From simple to complex

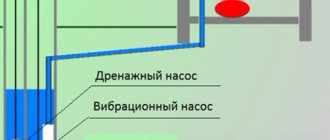

For deep-well pumps that have a large diameter and short length, the connection of which is carried out via a flexible polyethylene hose, and these are most often vibration pumps, during lifting a situation may arise when the electric cable of the pump gets caught between the pump housing and the wall of the casing pipe.

Such pumps are most often lifted by a cable and a hose, but the cable, the entrance to the pump body, which is located below the level of the hose connection and the cable fastening, is simply tightened periodically. At the moment when the cable is most weakened and has excessive length, it fixes the rise of the entire structure. The small distance between the housing and the wall into which the cable enters becomes a big obstacle to removing the equipment to the surface.

In fact, this is the simplest of all possible cases of jamming during lifting. The problem here can be solved quite simply - just lower the pump a little into the well and at the same time tighten the cable. After tensioning the cable, continue lifting, ensuring the tension of all elements - hose, cable and cable.

How to get a pump out of a well if it is stuck: the best methods to pull the pump out

If your pump gets stuck in a well or falls into it, then read our instructions. Work on lifting pumps should be carried out carefully, as there is a high probability of making a mistake and damaging expensive equipment.

5 reasons why pumps get stuck in wells

Before you pull the pump out of the well, you need to determine the exact reason why it is stuck. This will make it possible to choose the most effective option for troubleshooting, which will reduce the risk of pumping equipment failure.

There are 5 main reasons for the problem:

- Sagging power cable. This is the most common situation faced by every third owner of an autonomous water supply system. The main signs of the problem are not only sagging of the cable when lifting the pump from the shaft, but also its wrapping around the equipment body. In this case, even applying great force will not allow the device to move.

- Getting stuck in limestone. Rare maintenance of the mine causes water stagnation. Because of this, metal salts form limescale. It securely fixes the pump and makes it impossible to pull it up.

- Silting of the well. Using the pump for several years and not wanting to carry out cleaning activities leads to a large amount of sludge accumulating at the bottom. It completely covers the case and makes it impossible to lift the device up.

- Mechanical damage. The most common occurrence is that the pump gets stuck in the casing pipe, which was damaged as a result of a heavy object falling into the mine or careless human actions during cleaning activities.

- Hit by a foreign object. If it gets stuck in the pipe, it will not be possible to pull the pump out of it.

5 ways to get a pump out of a well

Experts recommend using several proven methods that can quickly fix the problem. To remove a stuck pump, do not use excessive force, which can only damage the device and render it inoperable.

How to remove a stuck pump

To quickly get rid of the problem, you need to know how to get the pump out of the well if it is stuck and does not move. For each reason there is a solution.

This is how a vibration pump can get stuck in a casing pipe

Available methods:

- Cable slack. If this situation occurs, you must lower the device slowly and carefully. As soon as it is at the bottom, loosen the cable and try to lift again. At the same time, they move slowly, trying to avoid sagging of the electrical wire and other structural elements (cable, hose).

- Siltation. With such a problem, it will be difficult to lift a stuck device. To correct the situation, silt deposits must first be washed away. To do this, carefully swing the cable, while simultaneously trying to lift the stuck device. Gradually, the “grip” of the sludge will weaken and after a few minutes of such work it will be possible to lift the equipment to the surface.

- Buried in limestone. If such a problem occurs, you should perform all the same actions as for silting. Slow rocking will gradually destroy deposits near the body and allow the device to be lifted from the bottom.

- Pipe damage. Rotational movements that need to be applied to its body will help you get stuck equipment. You need to lift the device slowly, as one careless movement will be enough to damage its outer part.

- Foreign object stuck in the shaft. In such a situation, you need to take the help of professionals, since it will be difficult to get this item with your own hands. This is due to the risk of it falling to the bottom of the well or damaging the housing.

What to do to prevent the pump from getting stuck

It is difficult to get a stuck pump out, so experts recommend taking all necessary measures to reduce the likelihood of a problem occurring. To do this, you need to perform several activities.

These include the following:

- Attaching the electrical cable to the hose. This simple step will help prevent the wire from sagging and wrapping around the body of the pumping equipment. Fixation is carried out using special clamps, which must be regularly replaced with new ones.

- Place the pump above the filter. This installation option will avoid sludge sticking to the body, which often causes the device to get stuck.

- Annual cleaning. Carrying out this activity regularly will prevent silt and sand from accumulating at the bottom of the well.

- Preventive treatment. In this case, professionals recommend using citric acid to remove limescale deposits. It will quickly deal with the problem and eliminate the possibility of the device getting stuck.

- When installing an autonomous water supply system, only high-quality pipes should be used. Thanks to this, there will be less risk of their breakage as a result of mechanical stress.

How to get a pump that has fallen into a well

If the cable breaks and the pump falls into the well, it will be difficult to get it from the bottom. Even if you manage to complete this work, you will have to change the device to a new one.

Procedure:

- Find a rod made of any durable metal. Its size should be enough to reach the bottom.

- A special screw attachment is attached to one edge, which is shaped like a corkscrew with a pointed end.

- A rod is fixed at the second end of the rod, allowing the homemade structure to be rotated.

- They lower the finished product and find the fallen equipment.

- Using force, screw the screw attachment into the device body.

- As soon as it deepens half its length, the pump slowly begins to rise.

What needs to be done to prevent the pump from falling

Lifting a pump from a well is considered a difficult undertaking, so you need to try to prevent it from falling to the bottom. To do this, you need to take several steps. Among them are the following:

- use the most rigid and durable cable;

- use a single long hose, rather than one assembled from several small pieces;

- the pipe diameter should be selected in a ratio of 3:2 with the dimensions of the pump;

- install a cap on the well to prevent objects from falling.

How to get a pump out of a well

Removing pumping equipment that is stuck or has fallen to the bottom of a well is carried out in exactly the same way as for a well. They use a homemade anchor.

Broken cable

The situation when the cable breaks and the entire structure slides down happens quite often. Typically, a metal cable does not break, just the fixing elements loosen over time due to corrosion of the metal, the threads are not able to fix the fastening and the cable is released. For the metal of a steel rope or cable, alloys that are not subject to corrosion or structures that have an additional protective sheath of plastic are usually selected. But an ordinary steel cable, being constantly in a state of tension, can develop abrasions and active corrosion at the point of fixation, because the pump experiences vibration during operation, which is transmitted to the cable.

In this case, it is recommended to continue lifting if the well is shallow and the pump is light in weight, using a hose or pipe as the main lifting device. The upward feed should be smooth, without sudden interceptions or jerks. The use of a cable as a lifting element is unacceptable! With this method, it is necessary to prevent the pump from rotating around its axis, since if the pump jams, a pipe or hose may become disconnected, which will further aggravate the situation.

A broken pump at the bottom of the well is also not the best option for the job, but if the power cable is intact and still attached to the pump body, then the chances of lifting the equipment increase significantly. For centrifugal pumps, screw pumps and vibration models, the cable usually has an entry into the housing slightly below the outlet and almost at the level of the cable mounting holes.

For lifting, a device made from a piece of metal pipe and welded wire, on the one hand, and a lifting cable on the other, can be used here. The cable is threaded into the pipe to the bottom, with a wire welded and bent into a hook. The hook is lowered along the cable and, having reached the lowest point on the pump body, is inserted into the eyelet for the cable. This operation is somewhat similar to winter fishing, when the bait is slightly twitched to attract fish, and the lifting hook, with small up and down movements, should enter the eye and engage the pump.

Siltation of the well

A well in clay soils or a sandy layer is most often susceptible to silting. The situation when soil gets through the drainage holes into the casing pipe and settles, preventing the equipment from being lifted, is most often typical for wells that have been maintained for a long time without maintenance.

For circulation or screw pumps, this is quite painful, since they have quite impressive dimensions, and the sludge does not just settle, but is tightly compacted between the pump body and the walls of the casing pipe. In this case, when it was not possible to pull out the pump the first time, it is necessary to apply the tactics of gradual release from the bottom sludge.

The pump is alternately raised and lowered, first by 5-10 mm, and then. When the dirt plug begins to become saturated with water and erode, gradually releasing the pump housing.

Entry of a foreign object between the casing and the casing

The problem of small stones, pieces of metal or fasteners getting into the cavity between the casing and the well wall can lead to very serious consequences, such as cable breakage or deformation of the casing at the junction of the pipes.

Most often, a small stone or fastener element falls into the well during repairs or installation of equipment. The operation of the electric motor with slight vibration can facilitate the passage of such a foreign object through the cavity until the moment when it does not completely fix the motor.

There are two main extraction methods:

- pushing a foreign object to the bottom of the well;

- releasing the pump with a powerful jerk.

The first method allows you to free the equipment if it is possible to lower the housing down a few centimeters. It is important here that it is possible to “swing” at least 1-2 cm, so that the structure begins to move, and the stone gradually moves along the body. Raising 2-3 cm to the next place of stupor should alternate with lowering the structure by 1-1.5 cm.

The second method must be used very carefully. A sharp jerk can damage the cable, so if the fixation is rigid and the movement cannot be traced, it is recommended to lift it with a uniform force, literally “dragging” the pump along the well.

Why did the unit fall into the well?

A pump falling into a well can occur for various reasons. In most cases, an idle unit falls to a depth when attempting to lift it. Often the pump gets stuck in the well, and any attempt to free the device leads to a break in the cable, cable or water pipe. In such cases, the owner of the equipment will incur additional costs not only for lifting the pumping unit, but also efforts will be required to restore the break.

Most often, a pump may fall into a well for the following reasons:

- deformation occurred on the casing;

- the apparatus was damaged by accumulated sludge;

- cables are tangled;

- the pump fell into the well during installation;

- an object fell into the well, dragging the unit with it to the bottom.

If the casing string is deformed, then most often a complete repair of the existing well or the laying of a new one is required. Moreover, this will need to be done regardless of whether the owner took his pump out of the well or not.

When not only the apparatus falls, but the cable, hoses, and cables go to the bottom along with it, the owner may lose not only the specified equipment, but also the entire well.

In all other cases, you can remove the equipment from the bottom and then continue operating the well.

For prevention, it is advisable to inspect the pipeline, the well itself and all equipment every 2-3 years. It is recommended to clean the well once every 2 years to remove accumulated sludge. You can do this yourself or call specialists.