general description

The compound in question, like steel, is made from iron and carbon. The carbon content in steel does not exceed 2.14%. The material under consideration is more saturated with it. Iron itself is ductile. Adding carbon allows you to achieve the required hardness and strength.

Whether cast iron is magnetic depends on its type, among which are the following:

- white;

- grey;

- malleable.

The white variety contains cementite - iron carbide. You can recognize it by looking at the break. It is white in color and resistant to wet corrosion. To obtain the gray variety, silicon and carbon are added in the form of graphite, a natural analogue. Its color at the break is grey.

The term “malleable” indicates plasticity, but not the possibility of using this processing method. And to make such a connection, only white types of metal are used. All products are manufactured exclusively by casting.

High-strength varieties deserve special attention. Nodular graphite is added to their composition. This substance does not make the metal base brittle and does not concentrate stress.

Main characteristics

The properties of cast iron can be classified according to the following points:

- Chemical.

- Thermal.

- Technological.

- Hydrodynamic.

The chemical characteristics of the metal are its tendency to corrode. It depends on the composition of the alloy and the elements that are included in it, as well as on environmental factors. Elements in the composition of the alloy can either reduce the susceptibility of the metal to corrosion or increase it, it all depends on their effect on the structure of the metal.

The thermal conductivity of iron decreases due to an increase in impurities in its composition. The thermal conductivity of the alloy changes due to the degree of its graphitization.

Fluidity is classified as a technological property; its degree is determined in various ways. This property increases with decreasing viscosity.

The viscosity of the metal decreases with an increase in the content of manganese in the composition, as well as with a decrease in the amount of sulfur and other non-metallic inclusions in the alloy. Viscosity also depends on temperature. It is proportional to the absolute temperature and the experience of contact with it.

There are also magnetic properties of cast iron, which mainly depend on the structure of the metal. They are divided into primary and secondary.

Primary characteristics include:

- magnetic transformation temperature;

- saturation;

- induction;

- permeability in strong fields.

These characteristics do not depend on the shape and distribution, but depend on the number and properties of the phenomenal phases.

Secondary characteristics include:

- permeability in weak and medium fields;

- coercive force;

- induction;

- saturation;

- residual magnetism.

Secondary properties are determined mainly by the shape and distribution of structural components.

There is paramagnetic or non-magnetic cast iron. This is a material that is used when it is necessary to reduce the magnetic properties of a metal, and it is not possible to replace it with an alloy of non-ferrous metals.

Metals that are often confused

A high-carbon iron alloy is often confused with other metals used for the production of plumbing fixtures, fittings, shut-off valves, machine tool parts, and radiators. People think about how to identify cast iron when trying to hand over scrap metal to a collection point. Scrap of this metal is one of the cheapest, since it is difficult to process, fragile, and harmful impurities (phosphorus and sulfur) are difficult to remove from it.

Therefore, before traveling to the collection point, it is important to determine whether it is cast iron or steel. It is also often confused with pure iron, aluminum and silumin - an alloy of aluminum and silicon used for the production of frying pans, pots, mixers, taps, etc. You can distinguish cast iron from iron and other metals at home: by color, magnetic properties, strength and even the sound!

Differences between steel and cast iron

A high-carbon alloy is always magnetic, while steel depends on its composition. Cast iron is also determined by the color and condition of the surface: products made from it have a dark, almost matte black color, and when broken, the metal is dark gray. Also, cast iron objects are more massive and weigh more compared to their steel counterparts, although the density of steel is much higher - up to 7900 kg / cubic meter. m.

Steel is easier to process, so items made from it are produced by stamping. Weak, non-ductile cast iron is suitable for the manufacture of cast products. It does not withstand strong impacts and can crack, so a strong blow with a hammer will help to distinguish it. At the same time, it is porous and retains heat longer, and therefore another test option is strong heating. Cast iron products heat up slowly but evenly, and cool down for at least 10 minutes.

How to distinguish cast iron from steel at home

The development of industry and the creation of synthetic materials cannot detract from the advantages and benefits of traditional materials. These include cast iron and steel. These are some of the oldest familiar alloys to human civilization.

The technology of repair and design work often includes various types of processing. It could be:

- mechanical

- chemical

- thermal

- electrolytic

- plasma and other types of processing.

Despite the fact that cast iron and steel differ from each other by a tiny difference in carbon content, the methods and methods of influencing factors on these alloys differ and require different ways of the same method to influence the shape and structure of the metal.

Factors affecting the processing of steel and cast iron

In order not to waste money and resources, it is very important to know how to identify cast iron or steel.

- Selecting a welding electrode

- drill sharpening angle

- drilling and milling mode

These are not all the factors that can complicate the life and work of a person who incorrectly determines the type of metal. Reducing mechanical, strength and violating guaranteed repair intervals is a much greater evil that can damage production and the budget in the event of an error.

Visual definition

How can you distinguish cast iron from steel visually without resorting to destructive testing methods?

If there is a question about welding a cracked section of a part or even a piece that has fallen off, then it is possible to examine the breakdown or structure of the crack.

The metal on a scrapped cast iron part will most likely be dark gray in color with a matte surface. Under the same conditions, the steel fracture will have a light gray, almost white color, with a glossy sheen.

The nature of cracks on the surface of high-carbon alloys is similar to a crack on pottery; low-carbon alloys are prone to plastic deformation and for this reason the crack has the shape of a rupture of plastic material.

Based on surface defects, only cast iron can be identified, which was poured into the mold at a low temperature, was not processed later, and a decorative paint layer was not applied. On such a product, hemispherical small grains are visible, formed due to non-shedding due to low temperature.

Don't forget about the correct visual method for identifying material. Soviet, modern and foreign GOSTs require the presence of material markings on all cast products. On domestic casting, the icons MF, HF, KCH - this means cast iron. L45, 45HL, 110G2S - indicates the use of steel casting for this element.

Mechanical determination by drilling

High-strength cast iron with nodular graphite is very similar in quality and visually to steel products. Testing a product by tearing it using a tensile testing machine is not entirely justified or reasonable.

To do this, you can select a non-working, inconspicuous area on the product and drill it not to the full depth with a drill of minimum diameter. The structure of cast iron is such that the chips are not able to form into a twisted loach. Graphite inclusions, even if they are not visible, crumble the chips at the stage of their formation.

Such shavings grind into dust in your hands and leave a black mark on your hands, like the lead of a simple pencil.

Steel shavings are capable of forming a loach longer than the length of the drill itself, and do not crumble in your hands. At high speeds it has a tarnished color on the surface.

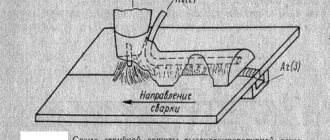

Mechanical determination by grinding

You can approach the issue of determining the material using a grinder (angle grinder). As in the previous method, we select a section that is not a friction plane, contact pad or other important design element. With the machine turned on, we come into contact with the surface under study and monitor the shape and color of the sparks.

In cast iron products this will be a short spark with a reddish tint on the sprocket at the end of the track.

In metal products, the sheaf of sparks will be relatively larger, the tracks will be longer, and the sparks will be dazzlingly white or yellow.

If there is uncertainty and uncertainty in the method and your assessment, then you can take a known material, for example, a cast iron cauldron in the corner of the garage and check what sparks fly when processed with a grinder. At the same time, we should not forget that a number of special-purpose steels, especially heat-resistant ones, produce a spark of minimal size, with a short track and cherry red color.

This material does not cover methods exotic for home use:

- spectral analysis

- microscopic analysis

- weighing and volume determination.

But for home needs, the above methods are more than enough. Regardless of the method and method of determining the material, try to use diagrams, drawings and other information for your unit or product. The amount of information on the World Wide Web is off the charts and can reach the most remote corner of a workshop or garage.

Features of the delivery of cast iron scrap

This type of ferrous scrap metal is the most in demand, and it is classified as metal waste. It is recycled, melted down in smelters, and even recycled into steel by reducing its carbon concentration. Most of the cast iron scrap is of industrial origin.

Outdated machines, equipment, and dismantled metal structures are sold for scrap metal. The cost of such scrap is relatively low, but due to the large mass, these items can fetch good money.

You can distinguish cast iron from aluminum, steel, and iron by color, weight, and even sound (cast iron products are the most resonant, so when struck they make loud, sharp sounds). But the most reliable way is to send a metal sample to our laboratory equipped with a spectrometer. We will accurately determine the composition of the alloy and offer the best price for scrap metal!

Cast iron is a combination of carbon (C) and iron (Fe), which has a number of characteristics and certain similarities to steel. Steel also contains carbon and iron. When analyzing the characteristics of metal as a chemical element, it is worth paying attention to whether cast iron is magnetic or not? What influences its characteristics and what do they depend on?

What is the visual difference between cast iron and steel?

An uninformed person believes that the main structural material of modern times is iron.

Anyone who understands it knows that the word “iron” means iron-carbon alloys - steel and cast iron. It would seem that these are two completely different materials and they are very easy to distinguish. However, given the wide range of their types and brands, the fine line of difference in the chemical composition of some of them is difficult to determine.

It is important to have additional skills in order to know the answer to the question: what is the difference between cast iron and steel?

Cast iron

An alloy containing iron, carbon in the amount of 2.14-6.67, sulfur, phosphorus, manganese, silicon and other additives is called cast iron. The history of smelting began in the Iron Age. An important structural material, the basis of metallurgy and all steelmaking.

Characteristics:

- Rough, matte gray in color.

- Melting at 1000-1600˚С depending on the composition (for industrial ones on average - 1000-1200˚С, white and pig iron melt at higher temperatures).

- Density: 7200-7600 kg/m3.

- Specific heat capacity: 540 J/(kg˚C).

- High hardness: 400-650HB.

- Low ductility, very crumbles when exposed to pressure; The highest values of relative elongation have ductile high-strength cast iron δ=6-12%.

- Low strength: 100-200 MPa, for malleable it reaches 300-370 MPa, for some brands of high-strength – 600-800 MPa.

- It is modeled using heat treatment, but rarely and with great care, since it is characterized by a cracking process.

- It is alloyed with the help of auxiliary chemical elements, but a significant degree of alloying further complicates the processing processes.

- It is characterized by satisfactory weldability, good machinability, and excellent casting properties. Cannot be forged or stamped.

- Good wear resistance and corrosion resistance.

Cast iron is a material for body parts, blocks, and machine components made by casting. It is the main charge component for steel smelting.

Steel

An iron-carbon alloy containing carbon in an amount of not more than 2.14% and iron - not less than 45% is called steel. Its main characteristics:

- Smooth, has a silvery color with a characteristic reflection.

- Melting within 1450˚С.

- Density ranges from 7700 to 7900 kg/m3.

- Heat capacity at room temperature: 462 J/(kg˚C).

- Low hardness, on average 120-250 HB.

- Excellent ductility: the relative elongation coefficient δ for different brands ranges from 5-35%, for most – δ≥20-40%.

- Average values of tensile strength for structural materials are 300-450 MPa; for especially strong alloyed ones – 600-800 MPa.

- It lends itself well to correction of properties using thermal and chemical-thermal treatment.

- It is actively doped with various chemical elements in order to change its properties and purpose.

- Qualitatively high indicators of weldability, machinability and cutting.

- Characterized by low corrosion resistance.

Steel is the main structural alloy in modern metallurgy, mechanical engineering, instrument making and technology.

Determining origin by type of part

Having examined the detailed characteristics of these alloys, you can confidently use the knowledge of how cast iron differs from steel. Having a metal object in front of you, doubting its origin, it is rational to immediately remember the main distinctive technological properties.

So, cast iron is a casting material. It is used to produce simple dishes, massive pipes, housings of machine tools, engines, and large objects of simple configuration.

Parts of all sizes and complexity are made from steel, as forging, stamping, drawing, rolling and other methods of metal forming are used for this purpose. Thus, if there is a question about the origin of the reinforcement, there can be no doubt - it is steel.

If you are interested in the origin of a massive cauldron, it is cast iron. If you need to find out what the engine housing or crankshaft is made of, you should resort to other recognition options, since both options are possible.

Color features and fragility analysis

In order to know how to distinguish cast iron from steel by eye, you need to remember the main visual differences. Cast iron is characterized by a matte gray color and a rougher external texture. Steel is characterized by its special silvery shiny hue and minimal roughness.

Also important knowledge on how to distinguish cast iron from steel visually is information about the ductility of these materials.

If the workpieces or metal objects being examined do not have serious value, you can test them for strength and ductility by applying impact force. Brittle cast iron will crumble into pieces, while steel will only deform.

With more serious crushing loads, cast iron crumbs will turn out to be of small, varied shapes, and pieces of steel will be large, with the correct configuration.

Cut and drill

How to distinguish cast iron from steel at home? It is necessary to obtain fine dust or shavings from it. Since steel has high ductility, its chips also have a tortuous character. Cast iron crumbles, and when drilling, small chips are formed along with dust.

To obtain dust, you can use a file or rasp and slightly sharpen the edge of the part of interest. Examine the resulting fine shavings on your hand or a white sheet of paper.

Cast iron contains large amounts of carbon in the form of graphite inclusions. Therefore, when rubbing its dust, a black graphite “trace” remains.

In steels, carbon is in a bound state, so mechanical influence on dust does not give any visible results.

Heat and sparkle

How to distinguish cast iron from steel? You need to operate with the necessary equipment and a little patience.

In the first case, you can resort to heating, for example, using a blowtorch, initially wearing special protective clothing and following safety rules at work. The temperature must be increased before the metal begins to melt.

It has already been said that the melting point of cast iron is higher than that of steel. However, this applies mainly to white and pig iron. Regarding all industrial grades, they contain carbon in an amount of no more than 4.3% and melt at 1000-1200˚C.

Thus, it can be melted much faster.

An educational method for obtaining information about how cast iron differs from steel is to use an experimental sample on a grinding machine or under a sharp wheel of a grinding machine. The analysis is carried out according to the characteristics of the sparks. Cast iron is characterized by dim red sparks, while steel is characterized by bright, blinding short rays with a white-yellow tint.

What does it sound like

An interesting feature is how to distinguish cast iron from steel by sound. The two alloys sound different. It is not at all necessary to produce musical accompaniment using existing experimental facilities.

But it is necessary to have both samples or have an experienced ear in this matter. Steel is characterized by a higher density, which is reflected in its sound.

When you hit it with a metal object, the sound is much louder than in the same situation with cast iron.

In order to know how cast iron differs from steel, you need to have a little knowledge about these materials and some experience. After all, an experienced professional in the field of forging, grinding, milling, drilling, turning, heat treatment or welding, a metallurgist or technician can easily distinguish them from each other, assessing them only visually or by touch.