An affordable and simple way is to scratch the glass with metal

In short

- Titanium will not scratch glass, but will leave a streak

- Stainless steel will scratch, but will not leave a dark mark

- Aluminum leaves no trace

Explanation, details

The method is based on the ability of titanium to leave characteristic dark marks on the surface of glass and tiles. In this case, the metal does not scratch the glass, but rather draws on its surface. Such a trace can be washed off only with a solution of hydrofluoric acid (HF). Stainless steel may scratch glass, but will not leave a dark mark. Aluminum is not capable of causing any damage at all.

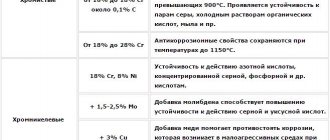

Distinctive characteristics of food grade stainless steel from technical grade

It must be said that the division of stainless steel into two types has a special character, since they differ in areas of use. The main difference between them is the surface treatment. For the food type, the surface is of particular importance, since the metal will come into contact with food products.

Distinctive features of food grade stainless steel are a smooth surface with a high level of processing. Food grade stainless steel is a highly alloyed metal that is resistant to corrosion and rust. The amount of additives affects the quality of product operation. The food grade is susceptible to the influence of an aggressive alkaline environment, so it adds more metal impurities. Based on the composition and markings, you can accurately determine what type of stainless steel it is.

Identify titanium by spark

In short

- Titanium: Will produce lots of bright white sparkles

- Stainless steel: less yellow or red sparks, or no sparks at all

- Aluminum: will not spark

Explanation, details

When processing titanium on a grinding machine or during sharp longitudinal friction on the abrasive surface of a grindstone, metal contact is accompanied by a scattering of bright white sparks.

If there is no abrasive, you can use a fine file or even plain concrete, although the effect will be less. Sparks from stainless steel have yellow and red tints. Much less of them fly out, and on concrete and files there will be none at all. Some grades of stainless steel have been developed to be fire resistant. Sparking during processing of such metals is technologically impossible. When aluminum rubs against a forming surface, sparks are not released, but characteristic silvery marks may remain on the surface.

This test for the possibility of spark formation is the most popular and simplest, since the color really differs very much, and their complete absence immediately indicates that this metal is not titanium.

After you determine which metal is in front of you, you can sell it at a favorable price:

- Titanium for 200 – 1000 rub/kg

- Stainless steel for 60 – 90 rub/kg

- Aluminum for 40 – 98 rub/kg

How to distinguish copper from brass, bronze, aluminum

Copper, as a metal, has pronounced ductility. The color of copper has a golden pink hue with the presence of a characteristic metallic sheen. As an element of the periodic table, it is designated Cu. The name comes from the Latin Cuprum, which is associated with the name of the island of Cyprus. There is scientific evidence that in ancient times there were mines where this metal was mined and then smelted.

Ancient culture is associated with the manufacture of jewelry, dishes, and other household items from it. But the main achievement of ancient metallurgy was the circumstance in which bronze was obtained - an alloy based on it.

Basic properties and parameters of copper

The following points are characteristic:

- In contact with atmospheric oxygen, it is capable of forming an oxide film, which is due to the appearance of a yellowish-red tint. This can answer the question, what color is copper? If you hold the thin plate up to the light, it will have a greenish-blue hue.

- In its pure form it has quite pronounced softness and plasticity. It is easy to roll and stretch. With the addition of impurities, the hardness increases.

- The breadth of application is due to its ability of excellent electrical conductivity.

- Has good thermal conductivity. According to this characteristic, only silver is ahead of it.

- It is characterized by high density, melting and boiling points.

- With the addition of impurities, the properties of thermal conductivity and electrical conductivity decrease.

- Resistance to processes associated with corrosion. In water, for example, iron will oxidize much faster.

- The material is easy to stretch into a fairly thin wire.

- The metal has diamagnetic properties.

Chemically, the activity is insignificant in magnitude. If the air is dry, then oxidation will not occur. The process takes place only in air with sufficient moisture content. Resistant to acids without oxidizing properties. From a chemical point of view, it is characterized by pronounced amphotericity. Depending on the conditions, its characteristics differ and take on the character of an acid or base.

Differences between copper and brass

The question often arises of how to distinguish copper from brass. Brass is an alloy containing 30% zinc. In half of the cases, technical zinc is used to produce brass, where only 50% is present. The rest consists of lead and other impurities. In order to distinguish these representatives, you need to know their characteristics. In this regard, the relevant question is how to determine copper?

To distinguish brass from copper, you need to perform a number of actions with which you can recognize copper at home:

- Clean the item that needs to be checked. To remove dirt, use an aqueous solution of vinegar. In this way, oxides are also removed.

- It is better to carry out the determination under white light. Copper products are characterized by a red-brown color. The brass surface shimmers in several colors. This is due to the presence of several representatives in its composition.

- Copper objects are soft and the impact on a hard surface is accompanied by a muffled sound. Brass doesn't have this. The sound is more sonorous in its characteristics.

- Items can contain marks in the form of the letter “M” or “L”. On this basis, these two species may also differ.

- You can also find out what exactly is in front of you by looking at the area of application of the product. Copper products are quite rare, but it is widely used for the production of wires.

Using the methods listed above, copper determination is carried out right at home.

Differences between copper and bronze

The two species are similar in color. Therefore, sometimes it is necessary to make distinctions. This is not so difficult to do if you know the features of the bronze composition. You can find out what exactly is in front of you using the following characteristics.

- Things made of more plastic material are characterized by the presence of a reddish-brown color. But bronze is characterized by a yellow-pink tint. Even by this feature you can distinguish copper from bronze.

- Products can also be distinguished by the nature of their interaction with the saline solution. If it is spilled on a copper object, a color change will be observed. The color of bronze will remain unchanged. This is also a characteristic difference.

- Both types differ in elasticity properties. If copper wire is easily bent with one hand, then bending a bronze product is very problematic.

- Copper items are subject to a natural patination process. With prolonged interaction with air, they become covered with a greenish coating. Bronze items do not have this feature.

Differences between copper and aluminum

The question of how to distinguish copper from aluminum often becomes relevant.

In terms of electrical conductivity properties, it is 1.5 times higher than that of aluminum. Such items are stronger than aluminum items. If you bend the aluminum wire several times, it will break, but the red wire rod will remain unharmed. You can even distinguish these species by weight. Aluminum products are much lighter. Aluminum has a much lower melting point. If at a temperature of 660 degrees it begins to melt, then this temperature is clearly not enough to melt copper.

The red wire is easy to solder and the contact will be very reliable. But soldering an aluminum wire using the usual method is very problematic.

He is a younger representative in terms of receiving it. It does not occur in nature in its pure form, but when interacting with oxygen in the air, it is capable of forming a stable compound. They began to obtain it only in 1825, while copper was smelted already in ancient times. Since it is much lighter, it is actively used in the production of aircraft. That is why it received the name “winged metal”. By adding copper to aluminum, an alloy called duralumin is obtained, which has higher strength characteristics.

Galvanic reaction test

To perform this test, you will need a DC source with a voltage of about 12 V. This can be a car battery or a converter transformer. Connect the plus wire of the battery to the test sample, and the minus wire to a metal rod, at the end of which cotton wool, gauze or a piece of cotton fabric is wound. Wet cotton wool with a weak solution of hydrochloric acid or regular Coca-Cola.

If it is titanium, then when you touch the metal, its surface will become colored as a result of the formation of an oxide film. The color shade depends on the voltage, the concentration of the acid in the solution and the exposure time. Stainless alloys and aluminum are not susceptible to this reaction.

How to determine aluminum at home - Metalist's Handbook

We welcome everyone who, being a real owner, draws knowledge and experience from our site. This suggests that today for some reason you are interested in the question of how to distinguish aluminum from stainless steel. But really, it’s not that simple.

Features of aluminum

Why is aluminum so valuable? This is a pure metal classified as non-ferrous. It is lightweight, durable, has a good degree of deformation, and is resistant to aggressive environments and corrosion.

All of the listed advantages allow it to be used in a variety of areas from industry and construction (except for industries where high-strength structures are manufactured) to domestic use.

The demand for the valuable metal is great, so it is important to know how to accurately distinguish it from other similar metal alloys.

There are several ways to help you do simple research on your own at home. Find out how to distinguish aluminum from stainless steel - advice from forum members and experts.

- Using a magnet. Aluminum of any grade will not stick to a magnet. Stainless steel also has this property. But there is an exception to the rule. If it contains nickel in sufficient quantities, the tested products will have some attraction. If there is a lot of chromium or copper in a stainless metal, it will not have any effect on the magnet.

- Marking on stainless steel. Some stainless steel products have identification markings. This already gives a hint on how to distinguish aluminum from stainless steel. If there are markings, for example, “STAINLESS” and the like, this is not aluminum.

- Plain paper won't lie. The method is very simple. Experiment conditions: you need white, as thick paper as possible (printer paper will also work). Use a thick cloth to remove dirt from the edges of the products being tested. Move the cleaned areas one by one with some pressure across the sheet. There will be no traces left of the stainless steel. Aluminum will draw gray stripes.

- How to distinguish aluminum from stainless steel by the color of the metal? The surface of the object has a shiny, colorless hue that does not change over time - it is stainless steel. The matte surface of a product that has a grayish or whitish color is aluminum. It will not be polished with sandpaper to a high gloss finish. Check it out.

- Under mechanical load. Another simple way will help you understand how to distinguish aluminum from stainless steel. Hit the product against the surface of any hard metal in the dark. Aluminum will never spark, unlike stainless steel.

- Thermal conductivity, melting. Compare where the water heats up faster. Of course, in an aluminum container. This metal has much better thermal conductivity. But it is not used on the burner of a gas furnace; the melting point is 660 °C. Stainless steel cannot be melted in the usual way (melting index is above 1800 °C).

- Testing for copper sulfate. An option available to everyone. Copper sulfate, after exposure to aluminum, will leave cloudy stains and traces on it, but will not appear on stainless steel.

- Alkaline solutions. Any housewife knows that it is impossible to boil aluminum cookware in alkaline solutions. It will darken and lose its appearance. Conclusion: aluminum products are afraid of alkali, both sodium and potassium. The same cannot be said about stainless steel.

- Acid test. All acids, starting with the usual citric acid and ending with more aggressive ones, will leave marks when they get on the aluminum surface. You won’t see them on stainless steel; it doesn’t react with acids.

Duralumin – an alloy of aluminum with transition metals

The industry is not able to provide itself only with pure metal, and duralumin comes to the rescue here - various combinations of manganese, copper and magnesium in an alloy with aluminum.

In addition to all the above properties of its older brother, the transition metal has:

- high degree of strength;

- long service life;

- plasticity;

- high hardness.

It accumulates fatigue properties more slowly and is resistant to cracking.

The disadvantage of products made of duralumin is susceptibility to corrosion, which can be prevented by anodizing, applying a thin layer of paints and varnishes, aluminum.

The choice between the two metals depends on the end use. We pay tribute to their advantages, but also foresee their disadvantages. The domestic sector leaves the choice to aluminum, while the industrial sector votes for the strength that duralumin has.

Naturally, the question arises of how to distinguish aluminum from duralumin. It is almost impossible to determine by eye which metal is which. The chemical laboratory will give you the exact answer. But experts on the forums have their own opinion on this matter.

- Follow the markings.

- The color of the alloy is steel gray.

- Scratches leave clear marks.

- A ringing sound is heard from the impact.

- During processing, the chips will break without ductility.

- The structure of the alloy is fine-crystalline.

You can determine the type of material by conducting an experiment. Apply a drop of sodium hydroxide to duralumin and aluminum samples for 10 minutes. After removing the substance, we learn about the metal from the resulting stains: the dark one is duralumin.

If you place a piece of aluminum in an acid with added alkali, it will dissolve, forming a white powdery precipitate. In the experiment with duralumin, blue copper granules will be present.

Unlike aluminum, the main characteristics of the alloy are lack of ductility, brittleness and hardness.

Everything can be learned by comparison; examine the parts of two samples several times, pick them up and compare the weight. Such familiarity will help you subsequently simply recognize metals.

Silumin - a twofold relationship

Products made from silumin, an aluminum-based alloy with the addition of silicon, literally flooded the market. Why does it attract the buyer and how to distinguish aluminum from silumin?

Advantages of silumin

Of course, this alloy of two materials has its “fans”. They call the following positive features of silumin:

- light in weight;

- highly durable;

- resistant to wear and corrosion;

- cheap price.

Cons of silumin

Silumin products should be treated with caution, unlike aluminum ones. in silumin, aluminum production waste, silumin-containing alloys, and metal powder do not have an exact proportion. It cannot be called high quality, since the manufacturer produces cheap products under the name of some brand.

The disadvantages of the alloy include:

- design flaws;

- they are unsuitable for food products;

- dangerous to health.

You can distinguish silumin from aluminum visually. The products have a glossy smooth gray surface.

Today, public dissatisfaction with plumbing products continues to grow due to the heterogeneous structure of the material with numerous internal stresses and voids. After 3-5 months, the water tap turns into dust, and the rotary steel ball rusts.

When replacing heating radiators, many are faced with the choice of which material to choose for the new design. Cast iron batteries are a thing of the past; manufacturers offer aluminum, steel and bimetallic ones.

While steel is easily recognizable in appearance, the problem with aluminum and bimetallic structures is that you can’t tell the difference by eye. Moreover, the latter option is in greatest demand.

In the store there is a chance not to buy a fake, but how to distinguish bimetal from aluminum at the market?

Visual recognition will not provide accurate results to the consumer. Both the aluminum and bimetallic systems have external fins made of aluminum. And it’s impossible to visually determine the weight of one section.

For reference: the aluminum section weighs 1–1.6 kg, the bimetallic radiator “compartment” weighs 1.5–2 kg.

You can use the “old-fashioned” method and arm yourself with a neodymium magnet, which has greater power.

Preliminary test. Place the magnet first on the steel, then on the aluminum radiator. The magnetic tester will attract the first option to the surface. The effect will be weaker for a bimetallic radiator. Its steel tubes are located under a diamagnetic material - aluminum. With a powerful neodymium magnet, it is possible to catch the attraction.

It is more difficult when the coolant tubes are made of copper, which, like aluminum, is impervious to the magnetic field.

Difference from other non-ferrous metals

It is known that metals have largely identical properties. But each element has its own distinctive characteristics. They allow you to understand how to distinguish metal from aluminum:

- copper is recognized by its bright reddish hue;

- iron and its alloys have high magnetic properties;

- You can recognize gold by its yellow color;

- Lead has high fragility and density;

- silver has a bright shine;

- Tin has high ductility.

The above methods are only estimates and approximate. More reliable information is available on the pages of special reference literature.

How to distinguish aluminum from stainless steel

Comparing specific gravity is a method that requires precise measurements.

Everyone knows that aluminum is the lightest of these three metals, and steel is the heaviest. But how can you determine if you have one sample and nothing to compare with? This can be done by measuring and calculating the density or specific gravity of the material, which is approximately:

- 2.7 g/cm3 for aluminum;

- 4.5 g/cm3 for titanium;

- 7.8 g/cm3 for stainless steel.

This method of determination requires precise scales and a container for immersing the sample in water.

After weighing the metal, it is necessary to determine its volume. The easiest way to do this is to use Archimedes’ law, known from school, by immersing the sample in a liquid. A change in water level will show the desired value.

This is a more complex and lengthy definition option and is therefore used very rarely. But it also produces results and should be considered.

Density check

One of the reliable ways to determine the type of metal or alloy is to determine its density.

For pure gold it is two times higher than for copper and almost three times higher than for iron. Platinum is even heavier than gold. Even an alloy of 585 gold is noticeably heavier than base metals. Of course, to determine the exact density of a small product you will need pharmaceutical scales, volume calculations (Archimedes' law to help) and tabular data on the density of base metals. But to solve the question of what the alloy is mainly made of, gold or another metal, rough estimates are sufficient. If you have at hand an object made of obviously genuine metal of approximately equal volume, then you may not even need a scale. A weight difference of two to three times is not so difficult to catch.

Separately, each of the considered methods will not give an exact answer to the question of what metal the product is made of. But if several different tests show the same results, you can be confident in the correct determination. If not, then you will have to turn to professionals.

Specific ways to determine titanium

In some cases, metal determination can be done in simple and very original ways:

- Set the metal on fire. Titanium filings ignite and burn quite easily.

- Heat the metal This metal is a good heat insulator and when one edge of the sample is heated, the rest of the sample will be cold

- Hold in your hands Low thermal conductivity gives the feeling of a warm object in your hands, unlike cold steel and aluminum

- Hit with a hammer Lastly, hit the sample with a hammer, this will leave no marks on the steel, a small dent will form on the titanium, and the aluminum will suffer the most.

What is the difference between aluminum and duralumin?

An accurate result in identifying these materials can only be obtained in a chemical laboratory. But there are a number of simple methods that will help distinguish an aluminum product from a duralumin one.

- Aluminum produces a higher ringing sound when impacted, unlike duralumin.

- After removing the chips, the aluminum surface is shiny.

- When drilling an aluminum surface, the chips do not stick to the drill.

It is extremely difficult to confuse aluminum with silver, because silver is much heavier.

In general, all methods can be considered approximate, because only specialists from a special laboratory will give an accurate result regarding the chemical composition of scrap metal.

Difference from other non-ferrous metals

It is known that metals have largely identical properties. But each element has its own distinctive characteristics. They allow you to understand how to distinguish metal from aluminum:

- copper is recognized by its bright reddish hue;

- iron and its alloys have high magnetic properties;

- You can recognize gold by its yellow color;

- Lead has high fragility and density;

- silver has a bright shine;

- Tin has high ductility.

The above methods are only estimates and approximate. More reliable information is available on the pages of special reference literature.

Features of aluminum

Why is aluminum so valuable? This is a pure metal classified as non-ferrous. It is lightweight, durable, has a good degree of deformation, and is resistant to aggressive environments and corrosion. All of the listed advantages allow it to be used in a variety of areas from industry and construction (except for industries where high-strength structures are manufactured) to domestic use. The demand for the valuable metal is great, so it is important to know how to accurately distinguish it from other similar metal alloys.

Bimetal and aluminum using radiators as an example

When replacing heating radiators, many are faced with the choice of which material to choose for the new design. Cast iron batteries are a thing of the past; manufacturers offer aluminum, steel and bimetallic ones. While steel is easily recognizable in appearance, the problem with aluminum and bimetallic structures is that you can’t tell the difference by eye. Moreover, the latter option is in greatest demand. In the store there is a chance not to buy a fake, but how to distinguish bimetal from aluminum at the market?

Visual recognition will not provide accurate results to the consumer. Both the aluminum and bimetallic systems have external fins made of aluminum. And it’s impossible to visually determine the weight of one section.

For reference: the aluminum section weighs 1–1.6 kg, the bimetallic radiator “compartment” weighs 1.5–2 kg.

You can use the “old-fashioned” method and arm yourself with a neodymium magnet, which has greater power.

Preliminary test. Place the magnet first on the steel, then on the aluminum radiator. The magnetic tester will attract the first option to the surface. The effect will be weaker for a bimetallic radiator. Its steel tubes are located under a diamagnetic material - aluminum. With a powerful neodymium magnet, it is possible to catch the attraction.

It is more difficult when the coolant tubes are made of copper, which, like aluminum, is impervious to the magnetic field.