- home

- Job training

- Roller

- Roller 4th category

For most blue-collar professions, there is a legislative requirement for advanced training at least once every 5 years. This requirement is regulated by the Labor Code of the Russian Federation, Professional Standards and federal laws. If this requirement is not established for a specific specialty, then according to Art. 196 of the Labor Code of the Russian Federation, the employer or the employee himself can make a decision on advanced training at any time.

Characteristics of the work.

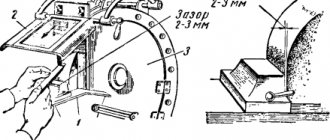

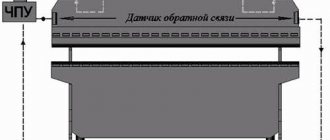

Conducting the technological process of primary plasticization, gelatinization, averaging, softening, dyeing, sheeting, calibration in the production of nitrolinoleum, polyvinyl chloride products (bypassing the calendering stage), polyvinyl chloride fabric, plates, briquettes, catalyst (chalk mixture), faolite, polystyrene, mixtures for the production of ordinary gramophone records, organosilicon powders, cellulose acetate etrol or in the manufacture of press materials based on phenol-formaldehyde resins, nitrocellulose etrol, celluloid, cellulose on rollers of various designs under the guidance of a more highly qualified roller, as well as in the manufacture of polymer mixtures (except rubber) on rollers with the length of the rollers over 800 mm. Checking the serviceability and preparing for operation of rollers, braking and starting devices, roll extension mechanisms, steam-water and transport communications and instrumentation. Setting the cycle duration, temperature conditions of rollers, frictions and gaps depending on the types and recipes of mixtures. Dosage of mixtures in a strictly defined sequence, monitoring the uniform distribution of the mass along the length of the rolls. Thorough mixing of the mixture, periodic cutting with a manual or mechanical knife, repeated rolling to the required plasticity. Determining the degree of readiness of the mixture according to the readings of instrumentation or visually. Removal of the rolled and sheeted mass, placement on a rack, cooling and transfer for further processing. Lubrication of bearings on rollers and gearbox. Monitoring the condition and operation of instrumentation.