Features and purpose of plasma spraying

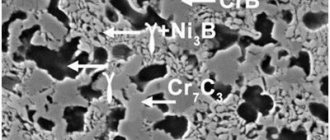

A special feature of the coating is its lamellar granular structure, resulting from thermal diffusion of small particles.

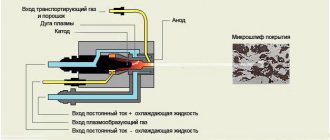

Stages of metal plasma spraying:

- Particle ionization.

- Spraying.

- Precipitation.

- Hardening.

At each stage it is necessary to control the temperature and speed of movement of the sprayed particles.

Deposition is a combination of two simultaneously occurring processes - a chemical bond, which is activated due to high temperatures in the processing zone, and mechanical interactions caused by the increased kinetic energy of the particles of the sprayed metal. An additional intensifying factor is the presence of an intermediate medium - gas/liquid - whose molecules accelerate and stabilize the metallization process. In this case, additional compounds are formed that improve the quality of the sprayed layer. For example, nitrogen forms highly hard metal nitrides, helium prevents surface oxidation, and copper improves friction conditions.

The process is used to create optimal surface layer characteristics and also as a method for restoring worn steel parts.

Plasma spraying of metals is often used to restore worn steel parts

Powder coating of metal allows you to obtain very high-quality coatings

Powder coating of metal polymer materials is by far the most modern and effective method of obtaining a decorative and protective coating for metal products that are used in various sectors of the national economy. At the moment, there are no analogues to powder painting on the market, since it has many undeniable economic and technological advantages, and most importantly, does not cause any harm to the environment. Unlike traditional liquid paints, powder paints do not contain solvents, and therefore are completely safe both for the people working with them and for the environment.The powder used for metal spraying is a mixture of tiny particles of rubber and a coloring pigment. During the spraying process, powder particles having an electrical charge are sprayed onto the surface of the product, which is neutral. This happens using a special electrostatic spray gun. After the spraying is completed, the metal product (or other material) is transported to another room - a polymerization chamber, in which the powder is heated and softened. The paint melts and spreads over the surface in an even layer, resulting in a durable, durable and very attractive coating that also has protective properties.

The technology of powder coating of metals is developing at a very fast pace, displacing traditional liquid paints from the market everywhere. Currently, work is underway to develop new methods of powder coating, which contributes to its even greater distribution.

Powder coating of metal allows you to obtain a very high-quality coating, which is a layer of powder applied to the surface of the product and then melted in a high-temperature oven.

Thus, powder coating consists of three main stages:

- Preliminary surface treatment and preparation for spraying. It consists of removing oxides and contaminants, phosphating and degreasing to ensure good adhesion and protect the painted product from corrosion.

- Direct application of a layer of powder paint to a metal part in a spray chamber.

- Heating and polymerization of the powder layer in the polymerization chamber, formation of a strong film, cooling and curing.

For powder coating of metal products, special painting lines are used, which can be automatic, semi-automatic or manual. For spraying large structures, a special transport system is provided that moves them from chamber to chamber. The principle of its operation is that the objects to be painted are fed on trolleys or suspensions that move on rails. With the help of a transport system, a continuous spraying process can be ensured, which significantly increases the productivity of painting lines.

At the beginning of the powder coating process, metal parts are loaded onto a conveyor belt and sent to a pre-treatment chamber. There they are fed into a five-stage cleaner and are treated with a cleaner, phosphating, anti-corrosion treatment, and then rinsed with clean water. After this, the products are dried in a special oven. This is done in order to completely prevent moisture from entering the surface. After drying, the products are cooled. They are then moved into a spray booth and powder is sprayed on them. In the polymerization chamber it melts and a high-quality coating is obtained.

It must be said that powder coating of metal allows one to obtain very high-quality coatings. This is achieved due to the fact that constant monitoring is carried out at all stages of the production process. For this, modern equipment is used. For example, for high-quality control of polymerization parameters and the formation of coatings on the surface of parts, a tomograph is used. The degree of charge of the powder paint is also controlled, as is the grounding of the parts.

See also:

- Powder painting of a flat surface is much more profitable than liquid paints

- Powder coating of brackets - allows you to get a high-quality coating

- Powder coating transport system ensures continuity and increases productivity

Back

Sputtering process technology

The starting material is fed into the plasma column in the form of a powder or wire. Ionized gases release active gas molecules, some of which (for example, hydrogen) further raise the temperature inside the plasma column, accelerating the process of converting the molecules of the original material into a vapor state. As a result, the settling of moving particles onto the substrate is accelerated. Ionization is possible not only from gas, but also from liquid evaporating in the arc column.

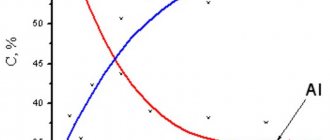

Spraying powders diversify the composition and properties of coatings, since a wide range of metals can be processed into a finely dispersed state.

Features of laser metal deposition

Due to the precise direction of the laser beam, during surfacing, a uniformly dense conglomerate of powder and base material is formed. The thickness of the metal liquefaction ranges from 0.2-1 mm; it is possible to create several such layers, located one above the other.

For drawing lines, edges or contours, the installation is equipped with an optical device with the ability to automatically move. The uniform distribution of layers is ensured by an intelligent sensor system. Progressive surfacing technology is implemented using two types of laser radiation – pulsed and continuous.

Subsequent treatment of the coating

The plasma atomization process is limited to materials that have a higher melting point than the flame. At lower temperatures and speeds (up to 40 m/s), the energy characteristics of moving particles decrease, which leads to oxidation, porosity and the presence of various inclusions in the finished coating. The strength of adhesion and adhesion between the coating and the substrate decreases. Such coatings are sanded or polished. In justified cases, heat treatment is provided - hardening, tempering, normalization.

Chemical chromium plating method

Chemical reagents are used as an active component to implement such spraying. The classic composition includes chromium chloride, sodium, acetic acid, and water with a solution of sodium hydroxide. The spraying process is carried out at a temperature of about 80 °C. Work begins with preparing the material. Typically, chrome plating is used to treat metal surfaces, in particular steel. Before the operation itself, the material is subjected to a primary coating with a copper layer. Next, chemical chrome plating is carried out using a sandblasting machine connected to a compressor unit. After completing the procedure, the product is washed in clean water and dried.

Plasma spraying equipment

For diffusion metallization, three types of devices are produced - with the combustion of an oxygen mixture, with the supply of an inert gas, and with thermal decomposition of a liquid. The coating thickness reaches 100…120 microns.

Plasma spraying installations using the energy of high-speed oxygen plasma operate at hypersonic gas velocities, reaching 1600...1800 m/s at the moment the jet hits the substrate. This is how plasma spraying of wear-resistant metal carbides is carried out when complete melting of ionized particles is not required.

Equipment where a plasma stream is formed in a jet of inert gas is used to produce coatings that require a combination of good wear resistance and impact resistance. Heating causes the gas to reach extreme temperatures, dissociate and ionize.

Vacuum spraying method

In this case, we are talking about a group of methods that involve the formation of thin films in a vacuum under the influence of direct vapor condensation. The technology is implemented in different ways, including through thermal effects, evaporation by electron and laser beams. Vacuum deposition is used to improve the technical qualities of parts, equipment and tools. For example, such processing allows the formation of special “working” coatings that can increase electrical conductivity, insulating properties, wear resistance and corrosion protection.

The technology is also used to create decorative coatings. In this case, the technology can be used in operations that require high precision. For example, vacuum deposition is used in the manufacture of gold-plated watches, to give an aesthetic appearance to eyeglass frames, etc.

Care

Further care must be carried out in accordance with the manufacturer’s recommendations, but as a rule, this does not require any special procedures - a simple washing or dusting is sufficient. If the spraying technology is fully followed and the paint is selected in accordance with operating conditions, then the service life exceeds that guaranteed by the manufacturer by at least one and a half times.

You can paint doors, radiators, or stylize objects as antiques using powder paints offered by our company, using the services of various enterprises in Moscow or any region of Russia, by contacting painting organizations cooperating with us, our manager will recommend a trusted contractor. The polyester powder paints we supply are certified according to the QUALIOCOAT system, which is a guarantee of the highest reliability.