There are four levels of professional training:

- Level I - certified welder;

- Level II - certified master welder;

- Level III - certified welding technologist;

- Level IV - certified welding engineer.

The knowledge and skills of certified welders and welding production specialists are tested by certification centers established in accordance with the current legislation of the Russian Federation.

Certified welders and welding production specialists are allowed to perform only those types of work that are specified in their certification certificates.

Welder qualification levels

NAKS certification for welders, the cost depends on the type of certificate obtained. The organization has identified four varieties:

- The simplest level is welder, intended for workers who work directly with welding equipment.

- The master welder is, in other words, a foreman (foreman), he gives instructions to the workers.

- Welding technologist - he monitors compliance with the standards and technologies of the welding process.

- Welding engineer is the highest level; a person with this level approves documentation and develops projects.

With increasing work experience, it is possible to advance in your career and assign increasing levels.

Certification of welders

Welders are subject to certification for the right to perform welding and surfacing work using specific types (methods) of fusion welding, carried out manually, mechanized (semi-automatic) and automated methods when working at facilities controlled by Rostechnadzor.

Types of certification of welders:

- Primary certification - welders who have not previously had permission pass.

- Additional certification is carried out by welders who have already passed the initial certification, but who want to expand the list of works specified in the certification certificates, or by welders who have had a break in welding work for more than six months.

- Periodic certification – all welders who have already passed certification undergo it in order to extend the validity of their certification certificates.

- Extraordinary certification - welders undergo before being allowed to perform welding after their temporary suspension from work due to violations of welding technology or repeated cases of poor-quality welded joints.

Certification of welders is carried out in order to establish the sufficiency of their theoretical and practical training, test their knowledge and skills and grant the right to welders to perform work at facilities controlled by the Gosgortekhnadzor of Russia.

Certification of welders is carried out at the production base of our certification center or at certification points.

Acceptance of certification exams is carried out by the certification commission. The composition of the certification commission is formed from qualified welding production specialists of level IV, who have extensive production experience and have been certified for the right to work in certification bodies.

Before certification, welders undergo special training according to programs approved by the Gosgortekhnadzor of Russia, in accordance with the declared level and direction of production activity.

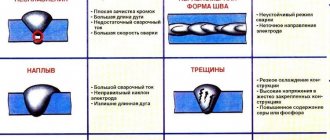

The programs include sections on welding equipment, basic and welding materials, welding technology, quality control of welded joints, defects in welded joints and methods for their correction, as well as rules for the safe performance of welding work.

Welders are subject to certification for the right to perform welding and surfacing work using specific fusion welding methods, carried out manually, mechanized (semi-automatic) and automated methods when working at facilities controlled by the State Mining and Technical Supervision of Russia.

After certification, the welder is assigned level I of professional training (certified welder).

Certification of welders is divided into primary, additional, periodic and extraordinary.

Welders who have not previously had access to welding and (or) surfacing (hereinafter referred to as welding) of connections of equipment, structures and pipelines controlled by the Gosgortechnadzor of Russia undergo primary certification.

Welders who have passed the initial certification undergo additional certification before being allowed to perform welding work not specified in their certification certificates, as well as after a break of more than 6 months in performing welding work specified in their certification certificates.

All welders undergo periodic certification in order to extend the specified validity period of their certification certificates for performing the relevant welding work.

Welders must undergo extraordinary certification before they are allowed to perform welding after their temporary suspension from work for violation of welding technology or repeated unsatisfactory quality of production welded joints made by them.

CERTIFICATION PROCEDURE

When submitting a welder for certification, the employer (applicant) sends an Application to the certification center. The candidate has the right to independently submit an Application for certification.

Certification of a welder is carried out by testing his practical skills and theoretical knowledge in accordance with the type (method) of welding (surfacing) for which he is certified and the direction of his production activity (group or name of technical devices that are welded by the welder in production, type of work performed - manufacturing, installation, repair).

The certification procedure includes passing the following exams by the certified welder:

- practical, general and special - during primary and extraordinary certifications;

- practical and special with additional and periodic certifications.

Theoretical and practical exams are carried out at the certification center or its certification point, registered in the register of the Certification System for welders and welding production specialists of the National Agency for Control and Welding.

Certification of welders begins with a practical exam. If a welder does not pass the practical exam, then he is not allowed to take further exams and is considered to have failed the certification. A welder can be re-certified after additional practical training no earlier than after 1 month.

At the general exam, the welder is asked 20 questions on the theoretical foundations of welding, and at the special exam, at least 15 randomly selected questions in accordance with the type (method) of welding (surfacing) for which he is certified and the direction of his production activity. The selection of questions is carried out by the certification commission based on collections of exam questions for general and special exams. Each collection must contain at least 100 questions.

If a welder is certified for two or three types (methods) of welding (surfacing), for example, manual arc welding with coated electrodes and manual argon-arc welding with a non-consumable electrode, the examination card must contain at least 5 questions for each type (method) of welding (surfacing) from relevant collections of examination questions. When certifying for welding objects included in two or three groups of dangerous technical devices, the welder must receive separate tickets for a special exam for each group of dangerous technical devices. The exam card must contain at least 5 questions for each group of dangerous technical devices.

General and special examinations are conducted in written form. By decision of the examination committee, an additional interview may be conducted with the certified person.

A welder is considered to have passed the general and special exams if he correctly answered at least 80% of the questions asked to him in each of the exams, taking into account the results of the interview.

A welder is considered certified upon successful passing of theoretical and practical exams.

If the welder has passed only the practical and one of the theoretical exams, then he is allowed to retake the failed exam on a previously submitted application within six months from the date of the first exam, but not earlier than a month after passing the exams. In case of repeated failure, all previously passed exams during certification are not counted, the welder is considered to have failed the certification and is allowed to participate in the certification procedure after additional theoretical and practical training with the registration of a new application.

The procedure for certification of welders:

- The employer sends an application to the certification center in the prescribed form (see Appendix 1 to RD 03-495-02).

- Certification begins with a practical exam (in case of negative results, the welder can re-pass certification no earlier than after 1 month).

- General and special examinations are conducted in written form or using a computer. The general exam consists of 20 questions on the theoretical fundamentals of welding, and the special exam consists of 15 questions depending on the type of welding for which it is certified. Questions are selected by the certification committee based on collections of exam questions. If the applicant correctly answers at least 80% of the questions, the exam is considered passed.

- In case of successful completion of practical and theoretical exams, the certification commission draws up a certification protocol separately for each person being certified for each type of welding. The report is accompanied by a conclusion or other documents with the results of quality control of control welded joints.

- The certification center issues a separate certification certificate for each type of welding according to the established sample (see Appendix 15 to RD 03-495-02).

The cover color of the metal materials welder certification certificate is blue.

The cover color of the polymer material welder is green.

Who should be certified

NAKS certification can be carried out for:

- Working personnel. Employees can improve their qualifications voluntarily, hoping for a better position or with an eye to another job. In addition, enterprise employees may be required to undergo certification before being involved in work on a large, responsible project. In order to receive documents confirming qualifications after NAKS certification, the welder must successfully pass practical, theoretical and special exams.

- Technologies. Technologies that are used in the installation, repair, and assembly of structures used at hazardous production facilities are subject to mandatory certification. Control welded joints (as a rule, products from various metals are welded) are subject to examination in the laboratory, after which the NAKS commission issues its verdict.

- Equipment and tools. When certifying equipment, the compliance of the actual technical characteristics of the devices with those specified in the passports is carefully checked, the degree of wear of the equipment and its completeness are studied. The tests also include analysis of welds made in the presence of a commission.

- Welding materials. As in the case of equipment, the characteristics specified in the technical passport must correspond to the real ones. As a rule, NAKS certificates for small-scale batches of consumables have a shorter validity period than those intended for serial batches.

Certification of welding production specialists

Certification of welding production specialists of levels II, III and IV is carried out in accordance with the direction of their production activities in the manufacture, installation, reconstruction and repair of equipment, pipelines and structures controlled by Rostechnadzor.

Types of activities of welding production specialists for which their certification is carried out:

- management and technical control of welding work;

- participation in the work of bodies for the training and certification of welders and welding production specialists.

Carrying out certification

In order for an enterprise that performs welding work to obtain certification for a specific welding technology, it must employ at least one welding specialist of level 3 and two of level 2. In this case, welders had to first undergo certification. Only if there are the necessary specialists and documents that confirm the level of qualifications, the enterprise can be allowed to carry out certification.

In this case, the enterprise itself must contact the relevant authorities with an application, which includes not only an application, but also certain documentation:

- charter of the enterprise;

- equipment diagrams;

- an agreement that must be concluded with a laboratory that checks the quality of welded joints;

- necessary documentation for welding equipment and materials used;

- documentation on whether employees have certification certificates corresponding to the level.

If all necessary documentation is available, the enterprise can be allowed to conduct an inspection. It is carried out according to a previously drawn up plan and schedule. The conditions under which an enterprise can obtain the necessary certificates are very clearly stated. Only after this will it be able to work using new technologies.

A certificate of certification of welding technology allows customers to verify that the workshop is equipped with appropriate equipment, and all employees of this production have the right to perform the specified types of work.

Welding specialists who must undergo certification:

- at level II: specialists whose written or oral instructions are mandatory for welders to carry out when carrying out welding work (foremen, foremen, etc.);

- at level III: specialists who are heads of individual departments of the enterprise that ensure the implementation of welding work, and whose signature is necessary and sufficient for the use of documents defining the technology of welding work at the enterprise (heads of departments, laboratories, sectors, technical bureaus, heads of working groups, etc. .P.); at level IV: specialists who are managers of the welding service of an enterprise (organization), whose signature is necessary and sufficient for the management of the enterprise (organization) to approve guidelines and regulatory documents for the performance of all types of welding work (chiefs, their deputies, etc.).

The procedure for certification of welding production specialists:

- The employer submits an application in the prescribed form to the certification center (see Appendix 18 to RD 03-495-02).

- Certification begins with a general exam, during which the specialist is asked 30 questions.

- A special exam is conducted, which consists of 20 questions and a practical task in accordance with the direction of production activity of a welding specialist.

- If the number of correct answers in the exams exceeds 80%, then the specialist is considered certified and, based on the results of the certification, minutes of the meeting of the certification commission are drawn up.

- Certified specialists are issued certificates of welding production specialists.

The cover color of the welding production specialist certification certificate is red.

Our company offers certification services for welders and welding production specialists. For questions regarding cooperation, please call.