A lifting hoist, also called a hoist, can be manual or electrically driven for automated use. According to technical characteristics, the equipment is a mechanism for lifting and moving various loads, including car parts.

The mobile trolley can be placed in any room, regardless of the available space and ceiling height. Depending on the type of design, the load capacity can reach 10 tons. A standard hoist is capable of lifting loads to a height of up to 12 m . The structure consists of the following elements:

- chain hoist, consisting of several blocks connected to each other;

- cylindrical coaxial gearbox;

- disc braking system;

- output shaft;

- hanger with hook.

Hoists are mechanical devices designed to lift, lower, drag and move loads. Unlike a crane, which has the ability to work in three directions, independent hoists are limited by two degrees of freedom and, accordingly, lift and move the load in only two planes

The main types of hoists according to the principle of lifting loads:

- electric hoists;

- manual hoists.

The main types of hoists based on the principle of moving loads along a T-beam, an I-beam or a monorail:

- stationary;

- mobile.

To implement the last type of hoists, carriages are needed, or as they are popularly called - hanging cats for hanging the hoist. A hoist carriage is a manual mechanism with wheels for moving hoists. The device for moving the hoist is compact and dismountable, which makes it possible to easily remove it and install it in another designated place. The cargo trolley for the hoist is produced in several versions:

- without drive (idle)

- with manual chain drive (drive)

- with electric drive (telpher)

The idle hoist trolley is more suitable for cases where the suspension height is relatively small and the suspended load is no more than 1-2 tons. The carriage moves without a drive by pushing it by the operator or by pulling it by a suspended hoist. Due to the operating principle, it is not convenient to move the idle trolley with a suspended load of more than 2 tons. Carriages without a drive are popular where a load capacity of 1t - 2t is required. The second type of hoist crampons is more popular, versatile and practical.

Manual carriage

The drive mechanisms for moving the hoist along the beam have a design similar to the idle trolley, but also have a chain drive for moving the trolley using a remotely located operator. The length of the drive chain must correspond to the reach height, or be calculated according to the principle: the distance from the floor to the suspended support beam minus one meter. To operate the drive carriage, one person (operator) is sufficient to operate the drive mechanism of the carriage using a drive chain. Chain-driven trolleys for hoists are practically necessary mechanisms.

the only one in Ukraine that offers a large selection of moving hoists, both with and without drive, from trusted manufacturers with a quality guarantee, at a low cost, which will pleasantly surprise every buyer. Without an idle or driven carriage, it is impossible to move the hoist along an I-beam or monorail. You can also use a hoist with drives. This will ensure faster lifting and movement of loads, but their price and dimensions are significantly higher than those of cats. Moreover, the drive carriages of the hoist do not require electricity, special adjustments or adjustments to be put into operation.

The range of load capacity of cargo trolleys for moving hoists with a drive is in the range of 1 - 10 tons, the length of the drive is from 1 to 12 meters.

Tools and materials

To create this mechanism in the garage, you will need the following tools and materials.

- Rolled metal – angle, channel, I-beam.

- Bearings of different sizes.

- Welding machine with electrodes.

- "Bulgarian".

- Drill or drilling machine.

- Actuating mechanism – hoist, hoist.

- Marking tool (ruler or caliper, tape measure, chalk or marker)

- Bolts, washers, nuts.

The length of the rolled metal is selected based on the size of the room, and its grade is determined from the calculations given below. Bearings can be taken in any suitable size. The quantity is selected according to the principle: 4 pcs. for one slide, 4 pcs. – for the second, plus 4 pcs. for the carriage (lift body). Total: 12 pieces. The bearings for the slide must be the same size; the carriage can be fitted with bearings of the same size or one size larger or smaller. Bolts for fastening must be selected with large metric threads. The actuator is selected according to its maximum load capacity and design loads.

Where is it used?

Initially, hoists were used in production and warehouse facilities. Later they found wide application in auto repair shops and loading and unloading areas.

Over time, hoists have not lost their relevance - on the contrary, they have become even more in demand.

They are widely used in garages and home workshops, as well as on construction sites.

Among the main advantages of a manual hoist, it is worth noting its compact size, light weight and good load capacity.

Telpher device

Schematic electrical diagrams of the hoist can be found here

The mechanical equipment of an electric hoist includes such important structural elements and assembly units as a lifting drum, gearbox, coupling, hook suspension, trolley, and cargo rope.

Lifting motor

In Bulgarian hoists of the T, MT, MN series, engines of the KG series are used.

Asynchronous two-speed electric motor with cone rotor and stator and built-in asbestos-free cone brake. The rotor has the ability to move with less resistance in the axial direction. In the event of a power failure, the brake is activated by the force of the coil spring. A wide range of possible combinations between motors and gearboxes with different technical characteristics expand the range of lifting loads and lifting speeds. Additionally, hoists are supplied with two-speed motors - having two stator windings (for operating speed and for precise positioning of the load). Another delivery option is with frequency converters for the smoothest possible starting and braking of drives.

Gearbox

Two-stage planetary gearbox installed on the opposite side of the electric motor. This design is preferred due to the need to ensure compactness of the hoist in the radial direction. Three stages of the gearbox provide reduction (reduction) of engine speed, as well as smooth starting and braking. High-quality materials are used for the manufacture of gears and other gear elements. The surfaces of the gear teeth are carburized and hardened, followed by grinding, which ensures a long service life and silent operation of the gears with high gear efficiency. An extended kinematic chain for transmitting engine torque to the drum reduces dynamic loads when operating an electric hoist.

Frame

The new body is box-shaped. It is a tightly welded flange-type connection between the engine and the gearbox. The rope output in all possible radial directions along the periphery of the housing ensures the operation of the electric hoist in a variety of mounting options and positions.

Elastic coupling

A special gearbox coupling is used, located inside the drum between the motor shaft and the gearbox shaft. The elastic package absorbs peak torque components. The design of the coupling ensures unhindered axial movement of the electric motor shaft. At the same time, it protects the shafts from any radial or tangential movements. This specificity is due to the fact that the rotor of the lifting electric motor is conical. When the drive is turned on, such a rotor extends along the axis, disengaging from the stator, and when turned off, it retracts back. Thus, the engine itself is able to brake the drive during a stop, that is, it has a built-in brake. The kinematic connection between the gearbox and the electric motor is unbreakable.

Drum

The lifting drum is a cylindrical hollow structure designed for winding a cargo rope. The surface of the drum is covered with special grooves - “streams”, thanks to which the cargo rope is wound in even rows, without overlaps or creases. Along with the rope, the rope layer also moves on the drum - a device necessary not so much for laying the rope in streams, but for turning on and off the limit switches for over-lifting and over-lowering.

Screw channels for the rope are made along the surface of the drum. A special rope wrap moves in these channels and ensures correct winding and unwinding of the rope, regardless of the size of the suspended load. The drum has two diaphragms. One of them is mounted on the front flange of the electric motor using a roller bearing. The torque from the outgoing hollow shaft of the gearbox is transmitted to the second diaphragm through a splined connection.

Gear manual hoists – is their popularity justified?

The main advantage of this type of hoists is considered to be simplicity of design and reliability. Many industries cannot do without them: neither in the construction, nor in the mining industry, nor in agriculture, nor in fuel and energy enterprises and others. Such a device can be used not only indoors, but also outdoors, even if there are no power sources. Moreover, such hoists are not only safe to use, but also unpretentious to use and have a durable mechanism.

Main characteristics

Main technical parameters of lifting equipment:

Jib crane - dimensions

- classification according to GOST 25546 - 2K, according to ISO 4301/1 - A2;

- execution – U, HL, UHL;

- placement according to standard 15150 – 1, 2, 3, 4;

- device rotation drive and control – manual;

- hoist control – manual, electric remote control;

- control position – from the floor;

- electrical wire – cable connection;

- load mass during testing – 1.25 for static testing, 1.1 for dynamic testing.

The last paragraph indicates a portion of the rated load capacity indicated in the passport.

Related video: Jib crane

Jib crane

Worm worm hoists - a compact strongman

In addition to these main types of manual hoists, there are also others. Lately, worm gear hoists are often used. To operate, they are hung stationary or a mobile “cat” is used. This is convenient for moving loads horizontally; such hoists can move along I-beams. There are a lot of models of this type of device. They are used for lifting or holding loads in a raised position; they are also suitable for moving. Everything happens along a special suspended track made of I-beam profile.

Their advantage is that work can be performed in small spaces, and the distance between beams and loads can be insignificant. Such hoists can also be used for work outdoors.

They have some features, for example, a rotating casing (and the design can rotate all 360 degrees) allows you to control work from anywhere, that is, you can raise and lower the load in any position. This creates additional safety; during operation, the operator can be located on the side of the hoists and also from the load itself. This type of hoist is also distinguished by its reliability, wear resistance and low-heating brake. All this makes them quiet and comfortable. And thanks to the low building height, you can work with this equipment in confined spaces in vertical positions.

Manual chain hoists, their fastening mechanisms

What types of manual hoists are there? What are their features and differences?

Manual lifting hoists are classified as small-scale mechanization equipment. Such hoists can be divided into two main groups: chain gear and chain lever.

Manual gear hoists

, as a rule, are suspended at a certain distance from the ground, controlled from the floor by alternating manual operation of the drive chain and serve mainly for lifting loads to a height.

Lever hoists

controlled directly by a lever built into the hoist body. This design obliges the operator to be close to the hoist, which is the main difference between these types. As a rule, lever hoists are used for horizontal movement (pulling) of loads, as well as for lifting/lowering loads from/to depth.

Both types of hoists have their own specifications for working loads and can be equipped with chains of various lengths.

Is it possible to replace the chain on the hoist?

Yes, sure. As a rule, replacing the chain is required in cases where it is necessary to increase the lifting height of the hoist. Simultaneously with installing another section of the lifting chain into the hoist, in gear hoists it is also necessary to replace the drive chain of the appropriate length. Replacing chains due to wear or breakage is extremely rare. SKIF INVEST LLC has in stock the entire range of G80 class chains used in lifting hoists. We offer our customers hoists with almost any lifting height.

Will the load fall off the hoist if the lift is stopped?

No, the load will not fall. Hoists of all types are equipped with a mechanism for fixing and holding the load (brake system), which reliably holds the suspended load. To prevent a sudden drop of the load, the brake release and free (idle) downward movement are not provided for by the design for obvious reasons.

Why doesn’t my lever hoist with a lifting capacity of 1500 kg lift a load weighing 20 kg?

You can get an answer from SKIF INVEST LLC from our managers

(056) 409 – 49 – 14; (056) 409 – 49 — 02

What is the safety margin of the hoists and what warranty periods do you provide?

All models of hoists, regardless of their structural differences and passport characteristics, have a safety margin 2:1

.

compulsorily carries out pre-sale preparation of hoists, checks their completeness and functionality of the mechanisms. We provide small mechanization equipment with a product passport describing the technical characteristics and operating principle, include a copy of the UKRSEPRO certificate of conformity, and also provide a guarantee of uninterrupted operation for 12 months from the date of purchase.

What lifting capacity do I need a hoist if I will lift a load of 850 kg?

This is a really important question. I would like to dwell on it in more detail. All small-scale mechanization equipment has passport characteristics of lifting capacity: 1,0

ton,

2.0

tons, etc.

Please note that this indicator is the maximum permissible or critical

. For example, a passenger car also has a maximum speed of 200 km/h according to its passport. How long do you think such a car will last if you constantly drive it at a speed of 170 km/h? We think the answer is obvious. In fact, cars don't break down so quickly for the sole reason that they are not used to their maximum potential. 95% of the operating period is spent on normal, quiet driving around the city in a conditionally average range of technical characteristics.

How to make a manual gear hoist for a workshop

This design is a little similar to the previous version, but there are some differences. For example, this gear hoist uses a drum brake from a moped.

To make a gear hoist for working in the garage with your own hands, you will need the following basic materials:

- two gears (large and small);

- bicycle wheel hub;

- sheet metal;

- threaded rod;

- round steel bar;

- a cable of suitable thickness with a lifting hook.

During the work we will use a grinder with a cutting disc, a drill, and a welding machine. You will also need hand tools, which everyone has in their workshop.

Let's get to work. We disassemble the bicycle wheel hub. In principle, you can use a piece of round steel pipe of suitable diameter instead.

We cut out two disks from sheet metal and drill holes in them. We put the discs on the bushing (or a piece of pipe) and scald them. As a result, we have a reel for winding the cable.

We insert bearings into the coil, through which we thread a threaded rod. A large gear is attached to one side.

On the other hand, the inner part of the drum brake from the moped is put on the stud. We assemble a mechanism that is used as a brake when lowering a load.

We make the hoist body from sheet metal. Using a grinder, you need to cut grooves on the sides to fit the shaft on which the coil is located.

Additionally, we drill holes for the drive shaft, for which we use a piece of round rod. We make a small gear (or you can rummage through spare parts and pick up a ready-made sprocket).

We put the gear on the shaft and weld it. Then we install the shaft inside the housing. We connect the large and small gears with a chain.

At the last stage, all that remains is to make a handle, which we attach to the drive shaft. For details on how to make a hoist with your own hands, see the author's video.

Comments

For especially large standard sizes, with a lifting capacity of more than 3 tons, the chassis is installed on two support trolleys, which turns the electric hoist into a mini-bridge crane or beam crane. Until the beginning of the 1920s, the Soviet Union produced a large amount of material handling equipment, but the demand for this equipment always exceeded production. The transmission of motion from shaft 3 to the wheel and drums is carried out using keys. The disadvantages include difficult operation in a limited space. Electrical diagram of the hoist You can check with our specialists for information about discounts, current prices and availability of products in stock by calling or sending a request by e-mail: info krantali.

It is important that the clamps 5 have no sharp edges that could rub the cable.

The moving link in which the satellite axes are located is called the carrier. Connecting electric hoist B Connecting electric hoist Work on connecting electric hoist B in accordance with technical requirements can only be carried out by specially trained specialists.

It is a mistake to assume that by increasing this parameter the performance of the hoist will improve: at the same time, the inertial components of the force also increase, which lead to unwanted swinging of the load. Fuses F1, F2, F3 protect the transformer windings. The gear drives of the gearbox are lubricated with liquid lubricant from an oil bath.

Hoist connection diagram Regardless of whether you want to connect a single-phase hoist without a contactor, or any other model, the diagram is located on the side cover of the electrical panel. The gear drives of the gearbox are lubricated with liquid lubricant from an oil bath.

Classification Can be performed according to the following parameters: Constructive. Typically, in this case, a double chain hoist is used, section A-A, Fig. This is explained by the fact that its use is not limited to the workshops of factories and factories. You should not purchase hoists that do not have a connection diagram.

Housing The new housing is box-shaped. To ensure work safety, hoists are equipped with appropriate devices, most of which operate automatically. The design of the coupling ensures unhindered axial movement of the electric motor shaft. Typically, in this case, a double chain hoist is used, section A-A, Fig. The starters are mounted on a DIN rail, but they are not available when controlling frequency converters. Electric hoist RA (electric hoist): unpacking, connection and first start-up

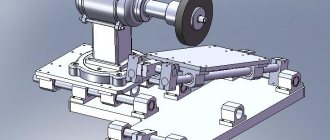

How to make a beam trolley for a hoist

In order for a manual hoist to move in a horizontal plane, it is necessary to make a beam trolley (or carriage) for it.

Materials that will be required to make homemade products:

- sheet metal;

- corner;

- timing belt rollers;

- guide rollers;

- fasteners (bolts, nuts).

First of all, we cut out four identical plates from sheet metal 5 mm thick.

After that, we drill holes in them and weld them in pairs - we get two blanks 10 mm thick.

We give the blanks the required shape using a grinder. We weld one elongated nut along the edges of each part - for bolts with guide rollers.

We weld a support shelf from a piece of angle to one of the parts. We clean the welds with a grinder, after which you can paint them.

At the last stage, we begin assembling the carriage for the hoist. We attach rollers for the timing belt and guide rollers to the metal plates.

We connect both parts of the beam trolley body together. We proceed to install the trolley to the beam.

In this case, an I-beam is used as a cantilever beam.

Then all that remains is to attach the hoist to the trolley, and you can use it. As you can see, making such a design is not difficult.

The step-by-step process of manufacturing and assembling the carriage can be seen in the video below.

How to choose an electric hoist?

Telpher (also known as electric hoist / electric hoist / electric hoist) is an electrically driven device for lifting and moving loads. It can work both as part of cranes and as a separate mechanism.

Application area:

- production of various types,

- warehouses and sites,

- premises for repair of equipment and machines,

- for construction and installation work in buildings and outdoors,

- auto repair shops,

- and other premises where there is a need to lift and move heavy loads.

To select a hoist yourself or with the help of a specialist (better), you need to know:

- maximum weight of the load being lifted;

- lifting height (from the floor to the top point of the hook). In this case, you need to make sure that the dimensions of the hoist will allow you to lift the load to the required height;

- operating mode (number of operating hours per day, number of cycles per hour);

- execution (general industrial, fireproof, explosion-proof);

- ambient temperature;

- other requirements based on the type of work (micro speeds, additional brake, etc.).

All hoists are manufactured in accordance with existing GOSTs and standards, and are tested and certified.

According to GOST 12971 , a plate is attached to a hoist of any type, which contains information about the following parameters:

- serial number according to the manufacturer's numbering system;

- operating voltage;

- symbol;

- name or trademark of the manufacturer;

- month and year of issue;

- rated load capacity;

- work classification (mode) group;

- lifting range.

How to make a homemade manual hoist: step-by-step instructions

When making a manual hoist yourself, just follow the step-by-step instructions. Equipment can be crafted by following these steps:

- Weld the faucet legs to the I-pipe.

- Position the metal corners at 45 degrees to create stiffening ribs that secure the rack. The bulk of the load being lifted falls on this rack, so for additional reliability, spacers need to be welded to it.

- If the hoist is mobile, rollers must be welded on each stand.

- Fix a pipe on the garage ceiling along which the lifting mechanism will move.

- Weld an I-beam in the center of the pipe to secure the roller mechanism.

- Insert the frame crossbar into the pipe.

- Drill through holes on both sides of the holder and fix the lifting mechanism.

Tools and materials

To build a hoist, you must first prepare a set of tools and components. In particular, to create a hoist you will need:

- an I-beam with a length of about 4-4.5 m (the exact length depends on the height of the ceiling in the garage);

- square pipe with dimensions 10x10 cm, 2 pipes with a diameter of 10-12 cm and a length of 2.5 m;

- Bulgarian;

- metal corners 10x10 cm;

- M16 bolts with nuts;

- lifting mechanism.

If you plan to install a mobile hoist, you will additionally need to use 4 rollers. The components are used to move the trolley.

Mounting nodes

One of the important stages in the construction of a mobile structure is the installation of components. First, you need to drill holes in the racks through which a rod with threads at the ends will be pulled. Washers are attached to the base of the rod and nuts are screwed on to limit the divergence of the posts. Then a chain is fixed on each side in the middle of the pole.

In order for the winch to move freely, there should be some slack in the chain. A block with a cable is installed on the chain, running along the middle pillar and fixed from the bottom.

Activation and performance testing

Before each start-up and operation of the hoist, it is recommended to check the functionality of the main elements. The following components are subject to inspection:

- Chain. Since the chain is responsible for holding the object at a height, it is important to check the load capacity. Periodic maintenance involves cleaning the chain from dirt and lubricating it with grease or similar materials.

- End chain. The element must be placed on the last loop.

- Top and bottom hooks. It is important to ensure that the hooks are intact and free of cracks, corrosion and other damage.

- Chain links. Mobile hoists must be stored in such a way as not to provoke twisting and bending of the links.

Preliminary testing of operability and compliance with equipment storage rules ensures stable operation without the risk of breakdown. Timely detection of problems with individual elements allows you to correct the breakdown and restore functionality.

We create a simple lifting mechanism with our own hands

Construction of a crane is not a quick task and is justified if it is required frequently or the volume of work is large enough. In cases where the load needs to be lifted urgently or this is a one-time operation, you can use improvised means.

To create a simple lifting device you will need a cord and two blocks. One block and the end of the rope are fixed motionless on the support. This will be the highest point to which the load can be lifted. We attach the second block to the load using slings or a hook. We first pull the rope along the block attached to the load, then pass it through the upper block. The gain in power will be 2 times. Using your own weight, you can easily lift a load weighing 100 kilograms to the required height.

DIY mini crane

If you add the ability to move the upper block along a guide, for example along a rail, you can get a do-it-yourself jib crane. It is useful in garage conditions for moving heavy machine parts.

It should be remembered that when working with the lift, you should not make sudden movements. The load must be lifted smoothly. And most importantly, do not stand under any lifted load. The same rule applies to a crane - standing under the arrow is prohibited.

Winch made from a cable and a piece of pipe

A version of the simplest winch, which can be made literally from scrap materials and in a few minutes, is popular among car enthusiasts. This design is a cable rigidly attached to a piece of pipe placed on an axle. The axle is driven into the ground or secured in some other way. Any lever is slipped under the bottom turn of the cable: a shovel handle, a pipe, a strong pole. By rotating the lever so that the cable is wound around the pipe, you can move a fairly heavy object, for example, a stuck car. This device cannot be called a full-fledged winch, but it performs its functions.

Manual winches include any devices that allow you to move loads and are manually driven. The most common are drum-type winches: a cable is wound on a reel, and the rotation of the reel is carried out using a handle through a gearbox: a worm or a system of sprockets of different sizes. The higher the gear ratio, the less force is required to apply to the handle.

For effective operation, the hand winch must be rigidly fixed to a stationary object; for this purpose, mounting holes are made on the winch frame. The handle is connected to a shaft on which a small sprocket is rigidly fixed. The coil is rigidly connected to a large sprocket, which has a clutch with a small one. The cable is attached at one end to the reel, and a carabiner or hook is attached to the other end.

The principle of operation of pulley hoists

The only simpler device for moving heavy objects is a metal scrap. The main element is a wheel with a chamfer in the middle of the outer surface, the axis of which is fixed to the ceiling beam. You can throw a hoist over it, and the lift with a gear ratio of 1 to 1 is ready. To increase the leverage, let's pass the hoist through another loose wheel, the axis of which is connected to the load, and fix the hoist at the top of the structure.

The transfer coefficient will become equal to 2 . Now let's attach another wheel to the ceiling, and pass the end of the hoist through it, securing it to the axis of the lower wheel. The gear ratio will become equal to 3. And so on, by adding one wheel at a time and changing the mounting location of the hoist, you can increase the gear ratio.

The location of the wheels relative to each other may be different.

The most compact designs are those with single-axle wheels. The design of such devices has two wheel holders. Having studied the drawings of the chain hoist, it will not be difficult to assemble it with your own hands. You will need two clips:

- traverse;

- carrying bracket;

- cheek for mounting parts;

- wheel (block);

- emphasis;

- bearing;

- sleeve;

- axis;

- axle holder;

- bearing oiler;

- hoist limiter;

- screw;

- bearing;

- cheek.

The end of the hoist is fixed to one of the clips.

Pulley hoists also have disadvantages. To increase the gear ratio by 1, you need to add one wheel each time, as a result the weight of the mechanism increases. In addition, bending the cable on each wheel requires force, reducing the efficiency of the device. You can reduce these losses by increasing the diameter of the wheels, but at the same time there will be an increase in the weight and dimensions of the pulley. Other types of lifts do not have these disadvantages.

Read also: Float system for water storage tank

Installation of lifting mechanism - manual or automatic

To mechanically lift loads onto the frame, you need to install a manual hoist - a worm winch and a cable. How to attach the hoist to the frame:

- on the side of the rack we install a manual worm winch (load capacity 800 kg, no less);

- The steel cable moves along rollers.

This mechanism makes it easy to lift the engine or car by the hood on one side.

You can use the lifting mechanism and rollers from the elevator door as a drive. The rollers there are reliable and durable.

An electric lift drive can also be installed on the manufactured base. A 300 - 500 W motor will be quite enough for simple repair work in the garage.

Such cranes are often used for the repair and reconstruction of old wooden houses. The construction of a log house will go faster if the logs are laid using a mobile homemade crane. In this case, the width of the frame is the length of the logs.

You can also make a simpler lift for the engine, on one support, watch the video.

A hoist is a device for lifting and lowering a load. In addition, such a mechanism can hold the load in a suspended position. Hoists can be manually or electrically driven. With an electric drive, an electric motor is responsible for the movement of the cables. The manual hoist uses a chain mechanism. Such a device can be gear or lever. In this article I will talk about the principles of operation of a manual hoist.

The most successful solution for lifting loads and working with them at height is a manual gear hoist. This mechanism is designed for raising and lowering loads of various configurations. As the name of this device implies, the mechanism is driven manually. This does not require an energy source. A person who does not have much strength can operate a manual chain hoist.

The operating principle of a chain hoist is not very complicated. This mechanism can be used as a stand-alone lift or as part of a crane beam structure. The hoist can be mobile, lever or stationary.

To work with a stationary hoist, the operator must be located directly next to the load. Thanks to the rotating casing, the load can not only be raised and lowered, but also unfolded for more convenient work with it.

The mobile chain hoist is attached to an I-beam profile, along which, using the carriage included in the hoist, loads can be moved in two directions: vertical and horizontal. Such a hoist, which is mounted on a carriage, is called a telpher.

How a chain hoist works A chain hoist consists of two blocks and a chain thrown between them. The lower block has a chain sprocket, and the upper block has two sprockets of different diameters. It is because of the difference in the diameters of the sprockets that the load is lifted more efficiently.

In addition, we should not forget about increasing the efficiency of the hoist due to the block system.

Advantage of a chain hoist: Compactness; Light weight; Ease of use; No energy consumption; Durability; Relatively low cost.

You can learn about chain hoists on the website stropu71.ru.

Here you can also purchase cable slings and other lifting mechanisms and accessories for them. The Partner StroyServis company has been supplying lifting and geodetic equipment for about ten years. In addition, the services of this company include the design and manufacture of slings and ropes of any size and type.

The movement mechanisms of hoists, the load capacity of which is 1, 2 and 3 tons, include such elements as a driven and idle trolley, and a traverse. Using the last element, the lifting mechanism is fixed and connected to the movement unit.

The hoist trolleys are attached to the traverse using vertical-type hinge pins. This design ensures a turning angle of the trolley of 15-18 degrees.

Thanks to the hinged design (guide rollers are provided on the vertical axes), the hoist with the movement mechanism freely passes along paths that have a minimum radius of curvature.

Due to the low-mounted electric motor, the movement mechanism of the electric hoist easily overcomes small switches.

The monorail mechanism for moving electric hoists is offered in normal and reduced dimensions.

The movement mechanisms of normal-sized hoists are equipped with one common sidewall on each side. The motor is mounted on one side via a flange. The connection between the motor shaft and the primary gear is realized through the use of a reduction attachment.

A hoist with a movement mechanism of reduced size is characterized by a different type of design. Instead of two, there are 4 sidewalls (two driven and two driven).

On devices with low load capacity and low lifting height, only 1 trolley is provided. The trolley is rigidly fixed to the body using a frame.

For hoists equipped with a pair of trolleys, 2 types of fastening are provided - rigid (frame) and hinged (special bolt).