Features of titanium soldering

There is an alpha coating on the surface of titanium, which suggests the presence of atmospheric gases.

Before the soldering process, the mentioned layer should be removed using sandblasting, which can be replaced by etching in a mixture with a certain composition: 20-30 ml of H2NO3, 30-40 ml of HCl and 1 liter of water. The etching period should be limited to 5-10 minutes. whereas the temperature indicator should be equal to 20 ° C. After such treatment, an oxide deposit of insignificant thickness will still be present on the surface of the material, which will prevent the base from being wetted with solder. For this reason, at home, craftsmen try to solder the material using special fluxes, the composition of which is similar to that of fluxes designed for working with aluminum. However, you should be prepared for the fact that the joints obtained using such fluxes do not have significant strength and quality.

Scheme of laser soldering of riving plates.

https://www.youtube.com/watch?v=OWpBz-eTpSY

As a rule, titanium and its alloys undergo soldering under vacuum or argon conditions, the latter must be freed from oxygen particles, water vapor and nitrogen. Only under ideal conditions, oxide and nitride deposits on the surface of the material are neutralized in the metal, which is true if the temperature during work exceeds 700° C.

Soldering of titanium alloys at high temperatures is not carried out so often, which is especially true for furnace melting. This is explained by the fact that during prolonged heating, when the temperature exceeds 900° C, there is a tendency to increase grain and deteriorate plastic characteristics. Since the strength level of the main metal remains almost unchanged, in some cases the mating of titanium alloys by soldering is carried out even at 1000° C.

Hydrogen, which is present in titanium and reduces its ductility, is eliminated during the soldering process or during heating at 900 ° C. Therefore, work with titanium should be done in a space devoid of air, this is preferable to working in a neutral atmosphere.

Increasing the welding temperature and subsequent cooling contribute to changes in the structure of the characteristics of cast iron in the melting and weld regions, which indicates that it is very difficult to obtain defect-free joints with the required level of properties.

Soldering Features:

- the need to use special fluxes;

- the need for a vacuum;

- It is recommended to use silver as a solder base.

Titanium is one of the most interesting and difficult metals to process. Its unique properties are widely used in various industries. Mechanical processing of titanium, in comparison with ordinary steel, is more than five times more difficult, so special techniques and equipment are used to create products from it.

The main problem encountered when machining titanium is its tendency to scuff and stick to the tool. Also one of the complicating factors is its low thermal conductivity. Most metals resist melting to a much lesser extent, so upon contact with titanium they dissolve in it, forming alloys. This leads to rapid wear of the tool used.

To reduce scuffing and sticking, as well as to remove generated heat, the following methods are used:

- When cutting, as well as other processing of titanium, coolants are used;

- sharpening of products is carried out using tools made of hard metal alloys;

- metal processing with cutters is performed at much lower speeds to avoid excessive heating.

The effects of titanium sticking and scuffing are due to its high coefficient of friction, which is considered a serious disadvantage of this metal.

Most products made of titanium quickly wear out, so the pure composition of this metal is rarely used for the manufacture of products that are used in conditions of friction and sliding.

During friction, titanium sticks to the rubbing surface, causing a binding effect and reducing the speed of movement of communicating parts. Methods that eliminate this negative effect are nitriding and oxidation of titanium.

Titanium nitriding is a technological process that involves heating a titanium alloy product to a temperature of 8500C - 9500C and keeping it for several days in an environment of pure nitrogen gas.

As a result of the chemical reactions that occur on the surfaces of the product, a film of titanium nitride is formed, which has a golden hue and has greater hardness, as well as greater resistance to abrasion.

Products that have undergone this treatment have increased wear resistance and are not inferior in their characteristics to products made from surface-hardened special steels.

Titanium oxidation is a common method that involves heating a titanium product to 8500C and sharply cooling it in an aqueous environment, which causes the formation of a dense film on the surface of the workpiece that binds well to the main layer of the material. At the same time, the abrasion resistance and overall strength of the product increases by 15-100 times.

Cutting blanks is a very complex technological process, accompanied by the use of special tools and equipment. Sheets are cut with guillotine shears, and billets from long products are sawn with a mechanical saw. Small diameter rods are cut using lathes.

Milling titanium remains the most difficult way to process it. It sticks to the teeth of the tool (cutter), which makes working with the workpiece much more difficult. Therefore, for this method, tools made of hard metal alloys are used, and the processing process is accompanied by the use of cooling lubricants and liquids that have high viscosity.

When performing drilling operations, it is important that chips generated as a result of drilling do not accumulate in the drainage channels, otherwise this can lead to premature wear and breakage of the tool. When drilling, cutters made of high-speed steel are used.

If a titanium product acts as a structural element, then joining parts made of titanium alloys allows the use of the following methods:

- welding;

- soldering

- mechanical connection using rivets

- connection using bolted fastening.

The main connection method is welding, which is a conventional industrial technology. To ensure the strength of the weld, the elements are connected in an inert gas environment or special oxygen-free fluxes.

Also for this purpose, the seam is protected using various protective elements.

The interaction of molten titanium with such chemical elements as hydrogen, oxygen and nitrogen contained in the air mixture when heated leads to growth of the metal grain, a change in its microstructure and brittleness of the weld. Welding work is performed at high speed.

There is also a method of welding in a controlled environment, which is used to perform jobs that require a lot of responsibility. If it is necessary to connect small elements, they are placed in special chambers filled with inert gas. In the case of connecting larger elements, welding work is performed in special hermetically sealed rooms. Welding titanium is a responsible job that is entrusted exclusively to trained specialists who have the necessary practical experience and skills.

Titanium soldering is used in cases where welding is impossible or impractical. It is also complicated by chemical reactions. Titanium in the molten state exhibits high chemical activity and is firmly bound to the oxide film formed on the surfaces of the workpiece.

Soldering titanium: what do you need to know about this procedure?

If soldering titanium is impractical or for some reason impossible, you can pay attention to joining this material with hard and soft solders (tinols). Despite the fact that the melting point of solid tinols is above 430 ° C, it is lower than the temperature at which the materials being joined melt.

Regarding soft tinols, they melt at temperatures below 430 ° C. Soft solders are used, for the most part, for joining materials of small thickness (for example, wire).

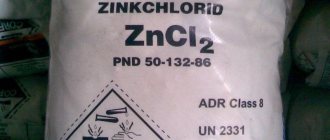

Tin and zinc do not sufficiently wet the metal. Instead of ordinary fluxes, which are not able to protect metal from oxidation, it became necessary to create special fluxes that ensure the formation of a protective metal film on the metal surface (by electrochemical means).

Intermetallics

When choosing a tinol, method and mode of joining titanium, it is necessary to remember that this material can form brittle intermetallic compounds in the weld with all the elements that make up the tinol. Silver is used as a base. Silver with the material in question forms intermetallic compounds, which have the least brittleness.

Soldering using tin-lead and other low-temperature tinols is used quite rarely. In a particular case, before starting the procedure, the metal is coated with nickel using a chemical or galvanic method.

In order to increase the adhesion of titanium to nickel, the parts are heated to a temperature of 250 ° C for one hour. After this procedure, the material is soldered with similar solders and fluxes as for pure nickel. The material, as well as its alloys, can be soldered using low-temperature solders after finishing the coating with silver, tin and copper.

To coat a product with tin, you need to immerse it in tin heated to 700 °C for a while (10-20 minutes). Using a flux containing tin chloride, you can coat metal with tin.

Titanium soldering methods

There are several basic methods for soldering titanium:

- Gas soldering;

- Soldering in the oven;

- Resistance soldering;

- Exposure to soft solder.

Gas soldering

Among the numerous gas welding techniques in the considered processing of titanium parts, the oxygen-acetylene flame turned out to be the most effective, since this method does not make the metal being fused brittle. Thus, using pure silver and any other flux, soldering titanium shows a fairly strong and ductile connection result.

Optimal strength is achieved by using a dual-tip gas torch, minimum temperature, and minimum melting time.

Pure aluminum in a titanium compound shows low quality material joints, but at the same time quite ductile. During gas bonding of aluminum to the metal in question, the part is completely immersed in the aluminum, after which the agitated part is joined to the aluminum using simple methods.

Soldering in the oven

During the bonding of titanium in a furnace with a protective atmosphere, the labor-intensive gas procedure is greatly simplified. Thus, a simple mixture of manganese and potassium chlorides, silver and potassium chlorides turns out to be a worthy alternative to special fluxes. It is quite possible to repeatedly process titanium with a uniform supply of heat to the metal surface of small parts limited by the size of the furnace.

Soldering using an oven requires a longer time investment due to the lack of local heating. As a result, thickening of the melted layers can be observed, which leads to a certain decrease in the strength and ductility of the material, especially when connecting with aluminum.

Welding and soldering can be done using the resistance method. The difference lies in the fact that in the second case a low-melting metal is placed between the surfaces. Water-cooled copper electrodes have proven to be superior to graphite electrodes, as well as other materials that have high electrical resistance but also contain contaminants.

By its nature, the material under consideration has sufficient resistance, which is necessary for heating metal surfaces. Brief soldering with silver at high electric current and low pressure allows you to achieve a stronger connection than gas soldering. The application of pressure makes it possible to eliminate fluxes.

Today it has been established that titanium can be soldered with soft solder. The use of soft tinols in the titanium processing process has some advantages, reflected in cost and speed, over other joining methods. Soldering titanium with soft solders is used in most cases in cases where high-strength connections are not required, at home.

The parts being joined are coated in the process with a thin layer of silver, tin or copper, which is achieved by heating titanium coated with a layer of chloride of one of the previously listed metals in a furnace under a helium atmosphere.

The resulting metal film must be “wetted” with solder (60% Sn 40% Pb or 50% Sn 50% Pb) not without the participation of industrial fluxes. Since metal films can dissolve in the solder, thereby exposing the titanium surface, adhesion occurs quite quickly, and at a minimum temperature.

Brands of soft solders for soldering with a soldering iron

Soft solders are used in conjunction with an electric soldering iron and flux. The tin included in the composition is an environmentally friendly product and can be used to connect elements of the food industry. The most common soldering product is the tertiary, which got its name due to the composition containing a third of lead . Soft solders are divided into varieties according to their purpose and melting temperature.

Low-melting solders are used for soldering heat-sensitive parts such as fuses and transistors. The composition includes lead, tin, bismuth and cadmium, the latter material is toxic and is not used in all areas of activity. Melting of Wood's products begins at the lowest temperature - 69 °C.

Domestic brands of products are labeled POS; with the addition of some substances, the name changes. For example, POSV - 33 has equal parts of lead, tin and copper, and is applied to brass and copper parts that require a sealed seam.

Main technical characteristics of soft solders for soldering with an electric soldering iron

The technical characteristics of materials used for soldering are divided into several parameters:

- conductivity or electrical resistivity is 0.1 ohm per meter. Tin-lead type solder conducts electric current an order of magnitude worse than aluminum or copper;

- Tensile strength is measured kg/mm; low-temperature solders do not include this parameter, because not designed for load. The parameter depends on the amount of tin; the more there is, the higher the number. For example, POS-61 brand solder has a strength of 4.3 kg per mm, and POS-90 solder has a strength of 4.9 kg/mm.

- The melting point depends on the purpose and components.

Recommendations for soldering

Wave soldering installation diagram.

Before soldering titanium at home, you need to choose the right solder, method and features of the work. It should be taken into account that titanium contributes to the formation of brittle intermetallic compounds in the solder seam with almost all elements that are in the solder. For this reason, as a rule, silver is preferred as a solder base, since it forms intermetallic compounds with titanium that are not so brittle compared to other metals.

It is very problematic to carry out high-quality soldering of cast iron yourself, which also applies to soldering titanium in a vacuum using non-added aluminum. This is explained by the fact that intermetallic phases appear in the weld, and the joint does not have any strength.

The thickness of the interlayer can be minimized if Ni-alloyed aluminum is used as the solder. This and some other elements, 1% each, affect the displacement of the intermetallic layer.

Soldering alloys of the described metal using tin-lead or other low-temperature solders is rarely used. In this case, before starting work, titanium must be coated with nickel using a chemical or galvanic method. But if you need to use cast iron in the soldering process, then it is preferable to entrust the matter to professionals.

General division

Solders are divided into two groups. These are soft and hard.

Soft ones have a melting point of up to 300 °C. Radio components are soldered with such solders, and these include tin-lead and lead-free materials. The main working tools with such materials are soldering irons up to 50 W and soldering guns.

Solids melt over 300 °C. These are durable materials with a high tensile strength compared to soft ones.

These include copper-zinc and silver. Such solders can only be worked with powerful soldering irons, blowtorches or torches.

This article will describe in detail the soft solders that are used for radio components and equipment repair.

Titanium welding technology - description and step-by-step instructions with video

This metal is not classified as rare. There is much more of it in the earth's crust than, for example, lead, zinc or copper. Titanium successfully combines the low density and strength of alloys based on it, and if we take into account the resistance to corrosion even in an aggressive environment, then the interest in it in many industries is quite understandable.

The high price of Ti (the 22nd element of the periodic table) is explained by the fact that its processing is a rather complex and expensive process. This article will introduce the reader to titanium welding technologies.

general information

Without knowing the properties and characteristics of the metal and its alloys, it is quite difficult to understand all the nuances of welding.

- Density of titanium (g/cm³) – 4.51.

- Strength (MPa): metal – within 267 – 337, alloys – up to 1,230.

- Melting point (ºС): 1668.

- The ability of titanium to spontaneously combust in an oxygen environment.

- Low thermal conductivity.

- Exceeding the temperature value by more than 400 ºС initiates the activity of the metal.

- Titanium intensively absorbs hydrogen and reacts violently to contact with nitrogen.

- Under the influence of carbon dioxide and water vapor, it quickly oxidizes.

In addition, it is necessary to take into account that the metal can be in one of two stable phases, which are denoted by the Latin letters α and β. How are they characterized?

- Phase α – titanium is in this state at ambient temperature. The structure is fine-grained, and the metal is completely inert to the cooling rate.

- Phase β – titanium enters this state at temperatures above 880 ºС. The grain becomes larger, and sensitivity to cooling (process speed) appears.

These phases can be stabilized by introducing certain additives and alloying elements into the metal - O, N, Al (for α) or V, Cr, Mn (for β). Therefore, titanium alloys, depending on the type of additives, are divided into groups:

- VT1 - VT5.1 They are called α - alloys. They have ductility and weld well, but heat treatment does not increase their strength.

- VT 15 - 22. Group β - alloys are welded much worse, and cold cracks may appear. At the same time, the grain sizes of the structure increase, and this affects the quality of the connection of the segments for the worse. The advantage is that heat treatment partially increases the strength of the alloy.

- VT4 – 8, OT4. The α β group is essentially an intermediate link. The properties of such alloys are largely determined by the type and percentage of added additives.

Not all common technologies are applicable to this metal and its alloys. The reason is the chemical activity of titanium. The entry of foreign compounds (nitrides, oxides, carbides) into the working area sharply reduces the quality of the weld.

- Arc flux.

- Cold.

- Electron beam (plasma arc).

- In an argon environment. The most popular option, although there are some others.

- High speed of technological operation. This is due to the fact that prolonged thermal exposure in a separate area leads to a change in the structure of the material due to an increase in grain size. As a result, the metal becomes brittle (brittle).

- Complete isolation from the atmosphere. And not only the working area (welding pool), but also those areas that are heated to 625 (or more) ºС.

Advantages:

- High quality welded joint.

- Work at low currents. Consequently, it is possible to weld parts of small thickness (thin-walled), since the likelihood of burn-through is practically eliminated.

- Possibility of increasing the volume of a part in defective areas (for example, in places where cavities form).

- Obtaining a seam with any parameters, which allows you to process (join) both large-sized samples and relatively small ones.

Mechanical treatment and degreasing, if necessary, acid etching. The goal is to completely remove the oxide film approximately 20 mm from the edges to be joined. The specificity is that all work must be carried out wearing protective gloves (mittens). Touching parts with hands is unacceptable due to possible contamination of the alloy.

If mechanical cleaning is not enough, then resort to oxygen gas cleaning (using a burner).

- Sandpaper.

- Scrapers.

- Metal brushes with stainless steel wire with a cross-section of 0.25 (±5) mm or other suitable devices (abrasive materials).

- Fluorine solution, hydrochloric acid (heated to 60 - 65 ºС).

- Absence of burrs, cracks, inclusions, etc. on the sample.

- Smooth silver shade of titanium alloy.

Wire

It is selected in accordance with the group of the alloy to be welded (see above). The tag (or packaging) must contain the necessary information, since all products are labeled.

Before use, the wire is cleaned (if necessary, with sandpaper no higher than No. 12) and degreased. It can be prepared in advance, but in this case it is sealed (for example, wrapped in plastic) and placed in a tightly closed pencil case (tube). But storage in such conditions is no more than 5 days.