Features of contact spot welding

This type of welding is considered thermomechanical. It is used if you need to solder thin metal sheets or homogeneous small elements together.

The photo of spot welding clearly shows its key phases:

- combining elements in the desired position;

- securing them between the electrode contacts of the unit;

- heating leading to the formation of a strong weld.

This method of connecting parts realized in metal to each other is very popular. Its advantages are as follows:

- ease of the process;

- low cost of consumables;

- high performance.

Basic functional principle

The spot welding scheme is simple. First, the metal products are pressed tightly against each other. Then, at short intervals, a current is supplied to them, which heats the metal and starts the diffusion process.

As soon as the device is turned off, the electrode contact area begins to cool and the material begins to crystallize.

Structural design of the welding unit

The pictures of spot welding show that its structural design is represented by three blocks (two main and one auxiliary). The mechanical unit includes:

- electrodes in the form of clamping pliers;

- clamping mechanism;

- rotation drive (in suture equipment);

- compression and upset mechanism (in butt welding).

Key elements of the electrical unit:

- transformer device;

- output voltage regulator;

- secondary contour unit;

- primary circuit breaker;

- cycle regulator.

The auxiliary unit contains water cooling and pneumatic hydraulic systems.

Note!

DIY induction heater ♨️ - reviews of the best manufacturing options. Varieties of homemade device designs + step-by-step master class (160 photos)

Do-it-yourself Gauss cannon: TOP-130 photos of the best ways to create it yourself. Design features + master class for beginners

DIY clamps - a step-by-step master class for beginners. Schemes for manufacturing different designs + 170 photos

To obtain a discharge of the required power at a low voltage, an induction transformer is required. A correctly selected balance of windings will provide the powerful impulse necessary for melting the metal in the contact zone of the electrodes.

The clamping pliers in a do-it-yourself spot welding machine look like two contacts made of graphite or copper. They are mounted on various levers and driven by a compression mechanism, the drive of which can be:

- mechanical;

- pneumatic;

- hydraulic;

- electromagnetic.

How to protect yourself

When working with a spot welder, it is very important to adhere to safety regulations. Incorrect or careless use of this device may result in electric shock, varying degrees of burns, and all kinds of injury.

The first thing you need to think about when creating an artificial welding machine with your own hands is grounding. The greatest danger is posed by the transformer itself - its primary winding. When working with secondary, you also need to be extremely careful. All these measures apply to working with an inverter.

It is necessary to ensure that the person operating the device has quick access to the shutdown mechanisms. All floor coverings near the appliance must be completely dry. You will also need a rubber mat (especially if the device is installed on the floor).

Among other things, it is advisable to stock up on special work clothes and ventilate the room well before using a homemade spot welding machine.

Author: Baranov Vitaly Petrovich

Education: secondary specialized. Specialty: car mechanic. Professional diagnostics, repair, maintenance of passenger cars of foreign production 2000-2015. Extensive experience working with Japanese and German cars.

2 comments

- Dmitry says:

How possible is DIY spot welding at home? What does she need?Expert says:

Good afternoon. The technology of this process makes it possible to organize it in a home garage - many car enthusiasts already have successful experience in this area. The process is carried out as follows: • The surfaces to be joined are first cleaned of pockets of corrosion and other foreign substances; • They are placed in the desired position and placed between the electrodes, pressing them against each other; • Due to the supply of a welding current pulse, the surfaces are heated and their joint temperature deformation occurs, which leads to welding. The advantages of spot welding include the cost-effectiveness of the process and the strength of the seams, while the disadvantages include the lack of tightness. To perform such work, you will need the appropriate equipment - there are many schemes on the Internet according to which you can assemble it yourself.

Required inventory

To get a compact welding tool, you will need a number of things:

- transformer device of an unnecessary microwave oven;

- terminal block;

- copper rod 0.17 cm thick;

- a piece of 8 mm multi-core cable;

- timer mechanism;

- adapter for 12 volts and 0.5 amperes;

- PSU case from an old computer;

- switch;

- micro button;

- lath (made of wood);

- steel spring.

Operating procedure

Below are instructions on how to make spot welding using a microwave you don’t need in your household:

Disassemble the old microwave oven. Pull out the 800 A transformer device. Disassemble the computer power supply. You only need a steel case and a 220 volt power connector. In the future, it will be used to accommodate the “filling” of the welding unit.

Note!

Do-it-yourself electric scooter - a master class with step-by-step instructions for doing it yourself. Tips and simple patterns for beginners + the best photo reviews

DIY rocking chair: TOP-120 photos of the best manufacturing options. Master class on creating a rocking chair at home

Smokehouse from a gas cylinder - the best master class on making a homemade smokehouse with step-by-step photo diagrams for beginners

Place the transformer, timer board and power adapter inside the case. Try on and mark the locations of the holes - then you will need to make them using a drill.

Remove the secondary winding of the transformer, replacing it with a power cable. In this case, there is no need to dismantle the transformer plates. It is enough to cut off the winding first from one edge, then from the other, using a chisel and hammer. After this, all that remains is to remove the remaining wire with a drill.

Make new windings from the power cable. Place the modified transformer in the housing. Drill 2 holes in the area where the grill is located. Pass the coil leads through them. Make more holes, now in the bottom of the body, to install the trans.

Connect the timer mechanism to the front panel. Insert the LED, soldered from the board and extended with wires, into the hole made earlier.

Attach the power switch to the rear panel. Cut off the plug from the adapter. Solder all the elements of the future device using wires and terminals. Connect a microbutton to the timer - there is no need to fix it. Set the pulse duration for welding.

Use steel corners to attach a wooden strip to the body of the welding machine.

Note!

Do-it-yourself compressor: TOP-130 photo reviews of finished compressors. Step-by-step instructions + diagrams and drawings

Do-it-yourself wind generator: TOP-170 photo reviews of finished devices. Detailed DIY instructions for beginners

Do-it-yourself tennis table: TOP-150 photos of the best manufacturing ideas. Master class on creating a tennis table at home

Remove the terminal strips from the terminal block, put them on the cable contacts that need to be cleaned beforehand, and screw them to the rail. Equip the rail with a start button, having previously made a hole for it.

Use copper wire to create electrodes. Don't forget to sharpen the ends. Secure the electrodes made of copper into the terminal blocks.

Supplement the design with a spring to return the device contacts to their original position. For this purpose, you need to screw another wooden strip to the top of the case. That's all. Work on creating a homemade spot welding unit has been completed.

The resulting tool has quite high power. Therefore, in order to avoid burning holes in thin metal sheets, it is recommended to set lower time parameters on the timer. In addition, the compact dimensions of such welding allow it to be placed even in a small studio.

Inverter spot welding machine

This device is assembled on the basis of pulse circuits and allows spot welding even when powered from low-voltage sources such as batteries.

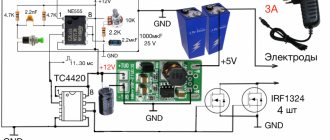

Diagram and necessary elements

The circuit of this device is an inverter that converts direct voltage into high-frequency oscillations with a frequency of 30-50 kHz.

To convert direct voltage into alternating voltage, a push-pull generator with powerful field-effect transistors is used. Transistors must pass a current of at least 40 A and have an allowable operating voltage of at least 50 V.

The oscillatory circuit of the generator is determined by the inductance of the primary winding of the transformer and a capacitor, the capacitance of which should not exceed 2 μF. In principle, the capacitance can be increased, but then the generator will operate at lower (audio) frequencies, causing the transformer to emit a whistle.

Algorithm for creating the device:

- A pulse transformer is made from the power transformer of the ATX 450 computer power supply.

- All windings are removed from the transformer and the primary winding is wound with a bundle of 3 wires with a diameter of 1 mm.

- 1 turn of the secondary winding is wound on top of the primary winding , which is a copper tape 22 mm wide and 1 mm thick.

- The secondary winding is fixed in the transformer with epoxy glue, and brass terminals are soldered onto its ends . Pieces of copper wire with a diameter of 2 mm are inserted and fixed into the terminals, which will act as electrodes.

- The inductor used in the circuit is made on a toroidal core and has from 10 to 30 turns of wire with a diameter of 1.5 mm.

- Transistor switches are mounted on small radiators.

- All elements are installed on a board made of insulating material and connected by soldering using wires in accordance with the device diagram.

- From above, the electrical circuit is covered with a housing made of insulating material.

- The control button is installed in a convenient place.

Advantages and disadvantages of the design

Advantages:

- Fairly high output power , allowing welding of batteries and other larger parts.

- The circuit can be powered from a DC source with voltage from 6 to 24 V.

- You can use either a mains power source (for example, a computer power supply) or a powerful battery.

- Light weight and dimensions.

- Low cost.

Flaws:

- Power must be supplied only from powerful sources . If the power supply current drops, malfunctions may appear in the device.

- When welding, it is necessary to perform the correct operating mode . After two seconds of welding, take a break for 2-3 seconds.

Spot welding from hand-assembled welding equipment

The algorithm for creating a unit for spot welding from a welding tool, as well as the materials required for this, are almost the same as in the case of a transformer from a microwave oven. But there are a number of points.

Creating resistance welding from an inverter device with your own hands is irrational, because direct current is not needed for operation. As a result, we opt for a transformer device from an alternating current device.

The number of turns is calculated using the following formula:

N=50/S. Here N is the number of turns, and S is the core size.

Handmade welding pliers

The pliers are an important part of the welding machine. Their design solution depends on what work is planned to be carried out, the expected dimensions of the elements to be connected and the type of drive. The electrodes are made of copper wire, the thickness of which must be equal to or greater than the thickness of the secondary winding cable.

Contactor from a welding transformer

Such equipment can be turned into a full-fledged resistance welding tool. The only drawback is the inability to control the current strength.

Drawing development

The correct choice of circuit helps to produce a working welding machine. Preference is given to simple drawings that include a minimum number of parts and blocks. Such options do not allow you to create an overly powerful device, but the device is sufficient to perform minor repairs on a car, garden equipment, and fences.

We recommend reading Description of resistance spot welding technology

List of parts and consumables

To convert a welding transformer into resistance welding equipment, you will need the following elements and materials:

- a transformer that converts electrical energy;

- thick cable;

- copper electrodes;

- bolts;

- tips;

- breaker;

- wooden blocks, plywood to create the body.

The process of creating a device

The homemade device is assembled as follows:

- The welding transformer is installed in a housing made of metal sheets. The electrical board is assembled on a textolite sheet more than 1 cm thick. The part is fixed in the body of the welding machine.

- A welding wire is bolted to the busbar and secondary winding. The remaining end of the cable is connected to the electrode.

- The power wire is connected to the contact block located on the electrical board.

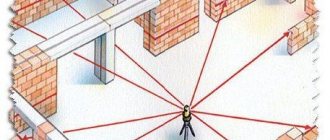

Spot Welding Operation

A master using a contact transformer apparatus must stand on a rubber mat and use protective gloves and goggles. The grounding cable is connected to the part to which another workpiece will be welded. After this, press the power key, compare the elements to be connected, and clamp with the electrode of the welding gun.

5 seconds after the start of the impact, the rod is transferred to the next point.

Welding nuances for lithium batteries

Often, craftsmen are faced with the need to attach a thin steel plate to lithium-ion batteries. And for 18650 batteries, elevated temperatures are terrible.

The solution to the problem is self-made special spot welding. Its specificity is the automatic control of the progress of work.

Basic DIY spot welding parts for batteries:

- modified microwave oven transformer;

- primary winding control board;

- auxiliary power supply;

- incoming circuit with fuse;

- microswitch;

- secondary winding wires with electrodes made from electric soldering iron tips.

Now let's look at how to make spot welding with your own hands for lithium batteries:

- Having stocked up with the necessary components, place the knobs that regulate the pulse time and power of the welding machine itself on the body.

- Install a switch from an old microwave oven.

- Take a steel plate and a lithium battery. Set the electric pulse time to 8-11 μs.

- Place the plate on the battery and place the contacts on top. The device is ready!

Transformer manufacturing

Figure No. 1 schematically shows the possible ratio of turns of the primary and secondary windings of the transformer necessary for resistance welding. A large number of outputs on the secondary winding is necessary in order to be able to roughly adjust the current parameters. But the presented circuit requires adjustment depending on the required current parameters. You can't do without preliminary calculations.

Where is spot welding used?

Spot welding is used if it is necessary to manufacture any metal structure. Advantages of this technology:

- environmental Safety;

- high strength characteristics of the connection;

- speed and ease of work automation.

Due to the above advantages, spot welding is used:

- in the automotive industry;

- in shipbuilding;

- in the aviation industry;

- in the production of electronic products and household appliances;

- when creating jewelry;

- at enterprises producing consumer goods, etc.

The power parameters and capabilities of manually made resistance type welding cannot be compared with the performance of a factory-assembled machine. Despite this, it can be used for welding metals of all types of steel and alloys.

Microwelding: nuances of creation and use

Having decided to make spot welding in artisanal conditions, you need to remember a number of nuances of its application:

- Before starting the device for the first time, you need to check the reliability of the insulation and connections of all parts of the structure.

- It is required to organize an auxiliary ventilation system.

- Do not use the device for a long time without breaks.

- Electrode tips must be sharpened regularly.

- Before starting work, it is worth performing a test run at low power.

Any craftsman can assemble spot welding with his own hands. You only need to have a minimum of knowledge in the field of electrical engineering. Making your own welding machine is much more profitable and fun than buying an industrial tool.

This equipment will invariably come in handy in a garage hangar, as well as for those who make jewelry or repair electronics.

Specifications

| Welding type | thermal contact |

| Diameter of wire used | 15-100 microns |

| Material of wire or tape used | gold, copper |

| Tool type | split electrode EK1-EK5; indirect heating electrode |

| Vertical tool movement | 7 mm |

| Adjusting the stage height | 27 mm |

| Working field diameter | up to ∅460 mm (with additional equipment) |

| Manipulator stroke (precision XY movement) | 28 x 28 mm |

| XY movement range of the manipulator | 120 x 120 mm |

| Tool penetration depth (without clamping jaws) | up to 40 mm |

| Compression force of welded elements | 20-700 grams / 0.2-7.0 H [electronic adjustment range: 100 grams / 1 H] |

| Tool loading method | spring + electronic |

| Non-destructive testing force range | 0 - 5 grams |

| Control type | mouse |

| Kinematic performance | 7200 welding points per hour |

| Welding pulse duration | 0.02 - 1 sec |

| Operating frequency of welding pulse | 1 kHz |

| Loop length | automatic mode: up to 5 mm; manual mode: unlimited |

| Heating table temperature | 20-200 ºС |

| Tool angle | will change automatically |

| Stitch formation | automatic |

| Maximum power consumption, W | 150 |

| Supply voltage (AC) | ~(180 – 264) V / ~(90 – 132) V, 47–63 Hz |

| Supply voltage (DC) | 254 – 373 V |

| Weight | 18 kg |

| Overall dimensions, length x width x height: | 400 x 310 x 360 mm |