

- electrochemically - when the cement solution interacts with the surface of the steel.

At the low price of A1 reinforcement per meter and ton, the material has a considerable number of advantageous characteristics:

- flexibility, elasticity;

- hardness, strength;

- ease of welding;

- resistance to corrosion, exposure to chemically aggressive environments (chlorine, natural gas);

- durability.

The second marking of reinforcement A1 - A240 - indicates the fluidity index, or the stress value, above which metal deformation begins.

Areas of application

- Construction: Reinforcement of beams, columns, floors, foundations, framing frames.

- Formation of cast and metal structures, reinforced concrete blocks.

- Strengthening the strength of monolithic structures - tunnels, bridges.

Table

| A1 fittings | A3 fittings |

| Has a smooth surface | Has a grooved surface |

| Made from carbon steels | Made from high alloy steels |

| Less durable | More durable |

| Provides weaker adhesion to concrete | Provides stronger adhesion to concrete |

| More resistant to low temperatures and their sudden change to higher ones | Less resistant to low temperatures and their frequent changes to higher ones |

Scope of use of metal products

The products are widely used in the manufacture of hinges intended for fastening reinforced concrete products to the foundation or to each other. Loop reinforcement can also be used to strap the main frame made of high-class products.

Among other things, bars with A1 marker are in demand for:

- strengthening reinforced concrete structures;

- production of reinforcing mesh;

- floor and wall reinforcement;

- production of decorative metal structures (fences, gazebos, stairs, etc.).

The products are also used in the manufacture of small-sized parts in the mechanical engineering sector (fasteners and other hardware).

Assortment of fittings

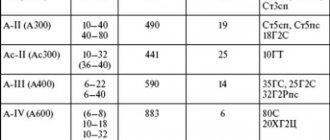

Steel grades used for the manufacture of fittings (GOST 5781-82):

| Reinforcement steel grade | Profile, diameter | steel grade |

| AI (A240) | 6-40 | St3kp, St3ps, St3sp |

| A-II (A300) | 10-40 40-80 | St5sp, St5ps 18G2S |

| Ac-II (Ac300) | 10-32 (36-40) | 10GT |

| A-III (A400) | 6-40 6-22 | 35GS, 25G2S 32G2Rps |

| A-IV (A600) | 0-18 (6-8) 10-32 (36-40) | 80С 20ХГ2Ц |

| AV (A800) | (6-8) 10-32 (36-40) | 23Х2Г2Т |

| A-VI (A1000) | 10-22 | 22Kh2G2AYu, 22Kh2G2R, 20Kh2G2SR |

Fittings of different diameters, parameters (according to GOST 5781-82):

| Profile No. | Number of m in 1 ton | Weight of 1m profile in kg | Sectional area (cm2) |

| 6 | 4504,50 | 0,222 | 0,283 |

| 8 | 2531,65 | 0,395 | 0,503 |

| 10 | 1620,75 | 0,617 | 0,785 |

| 12 | 1126,13 | 0,888 | 1,131 |

| 14 | 826,45 | 1,210 | 1,540 |

| 16 | 632,91 | 1,580 | 2,010 |

| 18 | 500,00 | 2,000 | 2,540 |

| 20 | 404,86 | 2,470 | 3,140 |

| 22 | 335,57 | 2,980 | 3,800 |

| 25 | 259,74 | 3,850 | 4,910 |

| 28 | 207,04 | 4,830 | 6,160 |

| 32 | 158,48 | 6,310 | 8,040 |

| 36 | 125,16 | 7,990 | 10,180 |

| 40 | 101,32 | 9,870 | 12,570 |

| 45 | 80,13 | 12,480 | 15,000 |

| 50 | 64,89 | 15,410 | 19,630 |

| 55 | 53,62 | 18,650 | 23,760 |

| 60 | 45,07 | 22,190 | 28,270 |

| 70 | 33,10 | 30,210 | 38,480 |

| 80 | 25,34 | 39,460 | 50,270 |