Sometimes at home you urgently need to weld a stainless steel container or pipe. Novice welders who have a household inverter in their household can fix the problem on their own. Although manual welding of stainless steel with an electrode is not practiced in industrial conditions, at home the defect can be eliminated using conventional electric welding. Experts will share their experience on how to weld stainless steel with an electrode. What features of alloyed metals need to be taken into account, what mode to adhere to when working.

Features of stainless steel welding

The main problem that inexperienced welders encounter is poor-quality welds. A pipe may leak even with low pressure. Cracks appear on the metal in the weld area.

When welding stainless steel with an electrode, you need to take into account a number of features of alloy steel and its physical properties:

- The metal has a high coefficient of expansion; after joining by electric welding, it contracts during the cooling process. If you cook stainless steel with a conventional additive for carbon steel, which has a small coefficient of expansion, cracks may appear on the seam - it will break due to internal stresses in the stainless steel.

- When the melt pool oxidizes, porosity is formed on the surface due to crystallization. If it is not possible to create a protective atmosphere over the working area, you need to select rods with a special coating containing components that prevent the flow of oxygen into the seam.

- Alloy steel used in everyday life melts at low temperatures. When exposed to an electric arc, stainless steel can burn out alloying additives. Without them, the metal will rust. To prevent overheating, the seam is made in a checkerboard pattern.

- The additive for welding stainless steel is selected taking into account the special properties of the alloy metal. It is advisable to know exactly the brand of workpieces being welded.

What is stainless steel

What is steel: it is an alloy of iron and carbon. The proportion of carbon can be different; the higher it is, the stronger the steel. Alloying elements are added to steel to adjust the properties of the steel.

What is stainless steel: Chromium is added to resist corrosion. Its share in the stainless alloy ranges from 12 to 30%. There is much less chromium and other components such as molybdenum, nickel, etc.; they work great for anti-corrosion protection, but do not facilitate the welding process at all. And that's putting it mildly. High-alloy stainless steel is one of the most difficult metals to weld.

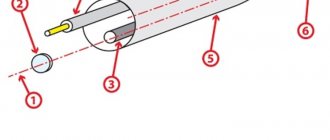

Diagram of the occurrence of a welding arc.

Here are the main factors influencing the welding process:

- Stainless steel has lower thermal conductivity than other types of steel. Therefore, it takes much longer to warm it up, and much more electricity is wasted.

- Stainless steel has a very high coefficient of expansion , so when connecting two surfaces of thick workpieces, there is a risk of microcracks occurring in large numbers. To minimize this problem, the gap between the workpieces must be wider than when working with other types of steel.

- The high resistance of stainless steel to melting processes leads to significant overheating of the electrodes. Therefore, you can only use special electrodes for stainless steel.

- Attention! The main enemy in welding steels is intergranular corrosion or ICC - a very dangerous deformation that can occur when stainless steel is heated above 500°C, therefore the welding mode must be determined most carefully, including forced cooling of steel workpieces.

Is it possible to cook stainless steel with conventional electrodes? Theoretically and even technically possible. But only when working with small metal parts for household use.

If we are talking about industrial structures, then no simple consumables! There is no need to talk about the reliability and solidity of seams using them. This option can only be regarded as an emergency solution in cases of urgent need.

Which electrodes to choose for stainless steel

The risk of cracking will be reduced if you choose an additive with a rod that is similar in chemical composition to the workpiece. Several types of rods are produced for welding stainless steel:

- TsL-11 was created for welding chromium-nickel alloy, they have a fluorine-carbonate coating, welding can be performed at temperatures up to +450°C. The electrode can be used in any position.

- OZL-6 is intended for heat-resistant steels; if you cook other workpieces with it, the electrode will straighten out more slowly and the weld will be weak;

- NZh-13 – for food grade stainless steel. Can be used for chromium-nickel steel alloyed with molybdenum. The coating forms a small layer of slag that protects the melt pool from oxidation.

- ZIO-8 is for heat-resistant alloys; problems will arise with it when welding household stainless steel.

- NII-48G is a universal additive with the main type of coating.

- EF400/10U, OLZ-17U – professional electrodes designed for austenitic alloys. It is not advisable to use such rods in everyday life; the coating contains harmful components.

Is it possible to weld stainless steel with a regular electrode?

Carbon rods should only be used in extreme cases. In this case, you should not expect special strength from the seam. When the connection cools, you can hear a crackling sound - the black metal will be torn by the shrinking stainless steel. Over time, rust will inevitably form in the work area; even under slight pressure, a leak will form.

Do NOT cook with a simple electrode:

- nichrome heating system pipes;

- heated towel rails;

- stainless steel containers.

For beginners who have an inverter at home, it is advisable to have a pack of universal electrodes for stainless steel in stock.

How to properly cook thin stainless steel?

When working with thin stainless sheets, there are certain rules that are important to follow to create a strong and neat seam. Step-by-step instructions on how to cook stainless steel:

- At the preparatory stage, you need to clean the parts from plaque, paint, and dirt.

- We spread the flux.

- Heat to approximately 250 degrees. At the same time, we observe a change in the color of the surface of the materials.

- Since we are working with thin sheets, we move the electrodes quickly so as not to melt the material.

- Cool the material with copper plates to avoid rust formation.

Stainless steel electrodes are performed at home and in production. In this case, temperature, equipment, current strength, steel thickness, and other features of the technology and the material itself may change.

Stainless steel electrode welding technology

The process of work is slightly different from electric welding of ferrous metals. There are subtleties in the formation of a seam, so welding technology must be followed. The preparatory stage is standard:

- The workpieces are cleaned, dirt, oil stains, and traces of paint are removed from them. All these components foam the melt bath.

- For parts thicker than 4 mm, edges are cut at an angle of 45°.

- The parts are laid end-to-end with a gap of at least 1 mm, this is due to the large coefficient of expansion of the stainless steel during the welding process.

- The strength of the seams increases if the parts are preheated to +150°C, then welding begins.

How to properly cook stainless steel with electrodes:

- First, the future seam is grabbed in several places.

- The rod must be held at an angle of 45 to 60°, tilted towards you or to the side.

- You need to be prepared for a thick melt bath; the liquid metal is viscous, like plasticine.

- The seam is applied with small stitches, quickly.

- It is necessary to maintain a short arc, oscillatory movements are unacceptable.

- When the joint cools, the metal is not further cooled; the seam must crystallize gradually so that internal stresses do not arise in the workpieces. Then the connection quality will be normal.

- Welding thin stainless steel with an electrode is carried out with a current of reverse polarity; with this connection of the terminals, the highest temperature will be concentrated at the tip of the filler rod.

Welding process

To successfully weld stainless steel with an inverter at home, you should follow certain stages of work:

- Remove any remaining paint, oil or debris from the joint. Stainless steel is a rather “capricious” metal and reacts poorly to such inclusions in the weld pool. Cleaning is carried out with a metal brush.

- Preliminary calcination of the electrodes will help restore the good properties of their coating, which will facilitate the welding process and subsequent processing.

- When working with joint edges that are thicker than 4 mm, a 45 degree bevel is required. This will ensure good penetration and filling of the contact zone with filler metal. The cutting can be done with a grinder or a file. In especially critical products, the bevel of the edges is performed on a milling machine. Additionally, a gap of 1-2 mm is set between the plates, which allows the hot metal to flow to the very base of the seam.

- If you are welding thin metal (1-2 mm) with an inverter, then there is no need for a gap. On the contrary, you need to bring the edges of the joint tightly together and tack.

- When working with thick sheets of iron (more than 7 mm), it is recommended to heat the product to 150 degrees. At home, this can be done with a blowtorch. This measure allows you to avoid a sharp temperature change when applying a weld to cold metal.

- The seam, when welding stainless steel with an inverter, is performed with a short arc, and is carried out a little faster than when welding “black” iron. To increase the penetration rate, do not use oscillatory movements of the electrode. The seam is narrow, but does not overheat the material. The electrode can be tilted towards you or in a convenient direction, and held at 40-60 degrees relative to the surface of the product.

- At the end of the seam it is necessary to make a “lock” to prevent subsequent cracks and fistulas. To do this, the weld pool is brought to the side onto the base metal, or onto the already solidified previous seam, and holding the electrode in place, the arc is interrupted.

- After stopping welding, the product must be allowed to cool down. You should not water it with water, speeding up the process, otherwise the high coefficient of linear expansion will negatively affect the quality of the joint.

- The slag is removed after 5 minutes so as not to leave traces of impact on the soft metal.

- The cleaned seam is inspected for defects. If the product is intended to work under pressure, then it is worth performing pressure testing. After which you can grind and polish the stainless steel structure to shine.

Which welding machine to choose

Some craftsmen rent welding machines. To work with alloy metal, you need to choose modern welding equipment that generates direct current; with such a device it is easier to maintain a short arc, and smooth seam stitches are obtained. You can weld metal with a transformer, but in this case, sagging may form, reducing the strength of the restored element. It is better to choose welders with additional functions. The risk of sticking the electrode and burning through the workpiece will be reduced. A good option is a universal generator that produces direct and alternating current. It is permissible to use an inverter that produces high-frequency alternating pulse current.

Setting up the welding machine

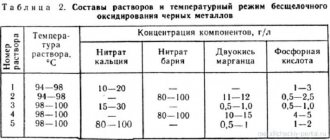

To weld stainless steel with electrodes, a certain operating mode is followed. To weld 4 mm workpieces, you need a machine that produces 100 A with a voltage of 16 V. Welding range for thinner parts:

| Workpiece thickness, mm | Current range, A | Recommended voltage, V |

| 1 | 30 — 40 | 12 |

| 1,5 | 40 — 60 | 13 |

| 2 — 3 | within 80 | 14 — 15 |

The diameter of the electrode should be less than the thickness of the workpiece; steel up to 3 mm is welded with double rods, 4 mm with 3 mm rods.

If you follow all the technological subtleties of welding alloy metals, you can get a fairly strong connection at home. For the restoration of pipes and containers designed for high pressure, it is better to resort to the services of professionals.

Stainless steel welding methods

We will consider 2 welding methods:

- Manual electrode;

- Manual argon.

Each of the methods presented below requires the use of specific equipment and precisely selected consumables.

Manual electrode

The quality of the weld seam obtained by this method is sufficient for this welding method to be used both in everyday life and in production. Manual welding using a coated electrode is considered universal and is used in all industries.

Advantages of MMA welding:

- simple and easy welding process;

- high operating time of the devices;

- compact units with low weight;

- obtaining strong welds;

- Suitable for self-learning this method.

The quality and reliability of the weld depends on the correct choice of welding materials.

For manual welding, the following brands of electrodes are recommended:

- ESAB OK 61.30 has high resistance to intergranular corrosion and produces a reliable welded joint. The slag layer falls off on its own, which increases the welding speed.

- AG E 308L-16 is suitable for metals exposed to low and high temperatures.

- ESAB OK 63.30 is used for welding metals in contact with aggressive environments. These electrodes can be used for welding with direct and alternating current.

To weld with this method, you must set the DC mode with reverse polarity.

Manual argon

Argon arc welding is used to obtain visually beautiful welds. This method has proven itself well when welding very thin parts.

To weld stainless steel with argon, tungsten electrodes must be used. If you follow this technology, the weld will certainly be strong and of high quality, even when performing welding work in domestic conditions. When welding using this method, there will be no slag layer on the seams and no spattering of metal. Tig welding is considered the cleanest method of joining metals.

For this method, direct current with straight polarity or alternating current is suitable.

Table 1. Dependence of current on metal thickness

| Metal thickness, mm | Type and polarity | Current strength, A | Electrode diameter, mm |

| 1 | Constant | 30-60 | 2 |

| Variable | 35-75 | ||

| 1,5 | Constant with straight polarity | 40-75 | 2 |

| Variable | 45-85 | ||

| 4 | Constant with straight polarity | 85-130 | 4 |

Features of argon arc welding:

- the arc is ignited without contact to avoid the tungsten coating from the electrode getting into the already molten metal;

- During welding, vibrations of the rod must be prevented. Otherwise, the protective barrier in the working area will be broken and, as a result, oxidation of the seam will occur.

This welding method allows to reduce the consumption of welding materials. After completing welding work, it is necessary to continue supplying argon for 10-15 seconds. These actions will help protect the hot electrode from active oxidation.