Types of electrode coating: basic, rutile, acidic, cellulose.

A welding electrode is a metal rod capable of conducting electricity. There are several types of welding electrodes, melting and non-melting. The consumable electrodes are coated with a special coating - coating, which consists of various components.

The main task of electrode coating is to protect the weld pool from external influences, ensure uninterrupted burning of the arc and create a seam that meets special characteristics. Therefore, depending on the welding tasks, electrodes are produced with different coatings: rutile, having a basic, cellulose and acid coating.

Types of electrode coating: basic, rutile, acidic, cellulose

Answering the question of how rutile electrodes differ from electrodes with a basic coating, one can understand that the main difference is in the composition of the coating. The filler in this case is various substances, the percentage of which varies greatly for electrodes with different coatings.

According to the type of coating, electrodes are divided into the following:

- Acidic - letter designation (A);

- With rutile coating (P);

- Having a basic coating (B);

- With cellulose coating (C);

- Having a mixed type of coating (two letters in the designation);

- Electrodes with other types of coatings (P).

Mixed types of coatings include electrodes coated with:

- Acid-rutile coating;

- Rutile-cellulose coating;

- Rutile base coat.

The characteristics of the electrodes largely depend on the type of coating. Therefore, it is very important to understand where it is best to use electrodes with the above four coatings: basic, rutile, cellulose and mixed.

Tungsten electrodes

Tungsten electrodes deserve special attention. They are widely used by everyone: both garage craftsmen and craftsmen in factories. Their popularity is due to their versatility. You can weld and cut any metal: aluminum, stainless steel, and non-ferrous metals. Carbon and graphite electrodes are not so widespread because they are inconvenient to use in home welding.

You probably already know that the gas shielded welding mode is set based on many parameters, for example, the thickness of the part, the metal from which it is made, the type of gas used, and much more. Tungsten electrodes are selected according to the same principle. Depending on their purpose, electrodes may have their own markings.

The electrode coating, based on the ratio of the total diameter of the electrode to the diameter of the core, is divided into the following categories (coefficient):

- Type M – thin coating (up to 1.2).

- C – average (up to 1.45).

- D – thick (up to 1.8).

- G – especially thick (over 1.8).

There is also a separate classification based on composition:

- A – sour.

- B – basic.

- C – cellulose.

- R – rutile.

- Two letters (mentioned above, as well as rutile-iron with the designation RZH) are a mixed type.

- P – other types.

The given letters are involved in the marking.

There is an additional division of electrodes into several groups, depending on the condition of the coating and the accuracy of manufacturing of these products.

Tungsten electrodes are separately color-coded, indicating the type and percentage weight of the oxide contained in the composition:

- Thorium – blue (0.35 – 0.55%), yellow (0.8 – 1.2%), red (1.7 – 2.2%), lilac (2.8 – 3.2%), orange (3.8 – 4.2%).

- Zirconium – brown (0.15 – 0.5%) and white (0.7 – 0.9%).

- Lanthanum oxide – black (0.9 – 1.2%), gold (1.4 – 1.6%), blue (1.8 – 2.2%).

- Cerium oxide – gray, corresponding to 1.8 – 2.2%.

Lilac and turquoise colors indicate mixed oxides consisting of rare earth elements. Green rods are made from pure tungsten.

For coated rods, through which arc welding is performed, GOST 9466-75 has been developed.

In addition, there are standards that apply to electrodes based on their purpose.

For example, these are GOST 9467-75, GOST 10052-75 and GOST 1051-75.

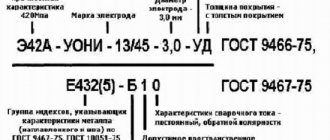

Marking of welding electrodes

Electrode marking can be simple, for example, consisting of literally 3 characters, or extremely complex.

As an example, we can cite products E50A and, for example, E42A, where:

- The first letter E literally means "electrode".

- The following number indicates the minimum tensile strength time.

- The following letters indicate the purpose of the product (A - the use of ductile deposited metal with increased viscosity is allowed, H - products for deposition on the surface, U - for carbon steels, T - for heat-resistant alloy steels).

Surfacing also contains a variety of chemical elements, which are marked with the letters X, M, B and F, which correspond to chromium, molybdenum, niobium and vanadium.

Regarding the core itself, it is marked as follows (sequentially):

- St – letter designation of welding wire type.

- A number indicating the percentage of carbon content.

- Letters that encrypt the code of the alloying substances contained.

- A number indicating the percentage of alloying substances.

Electrodes with basic coating

The basis of this coating is fluoride compounds. In terms of its chemical composition, the metal deposited with electrodes with a basic coating is very close to mild steel. The welding seam is characterized by high levels of impact strength, strength and ductility, due to the low content of electrodes, non-metallic inclusions, gases, and also harmful impurities in the coating composition.

Electrodes with a basic coating are somewhat inferior to other electrodes in terms of sensitivity when welding rusty metals. Also, during the welding process, pores often form on the seams. Electrodes with a base coating are quite sensitive to moisture, so they quickly become damp, requiring calcination before use.

Varieties

Arc surfacing involves using heat to straighten the filler material and then bond it to the base metal of the product. As a result, it is possible to obtain a deposited layer of various chemical compositions, having various properties of different thicknesses.

Depending on the goals and methods of use, fused electrodes are divided into six main groups according to the scope of application and available functional features. Before welding metal with an electrode, you should make the right choice depending on the specific job. The first group includes carbide electrodes for surfacing. One of the most commonly used consumable elements of this type are TsNIIN-4 electrodes.

They have a basic type of coating. The main elements of the chemical composition are chromium and manganese. Electrodes are produced with a diameter of four millimeters. The area of use is surfacing of products made from steels with a high manganese content. An example of such a brand is 110G13l. They are used to eliminate defects in railway crosspieces and other products made from steels with a high manganese content.

TsN electrodes from this series are also used for surfacing. In particular, TsN-6L electrodes are used for manual surfacing of sealing surfaces of fittings parts that are operated at a temperature of no more than 570 degrees. The pressure should not exceed 78 MPa. Surfacing with these electrodes is carried out in the lower position. Direct current is used. Available in two types of diameters - 4 and 5 millimeters.

Rutile coated electrodes

Rutile electrodes contain the highest percentage of natural titanium dioxide (rutile concentrate) in the coating composition. The weld seam obtained using rutile electrodes has less cracking, and its characteristics correspond to semi-quiet and calm steels.

Compared to other electrodes, rutile electrodes have many more advantages. First of all, these include easy slag separation and stable maintenance of the welding arc. When welding with rutile-coated electrodes, the metal spatters less, and the electrodes themselves are not so susceptible to moisture. They cook consistently even on poorly prepared, rusty metals.

Tungsten electrodes

Tungsten electrodes deserve special attention. They are widely used by everyone: both garage craftsmen and craftsmen in factories. Their popularity is due to their versatility. You can weld and cut any metal: aluminum, stainless steel, and non-ferrous metals. Carbon and graphite electrodes are not so widespread because they are inconvenient to use in home welding.

You probably already know that the gas shielded welding mode is set based on many parameters, for example, the thickness of the part, the metal from which it is made, the type of gas used, and much more. Tungsten electrodes are selected according to the same principle. Depending on their purpose, electrodes may have their own markings.

Acid coated electrodes

The composition of the coating of acid-coated electrodes contains the highest percentage of silicon, manganese and iron oxides. Acid-coated electrodes can be used for welding with both alternating and direct currents.

However, electrodes with this type of coating have one significant drawback, the formation of so-called “hot cracks”. Acid electrodes do not form pores when welding rusty metal, or, for example, when the welding arc is significantly extended.

Properties

Domestic manufacturers use the following designations for refractory non-consumable rods: EVL (lantinized), EVI (yttrium), EHF (for alternating current welding). They are most often used in work.

EVL and EVI are suitable for working with different currents and allow you to change the polarity. To make it easier to distinguish electrodes by type, just remember the colors. After a while you will stop paying attention to the markings.

Direct current is used when working with copper and stainless steel, and direct current is used when working with aluminum.

It is important to remember that refractory tungsten electrodes can become dull during use, so it is advisable to sharpen them occasionally. To do this, you need to sharpen them at an angle of 30 degrees, and then slightly blunt the end.

Thus, the service life of the rods will increase several times. We recommend that before lighting the arc, you first turn on the supply of shielding gas to the welding point.

Under no circumstances should you tap the rod on the surface. First light the arc and then start welding. Don't forget to set the required polarity. Direct and reverse will do.

In the first case, you need to set the mass to a negative position and the holder to a positive position. In the second case, everything is done exactly the opposite.

Polarity determines the quality and shape of the weld joint. The first setting will ensure the depth and narrowness of the seam. The other will make the seam wide. Do not forget about this nuance when using non-melting rods.

Cellulose coated electrodes

The coating of cellulose electrodes consists half of organic components, most often cellulose. A weld deposited with cellulose electrodes contains a high percentage of hydrogen. When welding with cellulose-coated electrodes, a uniform back bead is formed.

Electrodes with all of the above coatings are intended for welding low-alloy and carbon steels. All of them are used in order to obtain welded joints that differ in some special characteristics that are required by the operating conditions of metal structures.

Share on social networks

Classification by purpose

Electrodes are intended for welding:

- Steels: low-carbon, high-carbon, alloyed - including stainless and heat-resistant (austenitic).

- Cast iron - alloys with a high carbon content - 2.14% or more.

- Aluminum and alloys.

- Copper, brass and bronze.

- For welding steels of different grades

- For working with cast iron alloys

- For aluminum welding

- For working with copper and its alloys

Why is electrode coating needed?

When determining the composition of the electrode coating, the following series of priority tasks are identified:

- Electrode coating is a special coating. Which protects the welding area of the metal from oxidizing elements such as hydrogen, oxygen and nitrogen. During the welding process, at the point of contact of the electrode with the metal, a two-stage protection is created, which consists of carbon dioxide vapor and carbon monoxide. Which envelop the weld pool, as well as a slag film on the surface of the weld.

- Formation of active crystallization of the weld, preventing cracks and pores. And also the absence of slagging.

- Simplicity of the ignition process and ensuring uninterrupted operation in any operating mode of the welding machine.

- Metal refining by cleaning the weld pool from foreign impurities.

Thus, the electrodes perform important functions, without which the welding process would be more labor-intensive, and in some cases impossible. You can view other necessary information regarding welding technologies on the website mrmetall.ru.

Advice!

When making a purchase in a store, you must inform or indicate the purpose of the electrode coating to the seller. If the electrode is not suitable for its intended purpose, then the metal of the weld will differ from the base metal. This will thereby lead to the appearance of cracks and subsequent deterioration in performance.

Disadvantages and advantages of welding

Among the advantages of using non-consumable electrodes for arc welding are:

- Minimal deformation in metals after welding due to the minimal heating zone.

- High quality connection.

- Speed of work completion.

- Low barrier to entry.

- Availability of a wide range of materials for welding work.

The disadvantages include:

- Shielding gas is blown out of the welding zone, which makes it difficult to work outdoors in windy weather.

- Before carrying out welding work, high-quality preparation of the metal is required.

- Parts must be cleaned when igniting outside the welding zone.