Few people know that the Partner 350 chainsaw is directly related to the Husqvarna brand. The fact is that Partner is a subsidiary of this brand. The tool itself is very popular among consumers, which is easy to explain. After all, it has such significant advantages for every buyer as light weight, ease of use, high reliability and simplicity.

That is why the main users of this chainsaw are owners of summer cottages and private households. But you should not think that the purpose of the tool is limited only to trimming branches and branches and felling trees. This saw also has other properties that will be useful for many interested buyers to learn about.

Chainsaw Partner 350 with Malfunctions and their elimination. Malfunctions and their elimination

Chainsaw Partner 350 malfunctions mainly due to violation of operating rules. Eliminating most problems requires experience working with gas-powered tools and knowledge of the operating principles of two-stroke engines.

But, as practice shows, repairing a chainsaw with your own hands is possible even in the field. The main thing is that before repairing, correctly diagnose the cause of the breakdown, so as not to do unnecessary work and not aggravate the situation.

Breakdowns of a new tool are most often associated with the fuel system, and a saw that has already worked for a long time, having worn parts, can make troubleshooting very difficult.

Therefore, it is important to carry out timely adjustments and preventive maintenance, so that later you do not have to carry out repairs yourself in inappropriate conditions.

Why won't it start

If the chainsaw does not start, there may be several main reasons; they are listed in order of frequency of occurrence:

- lack of fuel in the gas tank;

- the stop toggle switch is not moved to the working position;

- the safety brake is engaged;

- the carburetor is clogged or not adjusted;

- The ignition system is faulty.

The first three reasons for device failure occur among inexperienced users, and the last two require immediate intervention.

It is easy to determine if the ignition system is faulty. You need to unscrew the spark plug and, if it looks good, lean its threaded part against the metal surface of the tool, then pull the starter. A spark jumping indicates that the ignition is working properly.

Fuel system malfunctions are caused by:

- clogged carburetor jets;

- fuel filter clogged;

- violation of the integrity of fuel hoses;

- incorrect setting;

- loss of crankcase tightness (failure of crankshaft seals or crankcase gaskets).

If the saw starts and stalls, first you need to adjust the idle speed, since this adjustment most often goes wrong.

The engine stalls when you press the gas in the following cases:

- incorrect adjustment or clogged jets;

- automatic brake activation;

- excessive chain tension.

The chainsaw stalls under load, mainly only when the carburetor malfunctions. With a light load, the saw may work normally, but it does not reach maximum power and stalls.

How to adjust a chainsaw

Do-it-yourself carburetor adjustment may be required during operation of the saw and after repairing the fuel system. Adjusting the carburetor of a chainsaw is a responsible matter.

Incorrect carburetor settings will, at best, lead to increased fuel consumption, and at worst, to engine failure.

To adjust the carburetor there are 3 screws:

- T - idle speed adjustment;

- L — fuel quantity screw for adjusting power at low and medium speeds;

- H - quality screw for adjusting maximum speed.

If the carburetor has been repaired or cleaned, adjust the chainsaw using the following procedure:

- Fully tighten the quantity and quality screws and then loosen them 1/5 of a turn.

- Start the chainsaw and let it warm up for 10-15 minutes.

- Tighten the quantity screw L until the speed reaches maximum. From the found position, turn it back a quarter turn.

- Use screw T to adjust the idle speed. It is necessary to set the value when the engine runs steadily and without interruption, and the saw chain does not rotate.

- Use the quality screw H to adjust the maximum speed on the tachometer. If there is no tachometer, then adjust until the sound of the engine begins to resemble the sound of a four-stroke engine. Exceeding the permissible number of maximum revolutions is fraught with damage to the cylinder-piston group.

The ignition system, with the exception of spark plugs, rarely fails.

If the chain is not lubricated

Chain lubrication is important to reduce link friction in the guide bar grooves. To adjust the lubrication system, an oil supply screw is provided. The chain is lubricated only while it is moving. You can check the operation of the oil pump by pointing the toe of the tire towards a light-colored surface. When you press the throttle, oil splashes should appear on the surface.

Service

The fuel mixture used consists of AI-95 or AI-92 gasoline and oil for two-stroke engines. Before starting work, it is necessary to run-in the engine at medium speeds and light loads. The ratio of gasoline and oil for Partner 350 chainsaws during break-in is 35 grams per 1 liter. After it, you need to dilute 20 grams of oil with one liter of gasoline. The break-in period for Partner 350 chainsaws should be 1.5-2 tanks.

Chain lubrication oil Oleo-Mac Polar Lube Oil for 2-stroke engines AL-KO

An important feature that determines the proper operation of Partner chainsaws is chain tension. You can do it yourself. Poor tension can cause the tire to fly off or be damaged. With excessive tension, the load on the motor increases, which subsequently wears out the saw faster.

The main aspect that determines the safety of working with a Partner chainsaw is the availability of protective clothing. Hands should be worn with gloves made of strong fabric. In general, pants with a special lining that will stop the movement of the saw during emergencies and the same jacket are perfect for the body. Shoes should be just as durable.

The main points related to using the Partner chainsaw can be found in the attached instructions.

It is strongly recommended that owners adhere to the following tips, which will make work much safer and more convenient:

- The saw should be kept as close to the body as possible - in this case, the hands will receive less load. This will also help you better maintain balance and control the process.

- When changing position, it is necessary to turn off the engine using the chain stop activator. Before performing a maneuver, you need to make sure that it does not rotate.

Also, it is necessary to comply with a number of felling safety requirements:

- It is necessary to determine the direction in which the tree will fall. It is necessary to take into account the direction of the wind, the slope of the soil, and the growth of the tree itself.

- The space around the tree must be cleared of bushes, undergrowth, and foreign objects. Clearing should be done at a 45 degree angle from the back and sides of the tree.

- A safe distance is considered to be two tree lengths. There should be no strangers in this gap.

Chainsaw Partner 350 oil pump repair. Oil pump repair and drive sprocket replacement

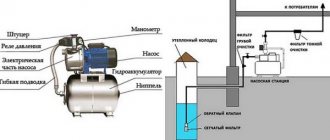

Repair of the oil pump on the Partner 350 chainsaw is necessary if the oil supply has completely or partially stopped. The oil pump mechanism includes the pump itself and a gear with a worm gear, which is driven by a sprocket connected to the clutch.

The most common problem with an oil pump is missing threads and splines on the gear or splines on the worm gear. The situation can be corrected by replacing the parts with new ones.

To remove the oil pump on the Partner 350, you need to remove the side cover and the chainsaw tire, then lock the piston and use a special wrench or a homemade wrench from the 24mm socket to unscrew the clutch.

The clutch has a high tension torque, so you need to use a wrench and turn it strictly clockwise. Do not try to unscrew the clutch with a hammer and chisel, this often leads to breakdown of the mechanism and also has a bad effect on the condition of the crankshaft bearings.

To replace the Partner 350 drive sprocket, you simply need to unscrew the clutch, remove the old part and install a new one. The sprocket is mounted on the shaft through a needle bearing. When replacing the sprocket, it must be checked for defects and lubricated. For lubrication, you can use regular Litol or any other that can withstand high speeds.

Basic equipment

In addition to the saw, the standard kit includes a chain, a bar, a set of special keys, and a tank for mixing gasoline and oil. Currently, the Husqvarna concern owns production facilities in several countries. Partner P350S chainsaws are manufactured in one of three factories in Sweden, four factories in the USA, Italy, China and Brazil.

Chainsaw Partner P350S: basic configuration

Naturally, the highest quality products are produced in Sweden, the USA, and Italy, and accordingly their cost is somewhat higher. Chinese assembly and components do not always correspond to European standards. However, according to reviews from owners, sometimes you come across specimens and individual batches of Partner chainsaws produced in China that are of fairly good quality.

You should carefully study the markings of the saw and decide what is more important for you: a budget price and assembly in China or an original unit from a famous brand.

To avoid falling for a good-looking fake with dubious characteristics, you should purchase equipment exclusively from reliable online stores from trusted dealers, and not second-hand from suspicious dealers. Today's prices for Partner chainsaws on the market fluctuate in the range of 7-9 thousand rubles.

Repair of chainsaw Partner 340. Repair and maintenance of chainsaw Partner P340S

I decided to work with a Partner 340 s chainsaw. About 20 days, 7-8 hours a day. The frosts were severe. There are no complaints about the starting and the engine, but the chain lubrication has disappeared. What to do? It is very likely that if the oil was thick, the oil pump drive was torn off. It’s as if there should be a weak point in the drive just in case - either a worm, or a gear on the plunger, but it’s not good to make it weak to such an extent. You need to remove the clutch, remove the pump and look. Or to the service. On the 3rd day of operation, the transmission mechanism failed, i.e. the motor is running, but the chain does not spin as at idle. What's the problem? Did some gear fly off? Saw Partner P340S, sawed wood. I took off the box and there was a drum under which the sprocket was hanging. Maybe marriage? I twist the chain by hand, the sprocket rotates, the inside is not movable, the drum itself is also not movable. In the assembled and wound up state and the brake is raised, the chain does not rotate either at low gas or at full throttle, there is no clutch. This means the sprocket has become unsoldered from the drum. Surely it’s a manufacturing defect, only the leading sprocket is classified as consumable by the manufacturers, many even clearly indicate this in the saw’s passport. The P340S model has this problem - I press the gas and it happens that there is a failure, as if there is not enough mixture, but the tank is full. The mixture was made 40:1, oil 2t, power active partner, pink, gasoline 92nd. The saw is new. I saw the board at low speeds and it might stall. And oil also leaks from the chain when it just sits unwound. The carburetor is most likely out of adjustment. Tell me about the Partner 340 S saw. It stopped starting completely. In use for a little over 2 years. At first it began to start intermittently, but it started every time. Now you can’t start it at all - the best you can do is pull the handle, start the engine for a couple of seconds and immediately stall, after which it won’t start. I changed the spark plug - there was almost no difference (the old one had a noticeably worse spark), except that it started catching at least for the first time. After you pull the winding handle several times, the spark plug becomes damp; after drying, you can only start it for 1-2 seconds, after which the spark plug floods again. I tried to bleed the carburetor, no change. What else can you see? Start by removing the muffler. It's quite simple there. In the outlet hole, inspect the condition of the piston. If you see longitudinal grooves, that's it - replace the piston.

Specifications

According to its data, Partner 350 belongs to the household (amateur) type and fully satisfies the needs of any consumer. To get a general overview of the chainsaw, just look at its main characteristics.

Characteristics of Partner 350

For those familiar with chainsaws, one glance is enough to determine the character of the 350 Partner. A fairly powerful engine and a decent length of tires mean that this will be an indispensable assistant on the farm, but it’s hardly suitable for professional felling.

Assembling the Partner 350 chainsaw. Characteristics of the Partner 350 chainsaw

This model is in considerable demand among consumers, but most often it is bought by summer residents for work on their plots. The saw is used not only for preparing firewood, but also in construction.

In general, Partner 350 chainsaws are distinguished by their compact size. They are equipped with a fairly powerful engine. Their main advantages are easy starting and reliable operation. performed by a high-quality electronic ignition system and fuel pump.

This chainsaw is completely safe to use. It has a built-in protective system that automatically triggers the inertial brake for the chain. In the same mode, its lubrication is carried out.

There will be no problems starting the Partner chainsaw even in winter, since it has a fuel primer. The starter drum is equipped with an impeller that helps clear dirt. In addition, the manufacturers have equipped the tool with the CCS system. This design traps residual particles and is also used when using the air filter for a long time.

To increase the service life of the chainsaw, the developers made chrome-plated walls on the piston group cylinder. This model also has an ergonomically shaped handle and an anti-vibration system.

Modifications of the Partner 350 model

The Partner model range is represented by the following modifications, each of them will be considered separately:

Chainsaw Partner P350S

- Partner to the P350S: A 2 HP/140 W motor drives a 3.8-inch pitch chain moving at 22 meters per second, tensioned on a 400 mm long bar - these parameters significantly increase productivity, making this model stand out among analog. The fuel tank capacity is 250 ml. The Partner P350S model uses new approaches to user safety: an inertial chain stopper, blocking using a special switch, a chain catcher, which allows it to be braked in different ways. The design also incorporates a fuel pump that also removes remaining air and fuel from the carburetor for easier starting.

Chainsaw Partner P350 XT CHROME

- Partner 350 XT CHROME: the chainsaw is equipped with an engine with a power of 1.3 hp\1300 W, which is excellent for carrying out work of medium complexity. High performance is ensured by a chain with a tooth pitch of 3.8 inches and a bar length of 400 millimeters. The fuel tank capacity is 400 milliliters - this guarantees a long operating time. Elements that optimize the operation of the chainsaw include a vibration damping system, which is achieved by using durable steel springs. Safety is ensured by a double brake system.

Chainsaw Partner 350 Chrome

- Partner 350 Chrome: has a motor with a power of 1.9 hp\1300 W. The bar length is 400 mm, the chain pitch is 0.325 inches. This significantly increases the performance of the chainsaw. The fuel tank capacity is 400 ml. The model is highly wear-resistant due to its chrome plating. Safety is ensured by an inertia-type chain stopper.

Disadvantages of a chainsaw

The chainsaw has its disadvantages, but compared to the advantages they do not look so significant. The disadvantages of the product include the following:

- Difficult access to the air filter.

- There is no visual control of the lubricant level.

- If you install a long tire, you may notice low engine power. But this phenomenon is considered natural. The longer the tire, the less engine power.

Sometimes chainsaw users report poor performance of the unit. In this case, it is worth considering whether a double violation has been committed - ignoring the requirements of the chainsaw operating instructions and placing additional load on the engine of the unit.

User manual

The instructions contain recommendations that, if followed, the owner of the Partner 350 chainsaw will not encounter problems when handling it. Safety measures and rules for operating the product during operation are described in detail. The issues of repair, maintenance and care of the Partner 350 chainsaw are covered.

The types of chainsaw repairs that you are allowed to do yourself are determined by the operating instructions. All other faults are repaired in a specialized workshop.

Partner 350 manual

The instruction manual should always be at hand, especially if this is your first chainsaw and you just bought it. First of all, be sure to read it, and resort to its help when questions arise while handling the instrument. You can download and print the operating instructions for the Partner 350 chainsaw using the link below.

How to prepare a chainsaw for work?

Before you start working with a chainsaw, you need to make some settings on the unit. A properly prepared device will never cause any complaints from users. Setting up a chainsaw is quite simple. Before starting the tool motor you need to check:

- serviceability of the brake;

- chain tension and ease of rotation;

- presence of oil and fuel in the unit;

- tire mount.

After the check, you need to start the engine. Warm it up well and feel free to get to work.

Advantages of a chainsaw

Like any other product, a chainsaw has its advantages and disadvantages. First, let's talk about the advantages of the device:

- The unit is produced at the plant of a well-known manufacturer. This can only speak about the quality of the chainsaw and the developed product maintenance service.

- The chainsaw engine is equipped with a primer, which makes starting the unit easier. In the cold season, primer is an indispensable element of a chainsaw.

- The engine cylinder and piston are treated with chrome. This is done in order to improve the performance of the product and extend the service life of the chainsaw as a whole.

- The chainsaw is lightweight and has a short bar - this makes working with the device much easier.