Hello, friends!

Did you know that initially the periodic table contained a zero group, in which ether stood along with the inert gases? Although that’s not what we’re talking about today. 10 million dollars - this is the amount that 1 gram of the rarest metal in the world, California, is valued at. The second place in rarity, and therefore in price, is occupied by osmium.

In addition, it is also the heaviest metal in the world, although some scientists believe that this position should be occupied by iridium.

Which metal is the heaviest?

To determine which is heavier, you need to compare atomic weights and see which has a higher density. According to these indicators, osmium and iridium, which is inferior to it by fractions of cubic centimeters, are considered the heaviest today. Imagine: an osmium cube with eight-centimeter sides weighs almost 12 kg!

I suggest you look at the photo of the heaviest metal:

And this is iridium:

Handsome, aren't they?

Top 10 heaviest metals in the world

I suggest you familiarize yourself with the elements according to their rating.

Tantalum

Considered a rare and not very heavy metal, it has a density of 16.65 g/cm³. It is used by surgeons - it is practically indestructible and rust-proof, and is easy to process.

Uranus

The density of uranium is 19.07 g/cm³. Its main difference from its counterparts is natural radioactivity. During the transformation process that uranium atoms undergo, the substance turns into another radiating element. The chain of transformations consists of 14 stages, one of them is the transformation into radium, the last stage is the formation of lead. True, it will take more than one billion years for the complete transition of uranium to lead.

Tungsten

Tungsten (19.25 g/cm³) is jokingly called an ideal candidate for counterfeiting gold bars. This is the most refractory material, the melting point is close to the photosphere of the Sun - 3422 °C. Therefore, it is best suited for filaments in incandescent lamps.

Gold

Gold density is 19.3 g/cm³. Soft, viscous, with good thermal and electrical conductivity, it is not afraid of chemical attack. Gold is not only found on the surface of the Earth. 5 times more of it is contained in the planet's core.

Plutonium

This element is one of the stages of radioactive transformation of uranium. It also exists in the depths of the planet, but in minute quantities. Its density is 19.7 g/cm³. Due to its radioactivity, plutonium is always warm and is a poor conductor of current and heat.

Neptunium

This is another creation of uranium, obtained through nuclear reactions. Density – 20.25 grams per cubic centimeter. Neptunium is a fairly soft and malleable material that reacts slowly with air and water.

Rhenium

Rhenium is another refractory, malleable, oxidation-resistant element. Melting point – 2000 °C. In total, the world's reserves of the element are approximately 17,000 tons. Rhenium density is 21.03 g/cm³. It is used in medicine, jewelry, vacuum technology, electronic devices and metallurgy.

Platinum

Platinum, although not the heaviest metal, is quite close to this - 21.45 g/cm³. It is used not only by jewelers, but also by surgeons, investment professionals, the chemical and glass industries, automotive, biomedicine and electronics. Platinum is extremely durable and products made from it are difficult to scratch. This element is found 30 times less frequently than gold.

Osmium

Density 22.6 g/cm³ - the heaviest metal in the world, it is hard, but quite brittle. No matter how much you heat it, it will not lose its shine and gray-bluish tint under any circumstances. It is difficult to process and mainly occurs in meteorite impact areas.

Iridium

The difference between iridium and osmium in density is in hundredths of a gram. Iridium is refractory and is considered rare and precious. Does not interact with acids, air and water. It is used to control welding seams, and in paleontology and geology it is used as an indicator of the layer formed after the fall of a meteorite.

Which is heavier: gold or lead?

Almost everyone in school was told by their chemistry teachers about the incredible density of the yellow metal. And most of the students asked what is heavier, gold or its counterpart on the periodic table - lead? It is about 19.3 grams per cubic centimeter. Due to its chemical composition, gold does not enter into any reactions with the environment.

That is why it is so actively used in dentistry. This metal can be not only yellow. It depends on the components included in its composition. However, regardless of color, products made from this metal are incredibly popular.

The question arises, how does the density of gold compare to the density of other metals? Which element has the largest mass? This article can answer these and many other questions.

Uses of gold

The demand for the yellow metal determines not only its use in the production of jewelry and the increase in the state’s gold and foreign exchange reserves. It is also very widely used in many other areas.

In industry, gold began to be actively used due to its chemical properties. It covers mirrors operating in the far infrared range. This is especially useful when conducting all kinds of nuclear research. Gold is also very often used for soldering components made of various materials.

Another area of application is dentistry. This is due not only to the impossibility of the yellow metal entering into a chemical bond with the human body, but also to its incredible corrosion resistance.

Pharmacology also cannot do without the use of this amazing yellow metal. Gold compounds are now actively used in various medical preparations that save from a wide variety of diseases.

These are not the only uses for gold. Due to rapid progress, there is an increasing need to use gold content in technological innovations. From this we can conclude that yellow metal is not only an attribute of luxury, but also a useful technical tool, the importance of which is increasing every year.

Silver

Silver, like gold, has been known to mankind since ancient times. It is used not only in the manufacture of jewelry, but also for the production of tableware.

Previously, silver was very actively used in coinage. And today you can see some coins containing a little silver.

When choosing a precious metal, the question often arises: what is heavier, gold or another precious metal - silver.

The density of this metal is slightly less than that of lead. It is equal to 10.5 grams per cubic centimeter. This means that gold is almost twice as heavy as silver.

In addition to creating silverware and various jewelry, this material is very actively used in industry, as well as in the photographic industry.

The main properties due to which this element has become so widely used in the industrial field are excellent thermal and electrical conductivity, excellent resistance to interaction with the environment, as well as excellent reflectivity.

Rapidly developing technological progress has significantly reduced the use of silver in the photographic industry. This is due to the fact that thanks to the introduction of modern technologies, the process of producing and using photographic equipment has become much more accessible to most people. This is what ensured a reduction in the use of silver by more than 3 times.

Due to its bactericidal properties, this metal is very actively used in medicine. Currently, silver is used to produce antibacterial patches, as well as to produce filters for purifying water from harmful microorganisms.

Silver nitrate used in medicine.

Lead

It should be said that the density of lead is almost 10 times less than the density of the noble yellow metal. To understand the density of lead, it should be said that the density of birch or linden is 25 times less. According to the density table, lead is in 20th place, and gold is in seventh. From this it is easy to conclude that the yellow metal is much heavier than its opponent.

This element is very well used in the production of various metal structures, as well as in the medical field. This is due to the non-transmission of X-ray rays.

The widespread use of lead in various fields is also associated with the very cheap cost of this metal. Its cost is almost half the cost of aluminum.

Another advantage is the relative ease of extraction of this material, which provides a huge supply to the world market.

Iron

It is one of the oldest metals known to man. The first metal products, according to the results of archaeological research, appeared in the fourth millennium BC. Iron is much cheaper than the yellow precious metal. This is due to the high content of iron ore in the depths. And as they say in the economics textbook, the greater the demand, the lower the price of the product.

Unlike gold, iron has several oxidation states, and it interacts very actively with the environment. Russia occupies a leading position in the world in terms of iron ore reserves.

You should immediately answer the question of interest: what is heavier, a precious metal such as gold or ordinary iron. To answer this you will need to look at the density of metals.

The density of the precious metal is already known, let’s find the value for iron. It is equal to 7.844 grams per cubic centimeter.

It follows from this that this metal, with an equal volume, is not only lighter than gold, but also silver and lead.

Heaviest elements

The density of five elements was given above, of which platinum is the heaviest. However, it is not the heaviest element existing on earth. The density of the heaviest element is 22.61 grams per cubic centimeter. His name is Osmium.

Only this is not the limit of density. True, this element was created artificially in 1984. They named it Hassiy, its density is almost twice that of osmium.

Surprisingly, this is not a chapel either. There are materials many tens of times higher than the density of Hassia. However, they are in outer space. The matter contained in white dwarfs can have a density of up to 1000 tons per cubic centimeter. This news shocked the world community.

However, this is not the limit. Neutron stars contain matter with a density of about 500 million tons per cubic centimeter. This figure can easily be surpassed by the density of black holes, however, due to the difficulties of conducting research, this is only theoretical.

Characteristics of the densest metal

Scientists agreed that, despite almost the same density, iridium is only slightly inferior to the heaviest metal. However, the physicochemical properties of these two elements have not yet been fully studied.

The rarity and labor-intensive nature of extraction determine the cost of osmium - on average, $15,000 per gram. It is included in the platinum group and is conventionally considered noble, but the name of the metal contradicts its status: in Greek “osme” means “smell”. Due to its high chemical activity, osmium smells like a mixture of garlic or radish with chlorine.

The melting point of the heaviest metal is 3033 °C, and it boils at 5012 °C.

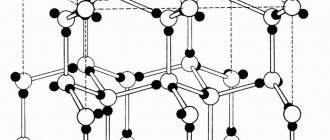

Solidifying from the melt, osmium forms beautiful crystals with an interesting blue or silver-blue tint. But, despite its beauty, it is not suitable for making precious accessories, since it does not have the properties necessary for jewelers: malleability and plasticity.

The element is valuable only because of its special strength. Alloys to which very small doses of the heaviest metal are added become incredibly wear-resistant. Usually it is used to cover units that are subject to constant friction.

History of discovery

The years 1803-1804 became a turning point for the heaviest metal: it was at this time that its discovery took place practically under competition conditions.

First, the English chemist Smithson Tennant and his assistant William Hyde Wollaston, who made more than one important discovery, discovered an unusual sediment with a characteristic odor during an experiment with platinum ores and nitric and hydrochloric acids and shared their discovery with others.

Then the French scientists Antoine de Fourcroy and Louis-Nicolas Vauquelin took over the baton and, based on previous and their own research, announced the discovery of a new element. The name was given to it “pten”, which means “flying”, since as a result of the experiments they received flying black smoke.

However, Tennant did not sleep either: he continued his research and did not lose sight of the experiments of the French. As a result, Smithson achieved more concrete results and, in an official document sent to the Royal Society of London, indicated that he had divided pten into two related elements: iridium (“rainbow”) and osmium (“smell”).

Where is it used?

The list of areas of application is quite extensive: aviation, military and missile technology, aerospace industry, medicine. Although weapons manufacturers are already thinking about what can replace the heaviest metal in the world, since osmium is too difficult to process.

Almost half of the world's reserves of the heaviest metal are devoted to the needs of the chemical industry. It is used to stain living tissues under a microscope, ensuring their preservation. In addition, it is used as a dye when painting porcelain.

Isotopes of the heaviest metal are used to make containers for storing nuclear waste.

This element is also used to make elite “eternal” fountain pens and Rolex watches.

Places of natural occurrence

It is almost impossible to detect osmium in its pure form. This heavy element is usually found in combination with iridium. The substance is contained in deposits of platinum ores and at the crash site or in the meteorites themselves that hit the Earth.

Impurities in steels: harmful and beneficial

Manganese, silicon, aluminum, sulfur and phosphorus

are classified as

permanent impurities

.

Aluminum, together with manganese and silicon, is used as a deoxidizer and therefore they are always present in small quantities in deoxidized steels. Iron ores, as well as fuels and fluxes, always contain a certain amount of phosphorus and sulfur, which remain in cast iron and then pass into steel

.

Nitrogen

called

a hidden

impurity - it enters steel mainly from the air.

To random

impurities include

copper, arsenic, tin, zinc, antimony, lead

and other elements. They end up in the steel with the charge - with ores from various deposits, as well as from iron scrap.

All impurities - permanent, hidden and accidental - are inevitable to varying degrees due to steel production technology.

Thus, mild steel usually contains these impurities within the following limits: 0.3-0.7% manganese; 0.2-0.4% silicon; 0.01-0.02% aluminum; 0.01-0.05% phosphorus, 0.01-0.04% sulfur, 0.-0.2% copper.

In these quantities, these elements are considered as impurities, and in larger quantities, which are intentionally added to steel, they are already considered alloying elements.

The influence of phosphorus on the properties of steels

Phosphorus (P) segregates during steel solidification, but to a lesser extent than carbon and sulfur. Phosphorus dissolves in ferrite and thereby increases the strength of steels. As the phosphorus content in steels increases, their ductility and toughness decrease and their tendency to cold brittleness increases.

The solubility of phosphorus at high temperatures reaches 1.2%. With decreasing temperature, the solubility of phosphorus in iron drops sharply to 0.02-0.03%. This amount of phosphorus is typical for steels, that is, all phosphorus is usually dissolved in alpha iron.

Phosphorus has a strong tendency to segregate at grain boundaries, resulting in temper brittleness in alloy steels, especially in manganese, chromium, magnesium-silicon, chromium-nickel and chromium-manganese steels. Phosphorus, in addition, increases the hardening of steels and, like silicon, slows down the decomposition of martensite in steels.

Increased phosphorus content is often specified in low-alloy steels to improve their machining, especially automatic machining.

In low-alloy structural steels with a carbon content of about 0.1%, phosphorus increases strength and resistance to atmospheric corrosion.

In austenitic chromium-nickel steels, phosphorus additions help increase the yield strength. In strong oxidizers, the presence of phosphorus in austenitic stainless steels can lead to grain boundary corrosion. This is due to the phenomenon of phosphorus segregation along grain boundaries.

The influence of sulfur on the properties of steels

sulfur (S) in high-quality steels does not exceed 0.02-0.03%. In general purpose steels, the permissible sulfur content is higher - 0.03-0.04%. By special treatment of liquid steel, the sulfur content in steel is brought to 0.005%.

Sulfur does not dissolve in iron, so any amount of it forms iron sulfide FeS with iron. This sulfide is part of the eutectic, which is formed at 988 °C.

An increased sulfur content in steels leads to their red brittleness due to low-melting sulfide eutectics that arise along grain boundaries. The phenomenon is red

brittleness occurs at a temperature of 800 °C, that is, at the

red-hot

of steel.

Sulfur has a detrimental effect on the ductility, toughness, weldability and surface quality of steels (especially in steels with low carbon and manganese content).

Sulfur has a very strong tendency to segregate at grain boundaries. This leads to a decrease in the ductility of steels in the hot state. However, 0.08 to 0.33% sulfur is deliberately added to steels for automatic machining. It is known that the presence of sulfur increases the fatigue strength of bearing steels.

The presence of manganese in steel reduces the harmful effects of sulfur. In liquid steel, the formation reaction of manganese sulfide occurs. This sulfide melts at 1620 °C - at temperatures much higher than the temperature of hot working of steels. Manganese sulfides are plastic at temperatures of hot processing of steels (800-1200°C) and therefore are easily deformed.

The influence of aluminum on the properties of steels

Aluminum (Al) is widely used for deoxidation of liquid steel, as well as for grain refinement of steel ingots. The harmful effects of aluminum include the fact that it promotes the graphitization of steels.

Although aluminum is often considered an impurity, it is also actively used as an alloying element. Because aluminum forms solid nitrides with nitrogen, it is usually an alloying element in nitrided steels.

Aluminum increases the resistance of steels to scaling, and therefore it is added to heat-resistant steels and alloys. In dispersion-hardening stainless steels, aluminum is used as an alloying element that accelerates the dispersion precipitation reaction.

Aluminum increases the corrosion resistance of low-carbon steels. Of all the alloying elements, aluminum is the most effective for controlling grain growth when heating steels for hardening.

The influence of nitrogen on the properties of steels

The harmful effect of nitrogen (N) is that the rather large, brittle non-metallic inclusions it forms - nitrides - worsen the properties of steel. A positive property of nitrogen is that it is capable of expanding the austenitic region of the phase diagram of steels.

Nitrogen stabilizes the austenitic structure and partially replaces nickel in austenitic steels. Nitride-forming elements vanadium, niobium and titanium are added to low-alloy steels.

When controlled by hot working and cooling, they form fine nitrides and carbonitrides, which significantly increase the strength of the steel.

The influence of copper on the properties of steels

Copper (Cu) has a moderate tendency to segregate. The harmful effects of copper include a decrease in the cold brittleness of steel. With an increased copper content, it negatively affects the quality of the steel surface during hot processing.

However, with a content of more than 0.20% copper increases its resistance to atmospheric corrosion, as well as the strength properties of alloy and low-alloy steels.

Copper in amounts greater than 1% increases the resistance of austenitic stainless steels to sulfuric and hydrochloric acids, as well as their resistance to stress corrosion.

The influence of tin on the properties of steels

Tin (Sn) is already harmful to steels in relatively small quantities. It has a very strong tendency to segregate to grain boundaries and cause temper brittleness in alloy steels. Tin has a detrimental effect on the surface quality of continuously cast ingots, and can also reduce the hot ductility of steels in the austenitic-ferritic region of the phase diagram.

The influence of antimony on the properties of steels

Antimony (Sb) has a strong tendency to segregate during steel solidification and is therefore detrimental to the surface quality of continuously cast steel ingots. In the solid state of steel, antimony readily segregates to the grain boundaries and causes temper brittleness in alloy steels.

Sources: Steel Heat Treatment: Metallurgy and Technologies, ed. GE Totten, 2006.

Gulyaev A.P. Metal science, 1986.