I. General provisions

1. A person who has professional training under vocational training programs, retraining programs for worker professions and office positions in a field corresponding to the focus (profile) of welding production is appointed to the position of gas welder.

2. Practical work experience of at least 6 months in the profession of gas welder of 2-3 categories.

3. Additional requirements:

— undergoing mandatory (upon employment) and periodic medical examinations (examinations), as well as extraordinary medical examinations (examinations) in the manner established by the legislation of the Russian Federation;

— completion of training and testing of knowledge of the norms and rules of work in electrical installations as electrical engineering personnel in the scope of group II on electrical safety or higher;

— undergoing training and testing knowledge of the rules for the safe operation of cylinders;

— training in fire safety measures, including undergoing fire safety training and fire-technical minimum according to the relevant program;

— completion of training on labor protection and testing of knowledge of labor protection requirements in the prescribed manner;

— availability of documents (diplomas, certificates, certificates) confirming qualifications: document on professional education or training; documents on permission to perform welding work (certificates, permits, certificates) in areas of activity that establish additional requirements in the field of welding production.

4. Appointment to the position of gas welder, as well as dismissal from it, is made by order of the head of the organization.

5. The gas welder must know:

5.1. Main types, structural elements and dimensions of welded joints made by gas welding (surfacing) and their designation in the drawings

5.2. Rules for preparing edges of products for welding

5.3. Main groups and grades of materials welded by gas welding (surfacing)

5.4. Welding (surfacing) materials for gas welding (surfacing)

5.5. Construction of welding and auxiliary equipment for gas welding (surfacing), purpose and operating conditions of instrumentation, rules of their operation and scope of application

5.6. Rules for assembling structural elements for welding

5.7. Types and purpose of assembly, technological devices and equipment

5.8. Technique and technology of gas welding (surfacing) of simple parts of non-critical structures in the lower, vertical and horizontal spatial position of the weld

5.9. Selecting a heating mode and the procedure for carrying out work on preliminary and concomitant (interlayer) heating of the metal

5.10. Causes of occurrence and measures to prevent internal stresses and deformations in welded (surfaced) products

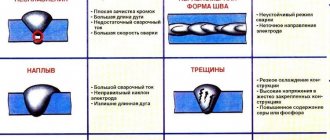

5.11. Causes of weld defects, ways to prevent and correct them

5.12. Rules for using gas cylinders

5.13. Rules for servicing portable gas generators

5.14. Rules for the technical operation of electrical installations

5.15. Fire safety standards and rules for welding work

5.16. Labor protection rules, including in the workplace

5.17. ___________________________________________________________________________

6. Characteristics of the work performed:

— tack welding of structural elements by gas welding in all spatial positions of the weld;

— gas welding of complex and critical structures (equipment, products, assemblies, pipelines, parts) from various materials (steels, cast iron, non-ferrous metals and alloys), designed to work under pressure, under static, dynamic and vibration loads, in all spatial positions weld;

— gas welding for eliminating cracks and cavities in products with a thickness of more than 0.2 mm and in products with places that are difficult to reach for welding;

— gas surfacing with hard alloys of parts of complex and critical structures in accordance with technological (regulatory, design) documents on surfacing;

— elimination of defects (sinks and cracks) by gas welding (surfacing) of complex and critical parts of devices, repair of defects in structures, parts, assemblies and pipelines made of various materials (steels, cast iron, non-ferrous metals and alloys) designed to operate under dynamic and vibration loads , elimination of defects in large cast iron and aluminum castings for subsequent machining;

— heating of structural parts during straightening, hot straightening of complex structures;

— preliminary and accompanying heating of parts during welding;

— correction of defects by welding.

7. The gas welder reports directly to ____________.

8. During the absence of the gas welder (vacation, illness, etc.), his duties are performed by a person appointed in the prescribed manner. This person acquires the corresponding rights and is responsible for their proper execution.

9. ________________________________________________________________

A 4th grade welder must be able to and know

- Seam structure;

- Methodology for choosing welding electrodes for a given type of metal and welding mode;

- The nuances of the design of the equipment used, which includes automatic machines, semi-automatic devices, transformers, plasma cutting machines, etc.;

- Types and methods of metal welding used for working procedures;

- How to properly prepare metal for welding;

- What properties does this or that electrode coating have?

- Why tensions arise and how to deal with these problems;

- Techniques for welding and surfacing of various types of metal;

- What modes are used for cutting metal;

- Labor safety rules

II. Job responsibilities

The responsibilities of a gas welder (4-5 category) include:

1. Carrying out preparatory and assembly operations before welding and cleaning welds after welding:

— Familiarization with design and production-technological documentation for welding

— Cleaning structural elements (products, assemblies, parts) for welding with a hand or power tool

— Selection of the spatial position of the weld for welding structural elements (products, assemblies, parts)

— Assembly of structural elements (products, assemblies, parts) for welding using assembly devices

— Assembly of structural elements (products, assemblies, parts) for tack welding

— Inspection using a measuring tool of prepared and assembled structural elements (products, assemblies, parts) using assembly devices for compliance of geometric dimensions with the requirements of design and production-technological documentation for welding

— Inspection using a measuring tool of prepared and tack-assembled structural elements (products, assemblies, parts) for compliance of geometric dimensions with the requirements of design and production-technological documentation for welding

— Cleaning weld seams with hand or power tools after welding

— Removal of surface defects (pores, slag inclusions, undercuts, metal splashes, sagging, etc.) using manual or power tools

2. Gas welding (surfacing) of simple parts of non-critical structures:

— Checking the equipment of the gas welding station

— Checking the functionality and serviceability of gas welding station equipment

— Setting up equipment for gas welding (surfacing)

— Performing preliminary and concomitant (interlayer) heating of the metal

— Performing gas welding (surfacing) of simple parts of non-critical structures

— Inspection using a measuring tool of gas-welded (surfaced) parts for compliance of geometric dimensions with the requirements of design and production-technological documentation for welding

3. Gas welding (surfacing) of complex and critical structures (equipment, products, assemblies, pipelines, parts) made of various materials (steels, cast iron, non-ferrous metals and alloys) designed to work under pressure, under static, dynamic and vibration loads:

— Gas welding (surfacing) of complex and critical structures

— Inspection using measuring tools of complex and critical structures welded by gas welding (surfacing) for compliance of geometric dimensions with the requirements of design and production-technological documentation for welding

— Correction of defects by gas welding

III. Rights

The gas welder has the right:

1. Request and receive the necessary information, as well as materials and documents related to issues of their activities.

2. Improve your qualifications, undergo retraining (retraining)

3. Take part in the discussion of issues included in his functional responsibilities.

4. Make suggestions and comments on how to improve activities in the assigned area of work.

5. Require the management of the organization to provide assistance, including ensuring organizational and technical conditions and execution of the established documents necessary for the performance of official duties.

6. Make independent decisions, guided by qualification requirements and job responsibilities

7. ___________________________________________________________

Main responsibilities of a 4th grade welder

Responsibilities of a 4th grade welder:

- Welding of various spherical parts, such as barrels, pontoons, buoys, etc.;

- Welding of various automotive equipment, both functional mechanisms and additional devices, which especially applies to agricultural equipment;

- Metal surfacing to correct defects in reinforcement that can withstand pressure up to 5 MPa;

- Cutting shaped profiles from metal blanks;

- Connecting transition areas, surfaces, frames and side parts of various structures with metal parts;

- Fusing holes of devices and mechanisms;

- Repair of diesel engines and internal combustion;

- Welding of cases up to 35 cm thick;

- Welding of couplings, rollers, pads;

- Connection of frames, shaped dies and pipes of various diameters;

- Fusing material onto gear teeth and cutting surfaces of mechanisms that wear out over time.

Rights

- Opportunity to improve your skills;

- Require management to provide appropriate working conditions to complete the task, as well as provide materials and tools for this;

- Mandatory provision of all social guarantees from the state;

- Receive information about projects related to your position.

IV. Responsibility

The gas welder is responsible:

1. For improper performance or failure to fulfill one’s job duties provided for in this job description - within the limits determined by the current labor legislation of the Russian Federation.

2. For offenses committed in the course of carrying out their activities - within the limits determined by the current administrative, criminal and civil legislation of the Russian Federation.

3. For causing material damage - within the limits determined by the current labor and civil legislation of the Russian Federation.

4. ____________________________________________________________________

This job description has been developed in accordance with the provisions (requirements) of the Labor Code of the Russian Federation dated December 30, 2001 No. 197 FZ (Labor Code of the Russian Federation) (with amendments and additions), the professional standard “Welder” approved by order of the Ministry of Labor and Social Protection of the Russian Federation from November 28, 2013 No. 701n (as amended by order of the Ministry of Labor of Russia dated December 12, 2016 No. 727n) and other legal acts governing labor relations.