Home / Accessories and parts

Back

Reading time: 4 min

0

1157

The place of a manual extruder for welding is one of honorable places on the shelves of hardware stores.

His main work is connecting polypropylene blanks and polypropylene parts, creating structures from plastics and objects from dense film, welding plastic sheets, soldering tanks, constructing playground items and the like.

However, this device is not suitable for soldering PVC parts, nor is it suitable for creating pipeline structures. The strength of extruded joints is less than 85 percent, so the pipeline will not be sufficiently sealed.

- general information

- Kinds

- MANUAL WELDING EXTRUDER: OPERATION SCHEME

- Types of seams

- Preparatory stage

- Performing welding

- Conclusion

general information

This device works according to the following system: the heated air mass coming from the extruder nozzles increases the temperature of the gap (ditch or joint) between the connecting parts, making the latter more plastic.

At the same time, a rod fits into the working area of the apparatus. It melts and connects with the disk (also called a screw), forming a homogeneous plastic mass.

The molten polymer mixture comes out through a die tool or welding shoe. The seam is formed when the entire mass cools to room temperature. It's like squeezing ketchup out of a container.

The surfaces that the master connects must be identical to each other. This implies that the constituent elements, material packing density and fluidity of the parts are the same.

The welding rod should also be similar to the elements according to these characteristics.

Features of DOHLE extruders

TsSP LLC is the official supplier of the German company DOHLE in Russia. The company produces manual extruders that combine high productivity with a reasonable price. Developing welding products since 1997, DOHLE engineers have gained unique experience in producing products that are easy to use and functional. Equipment advantages:

- high quality materials that are wear-resistant. The result is a reduced cost of service and a large resource;

- a large selection of additional components: nozzles and heads, holders for coils, vacuum pumps, compressors, caps, electrodes, devices for checking welds;

- variety of configurations.

The use of DOHLE welding extruders makes it possible to weld thick-walled parts in one pass. Welding is performed at high speed even with low operator qualifications. For the most durable connection, two conditions must be met: avoid welding surfaces with traces of oxidized material and connect parts only from the same thermoplastics. Polymers must be combined in chemical composition, density, and melt flow value. Similar requirements apply to filler material.

Kinds

- Screw. In them, the wire for the additive melts in the screw reservoir of the extruder apparatus and is squeezed out through a rod with a helical surface along the axis - the screw. Instead of wire, material in a granular state is also used. It is located in a special compartment, where it combines into a homogeneous molten mass and becomes suitable for serving.

- Screwless. The rod in these models is heated by electric heaters in the heating section. The rear end of the wire in this embodiment remains solid and pushes the heated viscous material to the area where the seam is formed.

- Combined. They combine screw and screwless types.

Welding technology

The main feature is that during welding there is no change in the chemical composition of the sheets. For this, joining material is used, as well as a welding rod, although the process can be done without it.

The main processes come down to three points:

- Heating the elements being connected until a viscous surface is formed;

- Joining of molten parts mechanically;

- Cooling of parts in a fixed state.

To obtain high quality seams, a number of conditions must be met:

- Ambient temperature not less than 15°C;

- Compliance of additives with the polypropylene being welded;

- High quality of welded surfaces;

- The correct choice of tools and attachments for them.

MANUAL WELDING EXTRUDER: OPERATION SCHEME

Before connecting the elements, they need to be heated. A hot air gun can be built into the body of the welding extruder for this purpose. It is needed so that the plastic parts are heated by the air flow before the filler material is applied to them.

The heated air mass can come not only from a hot air gun, but also from a compressor unit or an organizational pneumatic network. The filler wire is heated by electric heaters built around the extrusion department.

In older models of extruders, the screw chamber is heated by hot air, which also heats the welding area. Before “reaching welding,” air flows through the compartment with the disk and melts the materials for the additive.

The latter approaches the welding zone through the shoe in a state of a kind of lava.

A manual extruder welding machine is used mainly for soldering low-pressure polyethylene, polypropylene parts and other types of thermal plastics from the first group.

Their melting point and destruction temperature differ by 50 degrees Celsius. This reduces concerns about degradation, since even an overvoltage of 35-45 degrees does not damage the final connection.

The second group of thermal plastics includes polyvinylidene fluoride and polyvinyl chloride. They melt and collapse with a very small temperature difference, so it is important to strictly control the welding thermal regime.

In order for work with the 2nd group of thermoplastics to proceed “as it should,” the screw part must be special: have a special shape so that the mixing of the mass is uniform and the polymer itself does not overheat.

When working with elements made from these materials, the extruder must work in standby mode for a long time or it will not turn off for a long time.

Design and operating principle

A manual welding extruder is a thermomechanical device that sequentially carries out two processes - heating a low-melting plastic to a viscous state, and then squeezing the mass onto the surface in the joint area. There, HDPE, PVC and other low-melting plastics solidify, forming a strong weld.

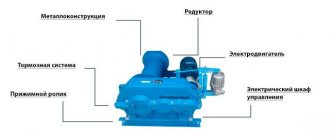

For compactness and ease of use, the equipment in question is usually designed in the form of a pistol with a handle (in which the drive electric motor is mounted) and an upper nozzle for heating the working mixture. The welding extruder consists of the following components:

- Electric motor.

- Feeder.

- Extrusion chamber.

- Crushing screw device.

- Chambers for melting plastic.

- Thermal heater.

- Welding nozzle.

- Control systems.

To operate, the device is pre-filled with a filler rod made of the material that will be used for welding. The process goes as follows. On the top panel of the extruder there is a receiving sleeve with a hole through which the filler rod is passed. The filling must be such that the free end of the rod falls into the area where it is captured by the auger. When the electric motor is turned on, two processes occur: heating the filler rod with a concentrated stream of hot air, and - after some time, which is determined by the device sensor - feeding the rod into the grinding zone.

There, a rotating auger crushes the plastic rod, turning it into a granular mass. The latter melts when heated, and, moving further, enters the melting zone. In this zone, the granulate is already mechanically and homogeneous. Under the influence of pressure from the screw, it passes into the welding zone, enters the welding nozzle and, in the process of pressing against the surface of the products being welded, is squeezed out into a uniform strip, the width of which depends on the configuration of the nozzle. Since the external temperature is much lower than that created by the thermal heater, the material of the filler rod instantly solidifies, forming a welding seam.

In less compact but more productive extruder models, the filler rod is heated using an external thermal heater, and air is supplied there from a small compressor. There may also be design differences in the method of heating the filler material: sometimes heating is carried out by ring heating elements coaxially placed in the thermal heater body.

The manual welding extruder control system performs the following functions:

- Pre-setting the heating temperature, which is determined by the melting temperature of the plastic (as is known, HDPE melts at 120...130ºС, PVC - at 150...220ºС, and polypropylene - at 170...190ºС).

- Turning on the thermal heater;

- Starting the drive of the auger grinder;

- “Cold start” blocking, when the screw can move still heterogeneous filler material;

- Switching off the thermal heater while the auger is still rotating, which eliminates the adhesion of granulate residues in the welding chamber.

Preparatory stage

The preparation time before extrusion welding differs from that for other types. But, as in other cases, the surfaces of the parts must be cleaned of dirt and dust, otherwise the seam will turn out to be of poor quality.

Plastics also oxidize easily due to exposure to air. The edges should be cleaned no more than twenty minutes before soldering begins.

If you do this earlier, the parts will still have to be cleared again. Do not try to use solvent for cleaning; it may deform the plastic.

Should I choose a hair dryer or an extruder?

If in the manufacture of products you use sheet plastics with a thickness of more than 10 mm, if you require a high-quality and durable connection and you have a budget of 100,000 rubles or more, then choose a welding extruder. For this money, the device will be equipped with an air heater with a built-in temperature controller, it will have good power and performance, and the welding seam will be performed in one pass. In addition, you can adjust the auger speed in the range from 20 to 100 percent.

A welding hair dryer is 4-5 times cheaper than a welding extruder, 1.5 times smaller in size and weighs no more than 1.3 kg including the cord, while even the smallest extruder weighs from 4 kg.

A welding gun is a universal little helper, without which no production can do. Consumables for a hair dryer are relatively inexpensive, so even a novice welder can afford to operate it. The hair dryer is great for repairing car bumpers and welding containers with a wall thickness of up to 6mm, as well as for use in hard-to-reach places when repairing plastic products.

To perform various welding seams, you will need welding attachments, which you can also purchase from our company.

Performing welding

If the extruder is not new and you have used it before, remove any remaining additive that you used before from the reservoir.

You need to do this even if you used the same material as this time. If the additive is heated again, its strength will decrease.

Then you need to remove the cold start lock, warm up the device and feed parts to the temperature at which you are going to work, and set the performance settings.

While you cook, maintain the required tilt of the extruder. It will depend on what type of seam you choose. If you've been working for a long time and need a break, place the welding machine on a welding stand.

If the pause is long, reduce the temperature of the device by about 45 degrees. The heating of the additive will stop, but there will be no problems with continuing the process.

Extruder welding steps

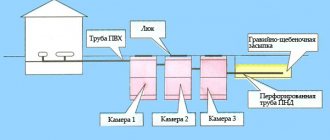

- Preparing parts for joining. The surfaces to be welded are thoroughly cleaned and then heated with hot air to the plasticization temperature. Also, a special groove can be formed on the parts, increasing the contact area.

- The material is fed into the extruder, usually in the form of granules or rods. Passing through heating elements located around the circumference of the extrusion chamber, the substance passes into a viscous-fluid state, after which it is mixed by a screw. The result is a homogeneous filler mass.

- Supply of material to the welding zone through the welding shoe. The design of the shoe directly affects the shape of the seam.

Welding extruders allow you to produce V-, X-, K-, HV-, Double HV-, E- and F-type seams. The choice of method depends on the shape and angle of connection of the parts. For maximum reliability, it is recommended to apply double-sided seams - this will not only strengthen the fastening with minimal expenditure of filler material, but will also reduce the deformation of parts during cooling.

Types of nozzles for welding plastics

Welding attachments differ in the type of seam that will be produced during the manufacture of the product. The seam can be butt, corner (external and internal). Depending on the type of seam, the welder selects the optimal cross-section of the welding rod that he will use. The rod can be round, oval, triangular, flat. Accordingly, the nozzles for welding will be for a round rod, for a triangular rod or flat-slit. These nozzles can be considered quick welding nozzles; in addition to them, there are also adapter nozzles that are used to switch to quick welding nozzles.

Attachments for welding polypropylene sheets with extruders also differ in the type of seams and rods that will be used in the work.