What the article is about:

Semi-automatic welding modes to weld 4,6,8 mm steel

Semi-automatic welding, for example, when repairing cars, is carried out with small stitches and dots. In this case, the main goal is achieved, not to burn through the thin metal and to melt only that part of it that requires connection.

Along with this, you can cook not only thin metal with a semi-automatic machine. Depending on the diameter of the welding wire, it is allowed to weld metals whose thickness exceeds 2 millimeters or more.

What semi-automatic welding modes are used? How to weld steel correctly with a semi-automatic machine?

The essence of semi-automatic welding

Before considering the main modes of semi-automatic welding, it is worth understanding what this technology is. During the process, the wire is fed at a certain speed. It is synchronized with the speed of its melting.

The main distinguishing feature of semi-automatic devices is that they operate in a protective gas environment. Welding technology can be produced in an inert environment (argon) and an active environment (carbon dioxide). In the first situation, the process is called MIG (metal inert gas), and in the second - MAG (metal active gas).

Gas mixtures provide isolation of the heating and melting region from oxides from the air. They are fed through a channel that is located on the sleeve along with the tube. The sleeve connects the body of semi-automatic welding equipment with the torch. But all processes are regulated by the “Start/Stop” button, which is located on the burner.

It is worth noting! If we compare semi-automatic welding with equipment for manual technology covered with electrodes, then it is complemented by an electric mechanism for feeding welding wire and gas cylinder equipment.

This is what increases the productivity of the process and improves the quality of welded joints.

Welding speed

In semi-automatic welding, the speed of movement of the torch is set by the welder. It is necessary to choose a speed at which high-quality formation of the weld is obtained. Thick-walled structures are usually welded at high speed, forming narrow seams. At high welding speeds, it is necessary to ensure that the end of the wire and weld metal does not oxidize through the exit from the gas protection zone. At low welding speeds, the weld width increases due to the expansion of the weld pool. The ability to form pores increases.

Main settings

To accurately select semi-automatic welding modes, it is worth understanding what they should consist of. There are certain criteria and settings for welding equipment, knowing which the welder will be able to do everything correctly.

Diameter and grade of wire

Before you start work, you should figure out what the correct wire diameter should be. Its value ranges from 0.5 to 3 mm. Calculation of welding modes in shielding gases must necessarily be carried out taking this indicator into account.

But still, in order to choose the correct wire diameter, it is worth considering the following nuances:

- The diameter of the filler material should be selected in accordance with the thickness of the metal product being welded.

- It is worth considering that each diameter has certain characteristics. For example, when using wire with a small diameter, many welders note that there is a steady burning of the arc and slight spattering of metal.

- When using wire with a larger diameter, it is always necessary to increase the amperage.

- It is important to consider the brand of wire used. Namely, the metal from which the wire is made, as well as the components included in the composition.

- To weld products made of low-carbon or low-alloy steel, it is worth using wires with the addition of deoxidizing agents. The composition should include components such as silicon and manganese.

- To process alloy or high-alloy steel in a protective gas environment, it is worth using wire made of the same metal as the part that will be welded.

Whatever gas welding mode is used, it is worth choosing the required diameter of the filler wire. This affects the strength of the connection.

Strength, polarity and type of welding current

Semi-automatic welding parameters include the correct setting of the current that is used during welding and processing of metal products. In a standard semi-automatic device, you can independently adjust the strength, polarity and type of welding current. But still, everyone has certain criteria.

For example, if you increase the current strength, then during the welding process the penetration depth will increase. The current increases in accordance with the diameter of the electrode. In addition, do not forget about the characteristics of the metal that is used for welding.

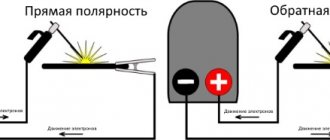

It is imperative to take into account the properties of polarity and type of current. Typically, the semi-automatic welding process is carried out using shielding gases, but it is necessary to select the necessary indicators of direct current and reverse polarity. Straight polarity is used in rare cases; these semi-automatic welding parameters are not capable of providing a stable arc, they worsen the welded joint. However, there are exceptions; alternating current is often used when working with aluminum products.

Many inexperienced welders often forget about an important parameter - the welding arc voltage. But this indicator has a major influence on the degree of metal penetration and the dimensions of the weld. Do not set the voltage too high, as this will cause the molten metal to splash heavily during the welding process and cause pores to appear in the joint. Gas mixtures will be able to sufficiently protect the weld pool. If you want to correctly set the arc voltage, you should focus on the current strength indicators.

Wire feeding speeds

When calculating the welding mode in carbon dioxide, it is worth taking into account the wire feed speed. This indicator has a huge impact on the weld.

The main features of the speed of the semi-automatic welding process include:

- wire feeding speeds are regulated in accordance with GOST standards;

- you can choose this indicator yourself, but you should rely on the features of the metal structure and its thickness;

- thick metal needs to be welded faster, and the joint must be thin;

- when welding, do not rush, otherwise the electrode will leave the area of protective gas mixtures, and this will lead to its oxidation under the influence of oxygen;

- too slow a speed results in the formation of a weak seam with a porous structure.

Exhaust gases

Semi-automatic welding modes involve the use of gas mixtures that provide maximum protection of the welding zone from oxidation by oxygen. The technology indicates that different gases can be used. But in practice, carbon dioxide is often used according to GOST 8050-85. The main criterion for choosing this product is its low cost and availability. It comes in cylinders.

You definitely need to know what pressure is in the carbon dioxide cylinder for welding. The operating pressure indicator is 60-70 kgf/cm2. On the surface there is a yellow inscription “Carbon Dioxide”.

What carbon dioxide pressure should be when welding with a semi-automatic machine can be found in the table below:

Also, the working pressure of carbon dioxide during semi-automatic welding can be found in special documentation and in GOST standards for semi-automatic welding devices that are intended for welding using protective gas mixtures.

In addition to carbon dioxide, other gas mixtures are used for semi-automatic welding, which have the following characteristic features:

- argon _ It is used quite often. But still, it is mainly used when carrying out the argon arc welding process. It is an inert gas, therefore suitable for welding chemically active and refractory metals;

- helium _ This is an inert gas that is often used in semi-automatic welding technology. It provides strong and wide welds;

- various mixtures of argon, helium and carbon dioxide.

Features of electrode tilt

When considering the modes of semi-automatic welding in shielding gases, it is worth studying the important criteria for the angle of inclination of the electrode. A common mistake that beginners make is holding the electrode the way they want while welding. But this is considered a grave mistake.

Important! The angle of inclination of the electrode has a huge impact on the penetration depth of the metal structure. The quality of the resulting welded joint also depends on this indicator.

There are two types of inclination of the electrode - a backward angle and a forward angle. Moreover, each position has positive and negative features. During forward angle welding, the electrode is guided at an angle of 30° to 60°. If you comply with this provision, you should be prepared for the fact that the molten coating will form a slag coating on top.

When positioned forward, the electrode moves after the weld pool, protecting it from the penetration of harmful gas mixtures. A certain amount of slag entering in front of the joint will be deposited on both sides of the joint. If a lot of slag is released, the slope decreases.

When holding the electrode at an angle backwards, the welding zone is less visible, but the condition of the edges is much better visible. A small penetration depth is also observed.

Note! For thin metals, it is recommended to hold the electrode tilted forward; this position is considered the most suitable. But at a backward angle you can weld metal products of any thickness.

Setting current and wire feed speed

First of all, the strength of the welding current is set, which depends on the type of material being welded and the thickness of the workpieces. This can be found out from the instructions for the semi-automatic machine or found in the relevant literature.

Then the wire feed speed is set. It can be adjusted stepwise or smoothly. With stepwise adjustment, it is not always possible to select the optimal operating mode. If you have the opportunity to choose a device, buy a semi-automatic welding machine with continuously adjustable wire feed speed .

The control unit must have a forward/reverse wire feed mode switch. When all the settings have been made in accordance with the operating instructions for the semi-automatic machine, you need to try working on a draft sample with the same parameters. This must be done because the recommendations are average, and in each individual case the conditions are unique.

At a high wire feed speed, the electrode simply will not have time to melt, there will be large deposits or shifts on top, and at a low speed it will burn out without melting the metal being welded, the weld bead will sag, and depressions or breaks will appear.

Tables

In order to correctly select and set the modes of semi-automatic welding in carbon dioxide, it is worth carefully considering all the important parameters of the technology. This especially applies to beginners, because experienced craftsmen are able to immediately determine the correct welding modes in carbon dioxide. But for beginners, special tables have been developed containing the main criteria for semi-automatic welding work.

Below is a table for setting up a semi-automatic welding machine. It should be used for butt welds in the lower spatial position and for welding technology of low-alloy and low-carbon metal products. An important condition for welding is the use of shielding gas and current with reverse polarity.

Table of semi-automatic welding modes with parameters that are suitable for rotary butt welds. During the welding process, it is recommended to use various protective gas mixtures.

Welding table for a semi-automatic machine with parameters that are suitable for forming an overlap joint. During welding, shielding gas and current with reverse polarity are used.

The table below contains recommended settings that should be used when welding carbon steel products in a vertical position in space. During the technology, current with reverse polarity and a mixture of protective gases are used.

Table of welding currents and other important parameters for a semi-automatic machine with suitable welding process modes using carbon dioxide using the “dot” method. It is recommended for use when working with carbon steels.

Main features of semi-automatic welding

It is important to know not only the gas welding modes and their correct choice, but also the main features of welding stainless steel products using semi-automatic equipment. The final result and the strength of the connections will depend on this.

Among the main features of semi-automatic welding of stainless steel elements are:

- When welding, it is recommended to use current with reverse polarity.

- The electrodes must be held at an angle of inclination. If the basic rules are not followed, for example, if the electrode deviates more forward, then the connection will be wide and the welding depth will be small. This tilting method should be used for thin metals.

- The largest wire extension should be no more than 12 mm.

- The carbon dioxide pressure when welding stainless steel with a semi-automatic machine should be the same as when welding other metals. The operating flow rate should be no more than 12 m3 per minute, but not less than 6 m3 per minute. If these conditions are not met, the quality of the seam will greatly deteriorate.

- When welding, be sure to use a desiccant. Copper sulfate is used as it, which is preheated at 200 degrees for 20 minutes.

- To protect yourself from splashes of hot molten metal, it is recommended to use aqueous solutions containing chalk.

- If you want to get an excellent connection when welding with an electrode, you should drive smoothly, without hesitation.

- When welding, you should retreat at least 5 cm from the edge of the workpiece.

Features of stainless steel welding

Alloying additives make stainless steel resistant to corrosion and acids, but at the same time it acquires properties that make welding difficult. Compared to conventional steel, thermal conductivity is reduced by half. This makes it difficult to remove heat from the welding site, which leads to overheating of the metal, burn-through and burnout of chrome. To prevent this phenomenon, welding is performed with a current 15 - 20% less than the standard one with additional cooling of the workpieces.

Stainless steel has a high coefficient of thermal expansion, which leads to cracking of the seam and the metal next to it. To neutralize it, a large gap is left between the workpieces. Due to the high electrical resistance of the material, the electrodes for welding stainless steel overheat, which does not have the best effect on the quality of the seam. Therefore, they are cut to the minimum possible size so that they do not have time to heat up.

Having learned about the difficulties, beginners ask the question: “Is it possible to weld stainless steel semi-automatically at home?” The answer, of course, is yes. Three methods are used to connect workpieces:

- short arc;

- impulse method;

- jet transfer.

Thin stainless steel is welded with a short arc, as it reduces the likelihood of burning through. The jet transfer method is used to join thick-walled parts made of stainless alloys in production. Welding is carried out using flux-cored wire and special heads.

To create a protective environment during pulse welding, a mixture of argon and carbon dioxide is used. The advantages of the method include:

- the ability to connect both thin and thick workpieces;

- feeding the wire in short pulses prevents splashing of molten metal;

- saving of filler material;

- excellent connection quality;

- high performance.

Advantages and disadvantages

Semi-automatic gas shielded welding has positive and negative qualities. Among the advantages it is worth highlighting:

- the technology has high productivity;

- it allows you to get an excellent welded joint. Correct adjustment of the semi-automatic welding machine ensures rational input of alloying elements and deoxidizers through the wire;

- no fluxes or coatings are required. This means that there is no need to clean the welded area from slag;

- high efficiency;

- Suitable for working with different steels and metals.

But there are some disadvantages:

- the equipment is complex and requires skills and knowledge to set it up;

- protection is required when working in open areas;

- additional costs for eye protection.

Carrying out semi-automatic welding technology requires compliance with important modes, on which the quality and strength of the connection depends. Each welder must know the wire diameter, current strength, polarity, types of protective gases, as well as what carbon dioxide pressure should be used when welding with a semi-automatic machine. To make the task easier, special tables were developed with the exact parameters of semi-automatic welding.

Adjusting parameters

Adjustment of current or voltage depends on the thickness of the workpieces. The thicker the product being welded, the greater the welding current. In simple semi-automatic welding devices, the current adjustment is combined with the wire feed speed.

In professional semi-automatic machines, the adjustments are separate. The correct setting can only be determined experimentally by making an experimental seam on a test piece. The roller should be of normal shape, the arc should be stable, without splashes.

Some semi-automatic models have inductance adjustment (arc settings). With low inductance, the arc temperature drops, the depth of metal penetration decreases, and the seam becomes convex.

This is used when welding thin metals and alloys that are sensitive to overheating. With high inductance, the melting temperature rises, the weld pool becomes more liquid and deeper. The seam bead becomes flat. Welding in this mode is used for thick workpieces.

The welding wire feed speed switch in models capable of working with different diameters requires additional adjustment taking into account the specific thickness of the wire.

Even after fully studying the manufacturer’s recommendations, it is not always possible to obtain the desired operating mode of the semi-automatic machine.

Having set the optimal settings for welding a workpiece today, it may turn out that the next day they will become suboptimal because the quality of the network has changed or the position of the product on the workbench has changed.

That is, setting the modes is a constant and individual process because it also depends on the work style of the welder himself.