When developing a PPR for the installation of metal structures, it is necessary to carry out

- Selection of brands and number of cranes based on the dimensions of the construction site, masses of mounted elements, position of cranes, installation height, etc.

- Calculate the danger zone when installing metal structures. If the hazardous zone extends beyond the work site, develop additional measures for safe work

- Describe the sequence of installation of elements by grips

- Show graphically the installation of elements in plan and in sections

- Develop slinging schemes

- Determine the location of installers, their responsibilities, and routes of movement around the construction site

- Carry out measures for the joint work of an assembly crane and other construction equipment

- Agree on the work plan for the installation of metal structures with the owner of the lifting mechanism and the customer

Initial data

- Stroygenplan

- Work schedule

- Working draft

- List of lifting equipment (if available or recommended)

- Special installation conditions (existing buildings, structures, power lines, cramped conditions, etc.)

Basic provisions on occupational safety:

All work must be carried out in accordance with the requirements:

— SNiP 12-03-2001 “Labor safety in construction” part 1;

— SNiP 12-04-2002 “Labor safety in construction” part 2;

— GOST 12.3.005-75 Group T58 “Painting works”

— RD 10-198-98 “Standard instructions for the safe conduct of work for cradle workers located on a lift (tower).” (Approved by Decree of the Gosgortekhnadzor of Russia dated 02.04.98 No. 21, date of implementation 1998-07-01);

— TOI R-66-13-93* “Standard labor protection instructions for operators of mast, rack or shaft lifts.” (Approved by Decree of the State Construction Committee of Russia dated November 22, 1993 No. 18-48. Date of introduction 1994-1-01);

— TOI R-66-29-95 “Standard instructions on labor protection for construction painters” (Approved by Resolution of the Ministry of Construction of Russia dated March 13, 1995 No. 18-22 Date of introduction 1995-07-01);

— TOI R-218-36-94 “Standard labor protection instructions for painters” (Approved by the Federal Road Department of the Ministry of Transport of the Russian Federation on March 24, 1994. Date of introduction 1994-07-01);

— TOI R-66-02-93* “Standard labor protection instructions for workers performing steeplejack work” Approved by Resolution of the State Construction Committee of Russia dated November 22, 1993 N 18-48 Date of introduction 1994-01-01;

— PB 10-115-96 “Rules for the design and safe operation of pressure vessels” Approved by Resolution of the State Technical Supervision Authority of Russia dated April 18, 1995 No. 20;

— POT R M-017-2001 “Inter-industry rules for labor protection during painting work”;

— Sanitary rules for painting work using hand sprayers.

What does (example) PPR for installation of metal structures look like?

Order PPR

possible by phone and email

+7(495)797-01-75

The email address is protected from spambots. Javascript must be enabled in your browser to view the address.

Initial data

- Construction Organization Project (COP)

- Working documentation

In accordance with the current regulatory documentation, construction and installation work is permitted only if there is a work execution plan (WPP).

Working without a work permit is a direct violation of the legislation of the Russian Federation.

For successful construction, it is necessary to resolve in advance issues regarding the organization and technology of work, model the construction site and perform scheduling.

The development of the PPR consists of a detailed study of the technology for carrying out work and organizing construction production.

This article contains answers to the most popular questions asked to our specialists.

The main regulatory document for PPR is the current SP 48.13330.2019 “Construction Organization”.

Completed projects for the installation of metal structures in industrial construction:

PPR for the installation of metal structures for the project “Aquapark complex with a hotel-office building and apartments” on site 4 of MIBC Moscow City”

Project for the installation of metal structures. Object: “Metallurgical plant in the area of CHPP-4, Balakovo, Saratov region, Electric steel melting shop”

LLC "Delta-K"

Development of a project for the installation of metal structures of the building for the project “2nd stage of reconstruction, restoration and technical equipment of the Bolshoi Theater complex of buildings at the address: Moscow, Teatralnaya Square, vl. 1"

Development of a project for the installation of metal structures for the project “Installation of light naphtha isomerization. Furnace block overpass and technological overpass Object: OJSC Gazpromneft-MNPZ at the address: Moscow, microdistrict. Kapotnya, 2nd quarter, 1 building 3"

Development of a project for the installation of metal structures for the project “Linking technological installations and waste management facilities to the in-plant process pipelines and utility networks of OJSC Gazpromneft-Moscow Refinery”

Development of a project for the installation of metal structures for the project “Reserve fuel gas line. Object: OJSC "Gazpromneft-MNPZ" at the address: Moscow, microdistrict. Kapotnya, 2nd quarter, 1 building 3"

Development of a project for the installation of metal structures of the dome for the object “Church of St. John the Evangelist under the Elm” (1825-1837), Moscow, Novaya Ploshchad, no. 12

Development of a project for the installation of metal structures for the project “Reconstruction of mechanical treatment facilities of the Moscow Oil Refinery OJSC.” Transformer substation TP-310"

Construction Directions LLC

Development of a production project for the installation of metal structures for the project “Car wash with a range of services and a store of related products at the address: Bolshaya Kosinskaya st., vl. 8"

Faston Engineering LLC

Development of a project for the execution of work on the object “Warehouse and office premises, Lyubertsy district, Tomilino village, st. Garshina, 11"

LLC "MVA-Service"

Development of a project for the execution of work on the superstructure of an administrative building at the address: Moscow, Central Administrative District, Pozharsky lane, 15 building 1

MERTON CONSTRUCTION AND ENGINEERING LLC

Development of a project for the installation of metal structures at the facility “Multifunctional center for the sale of auto accessories and vehicle maintenance “NORAUTO” at the address: Moscow region, Klimovsk, st. Molodezhnaya, 11"

Progress-Neva LLC

Development of a project for the installation of metal structures for the project “Sports complex with a universal games room in Ukhta”

LLC "SK Promstroyservis"

Development of a project for the installation of metal structures and facades for the project “Multifunctional administrative production and warehouse complex in Khimki, Moscow Region”

VSK-Electro LLC

Development of a project for the production of works for the installation of metal structures at the facility "OJSC MZ Elektrostal"

LLC "STEEL CONSTRUCTOR"

Development of a project for the installation of metal structures for the project “Construction of a business center. Moscow, Novoryazanskaya st. ow. 26-28, Novobasmannaya st. ow. 29"

CJSC PROCONS

Development of a project for the production of work for the main period for the object “Universal warehouse complex Zelenograd Autonomous Okrug, Moscow”

Stroyprogress LLC

Development of a project for the installation of metal structures for the project “Sports complex at the address: Lyubertsy, st. Electrification"

Main works

4.1. Applying primer to prepared surfaces, bolted and welded joints and restoration of defective areas.

Stelpant-PU-Zink primer is applied using airless sprayers.

To obtain a uniform layer and sufficient thickness of the coating, the primer is applied to flat surfaces in two passes. The thickness of the dry soil layer should be 80 ÷ 100 microns.

4.2. Application of paint and varnish coating.

The surface prepared for painting must be dry, dust-free, free from contamination with oils and greases (if any, degrease again). After inspecting the surface, a report is drawn up on the suitability of the surface for painting or an entry is made in the Work Production Log.

Application of paints and varnishes should be done using airless spraying. In hard-to-reach places, it is allowed to apply paints and varnishes using a brush or roller.

Application of Stelpant-PU-Zink can be carried out in the temperature range from -10 °C to +35 °C and relative air humidity from 30% to 98%.

Application of epoxy and vinyl epoxy materials (Vinikor 62) can be carried out in the temperature range from 0 °C to +35 °C and relative air humidity up to 85%.

Before applying the top coats (“Vinikor 62”), if necessary, stripe painting of the end edges of the linings of bolted joints, bolts, nuts and washers is carried out with a brush.

To ensure high-quality coverage when applying paints and varnishes, the spray nozzle should be located perpendicular to the surface to be painted at a distance not exceeding 250 - 300 m.

Important to remember

After writing the PPR documents, make sure that the described actions correspond to the actual actions of the team. To reduce the risk of errors when signing PPR and Technological sheets, it is important:

- Draw up a work plan based on a professional risk assessment report.

- In addition to the PPR, develop a rescue and evacuation plan.

- PPR and PSED should be developed taking into account the characteristics of each workplace.

- Carry out practical testing of each document in the workplace, taking into account the requirements of the employees themselves and their manager.

Why do you need an individually compiled PPSR?

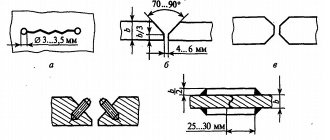

When developing a document, you must be guided by the GOST requirements for various technologies. These include electroslag, manual, automatic and semi-automatic electric arc welding , submerged arc welding, shielding gas, etc. There are standards for working with specific materials: reinforcement, T-beams, pipelines, different types of steels.

But at special facilities special rules apply. For example, welding of a tank can be carried out according to one of three GOST standards (depending on its purpose).

The connected structures differ in function and design features. Therefore, individual development of PPR for welding work . This document must take into account the specific features of the construction site and the selected technological processes.

When is the PPR developed?

The PPR is developed for objects that require a construction (reconstruction) permit in accordance with the Town Planning Code of the Russian Federation. In other cases, the PPR is developed at the request of the Customer (clause 6.3).

The PPR is developed immediately before the start of work.

Before starting construction and installation work, the Contractor (clause 5.19):

- Concludes a construction contract with the Customer for construction

- Receives a copy of the construction permit from the Customer

- Receives from the Customer design and working documentation approved for the execution of work

- Accepts the site for construction according to the act

- Agrees with the Customer on the composition of Subcontractors, concludes contracts with them and coordinates their activities

- Concludes contracts for the supply of material and technical resources

- Concludes contracts with laboratories to perform tests

- Draws up an approval certificate on the possible combination of work during the reconstruction of an existing enterprise facility

- Develops a work execution project (WPP)

- Provides engineering preparation of the construction site area

The developed PPR confirms the Contractor’s readiness to perform construction and installation work.

up

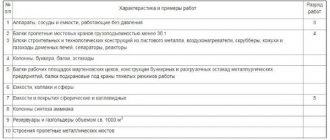

Irrelevant metal structures, assembly bolts, reinforcement welding area

Depending on the tasks to be solved, the PPR for welding work may contain special measures and technological processes. These include the production of non-critical metal structures during installation. But this requires production quality control in accordance with GOST 23118. It can only be performed by an independent laboratory that has the right to conduct tests and issue relevant documents.

The assembly bolts can remain in place or be removed upon completion of the CP. This depends on the PPSR and the documentation of the KMD brand.

If there is a reinforcement-welding section on the construction site, the current construction rules (SP 70.13330.2012) allow the production of reinforcement products and the enlarged assembly of reinforced concrete products using welding work. A separate PPSR is drawn up. It contains requirements similar to those for factory products.