I. General provisions

1. A person who has professional training under vocational training programs, retraining programs for worker professions and office positions, in an area corresponding to the focus (profile) of welding production, is appointed to the position of welder.

2. No practical experience is required. Carrying out work under the supervision of an employee of a higher qualification level.

3. Additional requirements:

— undergoing mandatory (upon employment) and periodic medical examinations (examinations), as well as extraordinary medical examinations (examinations) in the manner established by the legislation of the Russian Federation;

— completion of training and testing of knowledge of the norms and rules of work in electrical installations as electrical engineering personnel in the scope of group II on electrical safety or higher;

— undergoing training and testing knowledge of the rules for the safe operation of cylinders;

— training in fire safety measures, including undergoing fire safety training and fire-technical minimum according to the relevant program;

— completion of training on labor protection and testing of knowledge of labor protection requirements in the prescribed manner.

4. Appointment to the position of welder, as well as dismissal from it, is made by order of the head of the organization.

5. The welder must know:

5.1. Main types, structural elements, dimensions of welded joints and their designation in the drawings

5.2. Rules for preparing edges of products for welding

5.3. Main groups and brands of materials to be welded

5.4. Welding (surfacing) materials

5.5. Construction of welding and auxiliary equipment, purpose and operating conditions of instrumentation, rules of their operation and scope of application

5.6. Rules for assembling structural elements for welding

5.7. Types and purpose of assembly, technological devices and equipment

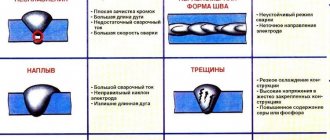

5.8. Methods for eliminating weld defects

5.9. Rules for the technical operation of electrical installations

5.10. Fire safety standards and rules for welding work

5.11. Labor protection rules, including in the workplace

5.12. ___________________________________________________________________________

6. The welder reports directly to ____________.

7. During the welder’s absence (vacation, illness, etc.), his duties are performed by a person appointed in the prescribed manner. This person acquires the corresponding rights and is responsible for their proper execution.

8. ________________________________________________________________

Categories of welders

Qualification is determined depending on the specialist’s ability to work with a certain set of welding technologies:

- spot welding involves joining metals without using electrodes. Simple manipulations that do not require long training;

- welders working with diffuse welding installations. The connection is characterized by increased strength characteristics of the seam;

- skills in working with electron beam equipment. Welding work is performed in a vacuum. The technology is in demand for joining parts made of various metal alloys;

- worker who knows how to handle thermite welding. Manipulations are performed on special welding presses. The parts are placed in molds that are heated;

- control of gas welding processes. In this case, the specialist is usually called a gas welder. He can also cut metals, armed with the appropriate devices - cutters;

- The last category consists of electric welders. They are in demand in manufacturing, the service sector and other areas of business.

II. Job responsibilities

The responsibilities of a welder (2-3 category) include:

1. Carrying out preparatory and assembly operations before welding and cleaning welds after welding:

— Familiarization with design and production-technological documentation for welding

— Checking the functionality and serviceability of welding equipment

— Cleaning structural elements (products, assemblies, parts) for welding with a hand or power tool

— Selection of the spatial position of the weld for welding structural elements (products, assemblies, parts)

— Assembly of structural elements (products, assemblies, parts) for welding using assembly devices

— Assembly of structural elements (products, assemblies, parts) for tack welding

— Inspection using a measuring tool of prepared and assembled structural elements (products, assemblies, parts) using assembly devices for compliance of geometric dimensions with the requirements of design and production-technological documentation for welding

— Inspection using a measuring tool of prepared and tack-assembled structural elements (products, assemblies, parts) for compliance of geometric dimensions with the requirements of design and production-technological documentation for welding

— Cleaning weld seams with hand or power tools after welding

— Removal of surface defects (pores, slag inclusions, undercuts, metal splashes, sagging, etc.) using manual or power tools

Welding discharges

Upon completion of their studies at the college or courses, candidates pass theoretical and practical exams by a special commission. The welder is given a diploma indicating his profession and is assigned a certain rank. The level of complexity of the work performed, to which a specialist can be admitted, and the amount of wages depend on the rank.

Usually after college they graduate with the 3rd category, and those who are especially successful in mastering the profession - with the 4th. You can further increase your rank in production or in advanced training courses. There are 6 categories in total. Let's take a closer look at what each digit means in practice.

1st category

This rank is assigned to college students after the first year of study. Essentially, these are students who already know how to hold an electric arc and perform tack work, so they will be able to participate in the assembly of structures.

2nd category

An employee who has mastered his specialty, but not well enough, can be released from college with this rank. It is capable of welding in the lower and vertical positions, surfacing layers of metal for grooving, but is not allowed for connecting pipes through which liquids and steam flow. A second-class welder is able to weld a crater, a crack, and heat the metal before straightening. It is expected that he himself will be able to prepare cylinders for gas welding and set up an acetylene generator. Second-class welders are used in non-critical processes.

3rd category

The specialist must be able to weld vertical, corner, and T-seams using electric arc and gas welding, and hermetically connect pipes. A 3rd category welder understands welding equipment and is able to service and set it up himself. The employee is expected to be able to read blueprints. The welder is allowed to weld carbon steels and structures of medium complexity, but such a specialist will not be able to perform ceiling welding efficiently. When flame cutting, the welder must be able to maintain specified dimensions and apply preliminary markings.

Immediately after college, it is difficult to get a well-paid job with a 3rd category. Employers argue this by lack of practice. But after a couple of years of work, great prospects open up.

4-digit

The specialist is able to assemble parts and structures of medium complexity and conduct high-quality welding in all spatial positions. Can weld pipes hermetically at permanent joints (when it is impossible to rotate the pipe along its axis by 180 degrees to bring the lower part to the top). A 4th category welder can weld using electric, gas, or semi-automatic welding. Can connect cast iron, high-carbon steel, non-ferrous alloys, and is proficient in air arc gouging. Reading drawings of medium complexity is required here by default.

5th category

The specialist is able to weld low-carbon and high-carbon steels, alloy metals, non-ferrous metals in all spatial positions. Suitable for working with critical structures that will undergo high dynamic loads. Welds pipelines, inside of which there will subsequently be high pressure. Able to cut parts of complex shapes to precisely specified dimensions.

6th category

A welder of the highest category, who can do everything as the previous ones, is only able to work with experimental alloys, independently determining the welding method, current strength, type of gases and filler materials. The specialist knows how to cook under water, so he is allowed to repair pipelines and ships that operate in difficult specific conditions under high loads.

III. Rights

The welder has the right:

1. Request and receive the necessary information, as well as materials and documents related to issues of their activities.

2. Improve your qualifications, undergo retraining (retraining)

3. Take part in the discussion of issues included in his functional responsibilities.

4. Make suggestions and comments on how to improve activities in the assigned area of work.

5. Require the management of the organization to provide assistance, including ensuring organizational and technical conditions and execution of the established documents necessary for the performance of official duties.

6. Make independent decisions, guided by qualification requirements and job responsibilities

7. ___________________________________________________________

Advantages of the profession

Why are courses for gas-electric welders so popular? The point is the undeniable advantages of this work activity:

- High wages (depending on the qualifications of the specialist).

- Kudos. Despite the fact that a gas-electric welder is a working profession, it remains honorable and respected.

- Opportunities for additional income. In addition to his main activity (say, at an enterprise), a specialist can take on additional private orders in his free time.

- Career opportunities. A professional in his field relatively quickly “grows up” to a foreman or engineer.

IV. Responsibility

The welder is responsible:

1. For improper performance or failure to fulfill one’s job duties provided for in this job description - within the limits determined by the current labor legislation of the Russian Federation.

2. For offenses committed in the course of carrying out their activities - within the limits determined by the current administrative, criminal and civil legislation of the Russian Federation.

3. For causing material damage - within the limits determined by the current labor and civil legislation of the Russian Federation.

4. ____________________________________________________________________

This job description has been developed in accordance with the provisions (requirements) of the Labor Code of the Russian Federation dated December 30, 2001 No. 197 FZ (Labor Code of the Russian Federation) (with amendments and additions), the professional standard “Welder” approved by order of the Ministry of Labor and Social Protection of the Russian Federation from November 28, 2013 No. 701n (as amended by order of the Ministry of Labor of Russia dated December 12, 2016 No. 727n) and other legal acts governing labor relations.

Pros and cons of the profession

The positive side is the constant demand for specialists in the labor market and high pay. But, like every profession, there are also negative aspects:

- welders often have to work in difficult, bordering on extreme, conditions;

- protective masks and special glasses cannot completely eliminate the negative effects of infrared and ultraviolet rays on the eyes;

- During welding of metals, harmful gases are released, which enter the human lungs and, over time, cause occupational diseases.

Every year, protective equipment and working conditions for welders are improved. Therefore, the popularity of the profession is only growing. Business owners and plant managers implement various incentive systems for welders to motivate them to work in their organization. On-the-job training is provided to “grow” your workforce. Due to objective circumstances, the welding profession remains quite popular among young people.

Applicant qualification requirements

The job description of a gas-electric welder assumes that a specialist must know:

- Types of titanium alloys, their mechanical and welding properties.

- Kinematic diagrams of automatic and semi-automatic devices, content of electronic control circuits.

- Rules for working with welding robotic systems.

- Types of metal corrosion, as well as the factors that cause it.

- Methods for conducting special tests of welded structures, the purpose of each of them (methods).

- Passing the fire minimum for a gas-electric welder.

- Basic methods of processing welded connecting seams.

- Basics of metallography of these welds.

Functional responsibilities of a specialist

We continue to analyze the job description of a gas-electric welder. An important point here will be the listing of the specialist’s responsibilities. The employee's job functions are as follows:

- Manual plasma, arc, gas welding of parts, devices, structures, assemblies, pipelines made of various steels, cast iron, non-ferrous alloys and metals that are designed to work under vibration and dynamic loads, under increased pressure.

- Manual gas-electric and arc welding of technological and construction parts, structures that operate under vibration and dynamic loads, and connections of complex configurations.

- Automatic welding of various structures from special alloy steels, titanium and other alloys on machines of various designs, multi-electrode and multi-arc devices equipped with photoelectronic, television and other special devices, on automanipulators (robots).

- Mechanized welding of components, apparatus, pipeline structures, technological and construction facilities operating under vibration and dynamic loads. Performing welds in a vertical and overhead position.

- Welding of a number of experimental structures made of metals and alloys with limited weldability, as well as titanium and its alloys.

- Welding of complex parts in a block structure in all positions in the weld space.