Home / Electrodes

Back

Reading time: 3 min

0

980

Surfacing electrodes are used to strengthen or repair welded joints and surfaces. The procedure is performed in the form of applying an additional layer of molten metal to an existing roller.

This technology improves the physical characteristics of the connection, provides additional reliability, and improves appearance.

The operation is performed with specialized surfacing electrodes. The article examines the types of such rods and their characteristic features.

- General information

- Varieties

- Application

Surfacing technology

Like electrode welding of carbon steels, surfacing also uses consumables. However, the ultimate goal is not the reliability of the formed connection, but its operational parameters:

- Hardness.

- Wear resistance.

- Dimensional stabilization.

- Corrosion resistance.

Taken together, these factors help reduce the cost of maintenance and replacement of worn parts.

The essence of surfacing is that a layer of metal (or alloy) is applied to the surface being processed in molten form, as a result of which the dimensions of the part are restored and its wear resistance increases.

Based on the surface heating method, surfacing is divided into gas and electric. The first includes surfacing with natural gases or an acetylene-oxygen flame. Varieties of electrical surfacing are arc, pulse, spark, as well as combinations of these methods.

UONI-13/NZh/20Х13 Current - constant reverse polarity (plus on the electrode)

RUB 408.96 ? with VAT per 1 kg.

ANP-13 Current - constant reverse polarity (plus on the electrode)

RUB 250.08 ? with VAT per 1 kg.

OZCh-2 Current - constant reverse polarity (plus on the electrode)

RUB 1,352.28 ? with VAT per 1 kg.

OZCh-6 Current - constant reverse polarity

RUB 1,304.52 ? with VAT per 1 kg.

Key points on surfacing with electrodes

The operating principle of the surfacing method is based on melting the electrode under the influence of a welding arc, creating one or several layers. How many there will be must be determined by paying attention to the properties of the part, depending on the requirements.

IMPORTANT! The chemical properties of the deposited metal layer, the composition of the electrode, must almost completely coincide with the characteristics of the steel of the part being repaired. This is important to consider when choosing a brand or type.

Good quality characteristics of the layer created by the welder are achieved depending on the depth of metal penetration. This figure should be minimal. This is important to take into account; it is necessary to achieve as little mixing of the welded steel as possible with the base steel. The welder must try to obtain a minimum residual stress and avoid deformation of the part he is processing. This requirement can be met only by observing the previous two, choosing the right electrode and minimal welding.

It is important to reduce the allowance values that are permissible during subsequent processing of parts after welding to the norms, and not to exceed them.

It is recommended to fuse a layer of metal with an electrode as much as required, and no more.

To prevent warping, it is best to carry out fusing in separate sections, and it is recommended to start laying each subsequent roller on the opposite side to the previous one.

Only by following these simple rules can protection of the deposited metal be achieved from the destructive effects of gases. The result is a dense layer that does not have pores, any types of cracks and foreign inclusions. It is also important to take into account that the surface of the part being repaired must be thoroughly cleaned of oil, traces of corrosion, rust and any other types of contaminants before starting surfacing work.

Surfacing electrodes

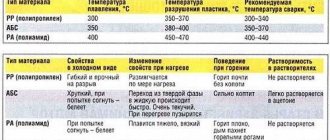

Like electrodes for welding carbon steels, for which GOST determines the grade of material and welding technology, surfacing electrodes are also distinguished by their functional features.

Important! There are electrodes that can be used to perform both welding and surfacing (GOST 9466-75), electrodes that perform manual arc surfacing (GOST 10051-75), as well as non-standardized electrodes for special applications (for example, for surfacing worn stamp engravings, dies or punches).

Types of electrodes determined by current state standards:

- Coated surfacing electrodes intended for surfacing low-alloy steels: T-590, T-620, OZN-6, ANP-13

- Welding surfacing electrodes used in processing stainless steels: TsN-6L, TsN-12M, UONI 13/NZh-20X13

- Carbide surfacing electrodes, effective in hardening metalworking tools: OZN-300M, OZN-400M

Features of application

Surfacing electrodes are used to apply a filler layer to a part. They make it possible to obtain a deposit that is resistant to abrasive effects and shock loads, and create a layer on the product with the necessary parameters.

TsNIIN-4 electrodes for surfacing.

With their help you can:

- give the part its original appearance;

- bring the product into compliance with the original geometric parameters;

- give new properties;

- increase resistance to wear and thermal effects.

The geometry of parts can be restored using carbide rods. By selecting the necessary brands, you can solve a wide variety of problems. They are used to restore cutting tools, as well as devices operating under high pressure.

To make connections in the lower and inclined position, T-620 electrodes are used. It is especially advisable to use them for metal parts characterized by rapid wear, as well as for cast iron products exposed to shock.

This brand, if necessary, may require calcination at temperatures up to two hundred degrees for three hours. The number of layers that can be created on metal with this rod is 2, and for cast iron - 1.

TsNIIN-4 is used to eliminate casting defects on crosspieces. The diameter of the rod is four millimeters. Also requires calcination, like T-620.

You can increase the hardness of a product by hardening using CS-2. The maximum layer thickness created by such a rod is four millimeters. After application, a quarter of the deposit can be removed. Used for repairing hardened products.

OZSh-6 – electrodes with a diameter of 2.5-4 millimeters, designed for connection in the lower position. Used for metallurgical and machine tools.

Currently, the market offers a wide range of electrodes that allow solving a wide variety of problems.

Features of the composition and structure of electrodes

There are operating conditions and the final characteristics of the surface of the part after surfacing. The material of the surfacing electrode must have an affinity for the base metal of the product, since a large difference between the sizes of the deposited particles and the underlying macrostructure contributes to the occurrence of internal stresses.

The surface layer of surfacing electrodes usually consists of wear-resistant metal carbides (less commonly, nitrides). The effectiveness of the coating is directly dependent on the amount of carbide-forming elements - chromium, molybdenum, tungsten, vanadium and iron - in combination with carbon.

Wear-resistant carbides are formed when one of these elements reacts with carbon and becomes completely saturated as a result, forming a carbide consisting of only carbon and metal. The balance of carbon remains in solution, forming a semi-austenitic matrix in which the hard, wear-resistant carbides are evenly distributed. As the ratio of wear-resistant carbides to alloy matrix increases, abrasion resistance increases (and toughness decreases).

TsN-6L Current - constant reverse polarity (plus on the electrode)

RUB 692.16 ? with VAT per 1 kg.

TsNIIN-4 Current - constant reverse polarity (on the electrode plus)

RUB 1,040.76 ? with VAT per 1 kg.

MEZT-590 Current - constant reverse polarity (on the electrode plus)

RUB 214.20 ? with VAT per 1 kg.

MEZT-620 Current - constant reverse polarity (on the electrode plus)

RUR 219.60 ? with VAT per 1 kg.

TO

category:

Maintenance of road vehicles

P

publication:

Surfacing of parts with special electrodes and hard alloys

H

read more:

Surfacing with tubular electrodes with ferromanganese

Surfacing of parts with special electrodes and hard alloys

Surfacing of worn parts of road machines is carried out: 1) to restore the original dimensions of parts (shafts, rollers, links, sprockets, etc.); 2) to restore the original performance of working parts (knives, cheeks, augers, etc.); 3) to increase the wear resistance and service life of wear parts and working parts after surfacing.

Wear on the blade of earth-moving machines occurs along the front cutting edge (dotted line in Fig. 129, a). If the knife (or tooth) has hard surfacing on the front plane, then the nature of wear changes (dotted line in Fig. 129, b) and the service life increases. However, if the base metal of the knife has low wear resistance, then wear occurs along the rear plane of the knife (Fig. 129, c), the deposited part protrudes outward, where due to increased hardness and fragility it can collapse.

Promotional offers based on your interests:

Rice. 129. Wear of the edge of the digging machine blade

To eliminate this phenomenon, such a knife must be fused in two layers of different hardness (Fig. 129, d). The layer is more wear-resistant than the layer, and the wear resistance of the latter is higher than the wear resistance of the base metal of the knife. In this case, the wear of the part occurs more evenly.

At the same time, the knife will self-sharpen (its cutting edge will remain sharp), as a result of which the productivity and wear resistance of the latter will increase.

Many wear parts of road cars are heavy, but only a thin outer layer is involved in their work, the weight of which often does not exceed 10-15% of the total weight. It is economically feasible to restore such parts by surfacing worn surfaces with electrodes and alloys with increased hardness.

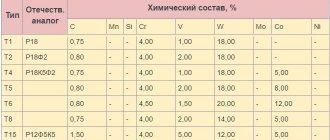

Special electrodes of grades 03H-250, OZN-ZOO, 03H-350, 03H-400 and U-340 are used to obtain medium-hard surfacing of parts made of carbon and medium-alloy steels (numerical indices indicate the average hardness of the third layer of surfacing according to Brinell).

The specified hardness of the surfacing is achieved by introducing one or more alloying elements (Mn, Cr, Si, etc.) into the deposited metal through the coating. This promotes the formation of hardening structures and strengthening of ferrite. The coating is applied to ordinary welding wire. Carbon in such electrodes is not the leading alloying element. Depending on the brand of electrode, the carbon content in the deposited metal ranges from 0.12 to 0.3%.

Attempts to use carbon as the main leading alloying element (increasing its content in the surfacing by more than 0.3%) led to the formation of cracks and pores in the deposited metal.

It should be noted that carbon steels with C = 0.3–0.7% are prone to the formation of hardening structures, which reduce the strength of the steel, and the formation of cracks during conventional welding methods used for low-carbon steels.

Experience in the use of OZN and U-340 electrodes indicates the high quality of electrodes with a slag-forming coating of the main type (marble, fluorspar) and with manganese introduced as the leading alloying element. The main advantage of these electrodes is their reduced tendency to crack.

The wear resistance of hardened metal deposited with an OZN-ZOO electrode is 1.5 times higher than that of hardened steel grade 40X. Electrodes OZN-ZOO and 03H-250 should be recommended for surfacing hardened parts from medium-carbon steels of grades 40 and 45, from chromium steels of grades ZОХ, 35Х, 40Х, etc. These electrodes are suitable for surfacing parts from low-carbon steels and steels of grades 35 and 40.

OZN-ZOO electrodes are used for surfacing the lower rollers of caterpillar tractors made of 50G steel.

Good results are obtained when surfacing hardened parts made of 40X steel using U-340 electrodes.

Metal deposited with 03H-250 electrodes can be easily processed with cutting tools. The hardness of metal deposited with OZN-ZOO and other electrodes can be reduced by annealing at 850° and cooling with the furnace.

During hardening, the deposited metal reaches a hardness of HB 400-460.

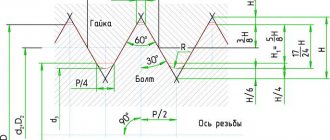

Electrodes OZN-ZOO, 03H-250 and U-340 are used to fuse worn splines of axle shafts of motor graders and motor rollers (Fig. 130). Surfacing is carried out using direct current with reverse polarity. The current for the U-340 electrode with a diameter of 4 mm is 135-170 A, and for the OZN electrode with a diameter of 5 mm - 210-240 A. If the OZN electrode coating contains potash, welding can be carried out using alternating current. After surfacing, the axle shaft is straightened, the spline part is turned, and the splines are milled. Then the axle shaft is heated to 840-860°, quenched in oil and tempered at 250-300°.

To obtain high hardness, electrodes T-540, T-590 and T-620 are used to overlay parts made of case-hardening and hardening steels, as well as parts of working parts of road machines.

The high hardness of the metal deposited with these electrodes is obtained as a result of the introduction of alloying elements into the coating composition: ferrochrome, ferrotitanium, ferroboron, carbide, boron and graphite.

When using T-590 and T-620 electrodes, due to the high degree of alloying Cr, B and Ti, the metal deposited by them has the structure of a carbide eutectic based on an α-solid solution and a large amount of primary carbides. As a result, heat treatment of the deposited metal results in a decrease in hardness, and mechanical processing is possible only with abrasives.

Due to the absence of primary carbides and the relatively low degree of alloying of austenite with chromium and titanium, the metal deposited with the T-540 electrode reduces the hardness during annealing and allows machining by cutting. The hardness of the metal deposited with T-540 electrodes immediately after surfacing is 35–45 HRC; after annealing at 900–950° it decreases to 24–28 HRC, and after quenching at the same temperature and tempering at 200–250° it is 57– 60 HRC. This electrode can be used to fuse worn gear teeth.

Rice. 130. Applying seams to the axle splines

Metal deposited with T-590 and T-620 electrodes is characterized by increased brittleness and a tendency to crack; Therefore, in case of significant wear, it is recommended to weld only the upper working layers. The lower layers are fused with softer electrodes.

These electrodes can be used to deposit the knives of earth-moving machines, the jaws and rollers of stone crushers, the teeth of excavator buckets, parts of dredgers, etc. The durability of the jaws of rock crushers increases after surfacing with a T-590 electrode by 2 times, the blades of motor graders and parts of dredgers - by 2-3 times.

Iron-chromium electrodes are cast hard alloys (stellites) such as sormite and powdered alloy - stalinite. Using sormite, good results are obtained when surfacing small worn surfaces of cemented and hardened parts.

Surfacing with sormite is carried out using gas or electric arc welding. Sormite is made from rods with a diameter of 5, 6 and 7 mm. When surfacing, electrodes of the TsS-1 and TsS-2 brands are used. The surface deposited with the TsS-1 electrode without heat treatment has a hardness of 48–54 HRC, and with the TsS-2 electrode—39–45 HRC. These electrodes differ from each other in that the layer deposited with the TsS-1 electrode does not accept subsequent heat treatment, while the layer deposited with the TsS-2 electrode accepts hardening, after which the hardness of the deposit increases to 56-60 HRC. These electrodes produce surfacing with direct and alternating current with a short arc. With direct current, reverse polarity is used and the thickness of the deposited layer is no more than 2.5–4.0 mm, taking into account an allowance for subsequent machining of 1.0–1.5 mm.

After normal welding, the gear teeth are cleaned and coated with a thin layer of sormite hard alloy. The size of the teeth after machining before surfacing should be less than the nominal size by up to 1.5 mm.

Surfacing of teeth is carried out in a bath of water. When surfacing the ends of the gear teeth of a motor grader gearbox, the latter is installed in the bath so that the teeth being welded are immersed in water to !/3-H* of their height. Using the flame of a gas burner No. 2 or 3 with an excess of acetylene, the tooth being deposited is heated until it fogs up, without bringing the metal to melting. Flux-borax is applied with a sormite rod, after which sormite is applied in drops to the required tooth size. After surfacing, the gear is left in the bath to cool to approximately 100°.

When surfacing the side surfaces of the teeth, the gear is installed in the bath (Fig. 131) and surfacing begins from the second tooth from the water surface. After surfacing the tooth, the gear is turned so that the deposited tooth does not touch the surface of the water, and the next (third) tooth is welded. After the deposited second tooth has cooled (to a dark cherry color), it is immersed in water to harden it.

In the same way, teeth are surfaced with martensitic cast iron. Surfacing is carried out using rods with a diameter of 2-3 mm with a neutral flame or with a slight excess of acetylene. The repaired teeth are then treated with an abrasive wheel with a grain size of 36-46.

The profile of the machined teeth is checked with special templates.

This method for restoring the thickness of the tooth profile should not be used due to the significant labor intensity of this process.

Stalinite is a powdered alloy that is melted by a carbon or steel electrode at direct current with straight polarity and applied to the part in a layer of 3-4 mm. Borax is used as a flux.

Stalinite can be mixed in liquid glass and applied in the form of a paste to the surface of the part, melting it. h.

Due to the high carbon content in the deposit, the part must be cooled slowly. Despite this, the deposited surface has a significant number of shallow cracks and pores.

To reduce the formation of cracks, the charge is fused with a steel electrode or the powdered charge is replaced with steel electrodes coated with stalinite. Stalinite is used to fuse parts of the working parts of road vehicles (knives, teeth, cheeks, etc.).

Promotional offers:

Read more: Surfacing with tubular electrodes with ferromanganese

TO

Category: — Maintenance of road vehicles

Home → Directory → Articles → Forum

Comparative metal efficiency of surfacing electrodes and their designation

In descending order of wear resistance, the composition of surfacing electrodes contains tungsten carbide, molybdenum carbide, chromium carbide, as well as multicomponent carbides.

Brands of electrodes take this circumstance into account. Common markings for surfacing electrodes include:

- Electrode type;

- Name of the electrode corresponding to the required GOST;

- Electrode diameter, mm;

- Special requirements for the surface to be deposited (optional);

- Electrode index with parameters of mechanical properties of the deposited layer;

- Mode of application;

- GOST number according to which the electrode is manufactured.

Principles for selecting surfacing electrodes

The effectiveness of surfacing is determined by the correctly selected final goal of the process - welding with a simultaneous increase in mechanical and/or corrosion strength, or a change in the characteristics of the original workpiece. The first goal is important when processing highly loaded machine parts and structures, and the second is important when hardening tooling.

Important! All carbide electrodes have very high compressive strength, which is usually accompanied by reduced ductility and shear strength. Such surfacing materials should be used in such a way that, as a result of the thermal impact on the treated steel surface, compressive stresses arise there. With high impact resistance after hard surfacing, the applied layer will not be destroyed in the event of an impact.

When choosing metal electrodes, it is worth remembering that the best performance characteristics are those that contain high-speed steels, austenitic manganese steels, combined alloys of the chromium-cobalt-tungsten system, austenitic iron with a high chromium content, as well as nickel alloys with chromium and boron.

You might be interested

Ø 4 (1 kg) Ø 4 (6 kg) Ø 5 (1 kg) Ø 5 (6 kg)

Electrodes for surfacing T-590 Current - direct polarity constant, alternating

RUB 577.68 ?

Price including VAT per 1 kg.

Ø 4 (1 kg) Ø 4 (6 kg) Ø 5 (1 kg) Ø 5 (6 kg)

Electrodes for surfacing T-620 Current - constant, straight polarity (minus on the electrode)

RUB 626.28 ?

Price including VAT per 1 kg.

Ø 3 (1 kg) Ø 3 (5 kg) Ø 4 (1 kg) Ø 4 (5 kg) Ø 5 (1 kg) Ø 5 (6 kg)

Electrodes for surfacing OZI-3 Current - constant reverse polarity

RUB 428.52 ?

Price including VAT per 1 kg.

Ø 4 (1 kg) Ø 4 (5 kg) Ø 5 (1 kg) Ø 5 (5 kg)

Electrodes for surfacing MEZT-590 Current - constant reverse polarity (plus on the electrode)

RUB 214.20 ?

Price including VAT per 1 kg.

Ø 3 (1 kg) Ø 3 (5 kg) Ø 4 (1 kg) Ø 4 (6 kg) Ø 5 (1 kg) Ø 5 (6 kg)

Electrodes for surfacing OZN-300M Current—alternating, constant, reverse polarity (on the electrode plus)

172.56 rub. ?

Price including VAT per 1 kg.

Ø 3 (1 kg) Ø 3 (5 kg) Ø 4 (1 kg) Ø 4 (6 kg) Ø 5 (1 kg) Ø 5 (6 kg)

Electrodes for surfacing OZN-400M Current - alternating, constant reverse polarity (plus on the electrode)

RUB 183.84 ?

Price including VAT per 1 kg.

Ø 4 (1 kg) Ø 4 (5.5 kg) Ø 5 (1 kg) Ø 5 (5.5 kg)

Electrodes for surfacing MEZT-620 Current - constant reverse polarity (plus on the electrode)

RUR 219.60 ?

Price including VAT per 1 kg.

Ø 3 (1 kg) Ø 3 (4.5 kg) Ø 4 (1 kg) Ø 4 (6 kg) Ø 5 (1 kg) Ø 5 (6 kg)

Electrodes for surfacing TsN-12M-67 Current - constant reverse polarity (plus on the electrode)

RUB 943.20 ?

Price including VAT per 1 kg.

Ø 4 (1 kg) Ø 4 (4.5 kg)

Electrodes for surfacing TsNIIN-4 Current - constant reverse polarity (on the electrode plus)

RUB 1,040.76 ?

Price including VAT per 1 kg.

Ø 3 (1 kg) Ø 3 (5 kg) Ø 4 (1 kg) Ø 4 (5 kg) Ø 5 (1 kg) Ø 5 (5 kg)

Electrodes for surfacing TsN-6L Current - constant reverse polarity (plus on the electrode)

RUB 692.16 ?

Price including VAT per 1 kg.

Ø 3 (1 kg) Ø 3 (4 kg) Ø 4 (1 kg) Ø 4 (6 kg) Ø 5 (1 kg) Ø 5 (6 kg)

Electrodes for surfacing ANP-13 Current - constant reverse polarity (plus on the electrode)

RUB 250.08 ?

Price including VAT per 1 kg.

Ø 3 (1 kg) Ø 3 (5 kg) Ø 4 (1 kg) Ø 4 (6.5 kg) Ø 5 (1 kg) Ø 5 (6.5 kg)

Electrodes for surfacing UONI-13/NZh/20Х13 Current - constant reverse polarity (plus on the electrode)

RUB 408.96 ?

Price including VAT per 1 kg.

Show 4 more products