What kind of alloy is this?

Brass is a double or more often multi-component copper-based alloy. The main alloying substance is zinc. In addition, the following can be added: tin, lead, manganese, nickel, iron. According to the metallurgical classification, brass does not belong to bronze alloys.

Brass dates back to ancient Rome, although zinc was only discovered in the 16th century. It was called “orichalk,” which meant “golden copper.” Previously, zinc ore, galmey, was used instead of zinc. An alloy of metallic zinc and copper was first obtained and patented by James Emerson.

The concentration of the base metal, copper, in the alloy is 56–67%. Brass may contain about 2.5% lead, the rest is zinc. In this condition, brass is now rarely used for making coins. In ancient Rome, coins were minted from brass, although these were most likely alloys similar to brass. In addition, brass coins were found in China, the GDR, and Bulgaria.

The alloy based on copper and zinc is not magnetic. But there are some subtypes of coins that look like brass, but at the same time have magnetic properties:

- Recently, some countries have used an alloy of copper and zinc with the addition of nickel to create coins. Since nickel is ferromagnetic, such a coin will still be attracted to the magnet.

- Making coins from non-ferrous metals is not a cheap pleasure, but somehow you need to make coins of different colors, including yellow, so sputtering is often used. For example, brass is applied to a steel coin. Such a coin is magnetic, but at the same time has the appearance of brass.

There is another method for obtaining magnetic coins. Brass becomes magnetic if a ferromagnetic substance, most often iron or nickel, gets into it during the manufacture of the alloy. It happens that this happened by mistake and, interestingly, such coins often have a high value. For example, some coins made in the USSR and Russia had properties that were different from the main batch, and now a copy of such a coin is expensive.

Rarely, the name brass also refers to other copper-based alloys. For example, a copper-nickel alloy, which, of course, will be magnetic. A variety of this alloy is cupronickel, used for making cutlery. In fact, calling it brass is not entirely correct, but such usage does occur.

What is bronze?

Before we figure out how to distinguish bronze from brass, let's find out what each alloy is. Let's start with bronze. So, bronze is an alloy of tin and copper, with admixtures of silicon, aluminum, beryllium and lead. It is the quality of the tin used that largely determines the nature of the future alloy.

There is a special type of bronze, in the manufacture of which tin is replaced with nickel or zinc. This alloy is known as spiatr. Essentially, the material is a cheap version of bronze, which is not of the best quality.

According to the above manufacturing principles, bronze is divided into tin and tin-free. At the beginning of the last century, metallurgists produced arsenic bronze. However, due to its high toxicity, the material was never widely used.

Nickel brass

Nickel brass is a copper-zinc alloy whose main alloying element is nickel. The latter has properties that significantly improve the performance of brass. It makes the alloy less susceptible to corrosion and refines the grain.

In industry, brass grade LN65-5 is often used. It contains 64-67% copper and 5-6% nickel, the rest is zinc. Impurities are allowed, the amount of which should not exceed 0.3%. It has increased mechanical properties, wear resistance, and can be processed. It is used to make condenser tubes for marine vessels, pressure gauges, and so on. There is another common alloy that contains 12-14% nickel, 26-30% zinc and 56-62% copper.

How to clean brass coins?

Like any other coin in numismatics, they need to be stored very carefully. Coins made from brass often show clouding, darkening, black, green or blue spots. All these are traces of external influences that need to be gotten rid of in order for the product to acquire its original appearance. How to clean brass products?

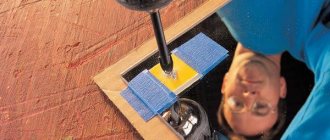

One of the most common cleaning methods is electrolysis. However, it is worth cautioning that a common side effect of using this cleaning on a copper-zinc alloy is a change in the color of the coin and the appearance of a copper tint. Particular attention should be paid to fixing the coin during cleaning, since if it touches the electrode, a short circuit may occur and the coin may become chipped. You can use a soda solution as an electrolyte, and a car battery will serve as the current source. The coin is attached to the negative charge, and a stainless steel electrode is attached to the positive charge. In five minutes, the coin is completely cleaned; you can then wipe it with a soda-based cleaning agent, but strong mechanical impact is not recommended.

Ammonia dissolves oxides and traces of corrosion on copper-zinc coins well. You just need to know that it is often used not only for cleaning coins containing copper, but also for patination. So after removing the coin from the solution, you should rinse it thoroughly.

Trilon B can also be used to clean brass coins. This solution removes all oxides and does not interact with the alloy from which the coin is made. Even if a coin is left in a solution of this substance for a long time, its color will not change and it will not be destroyed in any way. If the oxides stick quite firmly to the surface of the coin, then instead of significantly increasing the exposure time, you can simply warm up the solution a little.

The abrasive cleaning method is not suitable for coins that will be sold and have a high value. However, to add shine to a modern coin in a collection, it will do the job. For this, it is best to use GOI paste. Polishing can be done with a portable engraver. One more thing about this method: it cannot be used to clean coins with fine design details.

It's not common to find coins or other collectibles made of brass these days. But if they still have magnetic properties, this does not mean that they are made of any other alloy, although this may indicate surface application. Brass is not magnetic if there is little or no nickel or iron in its composition.

Collectors and numismatists often wonder: is brass magnetic or not? The fact is that this alloy is often used in the manufacture of coins. But it is quite difficult to evaluate found specimens using a magnet, because not all brass is magnetic.

How to tell the difference?

Most often you can distinguish by:

without the use of any tools or equipment.

But there are situations when, for accuracy, it is necessary to use :

- reagents,

- tools,

- devices.

Before assessing the scrap that you are going to take to the collection point, you need to clean it of dirt, otherwise you won’t be able to accurately determine it by eye.

By color

Both metals, although to varying degrees, can develop a patina .

Therefore, do not forget to clean the scrap well.

If an object has been in the open air or in water for a long time, the patina layer is difficult to remove.

Sometimes it will be justified to purchase a special cleaning product .

It is advisable to inspect the scrap under a powerful white light.

This implies that one can view either under the sun on a fine day or under a bright fluorescent lamp . Incandescent lamp is not suitable.

Pure copper will have a reddish-brown tint, sometimes with a pink tint. Keep in mind that brass can be red or orange. This type is commonly used for decorations and water pipes.

If the material has an orange, yellow or golden tint, you can be almost sure that it is brass.

If you are engaged in the collection and delivery of scrap metal, then it will be useful for you to know the prices for ferrous scrap metal. If you don’t know where to find ferrous metals, then read this article. Not sure which metal detector model to choose? Check out the review of popular models https://rcycle.net/metally/cvetnye/metalloiskateli-vidy-modelj-i-ceny.

It can also be light golden , pale yellow , and even off-white , but it is very rare for metal detectors, since such an alloy is difficult to process, and it is used mainly in jewelry.

The best recommendation is to carry an item that you are absolutely sure is made of pure copper . You will be able to compare it with the crowbar you found. Most often this method works well.

By sound

Another method that does not require special skills or equipment. You can learn to distinguish metals by sound after a short training. Hit the object with something metal. If it is made of copper, the sound will be muffled and low . This happens because the metal is soft.

Visual inspection and testing for sound and hardness are usually sufficient for field determination.

On the contrary, brass will produce a ringing and high-pitched sound when struck. The second most important inspection method for those who deal with scrap metal is after visual assessment in the light. But this method is justified only with large and voluminous objects - you need something to make a sound.

By hardness

Copper, as mentioned above, is a soft metal. Brass was specifically created to increase the hardness of copper while maintaining some of its other characteristics. Therefore, when damage is caused to scrap, copper will be the material that is more easily deformed . Brass, on the other hand, can withstand impacts .

By labeling

If an item has markings on it, identifying the metal or alloy can be simple and accurate.

As a rule, brass is marked with a mark that begins with the symbol “L” .

Accordingly, copper markings begin with “M” . True, copper quite often does not have any markings.

Here are some transcripts that may be useful:

- Copper markings begin with one letter “M” , followed by numbers. letter “L” on brass products; it can be followed by more letters, and only then by numbers.

- In the United States and Canada, the UNS , according to which brass is marked C2, C3, C4 .

- In the European Union, both metals are marked with the letter C , it all depends on the subsequent letters. For copper they will be B , C, D , and for brass alloy - L, M, N, P and R.

- Not so long ago, labeling consisting of icons of chemical elements was common. For example, Cu Zn (cuprum - zinc) will mean brass.

By weight

Brass is lighter than copper due to the addition of zinc. But in order to determine from a shapeless piece whether it is metal or an alloy, experience is required.

By chips

This test will require a metal drill or access to a machine to get the chips.

With brass it will be, as experts say, needle-shaped , since the material is hard.

It's kind of loose.

With copper, the shavings will be more plastic, so often they don’t even break and the result is ornate , in one continuous spiral.

Acid analysis

If you come across brass grade L-96 , which means the presence of 96% copper in the alloy, it is difficult to distinguish it from the metal without analysis. You can use hydrochloric acid for this. If you drop it on pure copper, it will simply cleanse it of patina and will not react with the metal itself.

If you apply hydrochloric acid to brass, zinc will react and a white oxide will appear on the surface - zinc chloride .

Analyzer

Our portal has detailed material about analyzers of metals and alloys. With the help of such a device you can accurately determine what is in front of you.

Such analyzers have a liquid crystal screen, on which, after interaction between the device and the metal object, a complete list of all constituent elements is displayed.

If it is 99% copper and tenths of a percent of some random impurities, it is copper. If there are other metals in significant quantities - brass. But the method is expensive .

By product type

Some products are made only from copper or only from brass.

This may provide additional guidance.

Tools are made exclusively from brass, which is harder.

Some parts of wind musical instruments are made from copper.

In principle, you need to start from the purpose of the item - if it should be:

- reliable,

- hard,

- stiff,

then, most likely, brass .

If, on the contrary, you need ductility , high electrical or thermal conductivity, then this is copper .

By heating

Another method in which you need to use a gas burner.

The indicator here will be zinc oxide, which forms as a pale white ash-colored coating only on brass if it is heated to temperatures above 600 degrees .

What kind of alloy is this?

Brass alloys and compounds like them have been used for coinage since ancient Roman times. The material was also popular in China, Bulgaria and the German Democratic Republic.

Brass is diamagnetic - alloys that are pushed out of a magnetic field. It is created on the basis of copper (56-67%) with the addition of zinc. The following can also be used as a ligature:

Brass should not be confused with other copper-zinc alloys. Only a compound with the above proportions of base metals is considered brass. If the ratio of alloying and base components is different, the alloy is called copper-zinc, not brass. For example, a similar connection was used to mint Soviet coins in denominations of 1, 3 and 5 kopecks from 1961 to 1991.

Nickel brass

Nickel-containing brass (NBR) was developed for electrical connectors, as a replacement for expensive silver plating. It is resistant to corrosion, abrasion, and has low transient resistance. The alloy has increased mechanical properties, but is well processed by pressure in cold and hot states.

Nickel brass is used for the minting of modern coins in many countries. In addition, the main areas of its application include the production of:

- pressure tubes;

- condenser tubes for legal proceedings;

- meshes for papermaking machines.

Externally, nickel brass can be confused with ferrous bronze (BRAZH). It is these two alloys that are usually tried to be distinguished by magnetic testing. This method has no scientific justification, since the magnetic properties do not depend on the basic components of the alloy (copper with zinc for brass or copper with tin for bronze), but on alloying additives (nickel, iron) and their proportions. The ligature varies depending on the specific brand.

Defining Differences Between Bronze and Brass

How to distinguish bronze from brass? The difference between the presented alloys is as follows:

- Brass is produced by combining zinc with copper. In turn, bronze is produced by alloying copper with tin.

- Bronze can be in contact with sea and salt water for a long time without destroying the structure of the material. Brass requires additional processing in the form of alloying.

- Bronze has increased resistance to mechanical wear and is a durable material. For this reason, the alloy is widely used to create all kinds of sculptures and monuments. Brass is not suitable for these purposes, although it is used as elements of artistic products.

- How to distinguish copper from brass and bronze? Copper has a reddish tint. At the same time, bronze has a dark brown color and a coarse-grained structure. Brass has a yellow tint and is a fine-grained material.

Tips and warnings

Experienced specialists distinguish nickel brass from ferrous bronze by the color of the chips in direct sunlight: brass will have a greenish tint, bronze will have a yellowish-reddish tint. An even more accurate result is obtained by spectral analysis of chemical compounds. Everything else is myths and speculation.

Copper alloys have a similar chemical composition, so the external characteristics of bronze and brass are the same. This creates difficulties when it comes to distinguishing between metals. The main reason for the difficulty in identifying a specific alloy is the large number of grades and modifications of compounds. Color often does not immediately reveal the type of alloy, so other ways to distinguish between brass and bronze are needed. Typically, owners need to determine the alloy when selling scrap to the secondary market. Our company accepts brass shavings and bronze scrap metal on favorable terms. We will evaluate the scrap free of charge to accurately identify the composition and grade of the metal, as well as maximum cash payments to customers.

Methods for visually identifying an alloy

Brass is made using an alloying component - zinc or tin. Their content is in the range of 4-45%. Bronze is a multicomponent alloy, including a large number of non-metallic components. The alloying element of bronze alloys can be several substances at once: magnesium, aluminum, silicon, beryllium or manganese. In both alloys, the amount of copper is limited to 60-90%, so it is difficult to distinguish between bronze and brass externally. Based on external properties, it is worth noting the following characteristics of specific alloys:

- Bronze. A number of grades of this metal contain a large amount of lead, which gives the alloy white-silver shades. With the maximum amount of copper present (about 90%), bronze is similar to copper, having reddish-brown hues.

- Brass. The zinc, tin or nickel content almost always contributes to the formation of a yellow-golden alloy. Brass compositions are closest in color to pure gold. However, such shades are obtained only if GOST is observed in production.

Visual approach

Alloys with a high content of the main alloying component are easily recognizable by color. The technique for visually distinguishing brass from bronze is as follows:

- Brass is an alloy with a high zinc content. This causes the color of the compound to shift from the pink-red hue of pure copper to golden yellow tones. We can confidently say that the color of brass is closer to gold. Although scrap brass comes in different forms and different states, and it’s certainly not easy to identify with your eyes, the same applies to scrap bronze.

- Bronze The quantitative content of tin in the alloy determines the color of the compound. Bronze with a maximum Sn content of 33% is characterized by a silvery-white color. The alloy, containing at least 90% copper, also borrows its color - closer to brown-red tones.

Since in practice, compounds with a high tin content are rare, you can trust the following rule. Brass is a golden-yellow hue, bronze is reddish.

How to distinguish bronze from brass using a magnet?

This method will not provide accurate information. However, according to physical laws, not all metals have magnetic properties. In brass and bronze, only iron and nickel are attracted by a magnet. These metals are present mainly in bronze alloys of the BrAZH, BrAZHN and similar brands. However, the percentage of iron and nickel in the composition is quite small (about 7-11%), so the experiment can only be carried out using a powerful magnet. In brass, the volume of metals with magnetic properties is only 1-3%. This is why bronze is more easily attracted to a magnet, but it is difficult to get an exact answer, and the method is not suitable for all brands of alloys.

Detection of brass and bronze by heat treatment

If you have equipment or instruments capable of producing temperatures in the range of 600-650 o C, you can try to determine the alloy by heating the metals. The method is applicable to brass because it contains zinc. When exposed to this temperature, zinc undergoes oxidation. As a result of the process, oxide (an ash-colored coating) is formed on the surface of the brass product. Also, the brass alloy itself will become more ductile, so it will not break under heavy loads, but will simply bend. Bronze at temperatures up to 650 o C will simply heat up without changing its physical properties. The method is also applicable only for brass alloys in which the alloying component is zinc, so it is easy to make a mistake if it is not present in the composition.

Methods for distinguishing brass from bronze at home

Very often, when old metal products are found or purchased, at first glance it is not clear what kind of alloy they are made of. Visually, objects made of brass and bronze are very similar. However, there are several proven methods that will help determine a particular alloy at home.

Heat treatment

Some metals are very sensitive to high temperatures. For example, for zinc 600-650 degrees will become critical. After such exposure it will oxidize. Knowing this, you can distinguish brass from bronze using a burner flame.

- If bronze is heated to the specified temperature, it will quickly become hot, but its color and mechanical characteristics will remain the same. If you try to bend a heated bronze object, it may break.

- Brass, which contains zinc, will react to high temperatures somewhat differently. Oxidation of zinc will cause an ashy coating on the surface of the product. In addition, after heat treatment at 600 degrees, the brass will become plastic, and the alloy sample will not break when bent, but simply bend.

You can distinguish brass from bronze using heat treatment.

To use this testing method, you will need to find a powerful burner, because A regular stove burner or fire flame will not work.

Chemical methods

Exposure of the alloy to chemical reagents is a fairly reliable way to distinguish bronze from brass. However, to carry it out you need to have special equipment, nitric acid and some experience in working with such substances.

In the absence of chemical reagents, you can use a solution of sea salt. When you place brass shavings in it, they will change their appearance, but the bronze shavings will remain the same as they were.

Using a magnet

Not all metals react equally to a magnet. Some stick to it thoroughly, some just rise slightly, and there are others who remain indifferent to it. Tin and lead, which are part of bronze, can be attracted by a magnet. The only thing is that for such a test you will need a fairly strong magnet. Bronze products, after exposure, will slightly stick to the surface. The magnet will not have any effect on brass.

Methods for chemical determination of alloys

Chemistry is a fairly effective way to identify brass and bronze. However, accurate results can only be obtained by reactions that destroy the metal, which will negatively affect the product. The chemical method includes the following steps:

- chips are removed from the copper alloy (so as not to damage the entire metal);

- mix a solution of nitric acid and water (in a ratio of 1:1);

- Next, you should place the chips in an acidic reagent;

- the solution is heated to boiling point after the chips are dissolved;

- The boiling temperature is maintained over low heat for half an hour.

If the shavings were brass, the solution in the container will remain transparent. When bronze dissolves, a tin precipitate (white) precipitates. Taking this into account, the method only works for bronze containing tin.